A cost measurement system of logistics process

Автор: Zine Benotmane, Ghalem Belalem, Abdelkader Neki

Журнал: International Journal of Information Engineering and Electronic Business @ijieeb

Статья в выпуске: 5 vol.10, 2018 года.

Бесплатный доступ

Because logistic is a process-oriented business, we propose in this paper a measurement system of decision support for assessing the costs associated with each logistics process. This system allows calculating economic, environmental and social costs of logistics process to ensure a sustainable logistics. We have formulated the problem and we present some simulation for testing our system. This proposition allows the decision-maker to have knowledge of economic, ecological and social cost before making a decision.

Sustainable Logistics, Economic parameters, Logistics process, Ecological parameters, Social parameters, Measurement system

Короткий адрес: https://sciup.org/15016147

IDR: 15016147 | DOI: 10.5815/ijieeb.2018.05.04

Текст научной статьи A cost measurement system of logistics process

Published Online September 2018 in MECS DOI: 10.5815/ijieeb.2018.05.04

Logistics can be viewed as the integration and collaboration of a set of activities; it aims to plan, implement and control a flow of physical entities from their point of origin to their point of consumption.

However, observations made in most organizations reveal a separation of activities related to logistics into three groups: activities directly related to internal production of goods and services (procurement, manufacturing, distribution, returns), management activities of transport of persons or goods to the company's external (often separated from the previous because they include in part the maintenance management) and indirect activities or support activities (without a direct link with production, but necessary for the deployment of operations).

However, with economic growth, three key challenges must be addressed:

-

• Economic prosperity: this is to promote a prosperous, innovative, knowledge-rich,

competitive and eco-efficient, ensuring a high standard of living, full employment and quality of work.

-

• Protection of the environment: it aims to preserve the ability of the earth to support life in all its diversity, respect the limits of natural resources of the planet, to prevent and reduce pollution environment and promote sustainable consumption and production patterns in order to break the link between economic growth and environmental degradation

-

• Social equity and cohesion: it is to promote a healthy, safe and just society based on social integration and cohesion, respect for fundamental rights and cultural diversity.

The emergence of sustainable development establishes the principle of coexistence of economic growth, respect for social aspects and preservation of natural resources.

In fact, with the growing of logistics networks, the creation of adapted services to ensure efficient and competitive management becomes necessary. From the end of the 1980s, the concept of corporate social responsibility enriched the concept of sustainable development and the company's decisions began to integrate environmental and social dimensions.

Nowadays, it is clear that no company is immune to the increase in fuel prices and energy sources used for air conditioning, refrigeration and heating, as well as traffic congestion and the degradation of road infrastructures, for this reason companies are more and more concerned about energy and environmental issues and have to revise their logistics in order to reduce their costs and increase their competitiveness. Concerned about their image, sensitive to societal expectations and driven by new government regulations, many of them are also moving towards controlling their greenhouse gas emissions. In this context, it is essential to ask the question of the environmental impacts, positive and negative of the logistics development, to use this tool effectively and in a concern for sustainable development.

To achieve a sustainable balance between economic, environmental and social objectives, we present in this paper a measuring system which calculates the different costs of a logistics process and provided results which aims to facilitate the decision making for leaders.

To prove the effectiveness of this approach, we present a study scenario of a vehicle loading process. The rest of the page is structured as follows:

-

• In the 2nd section, we include some related works.

-

• In the 3rd section, we describe the detail of the suggested approach.

-

• In the 5th section, we describe the scenario of study case and presented the different results.

-

• Finally, we conclude our work by some extensions which they will consider in the future.

-

II. Related Works

Inspired by research on performance measurement, authors in [2] have designed a method that links sustainability performance to supply chain decisions, and allows setting coherent performance measures, then they transposed this method to a multi-objective mathematical programming to optimize the supply chain planning while the economic, environmental and social performances are all coherently integrated into the model. To illustrate their approach, they applied it to a Canadian lumber industry case.

Still in the context of a green logistics, authors defined in [6] the impact of reverse logistics in green supply chain management by identifying key performance measures for green supply chains, the causal linkages between important variables in a typical supply chain, and by developing a dynamic simulation model for developing appropriate green policies and strategies when translating from reverse logistics to green supply chain.

The objective of paper [8] was to propose a conceptual framework to study the strategic orientations of Third-Party Logistics (3PLs) relating to the reverse logistics service offerings.

Authors in [9] have designed a two stage algorithm for the green traffic flow allocation problem on logistics network. In the first stage, alternative paths are generated for each origin-destination flow by iterating the k-shortest path algorithm. In the second stage, the solution of traffic allocation with best green utility is chosen from candidate solutions.

Authors have discussed in [7] about integrating environmental considerations into purchasing decisions which is called Eco-procurement. The advantages of this practice include cost savings, conservation of natural resources and energy, and compliance with environmental laws and regulations. In their paper they address the following two crucial issues, and propose a quantitative decision-making strategy for each of them: (1) which products must be chosen from a set of candidate-used products containing recyclable content? and (2) which suppliers, viz. companies that collect and sell the chosen used products, must be selected for ecoprocurement?

Authors in [3] have proposed to investigate the impact of green supply chain practices on organizational performance in Indian rubber industry. Their study has adopted two prolong strategies that includes critical literature review published in reputed journals to identify research gaps and identify variables and survey methodology using structured questionnaire. The multiple regression analysis suggested that 'supplier relationship management' and 'waste reduction through collaboration' are found to be positive determinants of 'business performance'.

In article [10], authors propose a system with RFID and sensor networks to guarantee the keeping quality of low-temperature logistics. 3G network and GPS transportations were incorporated to that system to create a full-time monitoring system and all the processing became transparent to the customers. The system can be connected with the customers’ system so that all the processing, storage, and transportation temperatures can be sent to the customers through extranet and WEB server of suppliers. The customers’ system can judge whether temperature data is normal or not before the food receives. This system was applied in the cold-chain logistics.

In [11], authors treat the problem of scheduling freight trains in rail-rail transshipment yards is considered. It is solved at a deeper level: besides scheduling service slots for trains, the article additionally solves a problem of assigning every train to a railway track. A mathematical model and a solving method for this problem are given. A key feature of the given mathematical model is that it doesn’t use Boolean variables but rather operates with combinatorial objects (tuples of permutations). The solution method is also based on generation of combinatorial sets, which is quite an unusual approach for solving such problems.

Authors in [4] have proposed a study which aims to identify critical success factors to achieve high Green supply chain management performances from three perspectives i.e., environmental, social and economic performance. The critical success factors to achieve high Green supply chain management performances relevant to Indian automobile industry have been identified and categorized according to the three perspectives and a conceptual model also have been put forward.

In [12], authors address the quality and safety of pharmacy by analyzing the characteristics of radio frequency identification (short for RFID) technology and the pharmacy logistics system. Then RFID technology is introduced into the Pharmacy Logistics System. That is to expound the application of RFID in the pharmacy logistics system; the service level of the pharmacy logistics system would be upgraded, and the supervision of the pharmacy would be strengthened.

Authors in [5] have provided thought their paper an interpretive structural modeling -based approach to implement and initiate green activities in supply chains. Variables such as supplier and stakeholder commitment, cost benefits, environmental issue, and customer redundancy, etc., have been identified and categorized under enablers; green and sustainable products, processing time and green productivity and efficiency, etc., under results.

Authors in [1] have tried to assess green logistics practices in automotive industry by using simulation method. The proposed model will assist decision makers acquire an in-depth understanding of environmental impacts and costs associated.

In this paper, we propose a measurement system for decision support which aims to improving economic, environmental and social performances of logistics process by providing associated costs to the decision maker.

-

III. Proposed Approach

Just a few years the cost of a product defined in purely monetary terms; nowadays it also integrates environmental aspect in order to achieve a more sustainable balance between economic, environmental and social. It is in this perspective that companies now making the switch to a new more comprehensive approach, and there is talk of logistical efficiency.

Logistics management includes economic, ecological and social costs.

Decision makers cannot easily estimate economic, ecological and social impact and cost of a new strategy adopted.

The adoption of a strategy in one dimension (economic, ecological or social) often leads to a negative impact on the remaining two dimensions.

Given this situation, we propose in this paper a measurement system which aims to improving economic, environmental and social performances of logistics process and because logistics is a process-oriented business, the aim of our system is to evaluate, improve and optimize logistics processes and the idea is that if we can control the smallest entity (process), we will succeed in control the entire chain.

To optimize logistical processes, we must use a measurement system that analyzes the various logistic parameters: ecological, economic and social, and at the end of this analysis the system must be able to display the total cost of each parameter. In this section we describe some UML diagram and formulas used to achieve our objective.

Logistical processes facilitate the relationships between production and the movement of products. Specifically, logistical processes should address many of the aspects of production, including time, costs and quality. When a company successfully coordinates these logistical processes, the company can track the process through production, consumption, storage and disposal.

In a previous work [13], we have proposed a system of agents based on cloud computing, which aims to contribute in improving economic, environmental and social performance, targeting optimization and sustainability of supply chain. The proposed system allows to analyze process information, to calculate economic, environmental and social costs of the process, and to evaluate strategic solutions, this enables decision makers to know the economic, ecological and social costs of each process in order to improve it and then, mastering the supply chain as a whole. The proposed system integrated: Cloud Computing technology, web services technology, multi-agent systems, and simulation model.

In another work [14], we have proposed a modified bin-packing algorithm for the loading vehicles process to select the vehicles that will make the pickup or the delivery tour from of their respective warehouses. This operates as follow:

-

• Sort vehicles capacities of each warehouse by

descending order, in a list.

-

• Sort available quantities at each supplier by

descending order, in a list.

-

• Load the first quantity from the list.

-

• If the Load is lower than the vehicle size: search the quantity completing the load to size which has the minimum cost, and load it.

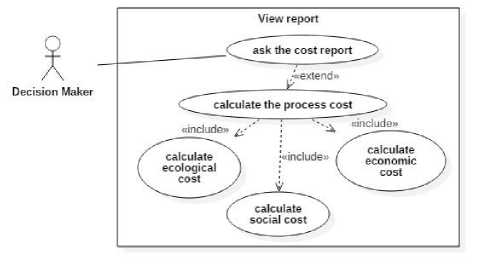

In this proposed system, two main stakeholders are distinguished, the employee and the decision-maker, in addition, the customer can intervene for an eventual claim:

The employee's role is to execute the process and to communicate with the system.

The decision maker's role is to consult overall economic ecological and social costs after a given period.

The customer may report a problem upon receipt of the product, and the decision maker can later associate his claim to one of a given process.

Our proposed system provides for the employee a veritable guide; on one side it displays him the steps to follow to execute the process, and on the other side it gives him the opportunity to report any problem encountered. This communication allows the system to collect the data necessary for the various calculations.

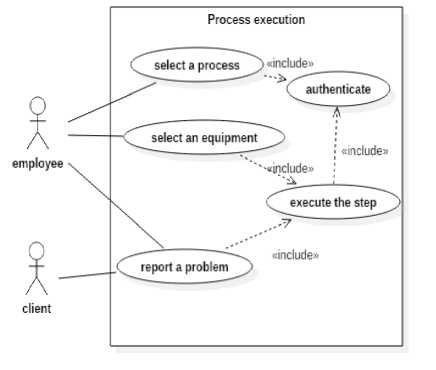

Fig.1. presents a use case diagram of process execution, it shows the different functions related to the employee who can:

-

• authenticate

-

• follow steps

-

• report any problems related to the execution of a

step (the client as a secondary actor can also report a problem or dissatisfaction associated with this process)

Fig.1. Use case diagram of process execution

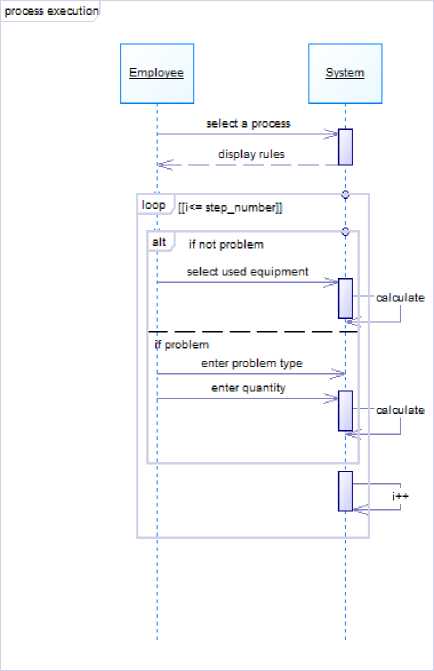

Fig.2. Interaction between employee and the proposed system

The sequence diagram of Fig.2. describes the interaction between the employee and the system:

The employee begins to authenticate

The system displays to the employee the various steps

At each step the employee reports or not any problems during the execution of the process (breakage, discomfort, damage, ..)

The employee mentions the type of equipment used for the execution of the process.

Once the process executed, the system can collect the following data:

-

• The time of starting the process.

-

• The time of the end of the process.

-

• The type of registered problem.

-

• The type of used equipment used.

This allows the system, using the various formulas presented in the section, to estimate the economic, environmental and social costs of the process.

The different measures are obtained using active data, these data are related to the execution of the process, as the area where the process is executed, or the type of equipment used to execute the process, this will allow the system to estimate by example energetic the cost (in terms of electricity, fuel, ...) associated with the process.

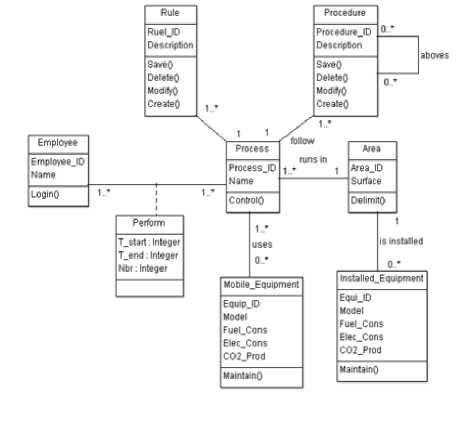

Fig.4. Relational diagram of the logistics process

-

IV. Mathematical Formulation of the Measurement System

As we mentioned before, in our approach we have considered the process as the basic entity. In fact, by considering the logistical process, authors try to find the best solution by decomposing the problem and finding a compromise between the different parameters. As part of this process, a company should always consider the location of a product and analyze the various factors associated with these locations. This includes related costs, personnel, the time and environmental costs.

For its calculations, the proposed system needs some passive data to evaluate the process, so, we present through the relational diagram in Fig.4., the relationship of the process with its environment.

A process runs over a duration T (see Formula (1)) estimated by Hour:

Tp = T _ end - T _ start (1)

For allowing a decision maker to have a detailed knowledge about the various factors, we associate to each process three vectors: Economic Vector V i , Ecological Vector V i and Social Vector V i , where each input vector is the cost associated to a factor during execution i .

-

A. Economic cost

To run a process, an equipment can be used, this can operate with electric or internal combustion engines, in addition, the area where the process is executed, may be cooled and / or lighted, these parameters represent a cost consumption that affects the product price or service delivered by the company; so, the economic cost includes:

Cost of air conditioning zone (warehouse ...)

Light cost of area (warehouse ...)

Consumer Cost of Electrical Equipment

Equipment cost to consumption engine

-

1) Energy cost

From Fig.4., a process is executed within an area in which several devices are installed. Therefore for one execution of the process, corresponding energy consumption includes electricity that was used to illuminate the area during T and electricity used for cooling; to this is added the energy consumed by equipments that the process uses; the correspond factor is done by Formula (2).

C 2 = E El ec ConsEle c HTp + E Euel Cons Euel H T p - (2)

e 1 e 2

With Elec electricity cost per hour, Fuel Fuel cost per hour, e is Installed_Equipment and e is Mobile_Equipment, Tp. is the time during which the Mobile_Equipment has been used.

-

2) Damage cost

This cost concerns the damage of products during the process, it is estimated according to the product type and by damaged quantity, see formula (3).

C 4 = P E QQdam * Price unit (3)

Prod

With Prod: the product, Qdam the amount of damaged units by form and Pr ice the damaged unit price, β is Boolean variable that is equal to 1 if there has been damaged 0 otherwise.

Economic costs associated to the process execution i , represent the inputs of the Economic Vector: VeCO = ( C , Ci , C 3, C 4) , and therefore objective function F can be deduced which represents the cost of one execution i of a process (Formula (4)).

F = C + C 2 + C 3 + C 4 =

NbrTpSalH + ElecHTp + CoolHTp + FuelHT. + a QCartPricekg + P E QdamPriceunit p PF

-

B. Environmental cost of process

We consider for environmental cost process, the amount of CO2 ( QCO ) generated by equipments that the process used and installed equipment in the area, the amount of solid ( QSol ), semi-solid ( QSSl ) and liquid ( QLiq ) matter resulting from its execution (see Formula (5)). Environmental vector associated to execution i of the process is defined by:

V env = ( QCO 2 T p , QSoiT p , QSsiT p , QLiqT p ) = ( C ’ c 2 , C 3 , c 4 ) (5)

-

C. Social cost of the process

We consider for the social cost in our approach, the following social factors: working conditions, health and safety and customer satisfaction, social vector is noted

Vi soc

-

1) Condition of work

The employee can feel discomfort resulting from sound pressure level forklifts for example or other equipment used by the process, his claim should be considered to improve working conditions. Let C the claim of employee which is 1 in cases where an employee has requested a discomfort during an execution of the process, 0 otherwise.

-

2) Health and security

The employee may face some hazards such as falls from heights or injuries resulting from the mechanical action of an equipment or a work tool. Dan is variable that is 1 if this problem was recorded during an execution of the process, 0 otherwise.

-

3) Customer satisfaction

A client cannot be satisfied by the quality after receipt of the product, which may result from the quality of packaging or bed stacking... Let Rec the variable which is 1 for any claim related in the process, 0 otherwise.

After defining social factors, social vector V i (Formula (8))associated to one process execution will be:

V Soc = ( C inc , Dan, Rec ) = ( Q" Q, C 3 ) (8)

-

V. Experimentations and Results

To show some advantages of our proposed system, we simulate some calculations assuming that a decision was taken.

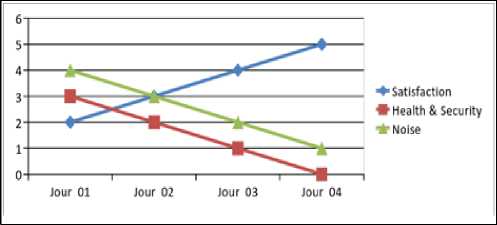

Scenario 1: In this scenario we assume that the decision maker find a solution to reduce the nuisance and dangers by equipping the employee each day with a working tool; for example, the first day a helmet, the second day gloves and held, etc. ... We also note the increase in the degree of satisfaction (Fig.5.).

Fig.5. Results of scenario 1

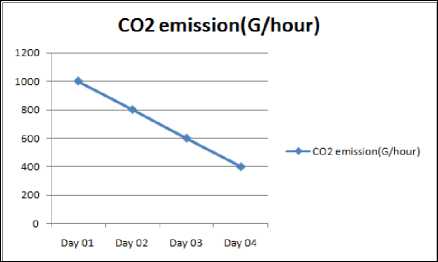

Scenario 2: In this scenario, we consider the CO2 emission factor relative to time, the decision maker has made a gradual replacement of equipment polluting engine (that rejects 200g/hour) by own electrical equipment that do not emit CO2, which explains the results in the Fig.6. (from 1000 kg to 400 kg).

Fig.6. Results of scenario 2

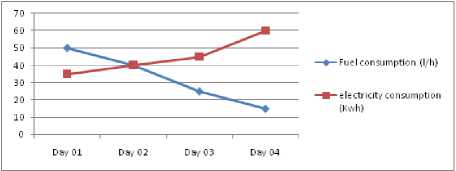

Scenario 3: In this scenario, we simulate the decision to successively replace the thermal equipment by electrical equipment and therefore the fuel consumption decreases and power consumption increases, it also reduces the CO2 emission (Fig.7.).

Fig.7. Results of scenario 3

-

VI. Conclusion

This paper aims to address the economic, environmental and social impacts of management practices in supply chains. In this context, our goal has been to provide an assessment of these impacts in the supply chain system. This is also to help the decision maker to have a global view and knowledge on the cost incurred by the execution of a logistics process. This proposed system of measurement uses mathematical formulas to reduce economic, ecological and social cost of logistics; by considering the process as a principal entity, it allows through its calculations, to assess the economic, environmental and social cost of a logistic process and to provide a decision-support for evaluating a decision before its application. Finally, we formulated the problem and we have discussed some simulations results. For future work, we will try to integrate this system in a cloud computing platform; we also propose to add a casebased system to propose strategic solutions to the decision maker.

Список литературы A cost measurement system of logistics process

- Abduaziz O, Cheng J K, Mat Tahar R, Varma R. A hybrid Simulation model for Green Logistics Assessment in Automotive Industry. The 25th International Symposium on Intelligent Manufacturing and Automation, DAAAM'2014, Vienna, Austria, 2014.

- Boukherroub T, Ruiz A, Guinet A, Fondrevelle J. An integrated approach for sustainable supply chain planning. Computers & Operations Research, 2015, 54: 180-194.

- Dubey R, Bag S, Ali S S. Green supply chain practices and its impact on organisational performance: an insight from Indian rubber industry. Int. J. of Logistics Systems and Management, 2014, 19(1): 20-42.

- Luthra S, Qadri M A, Garg D, Haleem A. Identification of critical success factors to achieve high green supply chain management performances in Indian automobile industry. Int. J. of Logistics Systems and Management, 2014, 18(2): 170-199.

- Mangla S, Madaan J, Sarma P R S, Gupta M P. Multi-objective decision modelling using interpretive structural modelling for green supply chains. Int. J. of Logistics Systems and Management, 2014, 17(2): 125-142.

- Mutingi M, The impact of reverse logistics in green supply chain management: a system dynamics analysis. International Journal of Industrial and Systems Engineering, 2014, 17(2): 186-201.

- Pochampally K K, Nukala S, M. Gupta S. Eco-procurement strategies for environmentally conscious manufacturers. Int. J. of Logistics Systems and Management, 2009, 5(1/2): 106-122.

- Shaharudin M R, Zailani S, Ismail M. Third-party logistics strategic orientation towards the reverse logistics service offerings. International Journal of Management Practice, 2015, 8(4): 356-374.

- Tao S, Hu Z.H, Sheng Z H. Greening flow allocation in logistics network based on a two-stage algorithm. International Journal of Applied Decision Sciences, 2015, 8(3): 223-240.

- Ting P.H. An Efficient and Guaranteed Cold-Chain Logistics for Temperature-Sensitive Foods: Applications of RFID and Sensor Networks, International Journal of Information Engineering and Electronic Business (IJIEEB), 2013, 5(6): 1-5.

- Grebennik I, Dupas R, Lytvynenko O, Urniaieva I. Scheduling Freight Trains in Rail-rail Transshipment Yards with Train Arrangements, International Journal of Intelligent Systems and Applications(IJISA), 2017, 9(10): 12-19.

- Weihua G, Yuwei Z, Tingting Z. Research on RFID Application in the Pharmacy Logistics System, International Journal of Education and Management Engineering (IJEME), 2012, 2(8): 13-19.

- Benotmane Z, Belalem G, Neki A. Towards a cloud computing in the service of green logistics. Int. J. of Logistics Systems and Management, 2018, 29(1): 470-483.

- Benotmane Z, Belalem G, Neki A. A cloud computing model for optimization of transport logistics process, Transport and Telecommunication, 2017 18(3): 194-206.