Additional screening tests at the testing technical center for ground power equipment

Автор: Aliseenko Y. V., Nesterishin M. V., Vorontsova E. O., Fedosov V. V., Pateleev V. I.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 4 vol.20, 2019 года.

Бесплатный доступ

When testing a spacecraft in a thermal vacuum chamber, special attention is paid to ensuring guaranteed continuous power supply to the spacecraft for a long time (up to several months). The de-energization of the spacecraft can lead to the failure of thermal control systems, up to the complete failure of the spacecraft worth several billion rubles. During the operation of ground power equipment, the necessary data on the intensity and types of failures in the operation of this ground power equipment were obtained, the result of which led to an increase in the test time and the risks of failure of the spacecraft at this stage. As a result of collaborative work of JSC “Academician M. F. Reshetnev Information Satellite Systems” and Research Institute of Automation and Electromechanics of Tomsk State University of Control Systems and Radioelectronics on the analysis of failure statistics obtained during operation, a technical task was worked out to develop methods for increasing the uptime of ground power equipment manufactured. One of the key requirements for the new generation of ground power equipment being manufactured is to ensure a high reliability indicator – “uptime”. Experience in the field of additional screening tests of electro-radio parts before their installation in a spacecraft allows us to propose a method for determining the quantitative value of the decreasing coefficient of screening tests using a method for evaluating the coefficients characterizing the degree of difference between radio-electronic products that have successfully passed additional screening tests and received ones from the factory manufacturer. As a result of the calculations of the decreasing coefficient and the mathematical calculations of the uptime, it is possible to determine the effect of the decreasing coefficient of screening tests on improving the reliability of ground power equipment. High requirements for uptime of ground power equipment for electrical tests of the spacecraft have led to the need for additional screening tests in special testing technical centers, where the verification of indicators of the number of failures by confidence probabilities should be carried out. The introduction of additional screening tests in the technological process of ground equipment manufacturing is the next step in the methods of increasing reliability.

Spacecraft, power ground equipment, reliability, screening tests, electro-radio parts.

Короткий адрес: https://sciup.org/148321707

IDR: 148321707 | УДК: 629.78.08.018 | DOI: 10.31772/2587-6066-2019-20-4-458-464

Текст научной статьи Additional screening tests at the testing technical center for ground power equipment

Introduction. When testing a spacecraft (SC) in a thermal vacuum chamber, special attention is paid to ensuring a guaranteed continuous power supply of the spacecraft for a long time (up to several months). The deenergization of the spacecraft can lead to the failure of thermal control systems, up to the complete failure of the spacecraft worth several billion rubles. During the operation of ground power equipment (GRE), the necessary data were obtained on the intensity and types of failures in the operation of this GPE, the result of which led to an increase in the testing time and risks of spacecraft failure at the stage of thermal vacuum tests [1; 2].

As a result of collaborative work of JSC “Academician M. F. Reshetnev Information Satellite Systems” and Research Institute of Automation and Electromechanics of Tomsk State University of Control Systems and

Radioelectronics on the analysis of failure statistics obtained during operation, a technical task was worked out to develop methods for increasing the uptime of ground power equipment manufactured.

One of the key requirements for the manufactured GPE of new-generation is to ensure a high reliability indicator – failure-free operation. Conducting continuous tests in a thermal vacuum chamber for up to 30 days depends entirely on the failure-free operation of the GPE – solar battery simulators (SBS) and storage battery simulation unit (SBSU).

In order to ensure the implementation of the technical task, the following methods for increasing reliability have been adopted [3; 4]:

– reservation of power channels of IBS with the possibility of on-line replacement of failed blocks from SPTA;

– BSU has developed eight identical independent power modules BIZR, with seven modules providing 100 % of the output power. Recovery of failed blocks from a set of spare parts in the on-line mode;

– introduction of technological vibration and thermal cycling procedures to the manufacturing process in order to identify manufacturing defects before preliminary acceptance tests;

– introduction of a screening test procedure (STP) for electro-radio products (ERP).This article discusses the method of additional screening tests (AST) as one of the methods for increasing the uptime of GPE. According to the results of the work, it is necessary to determine the effect of AST on improving the reliability of GPE.

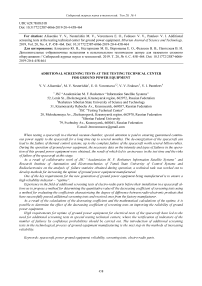

General concepts of improving the reliability. ERP reliability during operation is characterized by a time dependence on the failure rate curve (fig. 1) [5].

This curve shows a relatively high failure rate during the early failure period (initial operating period), a relatively low and stable failure rate during the operation period, and increasing intensity during the aging period (after about 10 years of normal operation).

Early failures usually arise due to design flaws and non-compliance with manufacturing standards. Under normal operating conditions, the initial operating period lasts up to 1000 hours or about 6 weeks. The end of the initial operating period is indicated by the alignment of the failure rate curve. The failure rate during the initial operating period tends to decrease as the design of the equipment and its manufacturing technology improve.

At present, two main directions of improving the reliability of manufactured ERP are generally accepted [5]:

-

1) elimination of the causes of failures in the manufacturing products process by studying and improving the production process, as well as strengthening of control. Thus, the production process is affected by establishing stable feedback of information transfer in the direction of creating ideally defect-free technology;

-

2) identification and removal from the finished batch, products with “weak points” that could lead to failures (actual or potential) before delivering them to the consumer.

The first method is a more effective method of improving the quality and reliability of manufactured prod- ucts. However, since failures cannot be avoided even for well-established production, a more common way to improve the quality and reliability of the manufactured batch of electronic components and integrated circuits is to carry out screening tests during the output control at the manufacturer. Moreover, the verification does not apply specifically to each product from a given batch, but to the entire batch of products [6].

It is believed that there are no accidental ERP failures, that each failure, on the one hand, has its own cause, and on the other hand, is a consequence of the application of a certain critical load to the product. Failures of GPE may be caused by “potentially unreliable” ERP, which remained undetected at the beginning of operation. The experience of using integrated circuits in spacecraft shows that the introduction of screening tests significantly increases the reliability level of GPE.

Modernization of the screening test method . For a long time, PJSC “ITC – NPO PM” and counterparties have been using ERP of the quality categories VP, OS and OSM, which underwent additional screening tests (AST), including diagnostic non-destructive testing (DNDT) and destructive physical analysis (DPA), in test technical centers (TTC) accredited by the “Voenelectron-sert” systems and the Federal Space Technology Certification System. According to the data of [6; 7], these tests increase the quality of the applied ERP batches, reduce the failure rate due to the elimination of ERP with hidden defects from them, and make it possible to use a decreasing coefficient KTTC , which refines the values of λэ, the value of the operational ERP failure rate [8].

However, at present, the correction coefficient K TTC is not taken into account when calculating the engineering estimate of the GPE reliability, since there is still no method for quantifying this coefficient. Thus, the task of technical justification of K TTC value for use by clarifying the value of the operational failure rate remains relevant [9].

Experience in the field of AST of ERP before their installation in the SC allows us to propose a method for determining K TTC using the method of evaluating the coefficients characterizing the degree of difference of ERP, which successfully passed AST and were received from the manufacturer [10].

Fig. 1. Typical dependence of ERP failure rate ontimе

Рис. 1. Типичная зависимость интенсивности отказов ЭРИ от времени

The essence of the method lies in the fact that, based on the generally accepted function of the ERP time failure rate, the required failure-free lifecycle of ERP as part of the equipment corresponds to the ERP failure-free period provided by the basic group average failure rate and the tolerance fields of the ERP parameters according to the technical condition (TC) as shown in fig. 1 [11].

The result of the failure statistics analysis shows that during normal operation of the equipment, ERP failures are mainly parametric, i. e. failures of the type “out of tolerance range” occur. AST allows one to classify elements with narrowed parameter values compared to the tolerance fields for technical specifications. This leads to an increase in the duration of the period of stable failure rate of ERP that have passed the classification.

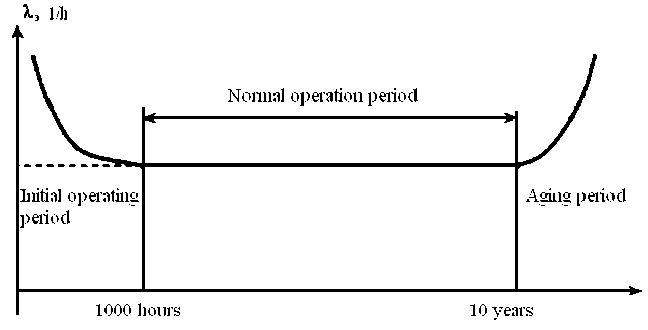

The validity of this approach is based on the fact that when assessing the failure rate according to the test results for failure, a complete loss of performance or departure of the parameters-criteria of validity are taken for the norms established in the technical specifications. An illustration of this approach is shown in fig. 2.

Designations of the following periods are introduced in fig. 2:

-

1) the initial operating period of ERP at the manufacturer;

-

2) the period of stable operation of ERP not subjected to AST;

-

3) the period of wear and aging of ERP not subjected to AST;

-

4) the AST period of the whole party of ERP;период ДОИ ЭРИ всей партии;

-

5) the period of stable operation of ERP subjected to AST;

-

6) the period of wear and aging of ERP subjected to AST.

Allowing for the fact that the test results for each type of additional test are independent events, K TTC is determined by the expression:

K TTC

= П 1 n k i ,

where k i – safety coefficient for i types of ST; п – the number of types of AST. The specific value of K TTC depends on the volume of AST.

The basis of the AST for ERP of GPE is presented by the ST conducted for ERP, which are part of the spacecraft, modified to meet the requirements of the technical task of JSC “ISS”. As a result, the range and scope of tests for GPE were determined [10].

The composition of the additional tests of ERP includes up to 100 % ERP and relays for the components of the product SBSU-200LI and SBS-160/4-8. The scope of additional tests of foreign ERP, component parts of SBSU – 200LI and SBS-160/4-8 are given in tab. 1.

It must be emphasized that the coefficient k i for tests related to the measurement of electrical parameters is complex, since it takes into account all the electrical parameters involved in the classification and is determined by the formula: k i = max k j , where k j is the coefficient for each AST parameter.

Thus, in accordance with tab. 1 the generalized safety factor for the parametric reliability of a particular batch of electronic components will be equal to:

K TTC = k TS × k D .

Where k TS is classification according to tightened standards, k D is drift estimation of parameters.

Fig. 2. Refinement of the function of the failure rate for ERP that passed ST: а – without ST; b – passed ST; Т АС – warranty period of the equipment and SC provided by the area of stable failure rate of ERP according to technical conditions; Δ Т АС – Т АС increase due to additional ST in testing technical centers

Рис. 2. Уточнение функции интенсивности отказов для ЭРИ, прошедших ОИ: а – без ОИ; б – прошедших ОИ; ТАС – гарантийный срок службы аппаратуры и КА, обеспечиваемый участком стабильной интенсивности отказов ЭРИ по техническим условиям; Δ Т АС – прирост Т АС за счёт ОИ в ИТЦ

Table 1

Scope of Additional Tests

|

№ |

Test Type |

Sampling |

Note |

|

1 |

Serializing Elements |

100 % |

|

|

2 |

Measurement of electrical parameters under normal conditions |

100 % |

with recording parameters |

|

3 |

Statistical processing of measurement results, the establishment of standards for “tightening” parameters |

||

|

4 |

Classification according to tightened standards for electrical parameters |

100 % |

in accordance with established tightened standards with recording parameters |

|

5 |

Burn-in testing |

100 % |

not less than 72 hours at 125 °C |

|

6 |

Measurement of electrical parameters under normal conditions |

100 % |

with recording parameters |

|

7 |

Statistical processing of measurement results and setting standards for parameter drift |

100 % |

|

|

8 |

Parameter drift classification |

100 % |

in accordance with established standards with recording parameters |

Additional Test Results

Table 2

|

Item |

Quantity of ERP |

|||

|

Tested |

Suitable |

Reject |

Potentially unreliable |

|

|

Generators |

117 |

115 |

0 |

2 |

|

Diodes |

31787 |

31171 |

305 |

313 |

|

Microchips |

11623 |

11104 |

115 |

404 |

|

Relay |

1749 |

1663 |

13 |

73 |

|

Zener diodes |

2840 |

2624 |

67 |

149 |

|

Thyristors |

1030 |

842 |

2 |

186 |

|

Transistors |

5505 |

5255 |

4 |

246 |

The minimum composition of additional tests of foreign ERP, component parts of SBSU-200LI and SBS-160/4-8 includes 100 % ERP:

-

1. Microchips, OE converter and generators.

-

2. Modularized secondary power supplies.

-

3. Semiconductors with a small housing size.

-

4. Semiconductor devices with a sufficient housing size for serialization [12].

Based on the results of the tests, we drew up the present act that JSC “ITC – NPO PM” carried out work on the topic “Conducting additional tests of electric radio products (ERP) intended for installation in products of SBS-160/4-8 and SBSU-200LI” in accordance with the terms of the contract concluded between JSC “ITC – NPO PM” and “NII AET TU SUR” [13; 14].

AST of ERP were carried out in accordance with the technical task for the implementation of the component of the development work.

The results of AST of ERP (the number of tested, suitable, rejected and classified as potentially unreliable – PU) intended for the assembly of SBSU-200LI and SBS-160/4-8 products are presented in tab. 2.

To bind the obtained coefficient, it is necessary to carry out a mathematical calculation of the reliability of SBS-160 – this is the probability of failure-free operation (FFO) in the ASRN-2006 program.

To calculate the operational failure rate of domestic ERP, the models given in the manual [15] are used.

The manual contains information intended for use in calculating the reliability indicators of equipment, the composition of sets of spare parts for military equipment, and predicting the reliability of new types of ERP in accordance with the requirements of fundamental documents on standardization.

To calculate the operational failure rate of foreign ERP, the models described in the manual [16] are used.

Calculation results. Calculations show that the FFO SBS-60/4-8 is 0.94677 for 1000 hours of operation, which meets the requirements of the technical task.

Taking into account the coefficient K TTC obtained in the calculations and the influence of AST on the reliability of GPE, the value of FFO of SBS-160/4-8 is 0.96599 for 1000 hours of operation.

Analysis of the calculation leads to the following conclusions:

-

1. Additional tests of the influence of various factors on the failure rate of a particular batch showed that screening for compliance with the technical specifications followed by the removal of low-quality products from factory batch led to a significant reduction in the likelihood of failure of calibration equipment.

-

2. It is possible to estimate K TTC coefficients for any batches of ERP for a certain period of their manufacture (for one year) and issue recommendations for conducting tests in order to reduce their volume and increase confidence probabilities in terms of parameters.

Conclusion. High requirements for the reliability of the GPE for the spacecraft EI have led to the need for additional screening tests in special testing technical centers, where the verification of indicators of the number of failures by confidence probabilities should be carried out. These tests lead to higher prices for manufactured products up to 40 % of the cost. Nevertheless, the introduction of additional screening tests in the manufacturing process of ground power equipment justifies the increase in cost by reducing the risks of failure of test objects. The introduction of additional screening tests into the technological process of manufacturing ground power equipment is the next step in the methods of increasing reliability [17].

Список литературы Additional screening tests at the testing technical center for ground power equipment

- Lizunov A., Tarasov V. [Methodology for accelerated thermal vacuum tests of storage batteries for a spacecraft]. Vestnik MGTU. 2011, No. 3, P. 43–47 (In Russ.).

- GOST R 56469–2015. Apparaty kosmicheskiye avtomaticheskiye. Termobalansnyye i termovakuumnyye ispytaniya [State Standard R 56469–2015. Space automatic devices. Thermal balance and thermal vacuum tests]. Moscow, 2017. 15 p.

- Aliseenko Y. V., Ivanov D. V., Bubnov O. V., Panteleev V. I. [Analysis of failure statistics and increased reliability of ground power equipment manufactured by NIIIAEM TUSUR]. Materialy Nauchno tekhnicheskoy konferentsii molodykh spetsialistov “Elektronnyye i elektromekhanicheskiye sistemy i ustroystva” [Materials of the Scientific and Technical Conference of Young Specialists “Electronic and Electromechanical Systems and Devices”]. Tomsk, 2018, p. 31–33 (In Russ.).

- Aliseenko Y. V., Leonov D. V., Golovko V. V. [Development of a solar simulator with redundancy and longer uptime]. Materialy mezhdunarodnoy nauchnoy konferentsii molodykh uchenykh “Tekhnicheskiye nauki: fundamental'nyye i prikladnyye issledovaniya”. [Materials of the international scientific conference of young scientists “Engineering: fundamental and applied research”]. Novosibirsk, 2016, P. 5–10 (In Russ.).

- Fedosov V. V. Nadezhnost' sistem upravleniya kosmicheskikh apparatov [Reliability of the control systems of spacecraft]. Krasnoyarsk, 2017, 360 p.

- Schwank J. R., Sexton F. W., Fleetwood D. M. Temperature effekts on the radiation respronse of MOS devices. IEEE Trans, 1988, Vol. 6. P. 1432–1437.

- Danilin N. S. Informatsionnyye tekhnologii i sertifikatsiya elementnoy bazy novykh rossiyskikh telekommunikatsiy [Information technology and certification of the element base of new Russian telecommunications]. Moscow, RTA GTK, 2000, Р. 76–78.

- Urlichich Y. M., Danilin N. S. Upravleniye kachestvom kosmicheskoy radioelektronnoy apparatury v usloviyakh global'noy otkrytoy ekonomiki [Quality management of space electronic equipment in a global open economy]. Moscow, Maks Press Publ., 2003, P. 198–199.

- Fedosov V. V., Patraev V. E. [Improving the reliability of spacecraft electronic equipment when using electronic radio products that have undergone additional screening tests in specialized testing technical centers]. Aviakosmicheskoye priborostroyeniye. 2006, No. 10, P. 50–55 (In Russ.).

- Gorlov M., Anufriev L., Stroganov A. [Screening technology tests as a means of increasing the reliability of IP batches]. Chip News. 2001, No. 5 (In Russ.).

- RD V 22.32.119–89. Metodicheskoye posobiye po vyboru i ispol'zovaniyu metodov i sredstv elektrofiziches ogo diagnostirovaniya elektroradioizdeliy [Methodological manual on the selection and use of methods and means of electrophysical diagnosis of radio products]. 22 CNII MO RF, 1989, 210 p.

- Integrated circuits, monolithic. ESA/SCC. Generic Specification No 9000. 1998, P. 36.

- RD 11 0682–89. Mikroskhemy integral'nyye. Metody nerazrushayushchego kontrolya diagnosticheskikh parametrov [Integrated circuits. Non-destructive testing methods for diagnostic parameters]. 1990, 77 p.

- Fedosov V. V., Orlov V. I.[ The minimum required test volume of microelectronics products at the input control stage]. Izv. Vuzov. Priborostroenie. 2011, Vol. 54, No. 4, P. 56–62 (In Russ.).

- Pritkoe S. F., Gorbacheva V. M., Borisov A. A. Nadezhnost' ERI [EEEs Reliability]. Moscow, 22 CNII MO RF, 2006, 641 p.

- Nadezhnost' ERI IP [EEEs Reliability of foreign manufacture]. St. Petersburg, RNII Electronstandart Publ., 2006, 52 p.

- Aliseenko Y. V., Vorontsova E. O., Pravikova A. A. [Increased reliability and feasibility study of ground power variation equipment manufactured by NIIIAEM TUSUR]. Tezisy dokladov vtoroy molodozhnoy konferentsii “Innovatsionnaya deyatel'nost' v nauke i tekhnike. Elektromekhanika, avtomatika i robototekhnika” [Abstracts of the second youth conference “Innovation in science and technology. Electromechanics, automation and robotics”]. Istra, 2018, P. 5–7 (In Russ.).