An approach to fault diagnosis of gearboxbased on an instantaneous angular acceleration. Experimental study

Автор: Sinitsin V.V., Shestakov A.L.

Рубрика: Приборостроение, метрология и информационно-измерительные приборы и системы

Статья в выпуске: 1 т.20, 2020 года.

Бесплатный доступ

Introduction. Gears are important parts of almost every operating mechanism in many industries. The gear condition monitoring is an important unit of condition monitoring of a mechanism as a whole. The vibration is one of the most used sources of information for equipment technical diagnostics. Traditionally, vibration is measured by accelerometers which are fixed on the mechanism body. Analyse of the measured data from the accelerometers requires applying the special methods and the staff with developed analytical skills. On the other hand, a novel approach to the accelerometer fitting location allows receiving extra diagnostic information and facilitating diagnosis. Aim. The present study shows the application of the novel approach to the accelerometer fitting location and the analyse of extra information for gearbox diagnosis. Materials and methods. The novel accelerometer fitting location is a rotating shaft of the mechanism. The extra diagnostic information is an angular acceleration of the rotating shaft. The theoretical base for the angular acceleration as diagnosis information is shown in the study. Results. The study contains experimental results of fault detecting such as the 'chipped tooth' and 'broken tooth' of a pinion. In addition, the study contains the proposed criteria for the detection of the local fault. Conclusion. The experimental results and the applied criteria show that the proposed approach allows detecting the pinion local defect on the first pinion rotation frequency clearly at various rotation frequencies.

Diagnostics, accelerometer, wireless acceleration sensor, rotating shaft, rotating machinery, angular acceleration

Короткий адрес: https://sciup.org/147232308

IDR: 147232308 | УДК: 53.083.1 | DOI: 10.14529/ctcr200109

Текст научной статьи An approach to fault diagnosis of gearboxbased on an instantaneous angular acceleration. Experimental study

Gears are widely used in operating mechanisms in many industries. Variable loads and speeds lead to gear wear. Moreover, the growth of the defect rapidly evaluates and can be a factor of irreparable harm. In addition, the diagnosis of the gears is highly important but it is a difficult problem because of non-steady-state operations, as previously mentioned.

The most common method of gears diagnosis is vibration diagnostics [1, 2]. Nevertheless, even a defect-free gear pair has some work vibration, which has a wide frequency band. The vibration is the result of key factors: cyclic variation of gear teeth stiffness in a meshing phase and manufacturing and assembly errors [3]. The cyclic variation and constant meshing tooth error excite oscillations on a gear-meshing frequency f z

-

fz = z1 f l = z 2 fЪ

where z 1 , z 2 are teeth number of pinion and gear, respectively. The f 1 , f 2 are rotation frequencies of the pinion and gear, respectively [4]. The variable meshing tooth appears on the rotation frequencies kf 1 , kf 2 ( k = 1, 2, 3, …), and the modulated frequencies mf z ± nf 1 , mf z ± nf 2 ( m , n = 1, 2, 3, …) [5]. At the same time, the frequency spectrum has components that are associated with cutting error of pinion and gear f d

-

f d = kzdf, k = 1,2,...,

where zd is the number of teeth of the gear wheel of the gear cutting machine. Operating defects of gears mating surfaces (such as wear, microchipping, sticking, crack, chipping, broke and related) are an additional consideration of frequency spectrum change. Moreover, a broken tooth is the most dangerous type of defect in view of rapid growth from crack to broke. Operational defects of gear at an early stage have a low energy contribution in the frequency spectrum that makes more complicated detecting them. Furthermore, commonly gearboxes are operated with other mechanical nodes, which also make high-level noises [6, 7]. That fact is challenging to methods of gearbox diagnosis and successfully fault detection [8, 9].

Traditional source of information about condition gearbox is accelerometers which are fixed on the gearbox body. Moreover, various methods, criteria, and indicators are used for gearbox diagnosis in the time-domain, frequency-domain, and time-frequency domain. The time-domain diagnosis is the poorly-successful and problematic approach. That fact was shown in studies [10–12]. On the other hand, diagnosis in frequency-domain and time-frequency domain are more successful approaches. The commonly conditional indicators in the frequency-domain are the kurtogram [13, 14], kurtogram with TSA [15], adaptive SK filtering method on the grounds of Morlet wavelet [16] et alii. The commonly conditional indicators in the time-frequency domain are Hilbert-transform based methods [17, 18].

The author in study [19] describes the 8-DOF dynamic model of a gearbox in detail with a local defect of the pinion. The function of gear tooth meshing stiffness varies according to the modelled defect type (chipped or broken tooth). The pinion has z 1 = 19 teeth; the gear has z 2 = 48 teeth. The frequency of pinion rotation is f1 = 30 Hz. The result shows a spectrum changing of gear linear accelerations with various local defects, which corresponds to the “canonical” non-monotonic behaviour described in the literature. However, focusing on the traditional measurement methods, the author considered the behaviour of only the linear acceleration spectrum. On the other hand, analysis of the spectrum of an angular acceleration gear allows for increasing possibilities of a gearbox diagnosis.

The approach of the shaft acceleration measuring from the rotating shaft, including angular acceleration, studied in [20]. Moreover, the mathematical model one of the design versions of the WAS-Technology sensor described in [21]. That design allows measuring angular acceleration, two linear accelerations in the diametrical plane and the turning angle of the shaft.

1. Method for processing of angular acceleration

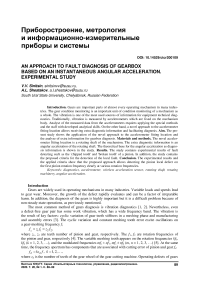

An analysis of the gear angular accelerations changing (dynamic model from Ref. [19]) under the influence of local defects shows that the changes of the spectrum discrete components are associated

Linear acceleration. Gear

Linear acceleration. Gear

a)

b)

c)

Fig. 1. Frequencies spectrum of the gear angular accelerations with a local defect: a – without defect; b – chipped tooth; c – broken tooth

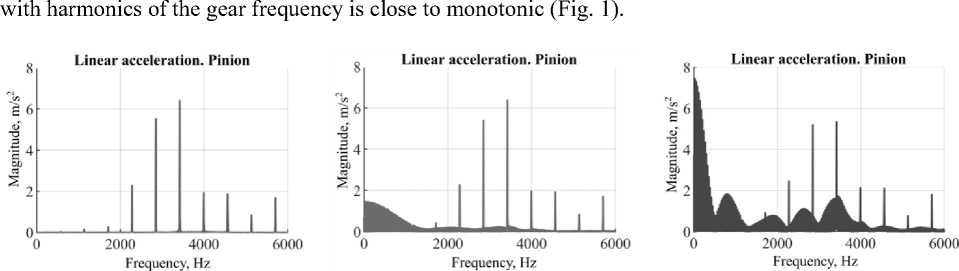

At the same time, a modulation index of the angular acceleration spectrum around harmonics of the gear frequency increases in the same way as the linear acceleration spectrum. Moreover, defects detection based on a comprehensive analysis of discrete components, which are associated with harmonics of the gear and rotation frequencies, by the Prism-method was studied in [22, 23]. On the other hand, the first pinion harmonic f 1 of the gear angular spectrum increases by increasing local defect, in other words, the level of harmonics of the frequency meshing defected tooth increases (Fig. 2).

Fig. 2. The first harmonic angular acceleration of defected pinion with various defects

Thus, the level of the first pinion harmonic can operate as a criterion for the detection of local defects, such as a chipped and broken tooth.

-

2. Test equipment

-

2.1. Experimental rig

-

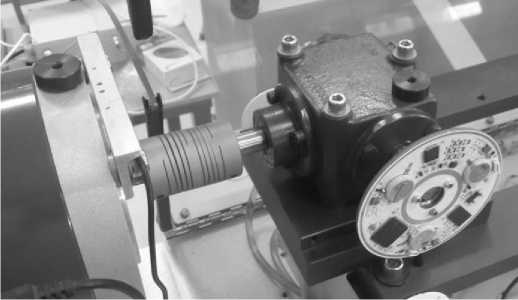

The applicability of the proposed criterion for the diagnosis of gear transmission is considered on the example of a single-stage gearbox of the experimental rig (MFS-Magnum from SpectraQuest) with bevel gears (Fig. 3).

The motor of the experimental rig is operated by the frequency drive that allows setting any motor rotation frequency in the operating range.

The pinion of the gearbox has z p = 18 teeth; the gear has z g = 27 teeth. The design of

Fig. 3. Gearbox with mounted the WAS-Sensor

the studied gearbox allows for the simulation of the pinion defects such as the chipped tooth (Fig. 4) and

the broken tooth (Fig. 5).

Fig. 4. Pinion with the chipped tooth

Fig. 5. Pinion with the broken tooth

Simulating the pinion defects due to pinion experiences more wear than the gear because pinion has fewer teeth and makes more revolutions.

-

2.2. WAS-Sensor

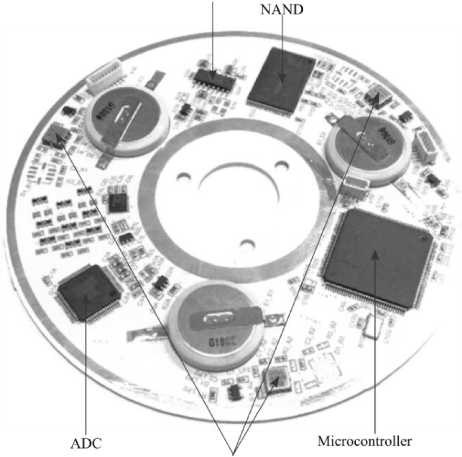

The applicability of the proposed criterion for the diagnosis of gear transmission designed the prototype of a WAS-Sensor based on WAS-Technology. The WAS-Sensor contains three MEMS-accelero-

RF-receiver

Accelerometers

Fig. 6. The prototype of the WAS-Sensor

meters (ADXL001-70 from Analog Devices) (Fig. 6). Each accelerometer has a measurement rate ±70g, resonance frequency 22 kHz, sensitivity 24.2 mV/g at 100 Hz. The mathematical model of the Sensor is described in the study [21]. Also, the WAS-Sensor contains ADC (AD7609 from Analog Devices) which samples of accelerometers signals at 39.4 kHz. Moreover, the WAS-Sensor contains microprocessor (STM32L476 from STMicroelectronics) which controls accelerometers and ADC, makes pre-filtering signals and writes data to NAND. Also, the WAS-Sensor has lithium batteries for power.

-

3. Experimental results

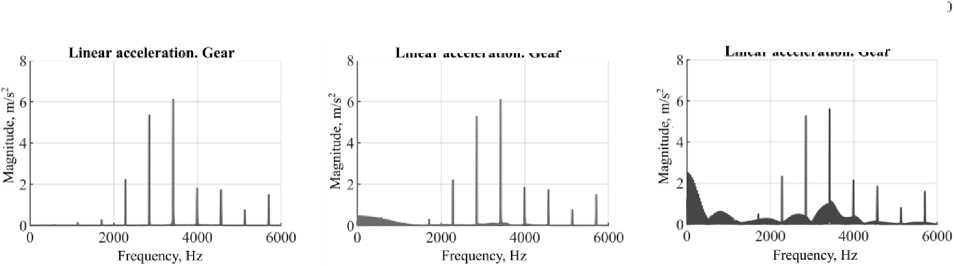

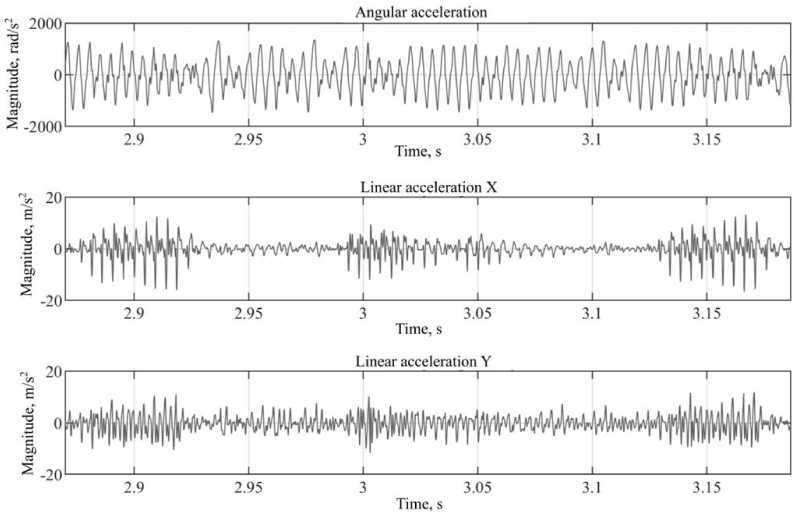

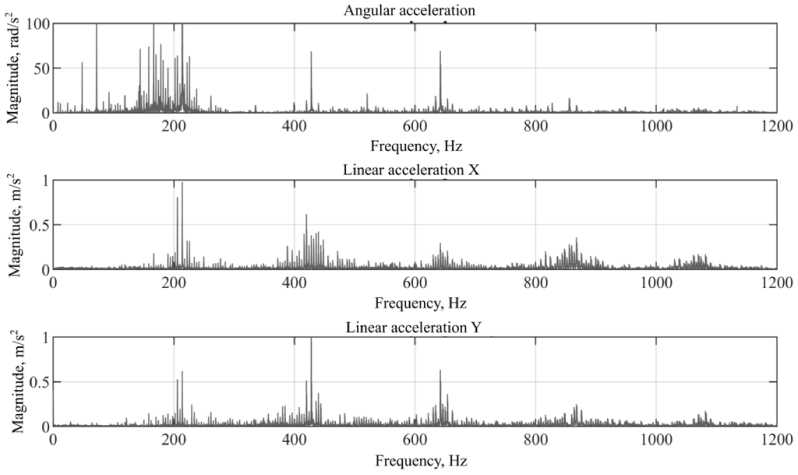

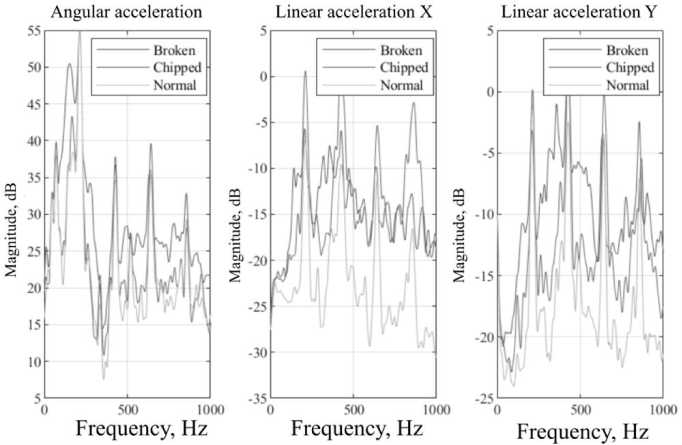

The WAS-Sensor was fixed on output shaft of their gearbox. The gearbox was diagnosed in a quasisteady operation. The simulator motor rotation frequency had 12 Hz. Thus, the output shaft was rotated with 8 Hz in accordance with gear-ratio kz = 1.5. The measured linear accelerations of the output shaft by the WAS-Sensor contain periodic high-frequency vibrations for the chipped tooth situation (Fig. 7). The frequency spectra of the accelerations measured by the sensor contain many components, including discrete peaks (Fig. 8).

Comparison of the power spectrum of each acceleration ϕ , x and y for each gear defect (Fig. 9) clearly shows the change of the vibration signals – the change in the energy ratio of the spectrum com- ponents.

Fig. 7. The measured angular and linear accelerations by the WAS-Sensor. The pinion with the chipped tooth. Time domain

Fig. 8. Separated angular and linear accelerations. Pinion with the chipped tooth. Frequency domain

Moreover, the power spectrum grows around multiple of the tooth ripples (214 Hz, 428 Hz, 642 Hz, 856 Hz), for the case 'the chipped tooth pinion'. Furthermore, the levels of discrete components of linear acceleration x are significantly lower in the region of multiple frequencies for broken tooth case than for the chipped tooth case. On the other hand, the depth of modulation around the multiple of the tooth ripples substantially increased (Fig. 9). Thus, the paradoxical behaviour of the spectral characteristics for the different size of the tooth defect is clearly shown.

As previously mentioned, the presence of local defects affects a change of the stiffness gearmeshing function. A change of stiffness effects on a change of the force in the tooth contact pattern and a change of the angular acceleration of the gears. Moreover, a local defect affects a change of the magnitude of the frequency components which are related to the frequency meshing defected tooth.

Fig. 9. The power spectrum for defects of the pinion. ‘Broken’ – broken tooth, ‘Chipped’ – chipped tooth, ‘Normal’ – without defect

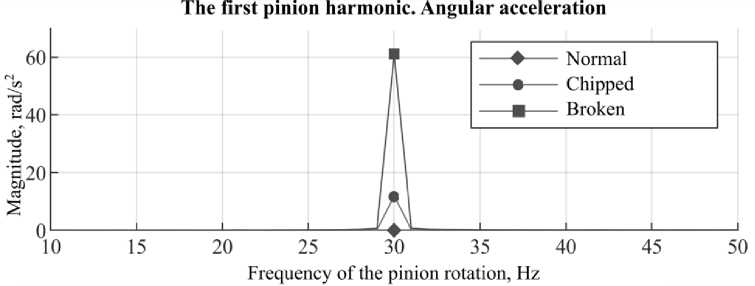

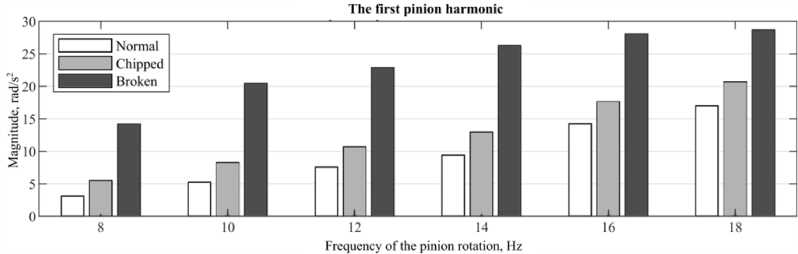

The growth of a local defect (from chipped to breaking) leads to an increase in the amplitude of the first harmonic of angular acceleration A p due to a reduction of the stiffness gear-meshing. Thus,

ANorma = 7,6rad/s2; AChipped = 10,7rad/s2; A^ = 22,9rad/s2, where А^оппai — the pinion without defect A^,hipped - the pinion with chipped tooth, Автокеп - the pinion with broken tooth.

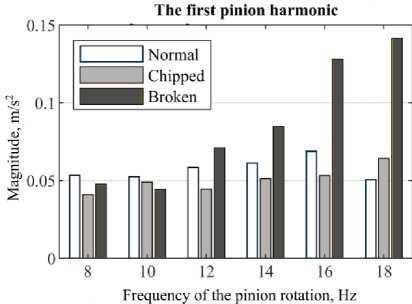

As a result, the grown of the local defect leads to a monotonic increase magnitude of the A ф. Moreover, that trend continues at other rotation frequencies of the pinion (Fig. 10).

Fig. 10. The magnitude of the first harmonic of the pinion in angular acceleration for various local defects. ‘Broken’ – the pinion with broken tooth, ‘Chipped’ – the pinion with chipped tooth, ‘Normal’ – the pinion without defects

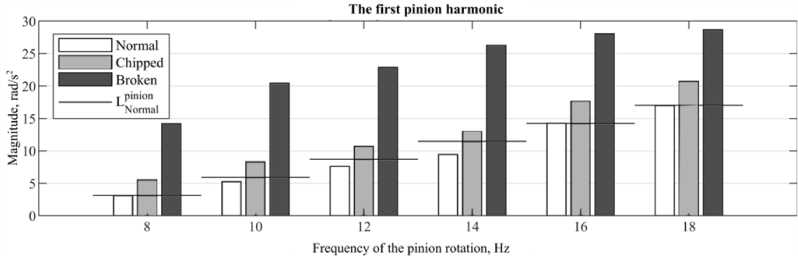

The amplitude of the first rotation frequency component in angular acceleration is increased with the increasing rotation frequency of the pinion. Moreover, the amplitude of the first rotation frequency component for the faultless case has an almost linear dependence on the rotation frequency from 8 to 18 Hz (Fig. 11).

Fig. 11. The magnitude of the first harmonic of the pinion in angular acceleration for various local defects. ‘Broken’ – the pinion with broken tooth, ‘Chipped’ – the pinion with chipped tooth, ‘Normal’ – the pinion without defects, L pinion – the linear function between the lower and the upper rotation frequency

Moreover, the amplitude of the first rotation frequency component is below the corresponding value of the bounding function LN^ (fpinion), where fpinion is frequency of the pinion rotation (Fig. 12). The function pinion

Normal (f pinion ) ^ототта! f pinion normal, where k – slope coefficient of the bounding function, bnormal – constant displacement of the bounding function.

For the experimental case

^ normal = 1,3898, b normal =— 7,9864.

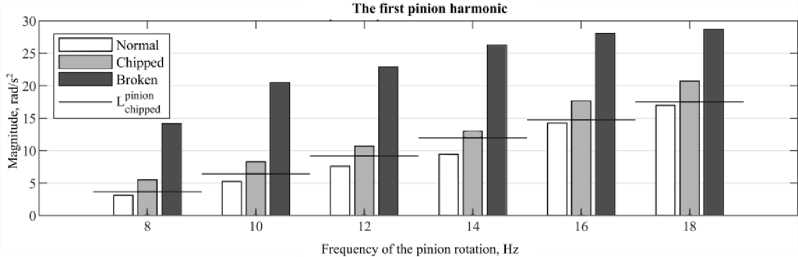

In turn, all values of the amplitudes of the first harmonic for each rotation frequency of each defective case are more than the values of the bounding function Lpno^ (fpinion). In addition, the values for both defects cases are close to direct dependence on the rotation frequency as well as for the defect-free case. Thus, a diagnostic criterion for detecting a local defect of the gearbox pinion is function Lpinion . The function pinion chipped

L chipped = k border * f pinion + b border ; k border k normal , b border = b normal + b shift *

where k – slope coefficient of the criteria function, b – constant displacement of the criteria function bchipped – constant displacement of the criteria function relatively the bounding function pinion

L Normal ( f pinion ) .

For the experimental case (Fig. 12) b chippped = 0,5 .

The difference between the values of the amplitude of the 'chipped pinion' and the value of the criteria function Lpinion vacillates between 1 and 3.2 rad/s2 for different rotation frequencies. The difference between the values of the amplitude of the 'broken pinion' and the value of the criteria function Lpinion are between 10.6 and 14.3 rad/s2 for different rotation frequencies.

Fig. 12. The magnitude of the first harmonic of the pinion in angular acceleration for various local defects at various rotation frequencies. ‘Broken’ – the pinion with broken tooth, ‘Chipped’ – the pinion with chipped tooth, ‘Normal’ – the pinion without defect, L c p h in ip io p n ed – the criteria function detecting of a 'chipped tooth' defect at various rotation frequencies

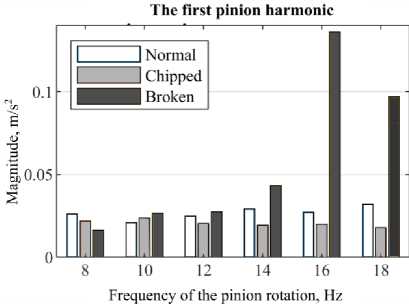

The ICP-accelerometer (by PCB Piezotronics) was mounted on the gearbox body for comparing the proposed approach with the traditional approach receiving diagnosis information (from a gearbox body). The ICP-accelerometer has a 3-axis with a sensitivity of 100 mV/g. The linear accelerations were measured at the same rotation frequencies and with the same defects such as the proposed approach. However, the results show the magnitude of the first harmonic of the pinion in linear accelerations does not depend on the rotation frequency and the defect (Fig. 13).

a)

Fig. 13. The magnitude of the first harmonic of the pinion in linear accelerations measured by the ICP-accele-rometer (a – horizontal axis, b – vertical axis) for various local defects at various rotation frequencies. ‘Broken’ – the pinion with broken tooth, ‘Chipped’ – the pinion with chipped tooth, ‘Normal’ – the pinion without defect

b)

Moreover, the value of the magnitude for a ‘normal’ case is more than the values of a ‘chipped’ and a ‘broken’ cases at some rotation frequencies.

Discussion

The proposed approach allows clearly detecting the pinion local defect on the first pinion rotation frequency. On the other hand, the local pinion defect information is hidden in data from the traditional approach (from a gearbox body). Hence, the measurement angular acceleration from a shaft allows receiving extended information about the behaviour of the mechanical system. The application of the proposed approach diagnosis allows detecting a local defect of the pinion, for example, 'chipped tooth' type easily. The approach dispenses without special signal processing methods unlike with the traditional approach. Nevertheless, the proposed approach requires an additional extended experimental investigation for various types of gearbox with various mechanical loads. It will be the topic of the future research.

Acknowledgments

The work was supported by Act 211 Government of the Russian Federation, contract 02.A03.21.0011.

Список литературы An approach to fault diagnosis of gearboxbased on an instantaneous angular acceleration. Experimental study

- Two New Features for Condition Monitoring and Fault Diagnosis of Planetary Gearboxes / Y. Lei, N. Li, J. Lin, Z. He // JVC/Journal of Vibration and Control. - 2015. - Vol. 21, no. 4. - P. 755-764. DOI: 10.1177/1077546313486284

- Nie, M. Review of Condition Monitoring and Fault Diagnosis Technologies for Wind Turbine Gearbox / M. Nie, L. Wang // Procedia CIRP Elsevier. - 2013. - 11. - P. 287-290. DOI: 10.1016/j.procir.2013.07.018

- Генкин, М.Д. Виброакустическая диагностика машин и механизмов / М.Д. Генкин, А.Г. Соколова. - М.: Машиностроение, 1987. - 288 с.

- Effect of Cracks and Pitting Defects on Gear Meshing / A.F. Rincon, F. Viadero, M. Iglesias et al. // Proceedings of the Institute of Mechanical Engineers C. - 2012. - 226 (11). - P. 2805-2815. DOI: 10.1177/0954406212437104

- McFadden, P.D. Detecting Fatigue Cracks in Gears by Amplitude and Phase Demodulation of the Meshing Vibration / McFadden P.D. // Journal of Vibration, Acoustics, Stress, and Reliability in Design. - 1986. - 108. - P. 165-170. DOI: 10.1115/1.3269317

- Gearbox Fault Diagnosis Based on Deep Random Forest Fusion of Acoustic and Vibratory Signals / C. Li, R. Sanchez, G. Zurita et al. // Mechanical Systems and Signal Processing. - 2016. - Vol. 76-77. - P. 283-293.

- DOI: 10.1016/j.ymssp.2016.02.007

- Loutridis, S.J. Gear Failure Prediction using Multi-scale Local Statistics / S.J. Loutridis // Engineering Structures. - 2008. - 30. - P. 1214-1223.

- DOI: 10.1016/j.engstruct.2007.07.022

- Samuel, P.D. A Review of Vibration-Based Techniques for Helicopter Transmission Diagnostics / P.D. Samuel, D.J. Pines // Journal of Sound and Vibration. - 2005. - 282. - P. 475-508.

- DOI: 10.1016/j.jsv.2004.02.058

- Condition Monitoring and Fault Diagnosis of Planetary Gearboxes: a Review / Y.G. Lei, J. Lin, M.J. Zou, Z.J. He // Measurement. - 2014. - 48. - P. 292-305.

- DOI: 10.1016/j.measurement.2013.11.012

- Zakrajsek, J.J. Detecting Gear Tooth Fatigue Cracks in Advance of Complete Fracture / J.J. Zakrajsek, D.G. Lewicki // Tribotest. - 1998. - Vol. 4, iss. 4. - P. 407-422.

- Evaluation of Gear Condition Indicator Performance on Rotorcraft Fleet / L.J. Antolick, J.S. Branning, D.R. Wade, P.J. Dempsey // AHS 66th Annual Forum and Technology Display. - Phoenix, United States, NASA, 2010, May. - P. 12.

- A New Feature Extraction Method for Gear Fault Diagnosis and Prognosis / X.H. Zhang, J.S. Kang, E. Bechhoefer, J. Zhao // Eksploatacja i Niezawodnosc - Maintenance Reliability. - 2014. - 16 (2). - P. 295-300.

- Antoni, J. The Spectral Kurtosis: a Useful Tool for Characterising Nonstationary Signals / J. Antoni // Mechanical Systems and Signal Processing. - 2006. - Vol. 20, no. 2. - P. 282-307.

- DOI: 10.1016/j.ymssp.2004.09.001

- Combet, F. Optimal Filtering of Signals for Early Damage Detection Based on the Spectral Kurtosis / F. Combet, L. Gelman // Mechanical Systems and Signal Processing. - 2009. - 23. - P. 652-668.

- DOI: 10.1016/j.ymssp.2008.08.002

- Barszcz, T. Application of Spectral Kurtosis for Detection of a Tooth Crack in a Planetary Gear of a Wind Turbine / T. Barszcz, R.B. Randall // Mechanical Systems and Signal Processing. - 2009. - 23. - P. 1352-1365.

- DOI: 10.1016/j.ymssp.2008.07.019

- Adaptive Spectral Kurtosis Filtering Based on Morlet Wavelet and its Application for Signal Transients Detection / H. Liu, W. Huang, S. Wang, Z. Zhu // Signal Processing. - 2014. - 96. - P. 118-124.

- DOI: 10.1016/j.sigpro.2013.05.013

- Feldman, M. Hilbert Transform in Vibration Analysis / M. Feldman // Mechanical Systems and Signal Processing. - 2011. - Vol. 25, no. 3. - P. 735-802.

- DOI: 10.1016/j.ymssp.2010.07.018

- Djebala, A. Application of theWavelet Multi-resolution Analysis and Hilbert Transform for the Prediction of Gear Tooth Defects / A. Djebala, N. Ouelaa, C. Benchaabane // Meccanica. - 2012, Oct. - Vol. 47, no. 7. - P. 1601-1612.

- DOI: 10.1007/s11012-012-9538-1

- Tian, X. Dynamic Simulation for System Response of Gearbox Including Localized Gear Faults / X. Tian // Dissertation of Master Degree, Edmonton, Canada, University of Alberta, 2004. - P. 194.

- Патент на полезную модель 142934 Российская Федерация, МПК7 G 01 P 15/02, G 01 H 9/00. Устройство измерения виброускорения подвижных элементов машин и механизмов / В.В. Синицин, А.С. Семенов, А.Л. Шестаков; заявитель и патентообладатель ФГБОУ ВПО "ЮУрГУ" (НИУ). - № 2014109714/28; заявл. 12.03.2014; опубл. 10.07.2014, Бюл. № 19.

- Sinitsin, V.V. Wireless Acceleration Sensor of Moving Elements for Condition Monitoring of Mechanisms / V.V. Sinitsin, A.L. Shestakov // Measurement Science and Technology. - 2017, Aug. - Vol. 28, no. 9. - P. 094002.

- DOI: 10.1088/1361-6501/aa7ab6

- Henry, M. Prism Signal Processing for Machine Condition Monitoring I: Design and Simulation / M. Henry, V.V. Sinitsin // IEEE Industrial Cyber-Physical Systems (ICPS). - St. Petersburg, Russia, IEEE, 2018, May. - P. 452-457.

- DOI: 10.1109/ICPHYS.2018.8390747

- Henry, M. Prism Signal Processing for Machine Condition Monitoring II: Experimental Data and Fault Detection / M. Henry, V.V. Sinitsin // IEEE Industrial Cyber-Physical Systems (ICPS). - St. Petersburg, Russia, IEEE, 2018, May. - P. 458-463.

- DOI: 10.1109/ICPHYS.2018.8390748