Application and properties of polymer composite carbon fibers

Автор: Nazarov B.J.

Журнал: Экономика и социум @ekonomika-socium

Рубрика: Основной раздел

Статья в выпуске: 4-1 (83), 2021 года.

Бесплатный доступ

The production of synthetic fibers based on polymer compounds, which is one of the achievements of modern science, and carbon fiber, one of the new synthetic fibers, can be found at every stage of our lives today. Today's development of industry, production, engineering and technology is related to carbon fiber. The article reviews the research and development work on carbon fiber over the last few decades. The two most important types of carbon fiber are the leading industrial polyacrylonitrile (LIP) and mesophase height (MH). The structure and composition of the precursor significantly affect the properties of the carbon fibers formed.

Carbon fiber, graphite, polyacrylonitrile, composite materials, polymer

Короткий адрес: https://sciup.org/140260431

IDR: 140260431

Текст научной статьи Application and properties of polymer composite carbon fibers

Introduction.

Carbon fiber is a long and thin material with a diameter of 0.0002-0.0004 (0.005-0.010 mm) and consists mainly of carbon atoms. Carbon atoms are bonded together in microscopic crystals that are more or less flattened parallel to the long axis of the fiber. The alignment of the crystal is extremely strong due to the size of the fiber. Several thousand carbon fibers are twisted together to form a yarn that can be used on its own or woven into a fabric. The yarn or fabric is bonded with epoxy and wrapped or shaped to form a variety of composite materials. Carbon fiber-reinforced composite materials include aircraft and spacecraft parts, racing car hulls, golf club shafts, bicycle frames, fishing rods, automotive welds, sailing poles, and carbon fiber, among other sports, aerospace, civil engineering, military, and motor sports. widely used in equipment. However, compared to similar fibers, they are relatively expensive glass fibers or plastic fibers. To produce carbon fiber, carbon atoms are bonded together in more or less flattened crystals parallel to the long axis of the fiber because the alignment of the crystal provides high strength.

In 1860, Joseph Swan first produced carbon fiber for use in light bulbs. [1] In 1879, Thomas Edison used carbon fiber in one of the first incandescent light bulbs to heat cotton yarn or bamboo yarn electrically heated to high temperatures. [2] In 1880, Lewis Latimer developed a reliable carbon wire filament for an electric incandescent bulb. released. [3]

In 1958, Roger Bacon created high-efficiency carbon fibers. [4] This process proved inefficient because the resulting fibers contained only 20% carbon and had low strength and hardness properties. Polyacrylonitrile (LIP) was developed by Dr. Akio Shindo in the early 1960s. This produced carbon fiber, which contained about 55% carbon. In 1960, H.I. Richard Millington. Thompson Fiberglas Co. developed the high-carbon (99%) fiber production process (U.S. Patent № 3,294,489), using the region as a pioneer. These carbon fibers are strong enough to be used to reinforce high-strength composites for weight and high temperature-resistant application.

Structure and properties:

Carbon fiber is often transferred continuously in a coil. A network is a collection of thousands of continuous carbon filaments that are joined together and protected by an organic coating or dimension, e.g. polyethylene oxide (PO) or polyvinyl alcohol (PA).

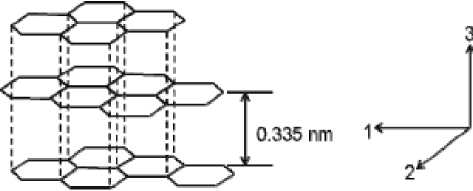

The atomic structure of the carbon fiber (Fig. 1) is similar to that of graphite, a hexagonal pattern in which the atoms of carbon layers are arranged in regular order (graphene tables), the difference being in the interconnection of these sheets. Graphite crystal sheets are regularly placed parallel to each other. The intermolecular forces between the sheets are relatively weak Van der Vals forces, giving graphite its` soft and brittle properties.

Figure 1. Structure of graphitic crystals and crystal directions.

Figure 1 . Structure of graphite crystals.

Depending on the fiber manufacturer, carbon fiber can be turbostratic or graphite, or it can have a hybrid structure with graphite and turbostratic components. In a turbostratic carbon fiber, the layers of carbon atoms are randomly folded or twisted. The resulting carbon fiber is polyacrylonitrile (LIP) turbostratic, while the carbon fiber obtained is graphite after heat treatment at temperatures above 2200 ° C with mesophase altitude.

Two different equations that control the exact elastic modulus of composite materials using the properties of carbon fibers and polymer matrices can also be applied to plastics reinforced with carbon fibers. [5] The following equation,

^C = + Vf Ef (1)

Fibers apply to composite materials according to the direction of load applied. ^C is the general composition modulus, Vm fin d Em are the corresponding volume fractions in the matrix and fiber composition, and Em and f are the matrix and fiber elasticity modules, respectively. Another extreme state of the elastic modulus of a composite with transversely oriented fibers can be found using the following equation. [5]

E C =( V m / E m + V f / E f ) (2)

The fracture toughness of carbon-fiber-reinforced plastics is governed by the following mechanisms: 1) decontamination between the carbon fiber and the polymer matrix, 2) tensile strength of the fiber, and 3) delamination between the carbon fiber plates. [6] Typically, epoxy-based carbon fibers exhibit almost no plasticity, which is less than 0.5% for failure. Although epoxy-operated carbon fibers have high strength and elastic modulus, brittle fracture mechanics pose specific challenges for engineers in determining failure. [6] Thus, recent efforts to harden carbon fibers include modifying the existing epoxy material and finding an alternative polymer matrix. One such highly promising material is PEEK, it exhibits a greater stiffness order with a similar elastic modulus and tensile strength. [6] However, PEEK processing is much more difficult and expensive. [6] Environmental influences such as temperature and humidity can have a major impact on polymer-based compositions, including most carbon fibers. Although carbon fibers exhibit excellent corrosion resistance, exposure to moisture over a wide temperature range can lead to deterioration of the mechanical properties of carbon fibers, particularly the matrix-fiber interface. [7] Moisture plasticizes the polymer matrix when the carbon fibers themselves are not affected by the moisture diffused into the material. [6] This led to significant changes in the properties affected by the matrix effect on the carbon fibers, such as compression, interlaminar shear, and impact properties. [8] The epoxy matrix used for engine fan blades is designed to be impermeable to reactive fuel, lubrication and rainwater, and external paint is applied to the composite parts to minimize damage from ultraviolet light. [6] [9]

Composite materials: Carbon fiber is a composite material used to reinforce, in particular, a class of materials known to be carbon fiber or graphite-reinforced polymers. Non-polymeric materials can also be used as a matrix for carbon fibers. Reinforced carbon-carbon (RCC) is a graphite-reinforced graphite that is used systematically in high-temperature applications. The formation of a thin carbon fiber layer significantly improves the fire resistance of polymers or thermoset composites because a dense, compact layer of carbon fiber effectively reflects heat. [10] The increasing use of carbon fiber composites due to galvanic corrosion problems is pushing aluminum out of aerospace applications in favor of other metals. [11] [12]

Carbon fiber can be used to make electrically conductive asphalt concrete in addition to asphalt. [13] The use of this composite material in transport infrastructure, especially on airport pavements, reduces some winter maintenance problems, leading to flight cancellations or delays due to the presence of ice and snow. The 3D network of carbon fibers passing through the composite material dissipates heat energy, which increases the surface temperature of the asphalt, over which ice and snow can melt. [14]

In textiles: Motorcycle racing gloves with carbon fiber protectors for the ligaments on your fingers. Carbon fiber yarns are used in several processing techniques: direct use pre-fabrication, yarn wrapping, pultrusion, weaving, knitting and more. For example, 200 tex for 3000 carbon fiber is three times stronger than 1000 carbon filament yarn, but at the same time three times heavier. The appearance of this fabric usually depends on the linear density of the yarn and the selected weave. Some of the most common types of fabric are round, satin, and flat.

Microelectrodes: Carbon fibers are also used to make microelectrodes. A single carbon fiber, typically 5–7 mm in diameter, is sealed in a glass capillary. [15] At the end, the capillary is sealed and polished with epoxy to form a carbon fiber disc microelectrode, or the fiber is cut to a length of 75–150 mm to form a carbon fiber cylindrical electrode. Carbon fiber is also used in microelectrodes to detect biochemical signaling by amperometry or rapidly checked cyclic voltammetry and in other cases.

Conclusion.

Of course, the use of carbon fiber is not one hundred percent beneficial, as these fibers can cause the following disadvantages: absorption, skin damage, and the negative impact of fibers on electrical equipment. In addition to being strong, carbon fiber is a good conductor of electricity. As a result, carbon fiber dust can cause springs and shorts in electrical equipment. Today, the latest development of carbon fiber technology is the so-called nanotubes of small carbon tubes, these hollow tubes with a diameter of 0.00004 (0.001 mm) have unique mechanical and electrical properties that make them a new high can be useful in the production of new semiconductor materials for strong fibers, submicroscopic test tubes, or integrated circuits.

Список литературы Application and properties of polymer composite carbon fibers

- Deng, Yuliang (2007). Carbon Fiber Electronic Communications (PDF) (Thesis). Archived (PDF) from the original on 2019-04-04. Retrieved 2017-03-02.

- "Highly effective carbon fibers". National historical chemical symbols. American Chemical Society. 2003. Archived from the original on 2014-04-27. Retrieved2014-04-26.

- "Talented People Who Worked for Edison." National Park Service. Archived from the original on 2015-02-07. Retrieved 2014-12-01.

- USA 2957756, Bacon, Roger, "Filamentary graphite and its production method", published in 1960-10-25

- Courtney, Thomas (2000). Mechanical movement of materials. United States: Waveland Press, Inc. Pages 247–249. ISBN 1-57766-425-6.

- Chawla, Krishan (2013). Composite materials. United States: Springer.ISBN 978-0-387-74364-6.

- Ray, B.C. (June 1, 2006). "Effect of temperature during wet aging on the interfaces of glass and carbon fiber reinforced epoxy compositions." Journal of Colloid and Interface Sciences. 298 (1): 111–117.Bibcode: 2006 JCIS..298..111R. doi: 10.1016 / j.jcis.2005.12.023. PMID 16386268.

- Almudaihesh, Fayzel; Holford, Karen; Pullin, Ris; Eaton, Mark (February 1, 2020). "Effect of water absorption on unilateral and 2-dimensional woven CFRP composites and their mechanical properties". Compositions Part B: Engineering.182: 107626. doi: 10.1016 / j.compositesb.2019.107626. ISSN 1359-8368.

- Guzman, Enrique; Kugnoni, Joel; Gmur, Thomas (May 2014). "Multifactor models of carbon fiber / epoxy composition that accelerate environmental aging." Composite structures. 111: 179–192.doi: 10.1016 / j.compstruct.2013.12.028.

- Zhao, Z .; Gou, J. (2009). "The fire resistance of thermoset composites modified with carbon nano fibers has been improved." Scientific work. Technol. Adv. Mater. 10 (1): 015005.Bibcode: 2009STAdM..10a5005Z.doi: 10.1088 / 1468-6996 / 10/1 / 015005.PMC 5109595. PMID 27877268.

- Banis, David; Marseau, J. Arthur; Mohaghegh, Michael (July 1999). "Design for Corrosion." Aero. № 7. Boeing. Archived from the original on 2013-09-02. Retrieved 2018-05-07.

- Warwick, Grem; Norris, Gay (2013-05-06). "Metallics are coming back with the flow of production." Aviation Week and Space Technology. Archived original on 2015-04-27.

- Notani, Muhammad Ali; Arabzoda, Ali; Jaylan, Halil; Kim, Sungxwan (June 2019). "Influence of carbon fiber properties on volumetric and ohmic heating of electrically conductive asphalt concrete". Journal of Building Materials. WE. 31 (9): 04019200. doi: 10.1061 / (ASCE) MT.1943-5533.0002868.

- Arabzoda, Ali; Notani, Muhammad Ali; Zadeh, Ayub Kazemiyan; Nahvi, Ali; Sassani, Alireza; Ceylan, Halil (2019-09-15). "Electrically Conductive Asphalt Concrete: An Alternative for Automating Winter Maintenance of Transport Infrastructure." Compositions Part B: Engineering. WE. 173: 106985. doi: 10.1016 / j.compositesb.2019.106985.

- Pike, Caroline M .; Grabner, Chad P .; Harkins, Amy B. (2009-05-04). "Manufacture of amperometric electrodes." Journal of Visual Experiments (27): 1040.doi: 10.3791 / 1040. PMC 2762914.PMID 19415069.

- “How is carbon fiber produced?”. Zoltek. 2017-08-10. Archived from the original on 2015-03-19.

- Books: Brady, George S., Henry R. Clauser, and John A. Vaccari. Materials Guide. McGraw-Hill, 1997. Croswitz, Jacqueline I., and Mary Howe-Grant, ed. Encyclopedia of Chemical Technology. John Wiley and Sons, Inc., 1993.