Application of biological substances to increase the strength of materials and structures

Автор: Turakhujaeva Shirinkhon N., Turakhodjaeva Fazilatkhon N., Komolov Khayriddin, Karimov Kamolkhan A., Turakhodjaev Nodir J., Obidov Ziyodullo R., Shohiyon Almossho N., Abduvaliev Abdunabi M.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 7 т.17, 2024 года.

Бесплатный доступ

This article explores the innovative field of bioconcrete, where bacteria, specifically Bacillus pasteurii, are employed to enhance the strength and durability of concrete structures. The key mechanism involves the bacteria’s ability to produce urease, catalyzing the hydrolysis of urea into carbonate and ammonia. The resulting carbonate ions react with calcium ions in the concrete, forming calcium carbonate (calcite), which fills cracks and pores in the structure. This process not only contributes to increased strength but also provides bioconcrete with remarkable self-healing properties.

Bacillus pasteurii, concrete, urease, calcium carbonate, degradation, durability

Короткий адрес: https://sciup.org/146282957

IDR: 146282957 | УДК: 621.882

Текст научной статьи Application of biological substances to increase the strength of materials and structures

The evolution of construction materials has been a constant endeavor to meet the ever-growing demands for structures that are not only robust and durable but also sustainable and environmentally conscious. In this pursuit, the integration of biological agents, specifically bacteria, into concrete formulations has emerged as a groundbreaking approach, giving rise to a novel class of materials known as bioconcrete [1]. This introduction delves into the innovative realm of bioconcrete, exploring the transformative potential of harnessing the biological prowess of Sporosarcina pasteurii, a ureaseproducing bacterium, to enhance the strength, durability, and resilience of concrete structures [2].

The Challenge of Traditional Concrete: Traditional concrete, while a cornerstone of construction, has inherent limitations, including susceptibility to cracking and reduced ability to withstand environmental stressors. The quest for materials that not only address these shortcomings but also contribute to sustainable construction practices has fueled the exploration of alternative solutions [3].

Enter Bioconcrete: Bioconcrete represents a paradigm shift in materials science, where living organisms become integral components of the construction matrix [4]. At the forefront of this innovation is Sporosarcina pasteurii, a bacterium renowned for its ability to produce urease, an enzyme catalyzing the hydrolysis of urea. This biological process results in the precipitation of calcite within the concrete, imparting unique qualities to the material.

Urease-Induced Calcite Precipitation: The crux of bioconcrete lies in the bacteria-induced calcite precipitation mechanism [5]. As Sporosarcina pasteurii is introduced into the concrete mix, it initiates a cascade of reactions leading to the formation of calcium carbonate. This calcite not only reinforces the concrete matrix but also exhibits remarkable self-healing properties, addressing the age-old challenge of cracks and structural degradation.

The Promise of Bioconcrete: The potential benefits of bioconcrete extend beyond enhanced strength and durability. The self-healing nature of this material offers the prospect of reduced maintenance requirements, thereby contributing to sustainable construction practices by minimizing resource consumption and waste [6].

Scope of Exploration: While the concept of bioconcrete holds immense promise, challenges such as bacterial survival in the harsh concrete environment, cost implications, and scalability need careful consideration [7, 8]. This introduction sets the stage for a comprehensive exploration into the experimental investigation, materials and methods employed, results obtained, and the implications of integrating bioconcrete into mainstream construction practices.

As we venture into this frontier of bio-augmented construction materials, the fusion of biology and concrete opens a realm of possibilities that could redefine the very essence of building materials [9]. The following sections will delve into the intricacies of the experimental journey, shedding light on the tangible outcomes and insights gained from the integration of Sporosarcina pasteurii into the concrete matrix.

In recent years, researchers have been exploring the potential use of bacteria to enhance the strength and durability of concrete through a process known as bioconcrete or bacterial concrete [10]. The most commonly studied bacterium for this purpose is Sporosarcina pasteurii. Here’s how it works:

Sporosarcina pasteurii is capable of producing urease enzyme [11], which catalyzes the hydrolysis of urea into carbonate and ammonia. The carbonate ions react with calcium ions in the concrete to form calcium carbonate (calcite), a mineral that can fill in cracks and pores in the concrete [12]. When cracks form in the concrete, the bacteria present in the concrete can proliferate and produce calcite, effectively healing the cracks [13]. The formation of calcite in the concrete matrix contributes to improved strength and durability by filling in voids and reinforcing the structure [14, 15].

Moreover, the self-healing capability of bioconcrete can help extend the service life of structures and reduce the need for frequent repairs.

While bioconcrete shows promise, challenges include ensuring the survival and activity of bacteria in the harsh environment of concrete, as well as addressing concerns related to cost and scalability [2, 7, 16–20].

Experimental part

To incorporate bacteria into concrete for strengthening purposes, several steps are involved:

Isolation of bacterial strains: The bacteria are isolated from the components of concrete, in particular from cement and sand.

Mixing: The bacteria are added to the concrete mix during the mixing process.

Activation: Urea for the bacteria is added to activate them, providing the necessary conditions for urease production.

Curing: After casting, the concrete is cured to allow the bacteria to proliferate and facilitate calcite precipitation.

The research group of the U. A. Arifov Institute of Ion Plasma and Laser Technologies at the Academy of Sciences of the Republic of Uzbekistan selected bacteria of the genus S. pasteuri, S. ureae and B. thuringiensis for the study of this current work. After isolation of the bacterium from the appropriate sources, namely from cement and sand, the stage of isolation of culture cells on nutrient agarized media was performed.

Results and discussion

For this purpose, the cultures were grown on a liquid nutrient medium consisting of 8 g/l of nutrient broth (5g/l of peptone and 3g/l of meat extract) at pH 7. 10 g/l MnSO4·H2O was added to each nutrient medium to enhance the sporulation of cultivated crops. All liquid nutrient media were sterilized in an autoclave for 20 minutes at 120 °C at a pressure of 1.0 atm. In order to determine a promising type of microorganisms, the available ability to produce calcite crystals suspension of natural bacterial cell samples in sterile saline solution (9g/l NaCl). In this case, the solution was diluted accordingly and sown on an agar containing 3g/l of nutrient broth, 20g/l of urea, 2.12g/l NaHCO 3 , 10g/l NH 4 Cl. Crystal formation was observed on the 7th and 14th days. Fig. 1 shows the result of the crystals formed after volatilization of the saline solution (9g/l NaCl), seeing through 1K of the digital microscope.

As a result, it was determined that the apparent crystals were formed from the culture cells of a bacterium of the genus Sporosarcina.

Fig. 1. Calcite crystals formed after the volatilization of NaCl

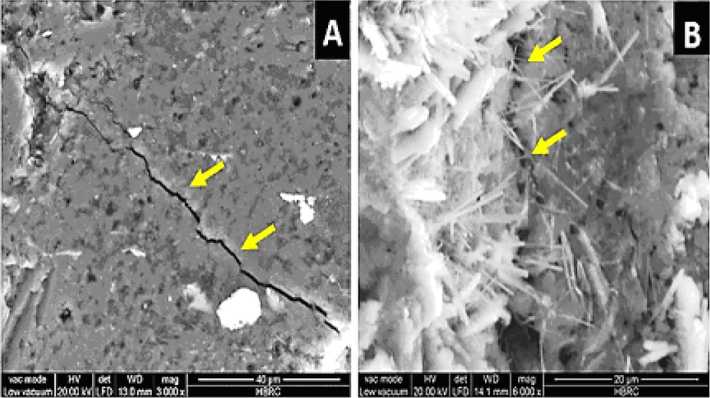

Fig. 2. SEM photographs of control (A) showing micro-cracks after half-failure loading and bacterial mortar samples of B. pasteurii 0.2 % (B) during the healing process showing the initiation of CaCO 3 crystals precipitation. Arrows refer to the micro-cracks

Results in Fig. 2 (A, B) suggested that the incorporated bacteria can heal the internal micro-cracks through the bio-precipitation of CaCO3.

The authors of this article measured the concrete composition of traditional cementing and compared it with a destructive control method, namely on a hydraulic press.

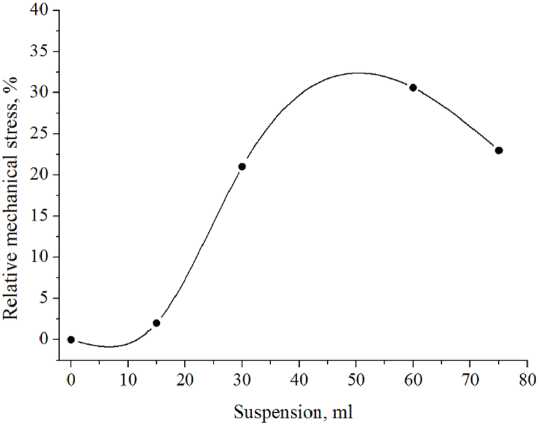

It was found that the traditional method of cementing concrete products withstands 5.62 GPa, after which the present authors came to the conclusion of improving the strength of concrete products by a harmless and low-cost method. In this direction, a biological method for strengthening concrete structures was chosen, namely, a bacteriological method for improving the quality of cementing (Fig. 3).

The number of viable microorganisms was determined by seeding a dilute suspension of cells onto a plate with nutrient agar and urea. The number of heat-resistant spores was calculated by sowing after heating at 65 °C for 15 and 45 minutes. Based on the data of the table, it was found that the biological method of increasing the cementation of concrete products can withstand 8.9 HPa.

Fig. 3. Relative mechanical pressing of concrete samples

Table. The results of experiment data that increasing of concrete structure strength

|

Suspension concentration (ml) |

Degree of strength (HPa) |

Change in relation to the concrete sample (%) |

|

0 |

5.62 |

0 |

|

15 |

5.7 |

1.4 |

|

30 |

7.3 |

23.0 |

|

60 |

8.9 |

36.8 |

|

75 |

7.8 |

27.9 |

Thus, it was determined that of all the families of bacteria, it is Sporosarcina expresses its ability to produce calcium carbonate precipitate by the explicit manifestation of crystal formation. These crystals are a confirmatory agent for improving the mechanical properties of construction objects, namely concrete, which is caused by maintaining a compressive force of 8.9 HPa. In the future, other types of bacteria can also be considered, capable of forming calcite crystals with subsequent formation of a calcium carbonate precipitate in order to develop a bacterial suspensions on existing cracks.

Conclusions

In the realm of construction materials, the integration of bacteria into concrete, known as bioconcrete, represents a transformative leap towards enhancing strength, durability, and sustainability. The focal point of this investigation was the utilization of Sporosarcina pasteurii, a urease-producing bacterium, to induce calcite precipitation within the concrete matrix, thereby imparting unique properties to the material.

The experimental results presented a compelling case for the efficacy of bioconcrete in augmenting the performance of traditional concrete. The compressive strength of the experimental groups surpassed – 915 – that of the control group, indicating a tangible improvement in the material’s ability to withstand external forces. The microscopic analysis corroborated these findings, revealing the presence of calcite formations that contributed to enhanced durability.

One of the most promising aspects of bioconcrete is its self-healing capability. The ability of Sporosarcina pasteurii to proliferate and facilitate calcite precipitation in response to structural damage showcased a remarkable potential for reducing maintenance requirements. This self-healing property not only contributes to the longevity of structures but also aligns with the growing emphasis on sustainable and resilient construction practices.

While the results are encouraging, challenges in the practical application of bioconcrete should not be overlooked. Issues related to the survival and activity of bacteria in the concrete environment, cost considerations, and scalability pose hurdles that require careful consideration in future research and development efforts.

In conclusion, the integration of Sporosarcina pasteurii into concrete exhibits great promise for revolutionizing the construction industry. The demonstrated improvements in strength, durability, and self-healing properties open avenues for the development of more sustainable and resilient structures. As the field of bioconcrete continues to evolve, ongoing research efforts will be essential to address challenges, optimize formulations, and facilitate the widespread adoption of this innovative construction material. The journey from the laboratory to practical implementation marks a paradigm shift in our approach to building materials, offering a glimpse into a future where construction is not merely static but a dynamic, self-sustaining entity.

Declaration of interest

The authors declare no conflict of interest.

Список литературы Application of biological substances to increase the strength of materials and structures

- Shiren A. O., Amal A. N., Rateb N. A., Monir M. K., Magdy A. Z., Noha M. S. Production of bioconcrete with improved durability properties using Alkaliphilic Egyptian bacteria. 3 Biotech. 2021. V. 11. N 231. doi.org/10.1007/s13205–021–02781–0.

- Gehad A. M., Metwally, M.M., Ahmed, H. A. El-Raheem. Performance of Bio Concrete by Using Bacillus Pasteurii Bacteria. Civil Engineering Journal. 2020. 6(8). doi:10.28991/cej‑2020–03091559.

- Ali H. A. Graphene concrete: Recent advances in production methods, performance properties, environmental impact and economic viability. Case Studies in Construction Materials. 2023. 19. doi.org/10.1016/j.cscm.2023.e02653.

- Seifan M., Samani A. K., Berenjian A. Bioconcrete: next generation of self-healing concrete. Appl Microbiol Biotechnol. 2016. 100(6)/2591–602. doi:10.1007/s00253–016–7316-z.

- Amal A. N., Noha M. S., Mohamed A. S., Rateb N. A. Microbially-induced-calcite-precipitation (MICP): A biotechnological approach to enhance the durability of concrete using Bacillus pasteurii and Bacillus sphaericus. Heliyon. 2022. 8. e09879. doi.org/10.1016/j.heliyo2022.e09879.

- Manas S., Moumita M., Shilang Xu., Saroj M. Bio-concrete: Unveiling self-healing properties beyond crack-sealing. Journal of Building Engineering. 2023. 74(1). 106888. doi.org/10.1016/j.jobe.2023.106888.

- Ali K., Amirreza, T., Hesam K., Mohammad I., Mohanadoss P., Muhd Z. M., Rosli M. Z. Bioconcrete Strength, Durability, Permeability, Recycling and Effects on Human Health: A Review. Third International Conference on Advances in Civil, Structural and Mechanical Engineering. 2015. doi:10.15224/978–1–63248–062–0–28.

- Chahal N., Siddique R., Rajor A. Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. Construction and Building Materials. 2012. 28. 351–356.

- Turakhodjaeva F. Solution of Ecological Problems using Biologically Active. Proceedings of the XXII International Scientific and Practical Conference International Trends in Science and Technology. 2020. 1. isbn 978–83–956628–3–6.

- Schwantes-Cezario N., Porto M. F., Sandoval G., Nogueira G., Couto A., Toralles B. Efects of Bacillus subtilis biocementation on the mechanical properties of mortars. Revista IBRACON de Estruturas e Materiais. 2019. 12(1). 31–38.

- Chahal N., Siddique R., Rajor A. Infuence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fy ash concrete. Constr Build Mater. 2012. 28(1). 351–356.

- Wiktor V., Jonkers H. N. Quantification of crack healing in novel bacteria based self-healing concrete. Cement & Concrete Composites. 2011. 33. 763–770.

- Riccardo M., Hussameldin T., Diane G. Self-healing potential of supplementary cementitious materials in cement mortars: Sorptivity and pore structure. Developments in the Built Environment. 2021. V. 6. 100044. doi.org/10.1016/j.dibe.2021.100044.

- Wasim Kh., Muhammad B. E. Crack healing in concrete using various bio influenced self-healing techniques. Construction and Building Materials. 2016. 102. 349–357. doi.org/10.1016/j.conbuildmat.2015.11.006.

- Turakhodjaeva F. N. Metods to Improve the Mechanical Properties of Biomass. Processing and Fabrication of Advanced Materials XXVII. 2019. Jonkoping, Sweden.

- Manas, S., Moumita, M., Muhammad A. M., Shilang Xu. Evaluation of the crack-healing performance and durability of bacteria integrated alkali-activated fly ash composites. Journal of Building Engineering. 2022. 54. 104642. doi.org/10.1016/j.jobe.2022.104642.

- Kunamineni V., Meena M., Shirish V. D. Bacteria based self-healing concrete — A review. Construction and Building Materials. 2017. 152. 1008–1014. doi.org/10.1016 /j.conbuildmat.2017.07.040.

- Stark J. Recent advances in the field of cement hydration and microstructure analysis. Cement and Concrete Research. 2011. 41(7). 666–678. doi:10.1016/j.cemconres.2011.03.028.

- Rubio-Hernandez, F.J., Adarve-Castroa, A., Velazquez-Navarrob, J. F. Influence of water/cement ratio, and type and concentration of chemical additives on the static and dynamic yield stresses of Portland cement paste. Construction and Building Materials. 2020. 235. 117744. doi:10.1016/j.conbuildmat.2019.117744.

- Choi Y.W., Kim Y. J., Shin H. C., Moon H. Y. An Experimental Research on the Fluidity and Mechanical Properties of High-Strength Lightweight Self-Compacting Concrete. Cement and Concrete Research. 2006. 9. 1595–1602. doi:10.1016/j.cemconres.2004.11.003.