Application of ultra cellulose fiber for the enhancement of the durability and shrinkage of cement pastes exposed to normal and aggressive curing conditions

Автор: Zaki Saaid

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Статья в выпуске: 4 т.7, 2015 года.

Бесплатный доступ

Ultra Cellulose Fibers are hydrophilic fibers which can hold most of their weight water when it is mixed into concrete, after concrete is hardened, these fi- bers will slowly release this water to unhydrated cement during the critical early phases of curing which assist in more complete hydration, this internal self cur- ing action results in more completely hydrated cement which contributes to more strength development and more control of internal microcracking, particularly when normal curing is not adequate. Also, these fibers can be used easily in ready mixed concrete batch plants and in hot weather environments. The results indicated clear improvements in both the shrinkage and com- pressive strength of all cement paste mixes contained these fibers in comparison with control ones in both normal and aggressive curing conditions.

Ultra cellulose fibers(ucf), self curing action, hydrophilic fi- bers, drying shrinkage, aggressive curing

Короткий адрес: https://sciup.org/14265776

IDR: 14265776 | УДК: 691 | DOI: 10.15828/2075-8545-2015-7-4-121-142

Текст научной статьи Application of ultra cellulose fiber for the enhancement of the durability and shrinkage of cement pastes exposed to normal and aggressive curing conditions

Previous research work concerning the effect of ultra cellulose fibers on the shrinkage and durability of cement pastes, mortars and concretes are so limited as follows :

Kawashima Sh. et al(1) (2011) studied the early-age autogenous and drying shrinkage behavior of cellulose fiber reinforced cementitious materials and found that the additions of 1% cellulose fiber by mass of cement showed signifiact drying cracking control, providing some internal curing, since cellulose fibers have the capacity to absorb and release water and considered as candidates for internal curing like superabsorbent polymers (SAP) and light weight aggregates (LWA) in addition to provide crack resistance, also they found that the addition of cellulose fiber did not lead to significant reduction in drying shrinkage.

Sarigaphuti(2) (1993) studied the shrinkage cracking and durability characteristics of cellulose fibers reinforced concrete and found that: cellulose fiber reinforcement of content 1% by weight of cement showed reduce to the crack width signiflicantly as compared to plain concrete(maximum crack width about 1/3 of that of plain concrete), also he found that the addition of cellulose fibers did not lead to significant reduction in drying shrinkage.

Bentchikon M, et al.(4) (2004) studied the effect of cellulose-recycled fiber on the thermal and mechanical properties of cement paste and found that, the compressive strength decreases with the increase in cellulose fiber cement up to 16% by mass and attributed that due to additional porosity induced by fibers, while flexture strength was improved with increase in cellulose fiber content up to 4% by mass and thermal conductivity decreased abruptly till 2% of fiber content.

Mohamed MAS. et al.(5) (2010) studied the valorization of micro-cel-lulose fibers in self-compacting concrete (SCC) in comparison with ordi-

FOREIGN EXPERIENCE nary compacting concrete having the same type of micro-cellulose fibers and found that, compressive strength of SCC containing 21% cellulose fiber enhanced 25% in comparison with nonfibered ones, on the other hand, when the cellulose fiber content increased to 41%, a reduction of about 5% of compressive strength was found. Also, compressive strength of ordinary compacting concrete was enhanced significantly for cellulose fiber content of about 21% by volume of cement, while the volumetric cellulose fiber content increased to 41%, the compressive strength and density are reduced, and the same trend was found for the flexture strength.

John VM et al.(6) (2005) studied the durability of slag mortar reinforced with coconut fiber and found that cellulose based fibers are porous and hydrophilic, consequently when incorporated to concrete they lead to decrease of its workability.

Parviz S.(7) (1998) studied the control of plastic shrinkage cracking with specially cellulose fibers and found that cellulose fibers reduced the maximam plastic shrinkage crack width of conventional and high-performance concrete by 47% and 34% respectively.

Parviz S.(8) (1999), studied high early strength of concrete using mixture proportioning with processed cellulose fibers for durability and found that processed cellulose fibers does not increase the restrained shrinkage of concrete, while increase the early age strength of concrete.

Macvicar R.(9) (1999) et al. studied the Aging mechanisms in cellulose fiber reinforced cement composites and found that substantial reduction in porosity, water absorption, and nitrogen permeability can be achived in collulose fiber reinforced cement composites using accelerated carbonation aging tests.

Xuli Fu and Chung D.L.L.(10) (1996) studied the effect of Methylcellulose admixture on the mechanical properties of cement and found that addition of methylcellulose(0.2–0.8% by weight of cement) to cement paste increased the tensile strength and tensile ductility, but decreased the compressive strength and compressive ductility.

Jarabo R. et al.(11) (2012) studied the use of cellulose fibers from hemp core in fiber – cement production, and effect on floccuation, retention, drainage and product preperties and found that the use of agricutural waste materials, particularly, industrial hemp straw as ecofriendly and renewable source of cellulose fibers and can be applied to enhance mechanical properties of cellulose fiber cement production.

FOREIGN EXPERIENCE

2. Experimental Work

In this work the effect of ultra celulose fibers on the properties of cement pastes under normal and aggressive curing conditions were investigated.

-

2.1. Materials2.1.1. Ordinary Portland cement (OPC)

-

2.1.2. Ultra Cellulose Fibers (UCF)

-

2.1.3. Superplasticizer (SP)

-

2.2. Mix design and preparation of specimens

Standard cement paste was prepared according to ESS (2421-1993) [13] to determine the standard water – cement ratio, which was found in this study 24.5% for all mixes, while superplasticizer changed from (0.8 to 1.7)% of cement to maintain the same water-cement ratio for all mixes.

The cementitious materials used during this study was ordinary partland cement (OPC), type (CEMI, 52.5N), obtained from Beni-Suef cement factory in Egypt and complies with ESS (4756-1-2006) [12], the chemical analysis of OPC is shown in table 1.

Ultra cellulose fibers (C6 H12 O5)n [20] during this study were obtained from textile departement in NRC, its physical and mechanical properties are shown in tables 2, 3, it was made from 100% virgin specially cellulose sheet with patented alkaline resistance, which was cut to small pieces 2 x 2 mm fig. 1 shows the shape of the fibers.

Polycarboxylic ether polymer based PCE sky, gelenium ACE 30 obtained from BASF company in Egypt was used during this study.

FOREIGN EXPERIENCE

Chemical Analysis of OPC, wt. %

Table 1.

|

Oxide content |

OPC |

|

SiO2 |

19.8 |

|

Al2O3 |

5.5 |

|

Fe2O3 |

3.4 |

|

CaO |

63 |

|

MgO |

1.2 |

|

Na2O |

0.46 |

|

K2O |

0.19 |

|

SO3 |

3 |

|

Loss on ignition |

2.5 |

Table 2.

Physical characteristics of ultra cellulose fibers

|

Description |

Results |

|

Water Absorption |

Up to 80% of fiber wt. |

|

App. Density(gm/cm3) |

1.1 |

|

Ave. dimensions(mm) |

2x2 mm |

|

Surface area(cm2/gm) |

25000 |

Table 3.

Mechanical properties of ultra cellulose fibers

|

Description |

Results |

|

Tensile strength (Ksi) |

90–130 |

|

Modulus of Elasticity (Mpa) |

8500 |

FOREIGN EXPERIENCE

-

2.2.1. Mix design

-

2.2.2. Mixing Procedure:

Cement pastes were prepared, mixed, casted, cured and tested in HBRC (Laboratories of Quality Control and Material Institute), five cement paste mixes are designed and shown in table 3, from which it can be norticed that mix M1 is control mix (without Ultra Cellulose Fibers ) (UCF), while mixes M2, M3, M4 and M5 are main mixes with different values of UCF (0.5, 1, 1.5, 2%), respectively as weight percentage of cement content.

-

• Cement and ultra cellulose fibers (UCF) are mixed in dry state for 1 min in a small planetary mixer with low speed, followed by addition of 50% of mixing water to cement and UCF mixed with high speed for 2 min, followed by addition of ready mixed liquid including superplasticizer and 50% remained water and mixed at low speed for 3 min, then for 1.5 min at high speed until the mix becomes homogenous.

-

• The mixture of each mix was poured into mould contained thirty cube of size 20x20x20 mm for compressive strength measurements for both normal and aggressive curing conditions, while the remained part of mix was poured in shrinkage mould of dimensions 25x25x280 mm for drying shrinkage measurements.

-

2.2.3. Curing Procedure

-

• All samples were demoulded 24 hours after casting and then water cured until the age of testing after 7, 14 and 28 days, then half of cubic samples are extracted from potable curing and put at the age 28 days in aggressive curing (0.1 N sulphuric acid i.e. 3.675 ml/liter) and tested after exposure time of 7, 14, 28 days and one year to evaluate the durability of UCF samples in comparison with control samples.

-

2.2.4. Testing Procedure2.2.4.1. Compressive Strength

-

2.2.4.2. Mass Loss

At the date of testing, three samples of each group were extracted from curing conditions, weighed and measured their dimensions, then tested in

FOREIGN EXPERIENCE compression testing machine and the average result is recorded in table 5 for normal curing samples and table 6 for aggressive curing samples.

The mass loss of specimens due to immersion in acidic solution was monitored at ages 7, 14, 28 days and one year. Before tests specimens were washed off with tap water and the mass loss is calculated as follows:

ML = (Wa – Wb) / Wa х 100%, [14] (1)

where Wa – the average initial weight of specimens before their immersion in sulphuric acid;

Wb – the average weigth of specimens after different immersion times in acidic solution;

ML – mass loss due to exposure to acidic solution for one year.

-

2.2.4.3. Drying Shrinkage

Drying shrinkage test was carried out according to ECP(16)(2003) and ASTM(15)(2004) using prisms of dimensions 25х25х280 mm with two nails were fixed for length measurement, immediately after mixing cement paste samples with the same mix design shown in table 4, each mix was cast in three prism molds in three layers and consolidated by manually rodding, then covered by polyethylene sheet and left for 24 hours in temperature 20оC and humidity 90%, then the prisms were demolded, and the distance betweens the two nails is measured using micrometer which will be the conference distance (Lo), then the samples were put in curing water for 48 hours and then left in air (23оC & 50% RH) until the age of testing 7, 14, 21 and 28 days.

The average result of the three prisms were taken for each mix and the following equation was used to determine the drying shrinkage:

d.s.s = 250 , [16] (2)

where, d.s.s – drying shrinkage strain, Lo – distance between the two nails after 24 hour (mm), Lf – distance between the two nails at the age of testing (mm).

FOREIGN EXPERIENCE

Mix composition, mass %

Fig. 1. The shape of the pieces of ultra cellulose fibers (UCF) before used in cement paste mixes

Table 4.

|

Mix. No. |

Mix type |

OPC |

UCF % |

w/c% |

SP% |

|

M1 |

Control |

100 |

0.0 |

24.5 |

0.85 |

|

M2 |

0.5 % UCF |

99.5 |

0.5 |

24.5 |

0.84 |

|

M3 |

1 % UCF |

99.0 |

1.0 |

24.5 |

1.3 |

|

M 4 |

1.5 % UCF |

98.5 |

1.5 |

24.5 |

1.5 |

|

M5 |

2 % UCF |

98.0 |

2.0 |

24.5 |

1.7 |

3. Analysis and Discussion of Test Results 3.1. Compressive Strength3.1.1. Normal Curing

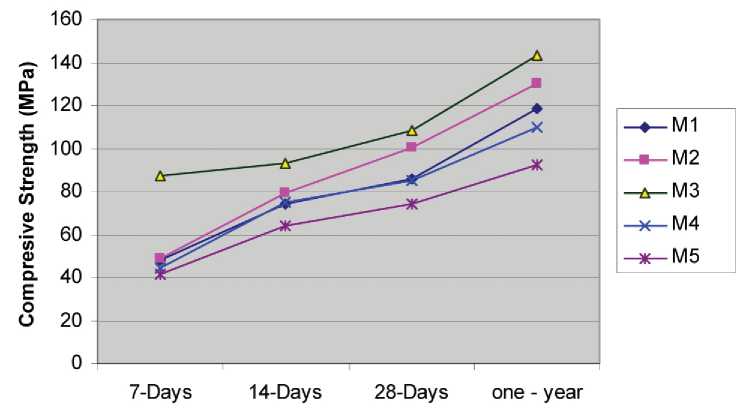

Table 5 and Fig. 2 show the development of compressive strength test results for cement pastes containing different amounts of cellulose fibers

FOREIGN EXPERIENCE

Table 5.

Compressive strength for normal curing of cellulose fiber mixes at different ages (MPa)

|

Mix No. |

Mix Type |

7-Days |

14-Days |

28-Days |

one-year |

|

M1 |

Control |

100 |

0.0 |

24.5 |

0.85 |

|

M 2 |

UF = Zero |

47.9 |

73.9 |

85.9 |

118.5 |

|

M3 |

UF = 0.5% |

48.8 |

79.6 |

100.3 |

130 |

|

M 4 |

UF = 1% |

87.2 |

93.1 |

108.5 |

143 |

|

M5 |

UF = 1.5% |

44.6 |

74.7 |

85 |

110 |

Note: units of compressive strength MPa.

Fig. 2. Compressive strength of cement pastes containing ultra cellulose fiber at different ages exposed to normal curing conditions at different ages in normal curing, from which it can be seen that: the effect of ultra cellulose fibers content which varied in this study from zero % (control mix – M1) to 2% of the weight of cement, improved significantly compressive strength for fiber content up to 1% which can be considered the optimum value, this is can be attributed due to the good dispersion, homogeneity and compaction between the ultra cellulose fibers of (UCF) in cement paste of content 1% and the cement matrix, which improves the

FOREIGN EXPERIENCE performance of UCF fibers in IMPROVING compressive strength, moreover the compressive strength decreased than control mix when the ultra cellulose fiber content exceeded than 1%, this can be attributed to the porosity increase related to the paste volume increase due to the increase of cellulose fibers than 1%, and can be attributed also to the light weight effect of ultra cellulose fibers which reduces the density of the mix, which leads to lower compressive strength.

-

3.1.2. Aggressive Curing

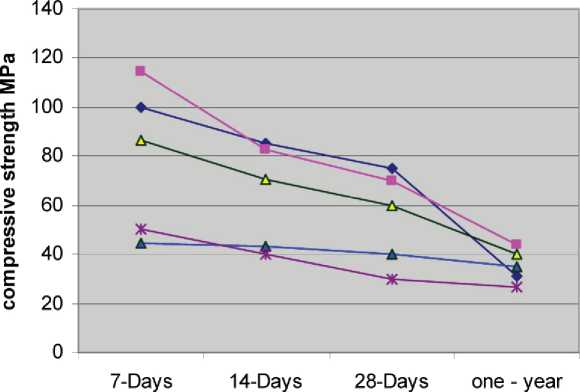

Table 6 and fig. 3 show the compressive strength of cement pastes containing ultra cellulose fibers and exposed to aggressive curing (0.1 N sulphuric acid) at different ages from 7 days up to one year (taken into consideration that the exposure to sulphuric acid began after curing 28 days in potable water), it can be seen that compressive strength of cement paste M2 which contained 0.5 UCF showed higher strength than control mix and other mixes at early ages up to 7 days and at later ages at one year, which means that crystalline structure of cement paste contained 0.5% UCF resisted deterioration by sulpuric acid better than control mix M1 without UCF), which will be illustrated in the microstructure study at item 4, on the contrary, the addition of cellulose fibers with percentages more than 0.5% by weight of cement reduced compressive strength at all ages in comparison to control mix M1 (without UCF) and 0.5% UCF mix (M2), which can be attributed due to the nature of UCF which is non-pozzolanic material and also free due to effect of hydrogen ions associated with the acid serve to accelerate the leaching of calcium hydroxide and may also attack the C-S-H gel to produce silica gel [17].

Although the crystalline structure of ultra cellulose fiber cement pastes seems to be more resisting to deterioration caused by sulphuric acid than control paste without UCF, they affected by the attack of sulphuric acid which is not a solvent for cellulose but penetrate the amorphous regions of the fibers resulting in heterogeneous deterioration [18]. In this type of degradation UCF maintain their fibrous nature to a certain degree but will disply a progress loss of fiber strength, if carried to completion, this deterioration process would ultimately progress to a complete loss of fiber structure as the cellulose microfiberils are broken down into glucose molecules and causes the reduction of strength [19].

FOREIGN EXPERIENCE

Table 6.

Compressive strength of cement pastes containing ultra cellulose fibers exposed to aggressive curing (0.1 N sulphuric acid)

|

Mix No. |

Mix Type |

Exposure Periods |

|||

|

7-Days |

14-Days |

28-Days |

one - year |

||

|

M1 |

Control UF = Zero |

99.7 |

85 |

75 |

31.2 |

|

M 2 |

UF = 0.5% |

114.6 |

83 |

70 |

44.1 |

|

M3 |

UF = 1% |

86.6 |

70.4 |

60 |

40 |

|

M 4 |

UF = 1.5% |

44.3 |

43 |

40 |

35 |

|

M5 |

UF = 2% |

50.4 |

39.8 |

30 |

26.6 |

Note: units of compressive strength MPa.

All the exposure periods began after 28 days of normal curing.

—Ф— М1

-«—М2

-^МЗ

-*-М4

-ж—М5

Fig. 3. Compressive strength of cement pastes containing ultra cellulose fibers exposed to aggressive curing conditions (0.1 N sulphuric acid)

-

3.2. Mass Loss

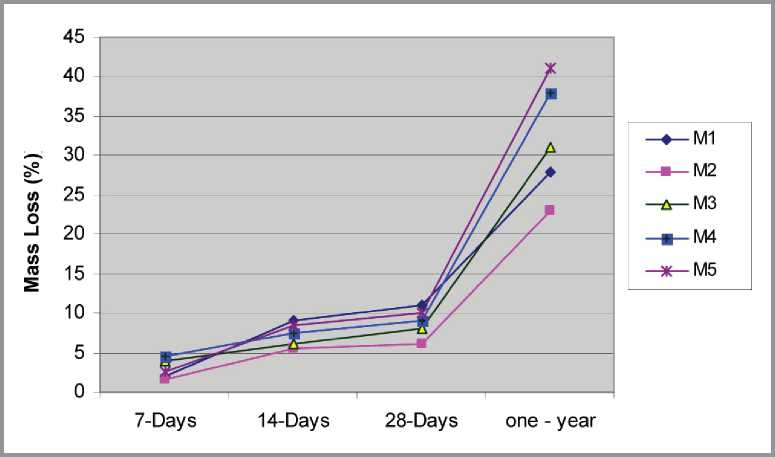

Fig. 4 and table 7 show the mass loss of cement pastes containing UCF after exposure to 0.1 N sulphuric acid (3.675 ml/lit), from which it was

FOREIGN EXPERIENCE

Mass loss for cement pastes containing ultra cellulose fibers after exposure to sulphuric acid (0.1N)

Fig. 4. (%) Mass Loss of cement pastes containing ultra cellulose fibers exposed to aggressive curing conditions (0.1 N sulphuric acid)

Table 7.

|

Mix No. |

Mix Type |

Exposure Periods |

|||

|

7-Days |

14-Days |

28-Days |

one - year |

||

|

M1 |

Control UF = Zero |

2 |

9 |

11 |

28 |

|

M 2 |

UF = 0.5% |

1.5 |

5.5 |

6 |

23 |

|

M3 |

UF = 1% |

4 |

6 |

8 |

31 |

|

M 4 |

UF = 1.5% |

4.5 |

7.5 |

9 |

38 |

|

M5 |

UF = 2% |

2.5 |

8.5 |

10 |

41 |

Note: all exposure periods was began after 28 days of normal curing.

observed that during early immersion periods up to 28 days, the mass of specimens decreased slightly, while after continuous sulphuric acid attack, relative mass reduction began to be sharp at the age of one year. Nevertheless, the replacement of cement by 0.5% UCF seemed to improve the acid

FOREIGN EXPERIENCE resistance, since the mass loss of mix M2 was the smallest at all ages than the control mix M1 and either mixes, while the increase of the amount of UCF than 0.5, increased the mass loss at all ages nearly, this is can be attributed due to the nature of UCF which is non-pozzolanic material.

Also, a white layer was observed outside the samples exposed to aggressive sulphuric acid after one year, which may be attributed to the reaction happened between sulphuric acid and portlandite in cementing paste, forming gypsum along with calcium silicate hydrate decomposed.

-

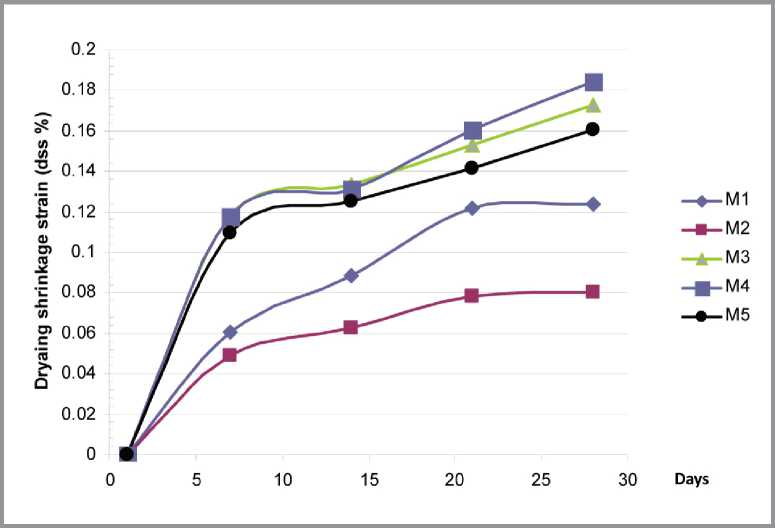

3.3. Drying shrinkage strain test results

Table 8 and fig. 5 show the drying shrinkage strain test results of cement pastes containing different values of ultra cellulose fibers at different ages, from which, it can be seen that.

The addition of cellulose fibers 0.5% by weight of cement, mix No(M2) reduced drying shrinkage strains in all ages in comparison with control mix without cellulose fibers (mix № M1), this is due to cellulose fibers act like flexible inclusions in the cementitous matrix, and penetrate between the grains to fill the voids between them when water absorbed is released the reduction of voids volume will occur and can be expressed in a decrease in shrinkage.

Table 8.

Drying shrinkage strain of cement pastes containing different values of ultra cellulose fibers at different ages

|

Mix No. |

Age(days) |

||||

|

1 |

7 |

14 |

21 |

28 |

|

|

M 1 |

0 |

0.060784314 |

0.088235 |

0.121569 |

0.1235294 |

|

M2 |

0 |

0.049019608 |

0.062745 |

0.078431 |

0.0803922 |

|

M3 |

0 |

0.117647059 |

0.133333 |

0.152941 |

0.172549 |

|

M4 |

0 |

0.117647059 |

0.131373 |

0.160784 |

0.1843137 |

|

M5 |

0 |

0.109803922 |

0.12549 |

0.141176 |

0.1607843 |

FOREIGN EXPERIENCE

Fig. 5. Drying shrinkage of cement pastes containing different values of ultra cellulose fibers at different ages

4. Microstructure

Scanning electronic microscope (SEM) examination was carried out in the laboratories of building physics institute in Housing and Building National Research Center using ESEM (Environmental Scanning Electronic Microscope), FEI inspect S, made in Holland.

The specimens were taken directly from cement paste samples after testing in compressive strength, the shape of specimens was regular, the surface was flat, and the magnification power was 1500.

-

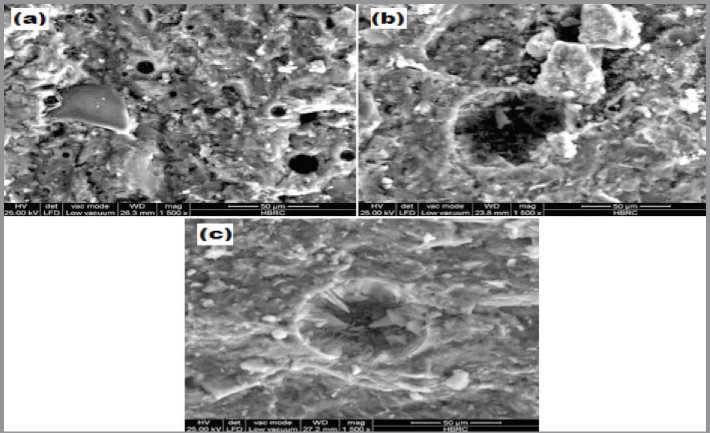

4.1. Normal Curing Samples

Fig. 6 shows the SEM micrograph of cement paste samples subjected to normal curing for one year with and without ultra cellulose fibers (UCF).

The microstructure of the control sample shows the formation of nearly amorphous and microcrystalline particles of tobermorite-like CSH phases as the dominant hydration products and hexagonal plates of calcium hydroxide, also many of open voids appear on the surface of the sample, which

FOREIGN EXPERIENCE

Fig. 6. SEM micrographs for control cement pastes (a), modified by 0.5 % UCF (b) and by 1% UCF (c) , cured in drink water:

a – OPC sample; b – OPC – 0.5% UCF; c –OPC – 1% UCF make the sample low dense and low compact in the structure and reduces the mechanical strength of the OPC sample.

Replacement of Portland cement by ultra cellulose fibers UCF was found to influence the hydration behavior according to the nature of cellulose fibers and lead to differences in the microstructure of the hardened OPC samples. The microstructure of hardened cement paste modified by UCF of 0.5% and 1% after one year of hydration are shown in fig. 6 (b, c). Accordingly, the samples appeared quite dense and compact due to the filling of voids and pores by UCF which lead to improve the mechanical strength of the cement paste samples modified by UCF.

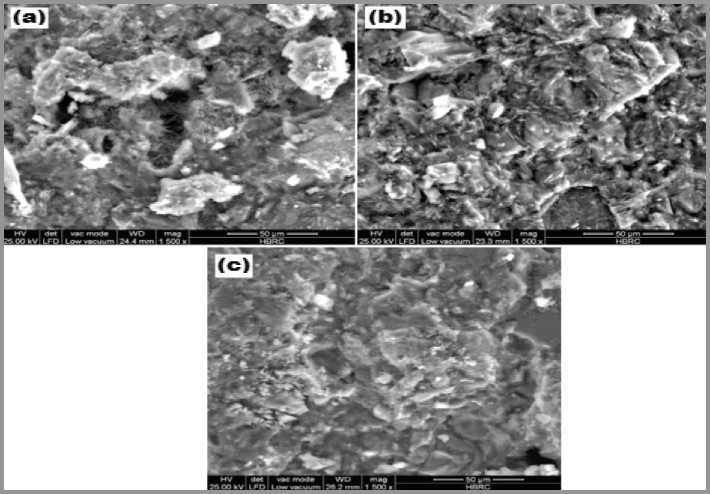

4.2. Aggressive Curing Samples

5. Conclusions

Fig. 7 shows the SEM micrograph of cement paste samples subjected to aggressive curing conditions (0.1 N sulphuric acid) for one year with and without ultra cellulose fibers.

Regarding to the microstructures of OPC samples modified by UCF at different ratios and cured for one year in diluted sulphric acid, fig. 2a shows the morphology of cement paste (control sample) having microcrystalline particles of tobermorite-like CSH phases andplates of calcium

FOREIGN EXPERIENCE

Fig. 7. SEM micrographs for control cement pastes (a), modified by 0.5 % UCF (b) and by 1% UCF (c), cured in (0.1 N sulphric acid):

a – OPC sample; b – OPC – 0.5% UCF; c – OPC – 1% UCF hydroxide connected with many needles of ettringite as a result of sulph-ric acid treatment, since the penetration of sulphate ions into the cement paste would results in conversion of calcium aluminate hydrate and mona-sulphate aluminate hydrate into ettringite which expands and resulting in internal stresses which allow ettringite crystals to grows and that lead to the reduction of the mechanical strength of OPC sample. In contrast the samples modified by UCF with the ratios of 0.5% and 1% which appear in fig. 7 (b, c), the surface appeared quite dense and compact in the structure due to the using of UCF which work as a physical filler and lead to improve the mechanical strength but the needle-like structure of ettringite still observed.

Based on the experimental work carried out during this study, the following conclusions can be concluded:

-

• Ultra cellulose fibers are hydrophilite fibers which can hold most of their weight water, when it is mixed into concrete, and after concrete

FOREIGN EXPERIENCE is hardened, these fibers will slowly release this water to an unhydrated cement during the critical early phases of curing which assist in more complete hydration of cement which contributes to more strength development and more control of drying shrinkage.

• The results showed that the addition of UCF of 0.5% tended to improve the durability of OPC cement pastes against aggressive sulphuric acid, this is can be attributed to the effect of UCF fibers which behaves not only as a filler to improve microstructure, but also in self curing action which resulting in completely hydrated cement which contributes to more strength development and lower drying shrinkage.

• The results indicated clear improvements in both shrinkage and compressive strength of cement paste mixes contained these fibers of amount 1% of cement weight in comparison with control ones in both normal and aggressive curing.

• When the amount of cellulose fibers are increased than 1%, the compressive strength and shrinkage were reduced, that is due to cellulose fibers have no pozzolanic activity.

• Replacement of cement by 0.5% UCF seemed to improve the mass loss for UCF specimens than exposed to sulphuric acid control ones.

• Replacement of Portland cement by ultra cellulose fibers UCF was found to influence the hydration behavior according to the nature of cellulose fibers and lead to differences in the microstructure of the hardened OPC samples. The microstructure of hardened cement paste modified by UCF at 0.5% after one year of normal curing hydration appeared quite dense and compact due to the filling of voids and pores by UCF which lead to improve the mechanical strength of the cement paste samples modified by UCF.

6. Acknowledgement

The author whishes to appreciate his acknowledgement to prof. Manal Elsheikh professor of textile in N.R.C. for her help in synthesis of cellulose fiber sheets used in this study.

The specialists may be interested in the results of the research pub- lished in sources [21–26].

FOREIGN EXPERIENCE

Список литературы Application of ultra cellulose fiber for the enhancement of the durability and shrinkage of cement pastes exposed to normal and aggressive curing conditions

- Kawashima Sh., Shah S.P. Early-age autogenous and drying shrinkage behavior of cellulose fiber reinfurced cementitious materials, Cement & Concrete Composites, 33(2011), pp. 201-208.

- Sarigaphuti M., Shah S.P., Vinson K.D. Shrinkage cracking and durability characteristics of cellulose fiber reinforced concrete, ACI materials Journal, vol. 90, no. 4, July-August 1993.

- Fisher A.K., Bullen F., and Beal D. The durability of cellulose fiber reinforced concrete pipes in sewage applirations, cement and concrete research 31(2001), pp. 543-553.

- Bentchikon M, Guidoum A., Scrivener K.L., Silhadi K., and Hanini S. Effect of cellulose fiber on the thermal and mechanical properties of cement paste. International RILEM conference on the use of recycled materils in building and structures, Barcelona, Spain, 2004, pp. 725-730.

- Mohamed MAS, Ghorbal E., Wardeh G. Valorization of micro-cellulose fibers in self-compacting concrete, Construction and Building Materials 24(2010), pp. 2473-2480.

- John V.M, Cincotto MA, Sjostrom C, Agopyan V., Qlivoira CTA. Durability of slag mortar reinforced with coconut fiber, cement and concrete compreites, 27(5), 2005, pp. 565-574.

- Parviz S., Siavosh R. Сontrol of plastic shrinkage cracking with specially cellulose fibers. ACI materials Journal, v. 95, No. 4, 1988.

- Parviz S., Siavosh R. High-Early strength concrete mixture proportioning with processed cellulose fibers for durability, ACI materials Journal, v. 96, No. 5, 1999.

- Macvicar R., Matuana L.M, Balatinecz JJ. Aging mechanisms in cellulose fiber reinforced cement composites, cements concrete composites Journal, 21(1999), pp. 189-196.

- Xuli Fu, Chung D.L.L. Effect of Methyl cellulose admixture on the mechanical properties of cement, cement and concrete research journal, v. 26, No. 4, 1996, pp. 535-538.

- Jarabo R., Fuente E, Monte M.C., Savastona H. Mutider, Negro C. Use of cellulose fibers from hemp core in fiber -cement production, Industrial crops and products journal, 39(2012), pp. 89-96.

- Egyptian Standard Specifications For Ordinary Partland Cement (Ess 4756-1-2006), General Organization For Specification And Quality In Egypt.

- Egyptian Standard Specifications (Ess 2441, 1993), Determination of standard water cement ratio for cement pastes.

- We Ye, Shi Liang, Liu JainZhang. Resistance of different cementing materials to regressive sulphuric acid attack. CONSEC 13, Sep. 2013, NanJing, China, pp. 761-768.

- ASTM C 157-04. Test method for length change of hardned hydraulic cement mortar and concrete, ASTM inter, 2004.

- ECP 203, Egyptian Code for Design and Construction of Concrete Structures, Tests Guide, part 1, Drying shrinkage of cement mortar containing portland cement, pp. (62-67), H.B.R.C. 2003.

- Mindess S., Young J.F. Concrete, Prentice Hall, New Jersey, 1981.

- Lai Y.Z. Chemical Degradation, Wood and Cellulose Chemistry, Marcel Dekker, New York, 1991, pp. 455-523.

- Browning B.L. The chemistry of wood Robert E. Kleiger Publishing, New York, 1975.

- Young J.F., Mindess S., Gray R.J., Bentur A. The Sciena and Technology of Civil Engineering Materials, Saddle River, Prentice -Hall, New Jersey, 1998.

- Gusev B.V., Minsadrov I.N., Miroevsky P.V. et al. Investigation of nanostructuring processes in fine-grained concretes with silicon dioxide nanoparticles admixture//Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2009. Vol. 1, no. 3. pp. 8-14. Available at: http://nanobuild.ru/en_EN/(date of access: 12.06.2015)..

- Falikman V.R., Sobolev K.G. «There's plenty of room at the bottom», or how nanotechnologies can change the world of concrete. Part 1//Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2010. Vol. 2, no. 6, pp. 17-31. Available at: http://nanobuild.ru/en_EN/(date of access: 12.06.2015)..

- Figovsky O.L., Beilin D.A, Ponomarev A.N. Successful implementation of nanotechnologies in building materials. Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2012, Vol. 4, no. 3, pp. 6-21. Available at: http://nanobuild.ru/en_EN/(date of access: 12.06.2015)..

- Falikman V., Vajner A. New high performance nanoadditives for photocatalytic concrete: synthesis and study. Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2015, Vol. 7, no. 1, pp. 18-28. DOI: DOI: 10.15828/2075-8545-2015-7-1-18-28

- Kudryavtsev P.G., Figovsky O.L. Nanostructured materials, production and application in construction. Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2014, Vol. 6, no. 6, pp. 27-45. DOI: DOI: 10.15828/2075-8545-2014-6-6-27-45

- Gusev B.V., Petrunin S.Y. Cavitation dispersion of carbon nanotubes and modification of cement systems. Nanotehnologii v stroitel'stve = Nanotechnologies in Construction. 2014, Vol. 6, no. 6, pp. 50-57. DOI: dx.doi.org/10.15828/2075-8545-2014-6-6-50-57.