Approach of recovering thin coal seams

Автор: Hoa Le Thi Thu, Pirat Jaroonpattanapong, Bui Xuan-Nam, Viet Pham Van, Hoang Nguyen, Thao Le Qui

Журнал: Горные науки и технологии @gornye-nauki-tekhnologii

Рубрика: Разработка месторождений полезных ископаемых

Статья в выпуске: 1, 2018 года.

Бесплатный доступ

The Mae Moh basin is situated in the Mae Moh District of Lampang Province, which is about 26 km east of Lampang City. The basin floor is about 320340 m above mean sea level. The Mae Moh basin consists of three formations, namely the Huai King, Na Khaem, and Huai Luang formations, in ascending order. The total thickness is nearly 1 000 m in ascending order. The Na Khaem formation is a coal measure comprising three main coal zones, Q, K, and J. This study introduces preliminary approaches to determine minimum thickness to excavate thin coal seams within coal quality requirements or maximum dilution thickness acceptance. The approach considers heating value as a main parameter to determine under different scenarios of loss and dilution. The results indicate the high quality of coal-bearing soil seams, such as BK and BK3 can be excavated with K3 and acceptable dilution thickness is between 1.685.3 m at 2 800 kcal/kg of heating value. These dilution thickness can be converted to 2050 % at any excavated thickness of K3 coal seam. Low quality of coal-bearing soil seams, such as TK1, TQ and BQ4, cannot be excavated with any K and Q coal seams. Coal-bearing parting layer should have heating value more than 1,000 kcal/kg to possibly be excavated with coal seams.

Coal, thin coal seam, mining, loss, dilution

Короткий адрес: https://sciup.org/140230096

IDR: 140230096 | DOI: 10.17073/2500-0632-2018-1-16-20

Текст научной статьи Approach of recovering thin coal seams

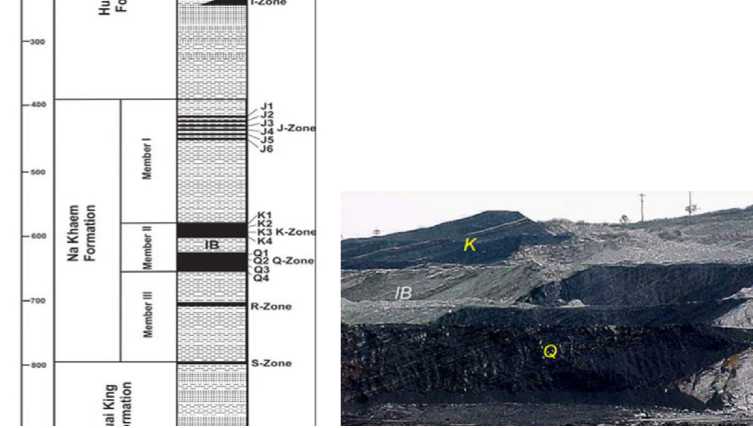

The Mae Moh basin is situated in the Mae Moh District of Lampang Province, which is about 26 km east of Lampang City (Fig. 1). The basin floor is about 320 - 340 m above mean sea level. The Mae Moh basin consists of three formations, namely the Huai King, Na Khaem, and Huai Luang formations, in ascending order. The total thickness is nearly 1 000 m in ascending order. The Na Khaem formation is a coal measure comprising three members as Member III, Member II, and Member I, in ascending order. The Member III, or the so-called underburden, is a greenish gray to gray claystone with a thin layer of coal, named the R coal zone. The Member II is composed of two main coal zones, which are the Q coal zone in the lowermost part and the K coal zone in the uppermost part, and are intercalated by an interburden of claystone. The Member I is a thick overburden consisting of claystone with a series of coal layers named the J coal zone [1]. The J coal zone is an intercalation between claystone and six main coal layers (Fig. 2).

Fig. 1. Map of northern Thailand showing location of the Mae Moh basin with respect to locations of some provincial cities (After Wickanet Songtha-ma, et. al. 2005)

An enlarged stratigraphic of coal seam K and Q (Fig. 2, b ) indicates many mid band layers (MD) within the coal seams. The boundary layers between coal seams and overburden (OB) or underburden (UB) are specified as letter T and B means top and bottom, respectively. For example, TK indicates layer on the top of K coal seam. Beside the hardness and characteristics of non-coal layers, thickness also plays an important role of mine production. Some are extracted with the coal, some are not.

a

Fig. 2 Schematic lithostratigraphic units of the Na Khaem Formation ( a - After Wickanet Songthama, et.al. 2005, b - modified by authors)

TQ,TQ1

b

BK,BK3

BQ,BQ4

This study introduces approaches to determine minimum thickness to excavate thin coal seams within predetermined coal quality requirements. The approach considers heating value as a main parameter to determine the minimum thickness of coal seam under different scenarios of loss and dilution.

-

2. THEORY

There are many methods to calculate the minimum thickness of coal seam which is allowed to be mined, such as heating value limit, economic limit, and selective ability of excavating equipment [2 - 8]. This study proposes the approaches to determine the minimum thickness of coal seam that is allowed to be mined in accordance with heating value allowance.

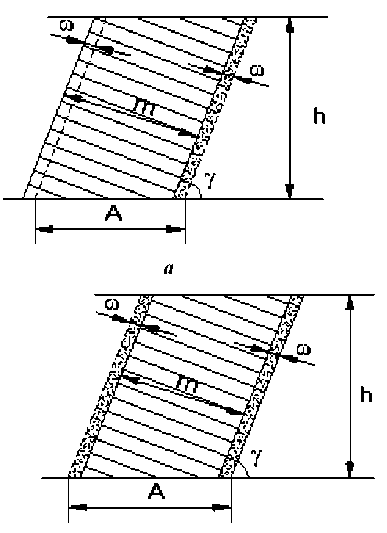

When bench height (sub bench) ( h ) has been suitable for selective excavating operation such as the thickness of recoverable coal (m), dip angle of coal seam ( γ ), two approaches for selective mining could be shown:

-

a - Acceptable loss at the roof of coal seam and dilution at the floor of coal seam (Fig. 3, a );

b - Acceptable dilution at both boundaries of coal seam, floor and roof without coal loss (Fig. 3, b ).

In both the two approaches, it is assumed that the loss or dilution layers are equal each other, represented by symbol ω , (m).

b

Fig. 3. Basic selective mining approaches for thin coal seams

Национальный исследовательский технологический университет

The analysis results are derived from the equivalent heating values by using scattering functions [9].

2.1. Determination of the minimum thickness of coal seam could be mined with acceptance of loss allowance at the roof and dilution allowance at the floor of a coal seam.

Excavated raw coal weight is determined by:

Wm = [( m - o)Y coal + ЮУ soil ] — , tons .(1) sin y

Weight of coal in the raw coal is determined by:

Wcoal = [( m - o)Y coal ]~ , tons. (2) sin у

Weight of coal-bearing soil in the raw coal is determined by:

Wsoil = [oY soil ] — , tons , (3)

sin y where m is true thickness of coal, meters, Yeo an Y Sou are coal and soil density, t/m3. Soil in this study means any coal-bearing soil layers that is adjacent main coal seam.

The heating value, H , are added into equation. HM is heating value of raw coal, kcal/kg. H is heating value of coal,

kcal/kg. And H is heating value of coalbearing soil, kcal/kg.

w H =W H +W H • yy m Mcoal VV coal coal + '' soil soil;

HM coal

HM coal

W и , + W „ coal coal soil soill

;

coal soil

_ [( m o)y coalHcoal ]+[oY soil H soil ]

Ю = m /

1 +

Y soil

Y coal

( m -o)Y coal + OY soil

.

If acceptable heating value of raw coal; H M , is equal to heating value requirement; H required , for coal fire power

plant. H Mcoal will be replaced with H required in equation (4).

After rearranging the equation, m or minimum thickness of coal seam can be de-

termined:

m = o

1 +

Y soil

Y coal

( H o

—

H

(h. d required

required

)1

-H , coal

, m. (5)

On the other hand, maximum layer of o can be determined as well if available coal thickness m is known.

( H„«

( H

^™

H

required

)1

required

-H 1

coal

, m. (6)

2.2. Determination of the minimum thickness of coal seam could be mined with dilution acceptance on both the floor and the roof of coal seam.

The above-mentioned method is applied to this scenario and H can be determined.

HM coal

m Y coal H coal + 2®Z soilHsoil ]^c^]/]^g (Y)

«Y coal + 2®Y soil ’

And after rearrangement,

m = 2 rn^ soiL

Y coal

co = m /

( H ,.,l

^“

( H req.M

H required ) .

-H i ) ;

coal

Y soil

Y coal

( H eeil

^“

( H requie,

н ..

required

)1

^“

Hi^ .

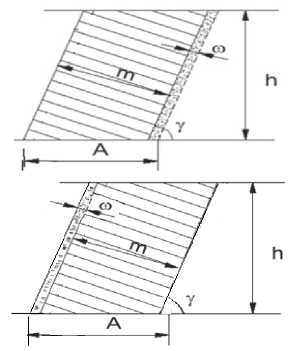

2.3 Determination of the minimum thickness of coal seam could be mined with dilution acceptance at floor or roof of the coal seam (Fig. 4).

Fig. 4. Alternative selective mining approaches for coal seams

In this scenario, H can be deter Mcoal

mined as follow

m = o

o = m /

Y soil

Y coal

Y soil

Y coal

( H .o,l

^™

( H requred

)

required

^™

H ,)

coal

;

( H„,

^™

(h. d required

H required

)1

—

H coal ) ■

3. DATA

The characteristics, such as heating value, density, percentage of ash, of productive coal seam K , Q , and other layers are summarized in the Table 1. The data is selected from some of working areas and averaged values.

Национальный исследовательский технологический университет

Properties of geological seams of A1 and A2 areas

Table 1

|

Area |

Seam Name |

Average Heating Value, H (kcal/kg) |

Average Ash (%) |

Density (ton/m3) |

|

TK1 |

435.7 |

52.2 |

1.95* |

|

|

PT |

379.1 |

49.6 |

1.81 |

|

|

A1, A2 |

K1 |

3,070 |

12.3 |

1.62 |

|

K2 |

2,854 |

16.6 |

||

|

K3 |

3,181 |

9.8 |

||

|

BK |

2,274 |

26.9 |

2.19 |

|

|

BK3 |

1,130 |

44 |

2.19 |

|

|

TQ |

268 |

52.8 |

2.06** |

|

|

Q1 |

2,757 |

16 |

1.5 |

|

|

Q2 |

2,600 |

20.7 |

||

|

Q3 |

1,782 |

34.2 |

||

|

Q4 |

2,702 |

18.5 |

||

|

BQ4 |

280 |

55.2 |

1.95* |

* using gray claystone density in over and under burden (OB and UB) layers

**using green zone density in interburden (IB) layers [3]

4. RESULTS

ters that have thickness much more than

From the schematic lithostratigraphic member I, II and III units of the Na Khaem Formation, this study focuses on four coal seam boundaries: (a) TK1 and K1 seam (b1) BK and K3 (b2) BK3 and K3 (c) TQ and Q1, and (d) BQ4 and Q4. Equation 10 and 11 can be applied to these scenarios.

From preliminary requirements of Mae Moh mine [10], the thickness of soil layer is allowed up to 0.30 meters ( to) and the heating value is accepted at 2,800 kcal/kg. Using these conditions and data from Tab. 1, the minimum thickness of coal seam ( m ) can be determined using equation 10 as shown in the Tab. 2.

Table 2 Minimum thickness of coal seam

K1, K3, Q1 and Q4

|

m (meters) |

||||

|

to = 0.30 (meters) |

K1 |

K3 |

Q1 |

Q4 |

|

TK1 |

3.16 |

|||

|

BK |

0.56 |

|||

|

BK3 |

1.78 |

|||

|

TQ |

N/A |

|||

|

BQ4 |

N/A |

|||

N/A indicates that the heating value of TQ and BQ4 are too low to be excavated with Q1 and Q4 coal seams in order to meet the minimum heating value 2,800 kcal/kg with dilution layer at 0.30 meters.

In addition, the geological thickness of coal seam K and Q vary between 10-35 me- minimum thickness indicated in the Table 2.

On the other hand, the allowable dilution thickness can be determined to meet any heating value requirement, with the assumption of excavation with K and Q coal seam 10 meters. By using equation 11, the results are displayed in Tab. 3.

Table 3 Allowable thickness of dilution layers when excavated with 10-meter thickness coal seam at any heating value requirement

|

ω (meters) |

||||

|

Heating value required (kcal/kg) |

2,800 |

2,900 |

3,000 |

3,100 |

|

TK1 |

0.94 |

0.57 |

0.22 |

N/A |

|

BK |

5.3 |

3.32 |

1.84 |

0.72 |

|

BK3 |

1.68 |

1.17 |

0.71 |

0.30 |

|

TQ |

N/A |

N/A |

N/A |

N/A |

|

BQ4 |

N/A |

N/A |

N/A |

N/A |

N/A indicates that the heating value of TQ and BQ4 (and TK1 at 3,100 kcal/kg) are too low to be excavated with Q1 and Q4 coal seams in order to meet any heating value requirements with the assumption of excavation with 10-meter coal thickness.

From Tab. 3, the allowable thickness of dilution layer decreases at higher heating value requirements. A simple rule of thumb to determine appropriate dilution thickness, for example, can be up to 10 % of TK1 (at 2 800 kcal/kg) at any excavated thickness of K1 coal seam or up to 50 %of BK (at 2 800 kcal/kg) at any excavated thickness of K3 coal seam.

Национальный исследовательский технологический университет

-

4. SUMMARY

This student introduces approaches to determine either minimum thickness of coal seam or allowable dilution thickness to be excavated with any loss and dilution scenarios. A study case is raised using schematic lithostratigraphic units of the Na Khaem Formation from Mae Moh mine, Thailand. Geological and properties data from parts of mine areas are provided and applied to an appropriate scenario and scattering equation. The study focuses on four boundaries of coal-bearing soil and coal seam: (a) TK1 and K1 seam (b1) BK and K3 (b2) BK3 and K3 (c) TQ and Q1, and (d) BQ4 and Q4. These conditions of boundaries are vary depending on geological structure of Mae Moh basin. From preliminary requirements, the results indicate that the high quality of coalbearing soil seams, such as BK and BK3 can be excavated with K3 and acceptable dilution thickness is between 1.68-5.3 meters at 2,800 kcal/kg of heating value. These dilution thickness can be converted to 20 - 50 % at any excavated thickness of K3 coal seam. Low quality of coal-bearing soil seams, such as TK1, TQ and BQ4, should not and cannot be excavated with any K and Q coal seams. Coal-bearing parting layer should have heating value more than 1,000 kcal.kg to possibly be excavated with coal seam. Finally, these approaches can only be used as a preliminary guideline to determine appropriate thickness of both coal and coal-bearing soil seams. Many parameters should be considered for making final acceptable dilution thickness.

ACKNOWLEDGEMENTS

This study cannot be done without data and supports from Mae Moh mine, the Electricity Generation Authority of Thailand (EGAT). The authors are also grateful to all geologists and engineers from geotechnical and mine planning sections for their kind assistances and supports.

sibly be excavated with coal seams.

Список литературы Approach of recovering thin coal seams

- S. Wickanet, et.al, (2005), Middle Miocene Molluscan Assemblages in Mae Moh Basin, Lampang Province, Northern Thailand, ScienceAsia 31, pp. 183-191.

- Bui Xuan Nam, Ho Si Giao, Tran Manh Xuan, Advances in Vietnam Surface Mining for Environment Protection and Sustainable Development., International Workshop on Advances in Surface Mining for Environment Protection and Sustainable Development, 23 October, 2015, Hanoi, Vietnam, pp. 6-22.

- Bui Xuan Nam. Research on selective mining technology by hydraulic backhoe excavators for surface coal mines in Quang Ninh, Viet Nam. The 3rd Int. Conf. on Advances in Mining and Tunneling, Vung Tau, 21-22 October 2014, pp. 135-143.

- Luu Van Thuc, Bui Xuan Nam, Le Thi Thu Hoa, Do Ngoc Hoan, Vu Dinh Truong. Selection on suitable mining technological schemes of hydraulic backhoe excavator for iron ore mines. The 2nd Int. Conf. on Advances in Mining and Tunneling. Hanoi, August 23-25, 2012. pp. 117-124.

- Tran Manh Xuan, Bui Xuan Nam, Le Thi Thu Hoa, Research on suitable technological schemes for mining the ore seam 1 at the Laocai apatite mine, Int. Conf. on Advanced Mining for Sustainable Development. 23-25 September, Halong Bay, Vietnam, pp.158-164.

- Bui Xuan Nam, Carsten Drebenstedt, (2009), Use of hydraulic backhoe excavator in surface mining,Innovative Entwicklung und Konzepte in der Tagebautechnik (Ed. Drebenstedt C.). TU Bergakademie Freiberg, Germany, February 2009, pp. 175-189.

- Tran Manh Xuan, Bui Xuan Nam, Le Thi Thu Hoa, Research on suitable selective mining technology for extracting the ore of type I at the Laocai apatite mine, Int. Conf.on Advances in Mining and Tunneling. Hanoi, August 20-21, 2008. PH for Science and Technology, pp. 133-140.

- Bùi Xuân Nam, Carsten Drebenstedt, Use of hydraulic backhoe excavator in Vietnam open pit coal mines, Mine Planning and Equipment Selection 2004. Hardygora, Paszkowska & Sikora (Eds.). A.A: BALKEMA PUBLISHERS, pp. 197-202.

- Le Thi Thu Hoa, Research on establishing loading schemes by hydraulic backhoe excavators in order to improve the efficiency of selective mining in some coal mines in Quang Ninh Area, Doctoral Thesis, Chapter 2, 2012.

- Anonymous. Geotechnical Report of Mae Moh Basin, 1985, Vol. 3.