Assessment of Readiness of the Regional Economic System for the Implementation of the Concept of Integrated Processing of Mineral Resources (On the Example of the Murmansk Oblast)

Автор: Bazhutova E.A., Skufina T.P.

Журнал: Arctic and North @arctic-and-north

Рубрика: Social and economic development

Статья в выпуске: 53, 2023 года.

Бесплатный доступ

For the Arctic regions, which have significant reserves of minerals, but the most environmentally fragile, the transition to the implementation of the concept of integrated processing of mineral resources becomes critically necessary due to the development of economic activity in this territory and the prospective plans for the development of new deposits, defined by the Strategy for the Development of the Arctic Zone of the Russian Federation up to 2035. The possibility of such a transition is ensured by the readiness of economic entities in the region to such changes. The purpose of this study is to assess the readiness of the regional economic system to the transition to the implementation of the concept of integrated processing of mineral resources on the example of the Murmansk Oblast and to determine the directions of implementation of such changes. As a result, it was revealed that the regional economic system of the Murmansk Oblast has a fairly high level of resistance and an average value of readiness for changes associated with the transition to the implementation of the concept of integrated processing of mineral resources, which characterizes the level of its readiness as the level of "unstable success". The key factors of resistance were identified and measures for their levelling were proposed, which allow concretizing the implementation of the Strategy for the Development of the Mineral Resource Base of the Russian Federation at the regional level and contributing to its further more effective execution.

Arctic, environmental management, sustainable development, mineral resource base

Короткий адрес: https://sciup.org/148329489

IDR: 148329489 | УДК: [338.45:622.7](470.21)(045) | DOI: 10.37482/issn2221-2698.2023.53.36

Текст научной статьи Assessment of Readiness of the Regional Economic System for the Implementation of the Concept of Integrated Processing of Mineral Resources (On the Example of the Murmansk Oblast)

One of the conditions for sustainable socio-economic development of territories and the most pressing issue of our time is the ecologization of the economy, which is aimed at reducing the environmental intensity of production [1, Saifidinov B.S., p. 110]. Therefore, the need for resource conservation is one of the important environmental requirements that determine the process of greening the economy.

Resource conservation involves the development of the following areas of activity:

-

• saving material and energy resources, reducing the resource intensity of products;

-

• recycling of raw materials, waste disposal;

-

• complex processing of raw materials [2, Tutarishev B.Z., p. 14].

At the same time, the concept of integrated processing of raw materials involves activities to reduce the resource intensity of products through the development of waste management areas. For Russia, which has significant mineral resource potential, this issue becomes the most pressing and requires great attention in the context of sustainable development.

A wide range of works has been accumulated on the issue of implementing the concept of integrated processing of mineral resources.

The ideas for the integrated development of the subsoil and waste-free technologies for processing mineral raw materials are reflected in the works of M.I. Agoshkov, A.E. Fersman, N.V. Melnikov, K.N. Trubetskoy, V.A. Chanturia, N.N. Semyonov, I.V. Petryanov-Sokolov, B.N. Laskorin, D.R. Kaplunov, V.Z. Persitsa, N.N. Chaplygin; classification, scientific and methodological approach to geological and technological study and assessment of technogenic deposits were developed by M.I. Agoshkov, N.V. Melnikov, K.N. Trubetskoy, V.N. Umanets, M.B. Nikitin, prof. G.V. Sekisov, A.A. Taskaev and others; the study of the conditions of formation and placement, technologies and methods for studying technogenic deposits are considered in the works of V.A. Naumov, V.A. Makarov, A.B. Makarov, A.G. Talalay, B.B. Zobnin, S.I. Mormil, I.I. Kovlekov. The works of A.P. Vinogradov, V.I. Vernadskiy, A.I. Perelman, E.F. Emlin, A.V. Khokhryakov, M.A. Saprykin, V.S. Samarin, A.Ya. Gaev, Yu.M. Nesterenko, V.Ya. Zakharov, A.P. Butolin are devoted to the issues of assessing the impact of technogenic mineral formations on the environment; methodological approaches to the environmental and economic assessment of the use of technogenic mineral formations were developed by F.D. Larichkin, D.R. Kaplunov, A.I. Semyachkov, V.V. Bolshenko and others. An integrated approach to connecting the criteria of technological mineralogy with the technological properties of minerals and ores is developed in the works of V.V. Shchiptsov, B.I. Pirogov, A.A. Rogozhin, E.G. Ozhogin, O.B. Kotovaya, E.N. Levchenko. The works of famous domestic scientists I.N. Plaksin, O.S. Bogdanov, V.A. Chanturia, S.B. Leonov, V.P. Nebery, L.A. Barskiy, V.A. Bocharov, V.V. Karmazin, G.V. Sedelnikova, P.M. Solozhenkin, A.N. Zelikman, S.I. Polkin, E.V. Adamov, V.Ya. Mostovich, I.V. Shadrunova, E.V. Zelinskaya, V.P. Myazin, Yu.P. Morozov, L.V. Shumilova, N.L. Medyanik, N.N. Orekhova, M.I. Fazlullin, B.D. Khalezova, A.I. Edilbaev and many others are devoted to the creation of new resource-saving technologies for processing technogenic mineral raw materials [3, Gorlova O.E., p. 6].

The ideas and achievements of scientists are reflected in the Strategy for the Development of the Mineral Resources Complex of the Russian Federation up to 2035. The goal of the Strategy is to create conditions for the sustainable supply of mineral raw materials for socio-economic development and maintaining a sufficient level of economic and energy security of the Russian Federation. The directions for its implementation include both increasing the volume of geological ex- ploration work and developing integrated processing of mineral raw materials, including through the involvement of accumulated technogenic deposits in processing. At the same time, the second direction has not yet received proper practical application, and it is necessary to strengthen measures to eliminate disproportionality in the implementation of the adopted Strategy.

The studies of assessing the readiness of Russia’s resource regions for the integrated development of subsoil resources have recently become the most relevant. The works of such scientists as E.V. Goosen, O.N. Kavkaeva, V.I. Klishin, S.M. Nikitenko, S.V. Kovrigina, A.E. Kontorovich, K.S. Sablin, E.O. Pakhomova, L.V. Edler, E. Kagan, M.N. Ignatyeva, V.V. Yurak, A.V. Dushin, I.G. Polyanskaya and others can be highlighted among them. Famous foreign researchers such as J.D. Sacha, A.M. Warner, A. Gelb, R.M. Auty, D.C. North, J.J. Wallis, B.R. Weingast considered the problems of interaction between business and the state, as well as the influence of the resource component on the development of countries and regions; as a research problem, they emphasized the need for a broad interregional comparison of the current state of subsoil development in the resource-producing regions of Russia for the purpose of theoretical justification and practical development of new promising project forms interaction between public authorities and business structures on the principles of public-private partnership in the field of integrated subsoil exploitation and the development of an active regional policy focused on solving the problems of innovative development, import substitution and sustainable socio-economic development of the regions [4, Kontorovich A.E.].

Within the analytical review of existing works, it is noted that there is a significant emphasis on studying the issue of integrated subsoil development at the macroeconomic level, when such general indicators as GRP per capita, the share of extractive industries in added value are taken as the basis for the analysis [5, Sablin K., Kagan E.], state balance of mineral reserves [6, Ignatieva M.N., Yurak V.V., Dushin A.V.] and other statistical data on the state of regions to assess the impact of extractive industries on the environment, economic potential and social economic development of the region as a whole. At the same time, the microeconomic context of resolving the issue of integrated subsoil development, associated with assessing the readiness of the direct actors of this process — economic entities, including scientific institutions, remains insufficiently studied. In this regard, the authors consider it advisable to focus attention on this aspect and explore the problem of practical implementation of the concept of integrated processing of mineral resources, including the involvement of technogenic deposits in the processing in the context of increasing the economic activity of business entities as key actors engaged in direct activities for the extraction and processing of minerals. Their attitude, intensity of participation in these processes, interest will determine the possibility of implementing the concept of integrated processing of mineral resources. At the same time, different initial conditions of economic activity in the regions, based on historical, natural, socio-economic characteristics, impose their imprint on the implementation of economic activity by business entities in a particular regional economic sys- tem [7, Bazhutova E.A., p. 61]. This necessitates clarification of ways to implement the Strategy at the regional level.

The most specific, and at the same time strategically important for the Russian economy, are the regions of the Arctic zone of the Russian Federation. These regions are given strategic importance by their rich resource potential. The specifics are determined not only by difficult climatic conditions, but also by the fragility of the Arctic ecological system, where the consequences of human activity can be critical and become irreversible [8, Zaikov K.S., Kondratov N.A., Kudryashova E.V., Lipina S.A. et al., pp. 10–12]. It is worth noting the negative trend emerging in the regions of the Russian Arctic in recent years. The share of generated waste in all-Russian indicators attributable to the Arctic regions of the Russian Federation is increasing, while the share of recycled waste is decreasing (Table 1). The largest share of waste among the Arctic regions is observed in the Republic of Sakha (Yakutia) (up to 48.8%) and the Murmansk Oblast (28%). However, the Murmansk Oblast has a higher growth rate of this indicator, which is a cause for concern.

The Murmansk Oblast is an industrially developed region, fully included in the Arctic zone. Most of its production potential is made up of enterprises of the mining and processing complex. The region’s share in the all-Russian production of apatite and nepheline concentrates is 100%, nickel — 95%, iron ore concentrate — 10% 1. At the same time, the existing waste management situation in the Murmansk Region is far from sustainable development standards. More than 98% (and in some years up to 99.8%) of all production and consumption waste in the region is generated by mining and mineral processing enterprises. Meanwhile, from 5 to 31% of the generated waste is used as a raw material for the manufacturing of products, for filling in the excavations of exhausted quarries and mines in different years. The remaining waste from the mining industry is buried in dumps and tailings [9, Klyuchnikova E.M., Masloboev V.A., p. 234]. As of 2020, the Murmansk Oblast has accumulated 3.5 billion tons of waste. At the same time, according to some estimates, only the processing waste from mining enterprises in the Murmansk Oblast contains reserves of non-ferrous metals (Ni, Cu, Co) in the amount of 1248 thousand tons, rare metals (loparite) of 100.8 thousand tons; iron — 31 million tons, zirconium — 0.7 thousand tons, apatite (P2O5) — 38.5 and nepheline (Al2O3) — 189.8 million tons [10, Larichkin F.D., Knysha V.A.]. These elements belong to strategic types of mineral raw materials, including those subject to the risks of import dependence [11, Bazhutova E.A., Skufina T.P.]. Leveling out this risk and solving the problem of self-sufficiency of the Russian national economy in such elements can be achieved by involving in the processing of accumulated technogenic deposits or organizing production in such a way as to extract them before they get into dumps.

Table 1

Dynamics of generation, recycling, neutralization and disposal of production and consumption waste in the Russian Federation and the Russian Arctic, thousand tons

|

Regions of the Russian Federation |

2018 |

2019 |

2020 |

||||||

|

ф 4—> ГО 5 С о Е с о с го с о "о ‘о с о го ф с ф о |

с •В -о Q. Ф Е £ с с Б ° 2 Е "О "го Ч- Ф сП 4-> Ф Б -ос |

го ф Е ъ s ■ s В о 2 ^ с ф ф £ ф ф О ф 5 Е о О- £ го о ■ о 42 £ ^ ф 6 |

Ф 4—> ГО 5 с го с о ‘о го о |

•В -о О Ф 8 м 2 Е "О "го Ч- Ф СП Р о 4-> Ф го Й ОС |

ГО ф Е ъ s в о 2 ^ с ф ф £ ф Ъ го -о г 2 ф 5 Е о О- $ го о ■ о 42 £ Я ф 6 |

Ф 4—> ГО С с го с о ‘о го о |

О -О Q. Ф 8 м Б ° 2 Е "О "го ч- Ф сп 4-> Ф го Й ОС |

"8 ГО _О Ф ъ s В о 2 ^ с ф ф £ ф го ■ о Г £ ф 5 Е о О- £ го Е го о ■ о 42 £ ^ ф 6 |

|

|

Russian Federation |

7 266 054 |

52.6 |

28.8 |

7828457 |

52.3 |

31.3 |

6 955 717 |

49.3 |

22.5 |

|

Partially Arctic regions |

|||||||||

|

Arkhangelsk Oblast and Nenets AO |

77 035 |

6.5 |

40 |

77579 |

4.1 |

44.4 |

34 221 |

4.6 |

26.9 |

|

Republic of Karelia |

141 847 |

18.4 |

99.3 |

151058 |

12.1 |

99.8 |

150 128 |

7.7 |

99.6 |

|

Komi Republic |

5 239 |

11.7 |

5.1 |

36025 |

12.4 |

87.1 |

40 225 |

1.0 |

89.5 |

|

Republic of Sakha (Yakutia) |

427 128 |

59.9 |

48.4 |

528990 |

53.7 |

50.6 |

528 999 |

50.1 |

49.5 |

|

Largest entirely Arctic regions (by population) |

|||||||||

|

Murmansk Oblast |

229 586 |

23.6 |

80 |

260049 |

15.6 |

75.1 |

305 637 |

12.2 |

32.1 |

|

Yamalo-Nenets AO |

939 |

91.7 |

99.7 |

1730 |

80.7 |

96.8 |

488 |

105.2 |

97.1 |

|

Small entirely Arctic regions (by population) |

|||||||||

|

Chukotka AO |

20 634 |

31.8 |

99.3 |

29246 |

44.7 |

79.9 |

23 715 |

69.3 |

92.2 |

|

Total for AZRF, people |

902 408 |

35.3 |

62.1 |

1084677 |

29.7 |

75.6 |

1 083 413 |

30.1 |

65.8 |

|

Share in the allRussian indicator, % |

12.4% |

13.9% |

15.6% |

||||||

The adverse impacts of mining waste disposal from the social aspect reduce the quality of life of the population of the Murmansk Oblast, 42% of which lives in towns and villages located in close proximity to mining enterprises. From the economic point of view, degradation of the natural environment reduces the investment attractiveness of the territory [12, Fomenko M.A.] with the active development of the tourism industry in the region.

The new ambitious strategy for the development of the Arctic zone of the Russian Federation, approved in October 2020, Strategy for the development of the Arctic zone of the Russian

Federation and ensuring national security for the period up to 2035, sets one of the goals of transforming the Murmansk Oblast into a strategic center, where it is planned to create progressive infrastructure and conditions for development mineral resource base. A step towards this goal in 2022 was the signing of a cooperation agreement by Rosgeologiya and the Government of the Murmansk Oblast during the St. Petersburg International Economic Forum. The new agreement defines the basis for cooperation and interaction between the parties in the field of comprehensive geological study of subsoil and geological exploration in the Murmansk Oblast as part of the implementation of the Strategy for the development of the mineral resource base of the Russian Federation up to 2035. In accordance with the document, the Government of the Murmansk Oblast will contribute to the creation of optimal conditions to attract investments necessary for the comprehensive study and reproduction of the region’s mineral resource base. Rosgeologiya will carry out work on comprehensive geological study, development and monitoring of the state of subsoil in the Murmansk Oblast using advanced methods and technologies of geological exploration, new high-tech methods for forecasting, identifying and integrated use of mineral raw materials 2. However, the implementation of these intentions without the involvement of economic entities of the region is impossible.

According to the system principle, one system is a subsystem of another of a higher order. Thus, economic entities are subsystems of the regional economic system, and the state economic system, in which the decision is made to change the existing structure for the implementation of a particular type of activity, will be of the upper level for the regional system. Thus, the transition to the implementation of the concept of integrated processing of mineral raw materials is a change for which the economic systems of the regions and their constituent economic entities in particular should be ready. Moreover, the success of change implementation depends on the involvement of its executors, direct participants. Making changes is more difficult the larger the organization and the higher the level of resistance of subsystems to introduced innovations. Partly the size of an organization is related to its stability, and partly to the duration of its existence. Both factors are to some extent associated with the reluctance of subsystems to improve due to satisfaction, to a greater or lesser extent, with the existing state of affairs. Considering this situation in relation to the adopted approach to conducting business in the mining and mineral processing industry in the Russian Federation, it can be stated that considerable preliminary work is required prior to the implementation of such a change in order for it to be successful. The historically established practice of one- and two-component mining in Russia, given the significant wealth of mineral deposits, is the traditional way of working of mining companies. Changing their attitude to this issue, involving them in the process of multicomponent extraction and processing requires an in-depth study of the factors influencing this change in order to ensure the readiness of economic entities and the regional economic system as a whole for such changes.

Thus, the purpose of this study is to assess the readiness of the regional economic system for the transition to the implementation of the concept of integrated processing of mineral resources in terms of assessing the readiness of its economic entities for such a change using the example of the Murmansk Oblast, as one of the regions of the Arctic zone of the Russian Federation, and to determine the directions for implementation such changes.

In order to achieve this goal, it is proposed to solve the following tasks:

-

• to review methods for assessing readiness for changes at the level of economic entities and the regional economic system as a whole;

-

• to identify factors that create opportunities and factors that hinder the implementation of integrated processing of mineral resources in relation to economic entities;

-

• to carry out an expert survey of key economic entities in the region’s industry using the example of the Murmansk Oblast;

-

• to assess the level of readiness of economic entities and the regional economic system as a whole, to propose measures to stimulate the transition to the implementation of the concept of integrated processing of mineral resources at the regional level.

Materials and methods

Review of methodologies for assessing readiness for change at the level of economic entities and the regional economic system as a whole

An integral aspect of the functioning of any system is its development. Development is a complex process of qualitative change in the system. In this case, the system can be understood as either a separate enterprise or a regional economic system as a whole. When initiating any changes at the upper-level system, it is necessary to understand the readiness of the lower-level subsystems to implement them. The understanding that change begins with determining the degree of readiness appeared in the world in the last decade of the last century thanks to the introduction of the term “organizational readiness for change” [13, Ansoff I.]. Its key idea is that it is possible to increase the probability of successful changes if one starts acting “before” the changes themselves. In Russia, interest in this development arose in the last 3–4 years [14, Khalitova I.V., p. 152–153]. The study of theoretical and methodological approaches to assessing the level of readiness was considered in management theory in the context of the situational approach (M. Fullan, M. Miles, G. Morgan, etc.), the human factor (Scott S., Jaf D., Kruger F., Price K., etc.), rationality: planning and control (Lepore D., Cohen O., Levin K., Bridges W., etc.), soft methods: organizational culture, power, conflicts, communications, etc. (Beriz L., Kruger F., Schwartz G., Davis S., etc.), system and factor approaches (Hannan M., Freeman J., Ulrich D., etc.), learning organizations (Kolb J., Rabin I., Osland J., Senge P., etc.), self-organization (Prigozhin I., Strengers I., Weick K., Quinn R., Sminia G.), “time theories” (Adesis I., Mintzberg G.). The practical aspect of assessing the readi- ness of these approaches is to conduct a survey (questionnaire). In this case, the questionnaire itself can use different factors and criteria of readiness depending on the adopted approach, as well as different methods of calculating the level of readiness. Among them are:

-

• Method for determining the probability of success in implementing changes [15, Pavlova A.V.]. The essence of the method is to consider a set of indicators that have an impact on the subject of change under study, and their assessment by collecting expert opinions. At the same time, the identified groups of indicators are considered both from the view of their positive impact, which contributes to changes and generally determines the level of readiness, and from view of their negative impact, which determines the level of resistance to change [15, Pavlova A.V.]

-

• Readiness matrix by O. Vikhanskiy and A. Naumov. The method is based on assessing readiness for change through assessing the psychological readiness of personnel. If the employee is satisfied with the existing situation, and the risk of change is high, changes become impossible. In conditions where employees are dissatisfied with the current state of affairs, and the risk does not frighten them, the organization has a great chance of making successful changes.

-

• Model of changes or the Beckhard-Harris Change Formula [16]. The essence of the method is expressed by formula (1):

С > R, or (Ds + V + Fs) > R (1), where

R — resistance to change;

-

C — readiness to change;

Ds — dissatisfaction with the current state of affairs;

-

V — vision of the desired future;

Fs — “first step” of the action program.

According to this formula, any change is possible only if the sum in brackets is greater than the elements of resistance to organizational change (R).

-

• Jody Spiro Questionnaire; according to this method, readiness consists of three factors:

-

• Experience of participation in change implementation processes;

-

• Existence of skills necessary for change implementation;

-

• Positive attitude towards change: enthusiasm and readiness for responsibility.

The indicator is determined for each criterion, taking into account each result obtained, rather than an average overall indicator. If at least one criterion is low, the readiness for change is low. If all three factors are high, the strategy can be less structured and less detailed. If all factors are high, autonomous teamwork can lead the company to change without even requiring the assistance of management.

-

• The methodology for a balanced approach to assessing the readiness of projects as a whole is the TPRL (Technology Project Readiness Level) methodology. The unified method for assessing the level of technology readiness TRL (Technology Readiness Level) [17, Mankins J.C.] and the Stage-Gate® method [18, Robert G.C., Scott J.E.] were taken as a starting point for the development of such a methodology. The TPRL methodology, TRL and Stage-Gate® methods use a systematic approach, which allows describing project readiness levels for a wide range of disciplines in unified terms. Methodology TPRL provides a preliminary assessment of projects based on documents, showing in digital and graphical form the level and index of project readiness for each parameter. The application of the TPRL methodology provides experts with the opportunity to work more efficiently using such preliminary assessments. The TPRL methodology is based on 6 parameters for assessing the degree of project readiness, which are the minimum necessary set for a comprehensive assessment of the main axes of project development and the readiness of the project as a whole. Taken together, these parameters can be used to judge not only the development of technology and production, but also other aspects important for the successful commercialization of projects.

-

• DICE method: according to this method, 4 hard factors are the litmus test for assessing the likelihood of success of a change project: duration, integrity, commitment, effort [19, Sirkin H.L., Keenan P., Jackson A.]. The readiness level is calculated using formula (2):

DICE = D + 2*I + 2*C1 + C2 + E (2), where

D — Duration — time between project milestones

I — Integrity — the quality of changes will depend on the skills of the performers

C — Commitment - support for change (influential employees, managers — C1; employees affected by changes — C2)

E — Effort — new responsibilities of employees regarding changes in addition to operational work

Each factor is assigned a number from 1 (favorable) to 4 (unlikely). Projects with DICE between 7 and 14 are the best (in the success zone), between 14 and 17 are risky (in the worry zone), and over 17 are very risky (in the disaster zone).

Taking into account the problem considered in this study, it is worth noting that the method of expert assessments was also justified by researchers of regions’ readiness for integrated subsoil development as necessary to take into account the significant differentiation of Russian regions and develop a methodology for searching for new implicit opportunities of regions [20, Sablin K.S., Kagan E. S., Sharov A.A., pp. 84–85]. The purpose of this approach was to assess the readiness of economic entities in the mining sector to form an integrated national economy through a comprehensive assessment of their readiness to develop domestic markets.

This study proposes to assess the readiness of business entities to transition to the implementation of the concept of integrated processing of mineral resources in terms of their perception of the factors that influence their adoption of such a decision, and to process the results obtained using the method of determining the likelihood of success in implementing the changes. The choice of this method was due to the fact that this methodology is applicable to any project, regardless of its scale, and can consider both a specific project or enterprise, and changes at the level of the economy as a whole, based on a wide range of indicators, which allows for a comprehensive assessment of upcoming changes.

Main research methods

The algorithm for applying the method for determining the likelihood of success in implementing changes includes the following steps:

-

• a set of indicators by which readiness for change will be assessed is established;

-

• each indicator is assigned a weight of its relative importance. Those indicators that are most important are given higher weights, and vice versa. For the convenience of calculations, the weights are distributed in such a way that their sum is equal to one;

-

• a significance coefficient is established for each of the indicators. The indicators are scored according to the extent to which the readiness characteristic contained in the indicator carries with it the capacity to change in principle. The assessment is carried out on a five-point scale: 5 — the most capable, 1 — the least capable indicator. The relative importance score of each indicator is multiplied by the corresponding importance coefficient of that indicator, and then the products are summed up. The sum results in an integral assessment of readiness to make changes. The maximum assessment of readiness of the enterprise can be 5, and the minimum — 1 [15, Pavlova A.V.].

A similar algorithm is used to assess the resistance level, where the selected indicators are considered from a risk perspective. An assessment is given of the probability of a risk occurring as a weight value and an assessment of its significance as the degree of influence on the result of the planned changes. Each resistance indicator is assigned its own significance coefficient (from 1 to 5) and its own weight, so that the sum of all weights equals 1.

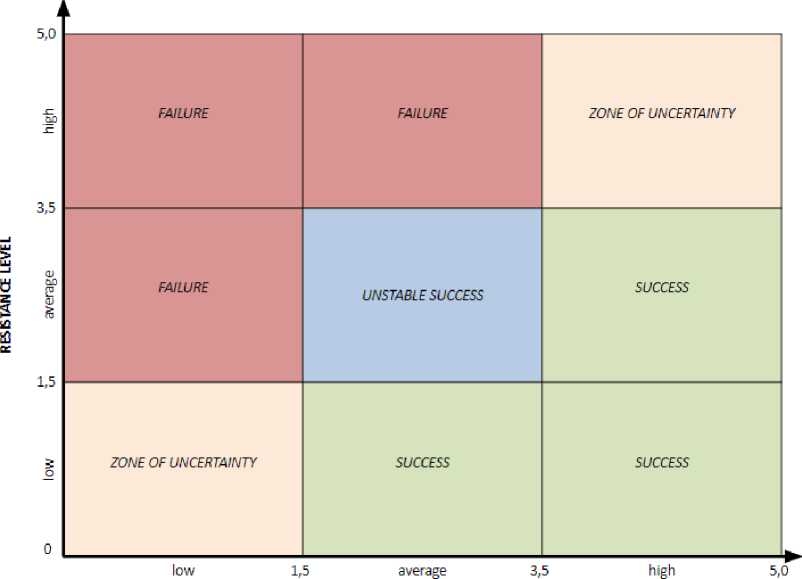

After the value of the enterprise’s readiness for change and the value of the level of resistance to change have been obtained, a matrix of the enterprise’s positioning regarding the success of the changes undertaken is constructed. It is proposed to display the level of readiness for change horizontally, and the level of resistance — vertically. Each of the axes is divided into three zones that characterize the degree of readiness for change (high, medium, low) and three zones that demonstrate the level of resistance to change (strong, medium, weak). Accordingly, nine quadrants are formed within the matrix, indicating the possibility of making changes. The form of the proposed matrix is shown in Fig. 1.

READINESS LEVEL

Fig. 1. Matrix of positioning of the enterprise regarding the success of implementing changes in its activities 3.

If the intersection of two values falls into the “success” quadrant, the company has the opportunity to make changes with minimal risks. If it is the “zone of uncertainty” quadrant, changes can have good results, but it is necessary to make great efforts to reduce the degree of resistance or increase the enterprise’s readiness to accept and implement changes. If, as a result of the assessment, the enterprise falls into the “unstable success” quadrant, it is difficult to clearly judge the possibility of making changes and their success. A decision regarding this situation can be made only after a more in-depth analysis of the situation [15, Pavlova A.V., p. 7].

Such a positioning matrix allows determining specific measures to reduce the level of resistance to changes, which will ensure their successful implementation.

The study is therefore based on a mixed methodological approach. The qualitative method is used in the case of systematizing the factors of readiness and resistance of business entities in the Murmansk Oblast to the transition to the implementation of the concept of integrated processing of mineral resources, identified on the basis of content analysis of publications on this topic. The quantitative method is used to analyze data obtained by issuing expert assessments by representatives of business entities in the mining and processing industry of minerals in the Murmansk Oblast on factors of readiness and resistance in terms of their significance and implementation. Based on the interpretation of quantitative results, a qualitative analysis was carried out, including an explanation of the obtained estimates.

Information basis of the study

The study is based on a review of publications devoted to the problems and prospects for implementing the concept of integrated processing of minerals in the Russian Federation. The content analysis allowed identifying 20 indicators, systematized by their general characteristics into 5 group factors [11, Bazhutova E.A., Skufina T.P.].

The first group, “Resource Component”, includes such indicators as: availability of mineral reserves, availability of production facilities, number of personnel and their qualifications, investment opportunities, sufficiency of components for production (additional substances, reagents, materials, components, etc.) and energy security.

The second group of factors, “Technological component”, includes the developed potential technology for processing mineral raw materials, as well as patents and licenses for activities.

The third group, “Institutional environment”, is represented by indicators that determine the legalization of an activity, namely the availability of permits to carry out an activity, the level of administrative barriers and state regulation of this activity in general.

Market factors are included in the fourth group “Market component” and include the level of prices, demand and competition in the market, entrepreneurial activity in the market in the form of the presence of the necessary suppliers and contractors who could be attracted to organize activities for the integrated processing of mineral resources.

And the fifth group of factors is designated as “Supporting environment” and is represented both by measures to support the type of activity on the part of the state, and by the development of partnership relationships, the readiness for cooperation of business entities to implement the integrated processing of mineral resources.

The presented classification of factors became the basis for the formation of an expert survey sheet, on the basis of which a study was conducted to assess the readiness and resistance of business entities in the Murmansk Oblast to the implementation of the concept of integrated processing of mineral resources.

Expert assessments were obtained from two major mining enterprises in the Murmansk Oblast, as well as from representatives of the scientific community. The key condition for conducting the survey was anonymity, so the results of the assessments obtained are presented in a generalized form. The assessment of the readiness of the regional economic system as a whole and the level of its resistance to upcoming changes was calculated as the average value of the assessments obtained for each economic entity in the region.

Discussion of results

As a result of the expert survey and the information obtained on the level of readiness and resistance, the following summary estimates of the level of readiness and resistance of the regional economic system of the Murmansk Oblast to the transition to the implementation of the con- cept of integrated processing of mineral resources were obtained, presented in tables 2 and 3, respectively.

Table 2

Summarized results of the readiness assessment 4

|

Name of indicator |

Summary assessment of readiness by economic entities of the region |

Summary assessment of readiness by business entities and scientific community |

||||

|

Relative weight |

Significance factor |

Result |

Relative weight |

Significance factor |

Result |

|

|

1. Resource component |

0.20 |

3.00 |

0.60 |

0.17 |

2.67 |

0.44 |

|

1.1. Mineral reserves |

0.10 |

4.50 |

0.45 |

0.13 |

4.67 |

0.62 |

|

1.2. Availability of production capacity |

0.15 |

3.00 |

0.45 |

0.15 |

2.33 |

0.36 |

|

1.3. Personnel |

0.20 |

1.00 |

0.20 |

0.19 |

1.00 |

0.19 |

|

1.4. Investments |

0.23 |

2.00 |

0.45 |

0.20 |

1.33 |

0.27 |

|

1.5. Components for production (additives, reagents, materials, components, etc.) |

0.15 |

3.50 |

0.53 |

0.15 |

2.67 |

0.41 |

|

1.6. Energy |

0.18 |

5.00 |

0.88 |

0.17 |

3.33 |

0.57 |

|

Other: |

||||||

|

2. Technological component |

0.25 |

2.10 |

0.53 |

0.27 |

1.73 |

0.46 |

|

2.1 Developed potential processing technology |

0.35 |

3.00 |

1.05 |

0.40 |

2.33 |

0.93 |

|

2.2 Patents, licenses to carry out activities |

0.35 |

1.50 |

0.53 |

0.40 |

1.33 |

0.53 |

|

Other: |

||||||

|

Availability and accessibility of equipment in the current geopolitical environment |

0.30 |

1.00 |

0.30 |

0.20 |

0.67 |

0.13 |

|

3. Regulatory component |

||||||

|

3.1 Permission to carry out an activity |

0.15 |

2.00 |

0.30 |

0.18 |

2.67 |

0.49 |

|

3.2 Administrative barriers |

0.55 |

2.50 |

1.38 |

0.53 |

3.33 |

1.78 |

|

3.3 Government regulation (state of legal framework) |

0.23 |

1.00 |

0.23 |

0.22 |

2.33 |

0.51 |

|

Other: |

0.23 |

2.50 |

0.56 |

0.25 |

2.33 |

0.58 |

|

4. Market component |

||||||

|

4.1 Market price |

0.23 |

1.25 |

0.28 |

0.22 |

1.83 |

0.40 |

|

4.2 Demand |

0.25 |

1.00 |

0.25 |

0.28 |

1.67 |

0.47 |

|

4.3 Competition |

0.25 |

1.50 |

0.38 |

0.28 |

2.00 |

0.57 |

|

4.4 Suppliers/ contractors |

0.25 |

1.00 |

0.25 |

0.23 |

1.67 |

0.39 |

|

Other: |

0.25 |

1.50 |

0.38 |

0.20 |

2.00 |

0.40 |

|

5. Supporting environment |

||||||

|

SOCIAL AND ECONOMIC DEVELOPMENT Ekaterina A. Bazhutova, Tatiana P. Skufina. Assessment of Readiness … |

46 |

|||||||

|

5.1 Partners (their availability and willingness to cooperate) |

0.18 |

1.10 |

0.19 |

0.17 |

1.40 |

0.23 |

||

|

5.2 Tax preferences from the state |

0.35 |

1.50 |

0.53 |

0.32 |

1.67 |

0.53 |

||

|

5.3 Preferences from the state in terms of subsidizing costs |

0.15 |

1.00 |

0.15 |

0.20 |

1.33 |

0.27 |

||

|

5.4 State preferences in terms of market regulation (prices) |

0.15 |

1.00 |

0.15 |

0.15 |

1.33 |

0.20 |

||

|

5.5 State preferences in terms of stimulating demand for a new product |

0.15 |

1.00 |

0.15 |

0.15 |

1.00 |

0.15 |

||

|

Other: |

||||||||

|

Readiness assessment |

1.81 |

2.01 |

||||||

Table 3

Summarized results of the resistance assessment 5

|

Name of indicator |

Summary assessment of resistance by economic entities of the region |

Summary assessment of resistance by business entities and scientific community |

||||

|

Relative weight |

Expert assessment |

Result |

Relative weight |

Expert assessment |

Result |

|

|

1. Resource component |

0.12 |

2.90 |

0.33 |

0.11 |

2.60 |

0.29 |

|

1.1 Insufficient reserves (content of valuable component) |

0.10 |

2.50 |

0.25 |

0.07 |

2.00 |

0.13 |

|

1.2 Insufficiency (absence) of available production capacities |

0.30 |

4.50 |

1.35 |

0.30 |

4.67 |

1.40 |

|

1.3 Insufficient number of personnel |

0.13 |

3.50 |

0.44 |

0.08 |

2.67 |

0.22 |

|

1.4 Insufficient qualifications of personnel |

0.13 |

4.00 |

0.50 |

0.13 |

3.33 |

0.44 |

|

1.5 High cost of components |

0.08 |

2.00 |

0.15 |

0.10 |

2.00 |

0.20 |

|

1.6 Insufficient number of components |

0.08 |

2.00 |

0.15 |

0.10 |

2.00 |

0.20 |

|

1.7 High energy costs |

0.10 |

2.00 |

0.20 |

0.13 |

2.00 |

0.27 |

|

1.8 Insufficient energy capacity |

0.10 |

3.00 |

0.30 |

0.08 |

2.33 |

0.19 |

|

1.9 Other: |

||||||

|

2. Technological component |

0.43 |

3.00 |

1.28 |

0.37 |

3.17 |

1.16 |

|

2.1 Economic inexpediency of the existing technology |

0.85 |

4.00 |

3.40 |

0.73 |

4.00 |

2.93 |

|

2.2 High cost of a patent and license to operate |

0.15 |

2.00 |

0.30 |

0.27 |

2.33 |

0.62 |

|

Other: |

||||||

|

3. Regulatory component |

0.13 |

2.00 |

0.25 |

0.18 |

1.67 |

0.31 |

|

3.1 Impossibility of obtaining permission to carry out an activity |

0.45 |

3.00 |

1.35 |

0.57 |

2.33 |

1.32 |

|

3.2 High administrative barriers to carrying out this type of activity |

0.03 |

2.00 |

0.05 |

0.05 |

1.67 |

0.08 |

|

3.3 Insufficient regulation by the state (absence or incompleteness of the legal framework) |

0.03 |

1.50 |

0.04 |

0.05 |

1.33 |

0.07 |

|

Other: |

||||||

|

4. Market component |

0.20 |

4.30 |

0.86 |

0.20 |

4.00 |

0.80 |

|

4.1 Low price for the finished product on the market |

0.15 |

4.00 |

0.60 |

0.17 |

3.33 |

0.56 |

|

4.2 Low demand for the finished product on the market |

0.15 |

4.50 |

0.68 |

0.17 |

4.00 |

0.67 |

|

4.3 High competition for the finished product produced |

0.15 |

4.50 |

0.68 |

0.18 |

4.33 |

0.79 |

|

4.4 Low competitive advantages of the new finished product |

0.40 |

4.50 |

1.80 |

0.35 |

4.33 |

1.52 |

|

4.5 Absence (inadequacy) of suppli-ers/contractors |

0.15 |

4.00 |

0.60 |

0.13 |

4.00 |

0.53 |

|

Other: |

||||||

|

5. Supporting environment |

0.14 |

3.00 |

0.41 |

0.14 |

3.00 |

0.42 |

|

5.2 Lack of partners for organizing joint production for complex processing of minerals |

0.23 |

3.50 |

0.79 |

0.22 |

3.00 |

0.65 |

|

5.3 Unwillingness of potential partners to co-operate |

0.18 |

3.50 |

0.61 |

0.18 |

3.00 |

0.55 |

|

5.4 Inadequacy (absence) of preferences from the state on taxes |

0.15 |

2.50 |

0.38 |

0.17 |

3.00 |

0.50 |

|

5.5 Inadequacy (absence) of preferences from the state to subsidize costs |

0.15 |

3.00 |

0.45 |

0.17 |

3.33 |

0.56 |

|

5.6 Inadequacy (absence) of preferences from the state for price regulation |

0.15 |

3.00 |

0.45 |

0.13 |

3.00 |

0.40 |

|

5.7 Insufficiency (absence) of preferences from the state to stimulate demand |

0.15 |

3.00 |

0.45 |

0.13 |

3.00 |

0.40 |

|

Other: |

||||||

|

Resistance assessment |

1.81 |

2.97 |

||||

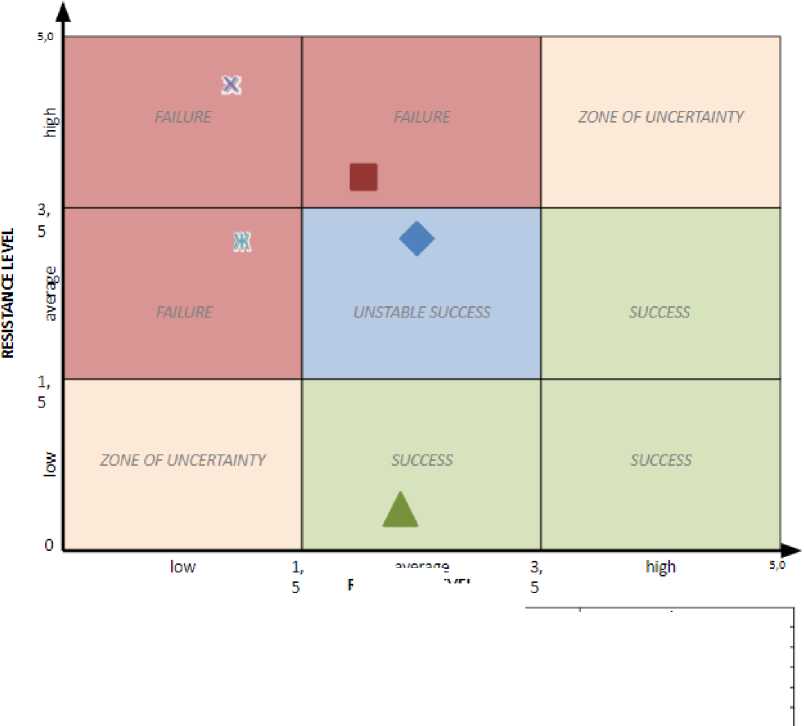

After the readiness of the regional economic system of the Murmansk Oblast for changes and the level of expected resistance to these changes were assessed, we positioned the economic entities of the region and the regional economic system as a whole, with and without taking into account the opinion of the scientific community regarding the success of the changes transition to the implementation of the concept of integrated processing of mineral resources. The obtained matrix of positioning regarding the success of changes is shown in Fig. 2.

|

Resistance level |

Readiness level |

|

|

Enterprise 1 |

3.02 |

2.15 |

|

Enterprise 2 |

3.38 |

1.48 |

|

Science community |

2.51 |

2.40 |

|

Summary assessment by economic entires |

3.20 |

1.S1 |

|

Summary assessment by economic entires and scientific community |

2.97 |

2.01 |

Fig. 2. Matrix of positioning of the regional economic system of the Murmansk Oblast regarding the success of the transition to the implementation of the concept of integrated processing of mineral resources 6.

In the process of managing the implementation of changes, it is important to assess the level of resistance in relation to each specific change. In this regard, the level of readiness and resistance was also assessed for each selected group of factors as the sum of its indicators.

Table 4 Assessment of groups of factors influencing the implementation of changes in the transition to the concept of integrated processing of mineral resources, according to the level of their readiness and resistance 7

|

Group of factors |

Summary assessment by economic entities in the region |

Summary assessment for business entities and scientific community |

||

|

Level of resistance |

Level of readiness |

Level of resistance |

Level of readiness |

|

|

Resource component |

3.34 |

2.95 |

3.06 |

2.41 |

|

Technological component |

3.70 |

1.88 |

3.56 |

1.60 |

|

Regulatory component |

1.44 |

2.16 |

1.47 |

2.87 |

6 Source: compiled by the authors based on the results of an expert survey.

7 Source: compiled by the authors based on the results of an expert survey.

|

Market component |

4.35 |

1.25 |

4.07 |

1.83 |

|

Supporting environment |

3.13 |

1.18 |

3.06 |

1.39 |

Positioning of the group of factors relative to the change implementation success matrix is

Thus, as a result of collection and processing of the received expert opinions, the assessment of the readiness of the regional economic system of the Murmansk Oblast was 1.81 points (out of 5 possible) with a resistance level of 3.20 points (out of 5, where 5 is the highest level of resistance), which may be characterized as a level of “unstable success” when positioning a regional economic system. This means that the regional economic system of the Murmansk Oblast has a fairly high level of resistance and an average level of readiness for changes associated with the transition to the implementation of the concept of integrated processing of mineral resources. A separate collection of expert opinions from the scientific community was conducted on the issue of transition to the implementation of the concept of integrated processing of mineral resources. The scores obtained are also positioned in the zone of “unstable success” with a readiness level of 2.40 points (out of 5 possible) and a resistance score of 2.51 (out of 5, where 5 is the highest level of resistance). It is necessary to reduce the level of resistance to change and, if possible, increase

-

8 Source: compiled by the authors based on the results of an expert survey.

the readiness of economic entities in the region to accept such changes. It was noted that the spread in the assessments of economic entities regarding their readiness has a differentiated value and ranges from 1.48 points (out of 5 possible) to 2.15 points (out of 5 possible), and the level of resistance is estimated almost equally from 3.02 up to 3.38 points (out of 5, where 5 is the highest level of resistance). In view of this, some enterprises are in the “failure” zone when making a decision on implementing the concept of integrated processing of mineral resources, i.e., the business entity is not ready to make changes and there are significant risks in their implementation. Others are in the zone of “unstable success”, it is difficult to clearly judge the possibility of making changes and their success. The difference in assessments of business entities is determined by the different experience of the surveyed business entities in this area and the presence of proven processing schemes for them. Thus, a decision can be made only after a deeper analysis of the situation.

An in-depth analysis of the situation to determine the conditions under which a decision can be made for the implementation of the concept of integrated processing of mineral resources by business entities was carried out regarding a selected set of 5 groups of indicators, on which an expert survey was conducted. These groups of indicators were also positioned using the positioning matrix method relative to the success of the changes being undertaken. As a result, the group of factors “Regulatory component” fell into the “Success” zone, having a readiness rating of 2.16 points (out of 5 possible) and 1.44 points for the level of resistance (out of 5, where 5 is the highest level of resistance). Experts’ comments indicated the relative transparency and clarity of the legal field, and the absence of administrative barriers to the implementation of this activity. The group of factors “Resource component” is in the zone of “Unstable success” with estimates of the readiness level of 2.95 points and the resistance level of 3.34 points. The lowest ratings included in the risk factors from this set of indicators, according to experts, were the insufficiency (absence) of existing production capacities and insufficient personnel: both their number and qualifications. The 3 remaining groups of factors were included in the “Failure” zone: “Supporting environment” (readiness level — 1.18 points; resistance level — 3.13 points), “Market component” (readiness level — 1.25 points; resistance level — 4.35 points), “Technological component” (readiness level — 1.88 points; resistance level — 3.70 points). The key risk indicators were the absence of regular consumers with a significant order volume; lack of interested partner companies ready to integrate into the existing technological process to implement additional extraction processes and more in-depth integrated processing of mineral resources; low competitive advantages of the additionally extracted valuable component compared to analogues on the market; lack of subsidizing costs from the state, especially in terms of conducting a feasibility study for the integrated processing of mineral resources; economic inexpediency of the existing technology for industrial development due to the above risks.

Conclusion

Thus, this study of assessing the readiness of the regional economic system to implement changes associated with the implementation of the concept of integrated processing of mineral resources allows us to formulate the following conclusions:

-

• The regional economic system of the Murmansk Oblast has a fairly high level of resistance and an average level of readiness for changes associated with the implementation of the concept of integrated processing of mineral resources.

-

• For the Murmansk Oblast, the factors of resistance are the groups of factors “Market component”, “Supporting environment”, “Technological component”, while readiness for the transition is ensured by the factors of the group “Resource component” and “Regulatory component”.

-

• The solution to the issue of transition to the implementation of the concept of integrated processing of mineral resources at the preparatory stage should be the fulfillment of a number of general conditions that can be of practical value for all resource regions of Russia. Firstly, this is a condition for ensuring the required level of demand. It is assumed that for the first periods it should be in the form of a state order, which would stimulate the economic activity of business entities for in-depth processing independently or within the framework of partner/outsourcing processes. The second condition is the need to develop marketing in the mining industry, not only from the point of view of the use of possible raw materials as a component for the production of any product, but also from a geological point of view, allowing at the time of developing feasibility studies for new deposits to assess the current possibilities of extracting the same useful component by deploying the concept of integrated processing at existing production facilities and comparing the resulting economic, environmental and social effects to make a final decision. The third condition, from a logistics point of view, is the creation of a logistics-distribution system through the establishment of a state management company that issues government orders, collects consumer orders on the market and redistributes completed government orders for the integrated processing of mineral resources in both small and large quantities, and also performing the function of searching for possible partners who could integrate into existing technological processes on outsourcing terms. In addition, an important condition of the first stage will be support from the state to subsidize the costs associated with conducting a feasibility study as a high-risk and costly activity for business entities. The mechanism for its implementation is possible through a grant system for the scientific community with corporate orders from business entities.

The results obtained allow us to highlight areas for studying the issue of ensuring integrated processing of mineral resources in relation to a specific regional economic system. Thus, this study can strengthen the practical orientation and develop the theoretical aspects of the concept presented in Fig. 3.

♦ Resource component

■ Technological component л Regulatory component

■ Market component

Supportive environment average

READINESS LEVEL

|

Resistance level |

Readiness level |

|

|

Resource component |

5.34 |

2.95 |

|

Technological component |

3.70 |

l.BE |

|

Regulatory component |

1.44 |

2.16 |

|

Market component |

4.35 |

1.25 |

|

Supporting environment |

3.13 |

1.18 |

Fig. 3. Matrix of positioning of groups of factors for the transition to the implementation of the concept of integrated processing of mineral resources according to estimates of business entities 8.

SOCIAL AND ECONOMIC DEVELOPMENT

Ekaterina A. Bazhutova, Tatiana P. Skufina. Assessment of Readiness … of integrated processing of mineral resources in the context of the regional economy, namely the management of the economic activity of economic entities in the region engaged in the extraction and processing of minerals, to stimulate their involvement in the implementation of integrated processing of mineral resources.

The originality of the research results lies in the identification of regional features that determine the readiness of the regional economic system, namely its economic entities, to implement the concept of integrated processing of mineral resources from the perspective of sustainable development, determining the directions for the formation of an organizational and economic mechanism for the implementation of this concept, which was previously insufficiently studied in independent scientific articles.

The results can be taken into account when developing specific measures for the implementation of the Strategy for the development of the Arctic zone of the Russian Federation and ensuring national security for the period up to 2035, contributing to the transformation of the Murmansk Oblast into a strategic center, where it is planned to create conditions for the development of the mineral resource base, as well as increase the efficiency of implementation Strategy for the development of the mineral resource complex of the Russian Federation up to 2035 by strengthening its adaptation to a specific region and using it as the basis for the development of a new Action Plan for the implementation of this strategy for the period of 2024–2030. According to the authors, for representatives of the state, business and science, the results of this study will contribute not only to the qualitative development of the Arctic territories of Russia, but also to the resolution of the accumulated environmental problems of the region.

Further research will be aimed at an in-depth study of the identified factors and the formation of a set of possible substantive solutions that can reduce resistance and increase the readiness of the regional economic system to implement the concept of integrated processing of mineral resources for the sustainable development of the Russian economy in general and its Arctic region in particular.

Список литературы Assessment of Readiness of the Regional Economic System for the Implementation of the Concept of Integrated Processing of Mineral Resources (On the Example of the Murmansk Oblast)

- Sayfidinov B.S., Tabatchikova A.P. Ekologizatsiya ekonomiki nasushchnyy vopros v XXI veke [Greening the Economy an Urgent Issue in the 21st Century]. NovaInfo, 2017, no. 65, pp. 110 114.

- Tutarishev B.Z. Organizatsionno ekonomicheskiy mekhanizm formirovaniya sistem ekologicheskogo menedzhmenta kachestva okruzhayushchey sredy v stroitel'nom komplekse: dis. dok. ekon. nauk [Organizational and Economic Mechanism of Formation of Environmental Quality Management Systems in the Construction Complex: Dr. Econ. Sci. Diss.]. Rostov on Don, 2004, 284 p. (In Russ.)

- Gorlova O.E. Razvitie nauchno metodologicheskikh osnov tekhnologii pererabotki gornopromyshlennykh otkhodov: dis. dok. tekhn. nauk [Development of Scientific and Methodological Foundations of Mining Waste Processing Technology: Dr. Tech. Sci. Diss.]. Magnitogorsk, 2020, 402 p. (In Russ.)

- Kontorovich A.E. Kompleksnoe osvoenie nedr. Industriya 4.0. Gosudarstvenno chastnoe partnerstvo biznesa v sfere kompleksnogo osvoeniya nedr [Complex Development of Mineral Resources. Industry 4.0. Public Private Partnership of Business in the Field of Integrated Development of Mineral Resources]. Sibirskaya izdatel'skaya gruppa Publ., 2018, 138 p. (In Russ.)

- Kagan E.S., Sablin K.S., Sharov A.A. Otsenka gotovnosti resursnykh regionov k kompleksnomu osvoeniyu nedr na osnove analiza strukturnykh sdvigov (shift share analysis) [Assessment of Resource Regions’ Readiness for Comprehensive Exploitation of Mineral Resources Based on Shift Share Analysis]. Naukoemkie tekhnologii razrabotki i ispol'zovaniya mineral'nykh resursov [IOP Conference Series: Earth and Environmental Science], 2018, no. 4, pp. 155 161.

- Ignatyeva M.N., Yurak V.V., Dushin A.V., Polyanskaya I.G. Assessing Challenges and Threats for Balanced Subsoil Use. Environment, Development and Sustainability, 2021, vol. 23, no. 12, pp. 17904 17922. DOI: 10.1007/s10668 021 01420 1

- Bazhutova E.A. Ekonomicheskaya aktivnost' v Murmanskoy oblasti: osobennosti proyavleniya i usloviya optimizatsii [Economic Activities in the Murmansk Region: Manifestation Specifics and Optimization Terms]. Sever i rynok: formirovanie ekonomicheskogo poryadka [The North and the Market: Forming the Economic Order], 2020, no. 2 (68), pp. 49 63. DOI: 10.37614/2220802X.2.2020.68.005

- Zaikov K.S., Kondratov N.A., Kudryashova E.V., Lipina S.A., Chistobaev A.I. Scenarios for the Development of the Arctic Region (2020 2035). Arktika i Sever [Arctic and North], 2019, no. 35, pp. 4 19. DOI: 10.17238/issn2221 2698.2019.35.5

- Klyuchnikova E.M., Masloboev V.A. Ekologo ekonomicheskiy analiz regional'noy politiki v sfere obrashcheniya s otkhodami (na primere Murmanskoy oblasti) [Ecological and Economic Analysis of Regional Policy in the Field of Waste Management (on the Example of the Murmansk Region)]. Vestnik MGTU [Vestnik of MSTU. Scientific Journal of Murmansk State Technical University], 2013, vol. 16, no. 2, pp. 233 241.

- Knysh V.A., Larichkin F.D., Nevskaya M.A., Fedoseev S.V., Bloshenko T.A., Melik Gaykazov T.A., Perein V.N., Novosel'tseva V.D., Goncharova L.I., Gilyarova A.A. Ratsional'noe ispol'zovanie vtorichnykh mineral'nykh resursov v usloviyakh ekologizatsii i vnedreniya nailuchshikh dostupnykh tekhnologiy: monografiya [Rational Use of Secondary Mineral Resources in the Conditions of Greening and Introduction of the Best Available Technologies]. Apatity, FRC KSC RAS Publ., 2019, 252 p. DOI: 10.37614/978.5.91137.417.4 (In Russ.)

- Bazhutova E.A., Skufina T.P. Integrated Processing of Mineral Raw Materials: Factors of Readiness and Resistance of Economic Entities. Arktika i Sever [Arctic and North], 2023, no. 52, pp. 100 120. DOI: 10.37482/issn2221 2698.2023.52.100

- Fomenko M.A. Mestnye programmy deystviy v sfere prirodopol'zovaniya dlya ustoychivogo razvitiya [Local Action Programs in the Field of Environmental Management for Sustainable Development]. Yaroslavl, Kadastr Publ., 2001, 159 p. (In Russ.)

- Ansoff I. Strategicheskoe upravlenie [Strategic Management]. Moscow, Ekonomika Publ., 1989, 519 p. (In Russ.)

- Khalitova I.V. Organizatsionnaya gotovnost' k izmeneniyam: obzor metodologii i prakticheskikh metodik otsenki gotovnosti [Organizational Readiness for Change: a Review of the Methodology and Methods of Readiness Evaluation]. Gosudarstvennoe upravlenie. Elektronnyy vestnik [Public Administration. E journal (Russia)], 2013, no. 39, pp. 152 162.

- Pavlova A.V. Pozitsionirovanie mashinostroitel'nogo predpriyatiya otnositel'no uspekha realizatsii izmeneniy v usloviyakh innovatsionno tekhnologicheskoy modernizatsii ego proizvodstva [Positioning Engineering Company with Respect to the Successful Implementation of Changes in Conditions of Innovation and Technological Upgrading of Its Production]. Sovremennaya ekonomika: problemy, tendentsii, perspektivy [Modern Economy: Problems, Trends, Prospects], 2011, no. 5, pp. 1 11.

- Beckhard R., Harris R.T. Organizational Transitions: Managing Complex Change. Addison Wesley Publishing Co., 1987, 150 p.

- Mankins J.C. Technology Readiness Levels A White Paper. Advanced Concepts Office of Space Access and Technology. NASA, 1995, 5 p.

- Cooper R., Edgett S. Stage Gate® and Critical Success Factors for New Product Development. Product Development Institute, 2006, 6 p.

- Sirkin H.L., Keenan P., Jackson A. The Hard Side of Change Management. Harvard Business Review, 2005, vol. 83 (10), pp. 108 118. DOI: 10.1109/EMR.2014.6966953

- Sablin K.S., Kagan E.S., Sharov A.A. Rossiyskie resursodobyvayushchie kompanii: sokhranenie anklavov bogatstva vs. dvizhenie k tselostnoy ekonomike [Russian Resource Extraction Companies: Conservation of Enclaves of Wealth vs. Movement toward Integrated Economy]. Zhurnal institutsional'nykh issledovaniy [Journal of Institutional Studies], 2021, vol. 13, no. 1, pp. 76 94. DOI: 10.17835/2076 6297.2021.13.1.076 094