Automated experiment systems for studying the properties of transport polymer materials in high-frequency electrothermia

Автор: N. G. Filippenko, A. G. Larchenko

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.21, 2020 года.

Бесплатный доступ

Recent decades have been characterized by increased activity in the use of polymer and composite materials in transport engineering. In this paper, the authors give a generalizing analysis of previously created systems of scientific research and analyze the principles of building automated systems of scientific research (ASSR) that allow solving the problems of determining the parameters of heat exchange, electrophysical parameters and phase transformations in polymer and composite materials when exposed to the HF field. The authors continue the research of the ASSR HF developed by the Irgups team, a number of other scientific schools working in the same direction.therefore, within the framework of the hardware created by these teams, both similar and original developments and solutions are viewed. The analysis of the software parts of the ASSR HF presented by a number of mathematical models and software complexes is given. Thus, the analysis of the structure of the developed systems of scientific research allows us to speak about its dynamic development. The developed and presented flowcharts of automated experiment and automated research systems allow the author to assert that the systems of automated experiment for studying the properties of polymer materials in RF electrothermia created for cer-tain tasks, despite the fact that they were conducted independently and separately, have a single construction methodology. Comparing the results of the research, the author concludes that the construction of a complex system of ASSR HF polar thermoplastic polymers is generally complete

Automated scientific research systems, high-frequency electrothermics, polymer products, meth-odology for building research systems.

Короткий адрес: https://sciup.org/148321747

IDR: 148321747 | УДК: 620.192 | DOI: 10.31772/2587-6066-2020-21-2-279-288

Текст научной статьи Automated experiment systems for studying the properties of transport polymer materials in high-frequency electrothermia

Introduction. The driving force of the growth of the polymer industry is still the ever-increasing standard of living of mankind. It should be noted that continuous growth is primarily demonstrated by the transport sector of the engineering industry.

In the modern world, polymer industry companies are building new capacities with minimal capital expenditures due to the use of advanced technologies that can reduce costs by reducing electricity consumption rates, and this primarily refers to high-frequency electrothermal technologies [1–15]. However, the introduction of these technologies is constrained by the lack of reliable data on the electrophysical properties of modern materials necessary for the organization of control processes. Therefore, the solution of this problem is an important national economic task.

In this regard, the aim of this work was to analyze existing scientific research automation systems (ASSR) and experimental automation systems (SAE) of the effects of high-frequency electrothermia on the properties of polymeric materials processed in the HF field over a wide temperature range.

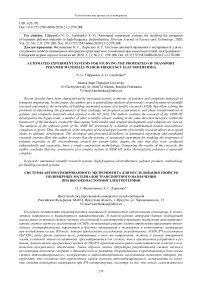

Analysis of the state of ASSR and SAE HF-electrothermics. In plastics processing, the HF heating method, as has been repeatedly noted, is one of the most advanced. The effectiveness of the use of HF heating is judged by the value of the dielectric loss factor of the dielectric constant –ε′, and the dielectric loss tangent –tgδ [16–23]. The authors of an automated research system for determining the permittivity – ε′ and dielectric loss tangent –tgδ, polyamide-610 performed the work using an E9 meter (Q-meter) using two and three-dimensional resonance methods [5]. The functional measurement scheme and the location of the processed material are

presented in fig. 1 and 2, respectively, where a sample of material placed between two plates of the working capacitor 2 was affected by an HF field. Temperature control was carried out by pyrometer 3 and thermocouples TE 4-1. The calculation of dielectric indicators was carried out by computing device 1.

The results of the work were the obtained data on the characteristic changes in the electrophysical parameters of PA-6 polyamide (ε′ and tgδ) depending on temperature. Nevertheless, even the authors themselves in the work point out the difficulties of using such a research system in determining the melt moment of a material, referring to a difficult to control process accompanied by gas formation at the time of a phase transition. The obvious drawbacks of the developed automated experiment are also the absence of immunity systems, and the mathematical model does not correspond to the real technological system and consists of one layer of material to be welded.

The mathematical apparatus of the HF heating model proposed by the authors [15; 20] describes the temperature distribution in the thickness of the thermoplastic, taking into account the design features of technological equipment (fig. 3).

The calculation of the welding process was carried out by numerically solving the equation for variable values of y and dependencies obtained by calculation and experimental methods were used.

The disadvantage of this system, as with previous authors, is also associated with the mathematical model. The model underwent changes, was expanded, but considers only a special case of processing, namely welding. The schematic diagram of the experimental setup is shown in fig. 4.

Fig. 1. Functional measurement scheme:

1 – computing device; 2 – upper and lower plates of the working capacitor;

3 – windows for temperature pyrometry

Рис. 1. Функциональная схема измерений:

1 – вычислительное устройство; 2 – верхняя и нижняя обкладки рабочего конденсатора; 3 – окна для пирометрии температуры

Fig. 2. The location of the welded material in the working capacitor:

1 – materials to be welded; 2 – electrodes

Рис. 1. Расположение свариваемого материала в рабочем конденсаторе:

1 – свариваемые материалы; 2 – электроды

Fig. 3. High-frequency welding of plastic parts in industrial equipment with one insulated electrode, where h 1 , h 4 is the thickness of the high potential and grounded electrodes; h 2 is the thickness of the insulating liner; l = h 3 /2 – thickness of the welded part; x i is the coordinate of the layer boundary; x s is the coordinate of the weld; y is the distance from the weld; U р is the voltage at the working capacitor

Рис. 2. Высокочастотная сварка деталей из пластмасс в технологической оснастке с одним изолированным электродом, где h 1, h 4 – толщина высокопотенциального и заземленного электродов; h 2 – толщина изоляционного вкладыша; l = h 3/2 – толщина свариваемой детали;

xi – координата границы слоя; x s – координата сварного шва; y – расстояние от сварного шва; Uр – напряжение на рабочем конденсаторе

Fig. 4. Schematic diagram of the experimental setup:

1 is a product sample; 2 is a product sample; 3 is for electrodes of the working capacitor; 4 is an insulating liner; 5-1 is an acoustic sensor; 5-2 is an analog-to-digital converter (ADC); 6 is a computing device; 7 is a HF generator;

8 is an ammeter of the anode current; 9 is a “START” button

Рис. 4. Принципиальная схема экспериментальной установки:

1 – образец изделия; 2 – образец изделия; 3 – электроды рабочего конденсатора; 4 – изоляционный вкладыш; 5-1 – акустический датчик;

5-2 – аналогово-цифровой преобразователь (АЦП); 6 – вычислительное устройство; 7 – ВЧ-генератор; 8 – амперметр анодного тока; 9 – кнопка «ПУСК»

Fig. 5. Applience for high-frequency processing of parts: h 1 , h 4 are thickness of high-potential and grounded electrodes; h 2 is the thickness of the insulating liners; l is the thickness of the processed (welded) part; x is the coordinate of the layer boundary; x s is the coordinate of the connection; y is the distance from the junction; U р is the voltage at the working capacitor

Рис. 3. Приспособление для высокочастотной обработки деталей: h 1 , h 4 – толщина высокопотенциального и заземленного электродов; h 2 – толщина изоляционных вкладышей; l – толщина обрабатываемой (свариваемой) детали; x – координата границы слоя; x s – координата соединения; y – расстояние от места соединения; U р – напряжение на рабочем конденсаторе

In [12], the shortcomings indicated in previous versions of automated experiments are not so obvious, but nevertheless, the presented SAE has limited capabilities and is applicable only in the study of polar thermoplastics. The device for high-frequency processing of parts is shown in fig. 5.

A solution was found to organize the calculation and measurement of temperature on the surface and inside the material and to protect the electrodes from breakdown, which was implemented both in the hardware and in the mathematical program part of the research system [4; 14; 23].

The ASSR hardware also underwent changes. Switching systems and control units were added.

Nevertheless, the presented model, although it expanded the capabilities of the technological system (the quantity of layers of material is increased up to five), but the possibility of its application is limited by a number of HF processing processes such as welding, drying, and acclimatization.

A feature of the works presented [7; 8] is the expansion of the capabilities of scientific HF research regarding diagnostic processes. A mathematical model was developed for measuring the capacitance of a working capaci- tor, and a software package was created for calculating the effective diagnostic parameters (fig. 6) under HF exposure, depending on the shape and size of the samples [7; 14; 22].

This automated system (fig. 7) of scientific research has expanded the possibility and list of technological processes of HF electrothermics, but concerns only one type of research, namely diagnostics

An analysis of one of the latest works of scientific research systems [8; 12] on the study of the interconnec- tions of electrophysical parameters of electrothermal equipment and polymer materials widely used in transport engineering shows that a number of problems that were not included in the work of previous authors were solved.

A mathematical model of the technological system was developed in a 3D setting (fig. 8, 9), which included a variable number of electrodes, insulators and processed materials, and the developed algorithm made it possible to calculate the temperature field taking into account the heating of the technological system.

Fig. 6. Interface of Aleo_HFH software complex

Рис. 6. Интерфейс программного комплекса Aleo_HFH

Fig. 7. Aleo-Diagnost software interface

Рис. 7. Интерфейс программного комплекса Aleo-Diagnost

Fig. 8. 3D five-layer high-frequency processing technological scheme.

The first group of the technological scheme consists of:

1 – low-potential electrode of the working capacitor; 2 – insulator; 2nd group: 3 – processed polymer (internal heat source); 3rd group: 5 – high-potential electrode of the working capacitor; 4 – insulator; X , Y , Z are coordinates of the boundaries of the layers; U р is the voltage at the working capacitor

Рис. 8. 3D пятислойная технологическая схема ВЧ-обработки.

1-я группа технологической схемы:

1 – низкопотенциальный электрод рабочего конденсатора; 2 – изолятор; 2-я группа: 3 – обрабатываемый полимер (внутренний источник тепла); 3-я группа: 5 – высокопотенциальный электрод рабочего конденсатора; 4 – изолятор; X , Y , Z – координаты границ слоев; Uр – напряжение на рабочем конденсаторе

Fig. 9. Scheme of an automated experimental setup for determining the amperometric dependence of dielectric loss in polymeric materials:

1 is a processed sample; 2 , 9 are heat-electric insulators; 3 is for electrodes of the working capacitor; 4 is a HF generator; 5 is a device for contact heating of the sample; 6 is an electric heating element; 7 is a thermocouple; 7-1 is a thermocouple thermometer;

8 is a protective screen; 8-1 is a current sensor; 10 is a computing unit; 11-1 is a linear thermal expansion sensor

Рис. 9. Схема автоматизированной экспериментальной установки по определению амперометрической зависимости диэлектрических потерь в полимерных материалах:

1 – обрабатываемый образец; 2 , 9 – тепло-, электроизоляторы; 3 – электроды рабочего конденсатора; 4 – ВЧ-генератор; 5 – приспособление для контактного нагрева образца; 6 – электронагревательный элемент; 7 – термопара; 7-1 – термопара-термометр; 8 – защитный экран; 8-1 – датчик тока; 10 – вычислительный блок; 11-1 – датчик линейного теплового расширения

To date, a full-fledged automated system of scientific research (ASSR HF) developed at the Irkutsk State Transport University (IrGUPS) can be considered the most system-developed one. It was finally formed and indicated in [1; 8; 12].

Two versions of the ASSR HF with different hardware have been developed chronologically. An industrial HF processing unit of the UZP-2500 model was used as a source of electromagnetic radiation. The developed and patented automation unit [4], performed registration, processing and transmission of information. It was implemented on the basis of the programmable controller ATmega 328.

We should note that this system, in addition to the hardware, was also provided with a software component, consisting of a number of software systems that implement automated research programs.

The basic principles for constructing a fully functional ASSR HF hardware and its structural scheme for studying the process of heat treatment of polymeric materials are presented in fig. 10.

The work of the unit is organized as follows. Simultaneously with turning on the high-frequency generator, the control unit and the automation unit are turned on. A linear Hall sensor measures the anode current of a high-frequency generator, and acoustic sensors detect partial discharges that occur on the polymer during HF processing. Data on anodic current of high frequency generator and partial discharges is transmitted to the computing device of a microcontroller assembled on the basis of the ATmega8 processor [2].

The microcontroller calculates the magnitude of the change in the anode current; drying time; interdischarge time; number of partial discharges. Installation of the unit and sensors was carried out without re-equipment of existing electrical circuits of HF installations [6; 17; 18].

The integration of ACS elements with reference to the HF equipment scheme of the UZP-2500 model is shown in fig. 11.

Fig. 10. Block diagram of the ASSR HF hardware:

1 is an automation unit; 2 is a shielding case; 3 is a coaxial cable;

4 is a constant voltage source; 5 is a high-frequency generator; 6 is an alarm control system; 7 is a generator control circuit; 8 is an actuator; 9 is a linear current sensor; 10 is a computing device; 11 are acoustic sensors for detecting partial discharges; 12 is a computing device;

13 is anti-interference housing; 14 is power supply; 15 is a variable capacitor; 16 is a microcontroller; 17 is a working capacitor

Рис. 10. Структурная схема аппаратной части АСНИ ВЧ:

1 – блок автоматизации; 2 – экранирующий корпус; 3 – коаксиальный кабель; 4 – источник постоянного напряжения; 5 – высокочастотный генератор; 6 – система управления сигнализацией; 7 – цепь управления генератором; 8 – исполнительный механизм; 9 – линейный токовый датчик; 10 – вычислительное устройство; 11 – акустические датчики регистрации частичных разрядов; 12 – вычислительное устройство; 13 – помехозащищенный корпус; 14 – блок питания;

15 – переменный конденсатор; 16 – микроконтроллер; 17 – рабочий конденсатор

Fig. 11. Integration of ACS elements with reference to the HF scheme of the installation of the model UZP-2500

Рис. 11. Интеграция элементов АСУ с привязкой к схеме ВЧ установки модели УЗП-2500

The unit of the registration and control device was implemented with the following technical characteristics:

– number of measurement channels – 6;

– measured current: 0.01...10 AC, VC;

– measured voltage: 100...4000 V AC;

– measurement interval: 0.005 s, (expansion to 8.10-6 s is possible);

– maximum measurement error: ± 1.5 %;

– non-volatile memory, 64 Kb;

– power –100...380 in VC;

– power consumption – 50 mA.

As it was mentioned above, along with the team of IrGUPS, a number of other scientific schools work in the same direction, therefore, within the hardware created by these teams, both similar and original developments and solutions are viewed. The software parts of ASSR HF are also represented by a number of mathematical models and software complexes.

Thus, the analysis of the structure of the developed systems of scientific research allows us to talk about its dynamic development. To date, comparing the research results, it is safe to say that the construction of an integrated ASSR HF system as a whole is completed. As can be seen from the block diagrams of automated experiment and automated research systems presented below, although they were created separately, specifically for certain tasks, a specific construction methodology is seen in all the works.

Conclusion. Thus, an analysis of the structure of the developed scientific research systems allows us to conclude that the dynamic development of ASSR and SAE by various scientific schools of electrothermists has led to a uniform methodology for constructing ASSR HF.

Comparing the research results, it can be argued that the construction of an integrated system of ASSR HF of polar thermoplastic polymeric materials as a whole is completed.

Список литературы Automated experiment systems for studying the properties of transport polymer materials in high-frequency electrothermia

- Shastin V. I., Kargapoltcev S. K., Gozbenko V. E., Livshits A. V., Filippenko N. G. Results of the complex studies of microstructural, physical and mechanical properties of engineering materials using innovative methods. International Journal of Applied Engineering Research. 2017, Vol. 12, No. 24, P. 15269–15272.

- Baranov V. N. Primeneniye mikrokontrollerov AVR: skhemy, algoritmy programmy [Application of AVR microcontrollers: circuits, program algorithms]. Moscow, Dodeka Publ., 2004, 288 p.

- Bezmenov F. V., Fedorova I. G. Vysokochastotnaya svarka plastmass [High frequency welding of plastics]. Moscow, Mashinostroyeniye Publ., 1989, 89 p.

- Filippenko N. G., Livshits A. V., Mashovich A. Ya., Kargapol'tsev S. K. Blok avtomatizatsii ustroystva vysokochastotnoy termoobrabotki polimernykh materialov [Automation unit for high-frequency heat treat-ment of polymer materials]. Patent RF, No. 118916. 2011.

- GOST 22372–77. Materialy dielektricheskiye. Metod opredeleniya dielektricheskoy pronitsayemosti i tangensa ugla dielektricheskikh poter' v diapazone chastot ot 100 do 5·10(6) Gts [State Standard 22372–77. Dielectric materials. The method for determining the dielectric constant and the dielectric loss tangent in the frequency range from 100 to 5 · 10 (6) Hz]. Moscow, Standartinform Publ., 1977. 52 p.

- Kiseleva T. F. Tekhnologiya sushki [Drying technology]. Kemerovo, Kemerovskiy tekhnologicheskiy institut pishchevoy promyshlennosti Publ., 2007.

- Larchenko A. G. Sistema avtomatizirovannogo upravleniya vysokochastotnym diagnostirovaniem pri pro-izvodstve i ekspluatatsii izdelii iz polimernykh materialov. Kand. Diss. [Automated control sys-tem for high-frequency diagnostics in the production and operation of products from polymeric materials. Cand. Diss.]. Irkutsk, 2014. 164 p.

- Larchenko A. G. [Automated Device for Diagnosing Polymeric Products of Complex Configuration by the Method of High-Frequency Radiation]. Kontrol'. Diagnostika. 2016, No. 2, P. 61–65 (In Russ.).

- Livshits A. V. Avtomatizirovannoye upravleniye tekhnologicheskimi protsessami vysokochastotnoy elek-trotermii polimerov. Dokt. diss. [Automated process control of high-frequency electrothermal pol-ymers. Doct. diss.]. Irkutsk, 2016. 351 p.

- Markova T. E. [The current state and development trends of the polymer industry]. Ekonomika i upravleniye. Available at: https://ecsn.ru/files/pdf/201406/ 201406_94.pdf (accessed 15.04.2020).

- Matsyuk L. N., Vishnevskaya N. V., Kotovshchikova O. A. [The effect of melt flow on the weldability of polymeric materials]. Svarochnoye proizvodstvo. 1975. P. 25–26.

- Obzor mirovoy polimernoy industrii [Overview of the global polymer industry]. Available at: https://polyprofi.ru/blogs/Blog_Poly_and_Pro/obzor-mirovoy-polimernoy-industrii.php (accessed 15.04.2020).

- Popov S. I. Avtomatizatsiya upravleniya tekhnologicheskimi protsessami vosstanovleniya ekspluatatsion-nykh svoystv polimerov. Kand. diss. [Automation of control of technological processes of restoration of operational properties of polymers. Cand. Diss.]. Irkutsk, 2013.150 p.

- [The order of Rosstat dated April 23, 2017 The industrial production index is calculated by type of activity: "Mining", "Manufacturing"]. Available at: https://www.gks.ru/bgd/free/B04_03/IssWWW.exe/Stg/d04/7.htm (accessed 15.04.2020).

- Rumynskiy S. N. Avtomatizirovannaya sistema upravleniya protsessom vysokochastotnoy svarki izdeliy iz poliamida. Kand. diss. [Automated control system for the process of high-frequency welding of products made of polyamide. Cand. Diss]. St. Petersburg, 2005. 133 p.

- Zaytsev K. I. Matsyuk L. N. Svarka polimernykh materialov [Welding of polymeric materials]. Moscow, Mashinostroenie Publ., 1988, 312.

- Sukhoguzov A. P., Kosyakov A. A [Investigation of partial discharges in electrical isolation]. Vestnik UGTU–UPI. 2003, No. 5 (25), Part 1, P. 363–371 (In Russ.).

- Skhemy upravleniya v ASUTP [Control schemes in process control systems]. Available at: http://automation-system.ru/main/item/42-sxemy-upravleniya-v-asutp.html (accessed 15.04.2020).

- Trostyanskaya Ye. B., Komarov G. V., Shishkin V. A. Svarka plastmass [Welding plastics]. Moscow, Mashinostroenie Publ., 1967, 251 p.

- Trofimov N. V., Markov A. V. [Mathematical model of the optimal mode of high-frequency welding of plastics]. Matematicheskiye metody v tekhnike i tekhnologiyakh (MMTT-21) [Mathematical methods in engineering and technology (MMTT-21)]. Pskov, 2009, P. 71–73.

- Trofimov N. V. Upravleniye rezhimom vysokochastotnoy svarki izdeliy iz plastmass slozhnoy formy. Kand. diss. [Control of high-frequency welding of plastic products of complex shape. Cand. Diss]. St. Petersburg, 2011. 112 p.

- Shengeliya R. G. [On the application of the method of three measurements on a meter when measuring ε and tanδ of materials with large losses]. Elektrichestvo. 1966, P. 79–81 (In Russ.).

- Larchenko A. G. [Evaluation of the quality of products from polymeric materials for engineering purposes]. Vestnik Irkutskogo gosudarstvennogo tekhnicheskogo universiteta. 2019. Vol. 23, No. 3, P. 463–471 (In Russ.).