Bending of composite timber

Автор: Senashov S.I., Savostyanova I.L., Yakhno A.N.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Informatics, computer technology and management

Статья в выпуске: 1 vol.25, 2024 года.

Бесплатный доступ

Technologies and production widely use composite materials now. “Mechanics of deformable solids” was formed as a science based on the study of materials used in the 19th and 20th centuries. Modern composite materials require new theoretical and experimental studies. Determining the stresses and deformations that occur at the points of contact of the matrix with the fibers is a special problem. Composites with a plastic matrix play an important role in modern technology. These materials successfully cope with cracking and significantly slow down the growth of cracks. In this article, the problem of the stress state of a composite beam with an elastic-plastic matrix and elastic fibers located along the axis of the beam is solved. It is assumed that in the zone of contact of the matrix with the fibers, according to the model of Yu. N. Rabotnov, a constant tangential stress is realized, less than the yield strength of the fiber. One end of the beam is fixed, and a constant force applied to the center of gravity coinciding with the origin of coordinates acts on the second. It is assumed that at the free boundary of the beam and at the points of contact of the beam with the fibers, the stresses reach the plasticity limit. The problem is solved with the help of conservation laws. This makes it possible to find the stress state at an arbitrary point of the section as a calculation of integrals along the outer boundary of the beam and the boundaries of the matrix and fibers.

Composite beam, stress state, conservation laws of differential equations

Короткий адрес: https://sciup.org/148329721

IDR: 148329721 | УДК: 539.374 | DOI: 10.31772/2712-8970-2024-25-1-25-32

Текст научной статьи Bending of composite timber

Currently, much attention is paid to comprehensive research of composite materials. Thus, in [1] multilayer armor was developed – aluminum oxide ceramics (woven material), reinforced with epoxy resin and aluminum alloy. In [2], the vibrations of a composite beam made of a functionally gradient material in two directions reinforced with carbon nanotubes were studied. In [3], the effectiveness of various schemes for cladding a plate with composite coatings was determined and compared. В [4] исследована устойчивость подкрепленного отсека фюзеляжа самолета, выполненного из композиционного материала, при чистом изгибе и нагружении внутренним давлением. In [4], the stability of a reinforced aircraft fuselage compartment made of a composite material was studied under pure bending and internal pressure loading. In [5], studies of the resistance of the formed composite material under highspeed impact were carried out. In [6], a mathematical formulation of the problem of forced steady-state and natural vibrations of the smart systems under consideration is given, as well as the results of numerical calculations, from which it follows that graphene composites can be used for additional damping of vibrations of smart structures based on piezoelectric elements. In [7], based on the finite element method, a computational algorithm was developed to solve a limited class of problems on the bending of composite plates reinforced with systems of unidirectional high-strength fibers. A model of dynamic deformation and fracture of composite materials has been developed, which takes into account the nonlinearity of impact loading diagrams with hardening depending on the strain rate [8] .

In [9], Yu. N. Rabotnov proposed a model of a composite material with an elastic-plastic binder and elastic fibers. In this case, a constant shear stress acts between the fibers and the binder during loading. Based on this model, this article examines the stress state of a beam made of composite materials. The problem was solved using conservation laws constructed for a system of differential equations describing the stressed state of the beam. The methodology for constructing conservation laws can be found in [10; 11]. Conservation laws make it possible to effectively solve boundary value problems for a number of equations of mechanics of a deformable solid. Examples of solutions for such problems can be found in [12–15].

Formulation of the problem

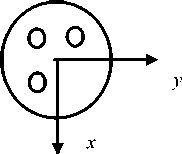

We consider a beam made of elastic-plastic material, reinforced with n elastic fibers. One end of the beam is fixed at point z = 0, at the second end of the beam z = l a load of weight Р is suspended at the origin, which coincides with the center of gravity of the section (Fig. 1).

The timber matrix has an elastic modulus G and a pure shear yield strength k s . The fibers are located along the axis of the beam in a random order parallel to the axis z . Each fiber has a circular cross-section, the center of the fiber is located at the point with coordinates ( xi , yi ) , fi ber radius is R , модуль elastic modulus упругости G i . The yield strength of the fibers exceeds the yield strength of the matrix. The shear stress between the fiber and the matrix is T < k s •

о о

о

z

P

l

x

Рис. 1. Брус с волокнами с подвешенным грузом

Fig. 1. A fiber beam with a suspended load

The given process is described by the equilibrium equation and the equations of compatibility of deformations [13]:

∂τ xz + ∂τ yz =- Px ∂ 2 τ xz + ∂ 2 τ xz =- P ∂ 2 τ yz + ∂ 2 τ yz

∂ x ∂ y I , ∂ x 2 ∂ y 2 (1 + ν ) I , ∂ x 2 ∂ y 2

σ z

P ( l - z ) x I

I = ∫ x 2 ds . S

From the last two equations (1), taking into account the first, we obtain

∂τ xz yz

-

∂ y ∂ x

P ν

I (1 +ν ) y

2 K ,

where K is constant, which is the angle of rotation of the volumetric element of the beam relative to the axis z ; τ xz , τ yz , σ z is stress tensor components; S is beam cross section; I is moment of inertia about the axis y ; ν is Poisson's ratio.

The boundary conditions on the side surface of the beam, free from stress and in a plastic state, have the form

τ n +τ m = 0, τ2 +τ2 =k2 =k2 -1/3σ2, xz yz xz yz s z wheren0, m0 components of the normal vector to the lateral surface, which can be written as are

τ xz = m mk , τ yz =± nk . (3)

At the boundary between the fiber and the matrix, the following conditions are met:

τxzmi -τyzni =τ, τ2xz + τ2yz =k2, where ni,mi are components of the normal vector to the lateral surface of the i-th fiber, which we write in the form

τ xz = mi τ ± ni 4k 2 -τ 2 , τ yz = ni τ m mi 7 k 2 -τ 2. (4)

Next, in formulas (3)–(4), the upper sign is selected.

Conservation laws for equations (1)–(2)

For the convenience of further calculations, we introduce the following notation:

τ xz = u , τ yz = v .

Then problem (1)–(4) will be written as follows:

F 1 = u x - v y + Px / I = 0,

F = u - vx--y + 2 K = 0,

-

2 y x (1 + v/

on the side surface:

u = - mk, v = nk, at the fiber-matrix interface:

u = m i т + n i 4 k2 -t 2, v = n i т - m i 4 k 2 - t 2 .

We call the conservation law for the system of equations (5) an expression of the form Definition

Ax ( x , y , u , v ) + By ( x , y , u , v ) = « 1 F 1 + « 2 F 2 , (6)

where « 1 , « 2 are some linear operators that are not identically equal to zero at the same time.

More details on the technique of calculating conservation laws and their use can be found in [3–5] . Let it be

A = a 1 u + p 1 v + Y 1, B = a 2 u + в 2 v + Y 2 , (7)

where a i , 3 i , у ’ are functions only from x , y ’

Substituting (7) into (6) we get aX + ay = 0, px + 32 = 0, a1 = «1, p1 = -«2, a2 = «2, 32 = «1,

Y x + у y = -a 1 Px / 1 + p 1[2 K - P v y / ( I (1 + v ))].

This implies ax-py = 0, px + ay = 0,

Yx + уy = -a1 Px /1 + p1[2K - Pvy / (I(1 + v))].

for the system of equations we consider (8) two solutions that have singularities x 0 , y 0 at an arbitrary point of the section:

-

1) 1 x - x 0 R1_ y - y 0

-

a 9 9, p 99,

( x - x 0 ) + ( y - y 0 ) ( x - x 0 ) + ( y - y 0 )

-

Y1 = 0, у2 = -Pxarctg y y0 + Pv (y - y0 + ( y0 + x - x0)arctg y y0 +

I x - x 0 I (1 + v ) x - x 0 x - x 0

-

+ 2 ln(( x - x 0 ) 2 + ( y - y 0 ) 2 ) - K ln(( x - x 0 ) 2 + ( y - y 0 ) 2 ) ,

-

2) „1- y - y 0 R1- x x 0

-

a* — 9 9 , p* — 99 ,

( x - x 0 ) + ( y - y 0 ) ( x - x 0 ) + ( y - y 0 )

-

Y* = 0, у2 = 2Karctg y y0 - Pv [y0arctg y y0 + x—x0ln((x -x0)2 + (y - y0)2)] -

- x - x0 I (1 + v) x - x02

-

- Px -ln(( x - x 0 ) 2 + ( у - y 0 ) 2 ) ,

where x 0 , y 0 are constants.

Calculation of the stress state at a point x0 , y 0

Let ( x 0 , y 0 ) be a arbitrary point belonging to the connector, and let the conserved current at this point have a singularity of the form (9) or (10). Then from (6) it follows

JJ ( A x + B y ) dxdy = J Ady - Bdx - ^ [J Ady - Bdx - [J Ady - Bdx = 0, (11)

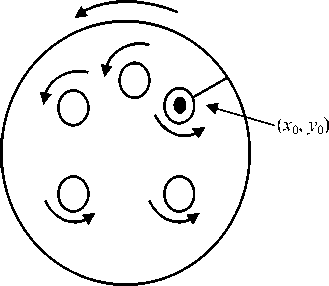

S Г0 i=1 Гi ε where ε is circle (x - x0)2 + (y - y0)2 = ε2 (Fig. 2).

Рис. 2. Вычисление напряженного состояния в точке x 0, y 0

Fig. 2. Calculation of the stress state at a point x 0, y 0

We consider solution (9), assuming x count (9), where ε → 0 , we get

-

x 0 = ε сos ϕ , y - y 0 = ε sin ϕ , then from (11) taking into ac-

2 пт xz ( x 0 , y o ) = J ( m 0 k

Г 0

x - x 0

( x - x 0)2 + ( y - y 0)2

- n 0 k y - y 0 ) dy

( x - x 0)2 + ( y - y 0)2

-

- ( m 0 k------y—y 0----- у + n 0 k------ x x 0 -----— + у 2) dx +

( x - x 0)2 + ( y - y 0)2 ( x - x 0)2 + ( y - y )2

у J ( ( m i т + n^k 2 -T 2)( x - x 0 ) - ( - n i т + m^k2 -t 2 )( y - y 0 ) ) dy i = 1 Г i ( x - x 0)2 + ( y - y 0)2 ( x - x 0)2 + ( y - y 0)2

- (( mi τ+ ni k 2 -τ 2) y 2 - y 0 2 +

( x - x 0) + ( y - y 0)

+ ( ni τ + mi

k 2 -τ 2) x - x 0

( x - x 0)2 + ( y - y )2

+ у 2) dx .

We consider another solution to equations (8) of the form (9). Repeating the previous arguments almost verbatim with solution (12), we obtain

2 nT 23 ( x 0 , y 0 ) = J ( m 0 k-------y-y 0----- -y + n 0 k

Г 0 ( x - x 0)2 + ( y - y 0)2

x - x 0

( x - x 0)2 + ( y - y 0)

2 ) dy -

- ( - m 0 k

x - x 0

( x - x 0)2 + ( y - y 0)2

y - y 2

+ n k----------------- — + y* )) dx +

0 ( x - x 0 )2 + ( y - y )2 *

n

+S J (i=1 Гi

( mi τ + ni k 2 -τ 2 )( y - y 0) + ( - ni τ+ mi k 2 -τ 2 )( x - x 0) ( x - x 0)2 + ( y - y 0)2 ( x - x 0)2 + ( y - y 0)2

-

) dy -

- ( - ( m t + n^k2 -t 2 )------ x—x 0-----у + ( n t + mt 4k2 -t 2 )----- y y 0 -----у + у 2 ) dx .

i i ( x - x 0 )2 + ( y - y 0 )2 i i ( x - x 0 )2 + ( y - y )2

Conclusion

The resulting formulas make it possible to calculate the stress state at any point of the binder material. The points where T Xz + ^ z = k 2 , will be in a plastic state, other points of the medium, as well as fibers, will remain elastic. The proposed solution method allows us to construct an elastic-plastic boundary in a bendable composite beam and thereby evaluate its load-bearing capacity. The variety of composites [14 – 16] and their enormous practical importance allow us to hope that the methodology proposed by the authors will make it possible to evaluate the strength of structures made from composites.

Список литературы Bending of composite timber

- Ахмед П. С., Абед М. С., Салим И. А. Экспериментальное исследование и численное моделирование баллистического воздействия на гибридный композит (оксид алюминия – тканый материал – эпоксидная смола – алюминий), используемый при изготовлении бронежилета // ПМТФ. 2023. № 4. C. 3–13.

- Пан М., Чжоу С. М., Ху Б. Л., Чзан Ю. Ц. Свободные колебания композитной балки из функционально-градиентного в двух направлениях материала, армированной углеродными нанотрубками // ПМТФ. 2023. № 5. C. 166–178.

- Кирпичников В. Ю., Кощеев А. П., Сятковский А. И. Экспериментальное исследование эффективности армированных вибропоглощающих покрытий // ПМТФ. 2022. № 1. C. 65–70.

- Железнов Л. П., Серьезнов А. Н. Исследование нелинейного деформирования и устойчивости композитной оболочки при чистом изгибе и внутреннем давлении // ПМТФ. 2022. № 2. C. 207–216.

- Голышев А. А., Долгова С. В. Влияние керамического волокна SiC в металломатричном композите на его стойкость при высокоскоростном нагружении // ПМТФ. 2022. № 6. C. 145–149.

- Матвеенко В. П., Ошмарин Д. А., Юрлова Н. А. Использование электропроводящих композиционных материалов для дополнительного демпфирования смарт-систем на основе пьезоэлементов // ПМТФ. 2021. № 5. C. 45–57.

- Петраков И. Е., Садовский В. М., Садовская О. В. Анализ изгиба композитных пластин с учетом различия сопротивлений растяжению и сжатию // ПМТФ. 2021. № 1. C. 172–183.

- Федоренко А. Н., Федулов Б. Н., Ломакин Е. В. Моделирование ударного воздействия на демпфирующие элементы, изготовленные из композитных материалов // ПМТФ. 2021. № 1. C. 100–107.

- Работнов Ю. Н. Механика деформируемого твердого тела. Москва: Наука, 1979. 743 с.

- Vinogradov A. M. Local symmetries and conservation laws // Acta Appl. Math. 1984. No. 2. P. 21–78.

- Senashov S. I., Vinogradov A. M. Symmetries and conservation laws of 2-dimensional ideal plasticity // Proc. Edinburg Math. Soc. 1988. No. 31. P. 415–439.

- Senashov S. I., Savostyanova I. L. Using conservation laws to solve boundary value problems of the Moisila-Teodorescu system // J. Appl. Industr. Math. 2022. Vol. 25, No. 2.P. 101–109.

- Gomonova O. V., Senashov S. I. Determining elastic and plastic deformation regions in a problem of unixaxial tension of a plate weakened by holes // J. Appl. Mech. Tech. Phys. 2021. Vol. 62, No. 1, P. 157–163.

- Senashov S. I., Savostyanova I. L., Cherepanova O. N. Elastoplastic bending of the console with transverse force // J. of the Siberian Federal University. Math. and Phys. 2019. Vol. 12, No. 5, P. 637–643.

- Сенашов С. И., Савостьянова И. Л. Об упругом кручении вокруг трех осей // Сибирский журнал индустриальной математики. 2021. Т. 24, № 1. С. 120–125.

- Новацкий В. Теория упругости. М.: Мир, 1975. 872 с.

- Милейко С. Т. Антони Келли и композиты сегодня. Ч. 2. Композиты с металлической матрицей // Композиты и наноструктуры. 2021. В. 1, № 3–4 (51–52). С. 59–107.

- Милейко С. Т. Композиты и наноструктуры // Композиты и наноструктуры. 2009. Вып. 1. C. 6– 37.

- Келли А. Инженерный триумф углеводородов // Композиты и наноструктуры. 2009. Вып. 1. C. 38–49.