Carbon-containing modifier for fluoranhydrite binder

Автор: Gordina Anastasia F., Gumenyuk Alexander N., Polyanskikh Irina S., Zaripova Regina I.

Журнал: Нанотехнологии в строительстве: научный интернет-журнал @nanobuild

Рубрика: Исследование свойств наноматериалов

Статья в выпуске: 5 т.14, 2022 года.

Бесплатный доступ

Introduction. In order to widen the functionality of construction and building materials and widespread electrically conductive building constructions, it is highly recommended to reduce cost of the solutions. This can be achieved by replacing binders with the industrial by-products. At the same time, there are a few articles about adjustment of electrically conductive properties of materials based on by-product binders and this field is of a great importance. Also, highly dispersed particles in modifiers and their role might be considered as important to find out, especially when such additives are used to improve structure and properties of composites. Methods and materials. To study the possibility of controlling the electrical properties of the matrix, compositions based on fluoroanhydrite, sodium sulfate as a hardening activator, and UPC-MIX-1 suspension as an electrically conductive additive, were made. The effect of UPC-MIX-1 suspension on the electrical performance and structure formation of a mineral matrix containing dispersed carbon black particles was studied. The polydisperse nature of the modifying additive and the ratio of the nanodispersed and microdispersed parts of the solid phase were determined. Indicators for calculating the specific volumetric electrical resistance were determined by the probe method. The influence of the dispersed additive on the characteristics of the fluoroanhydrite composite was evaluated by standard laboratory methods. Features of structure formation were evaluated using the methods of physicochemical analysis. Results and discussion. It was confirmed that a fluoranhydrite-based mineral binder with sodium sulfate has moderate physical mechanical properties and might be used as a substitute for gypsum binder. The usage of an electrically conductive additive as a modifier enhances such mechanical properties as flexural compressive strength and compressive strength which increase by 51% and 65% correspondingly. Also, hydro physical properties have been improved, for instance the coefficient of softening for the FD-4 sample has increased by 39%, and the water absorption by mass for the same sample has decreased by 36%. Specific volume electrical resistance has decreased by 49-52% and equals13,6 kOm • cm, 8% of electrically conductive additive being added. The physical and technical properties of the presented composite are due to significant changes of the physical and chemical properties including the features of structure formation. Conclusions. The obtained compositions require extra optimization in order to be used as a heating component. At the same time, the achieved electrical conductivity is sufficient to level the electrostatic effect of self-leveling floors. Regularities in the formation of the structure of the fluoroanhydrite composite have been established, which manifest themselves in the formation of a larger number of contacts for the intergrowth of crystalline hydrate new formations ensured by the presence of a nanodispersed part in the modifying additive.

Fluoranhydrite, electrical conductivity, hardening activator, modifying additive, microstructure, structure formation, dispersion, carbon black, nanosized particles

Короткий адрес: https://sciup.org/142236263

IDR: 142236263 | УДК: 691 | DOI: 10.15828/2075-8545-2022-14-5-381-391

Текст научной статьи Carbon-containing modifier for fluoranhydrite binder

Original article

The construction materials industry is traditionally one of the most conservative branches of the modern economy, in which the pace of implementation of innovative “green” solutions and the growth of economic efficiency significantly lags behind the average rates demonstrated by the global economy [1–3]. The use of man-made waste, the volumes of which are growing every year, can be the driver of innovative development of the global construction industry taking into account the latest global trends in the field of self-healing materials, the use of carbon nanotubes, the development of concrete compositions for 3D printing, and electrically conductive concrete [4–6]. Taking into account the obvious needs of the market and the environment for “green” solutions,

THE STUDY OF THE PROPERTIES OF NANOMATERIALS strategies for the development of the construction materials industry have been adopted in a number of countries [7–9]. The strategies are focused on alternative versions of construction products manufactured using some industrial wastes [10, 11].

To date, experts estimate the volume of annual formation of synthetic anhydrite (fluoranhydride, phosphoanhydrite, titanogypsum, etc.) on a global scale of about 170 million tons per year [12, 13]. The volume of global production of fluoranhydrite is 4 million tons per year. The radiation-hygienic characteristics of this raw material meet the requirements of sanitary rules and regulations, which makes it possible to consider this material for use in the production of building materials [14–16].

Fluoranhydrite wastes generated at chemical industry enterprises in Russia have a similar chemical composition with the content of the same chemical compounds (β-CaSO4 and γ-CaSO4, free H2SO4, CaF2, Ca(SO3F)2, while differing in percentage ratio and particle size composition [17]. In particular, fluoranhydrite in the amount of 150 thousand tons is produced annually in Halogen, Ltd, in the Russian city of Perm. It is characterized by uniformity of chemical and mineralogical compositions and an insignificant amount of impurities [18–20].

It was found that the binder based on technogenic anhydrite has very low activity and is not able to attach free water without additional activators [21–23]. Studies in the field of activation of this binder have shown that the following three types of activation are the most effective: mechanical, chemical, and mechanical-chemical [24–26]. From the point of view of technological requirements, in the production of structural building materials, the method of chemical activation is the most promising [27-29]. The addition of alkali metals (Na2SO4, К2SO4, CuSO4, MgSO4, FeSO4, BaSO4) as chemical catalysts for hardening the sulfates accelerates the setting time of the fluoranhydrite binder by increasing the solubility of calcium sulfate. These additives do not affect the water demand of the binder providing rapid crystallization of calcium sulfate from the solution and contributing to the formation of hydrate phase nuclei [23, 25, 27].

The main properties of artificial matrix based on fluoranhydrite include resistance to chemical agents. This resistance largely depends on the concentration, duration of exposure, and temperature of acids, alkalis, and salts in an aggressive environment. Considerable attention is paid to the disposal of solid wastes from the chemical industry through their use as binders, mortars, plaster mixes, plasterboard/gypsum fibre boards, self-levelling floors, road foundations, blocks [30–32]. In Russia there is a large-scale production of structural panels based on fluoranhydrite with the total consumption of man-made raw materials of 5.7 million tons per year [17]. Analysis of the use of technical anhydrite in the building materials industry shows [17, 23, 31,32] that in the near future this type of binder can be used in the production of a large volume of dry building mixes for self-levelling floors.

In recent years active researches have been carried out in the field of increasing the antistatic protection and functional load of traditional structural materials and antistatic coatings by regulating electrical properties [33– 36]. This interest to concrete as an electrically conductive material is caused by the prospects of construction, electric power, and other branches of technology provided reproducible results are obtained [37-39].

Today energy infrastructure facilities as well as industrial enterprises with increased energy consumption face the problem of static voltage. The experience of using self-leveling floors in industrial enterprises has shown that static voltage in this type of floor coverings leads to accidents and failure of expensive software-controlled equipment [40, 41]. The features of the fluoranhydritebased mineral matrix determine its dielectric properties (E > 3.5 eV). In most cases the ionic nature of electrical conductivity in the volume of the anhydrite matrix is realized due to the movement of the ion charge [42]. Studies of traditional cement concrete have shown that during operation free water in the pore space is represented by an electrolyte containing ions in metastable equilibrium. The electrical conductivity of the electrolyte in concrete reflects the kinetics of physical-chemical processes during the hardening of cement matrix [43]. Due to the complex macro- and micro capillary structure, the electrolyte located in the pore space differs in physical-chemical properties from ordinary liquid electrolytes and these properties continuously change over time. A constant presence of free water in the pore space is necessary for a consistently low specific volumetric electrical resistance in the mineral matrix [42].

The mechanical strength of the anhydrite matrix decreases by 50–60% when saturated with water [17]. It can be assumed that the absence of free water ions will have a negative effect on the threshold percolation coefficient of the electrically conductive cluster structure of the anhydrite matrix [39].

Anhydrite materials have a reduced electrical conductivity up to 104 Ohms•m and are dielectric materials. Electric charges are known to occur when dielectrics are deformed. It is associated with the redistribution of charges in the dielectric under the influence of mechanical load, the so-called electrostatic effect [41].

This effect has a negative practical significance since the charge is often stored in materials with low electrical conductivity [40]. For example, a person can receive an electric charge if the soles of his shoes are insulators, or if he walks on a floor covered with an insulating material.

The key direction of solving the problem of the occurrence of an electrostatic effect as well as increasing the functional load on self-leveling floors based on an anhydrite matrix is to reduce the specific volumetric electrical

THE STUDY OF THE PROPERTIES OF NANOMATERIALS resistance by modifying the compositions. As a result of modification, the anhydrite matrix becomes a stable conductor of electric current, which provides low resistance required for the continuous movement of charged electrons both on the coating surface and in the material volume. In this case, the electrically conductive structure of the modified composite will ensure a rapid volumetric flow of charge to the boundaries of the material and its further transition to other conductive materials in direct contact with them.

The main component for ensuring electrical conductivity in the mineral matrix is the component that forms a continuous path for electric current. Some published papers [31, 32, 33] differentiate additives with such particles according their morphology as following: dispersed additives with highly developed surface area and forming clusters and conductive particles with high elongation such as fibers forming conductive bridges that allow a charge to be transmitted for a long distance.

Other researches [28, 38, 45] have confirmed that the origin of electrically conductive additives has a different impact on electrical properties of mineral composites.

Most cases [26, 31, 35] have shown that man-made electrically conductive particles have an inhomogeneous morphology, which in turn leads to an optimal package of particles in the structure and their satisfying distribution within the volume of a material.

In turn, the dense packing of the mineral matrix and the optimal distribution of the electrically conductive component in its structure makes it possible to provide a lower percolation threshold and a lower breakdown voltage level. [36, 41, 42]. Also, it should be taken into consideration that the content of electrically conductive additive has to be within limits which allow the percolation threshold to be achieved. At the same time this content is not supposed to have negative influence on workability and segregation of a mix and the physical mechanical properties as well [42, 43].

The impact of different man-made materials with electrically conductive particles on mineral matrices have been esteemed for the following materials: carbon black [28], asphaltene [35], steel shaving [34], slag [37], industrial carbon [42], fly ash [38], powdered coke [43], carbon-contained slag from aluminum production [2]. All that researches have provided enough data to make a conclusion that the impact of morphology, size of particles and distribution on structure formation is much more significant than the role of the content.

The aim of the paper is to study the possibility of utilization of man-made wastes to obtain an electrically conductive material based on a fluoranhydrite binder and additives contained nanosized particles.

METHODS AND MATERIALS

Binder. The main binder component of fluoranhydrite is a waste product of the production of hydrofluoric acid and hydrogen fluoride. The raw materials were obtained from the storage facility of the Halogen, Ltd in Perm. The average chemical composition of fluoranhydrite: CaSO4 (at least 20% of γ-CaSO4 and up to 78% of β-CaSO4); CaF2 – from 1.0 to 1.8%; H2SO4 – from 1.0 to 1.2%.

Hardening activator. Taking into account the previous studies and analysis of publications [7,24], sodium sulfate (Na2SO4) was selected as an activator of fluoranhydrite hardening in the amount of 2% by the mass of the binder.

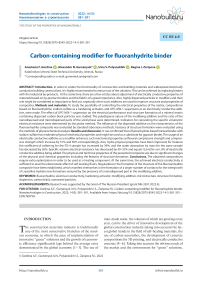

Electrically conductive additive. To ensure stable electrical conductivity, the UPC-MIX-1 pigment concentrate (technical soot suspension) was added in the amount from 0% to 10% by the mass of the binder. The composition of the pigment concentrate contains: technical soot – 62%; water – 20%; propylene glycol – 10%, special additives – 8%. The analysis of the particle distribution in the technical soot suspension shows that the additive has a poly-dimensional dispersed phase with micro- and

Fig. 1. Granulometric composition of the dispersed phase of the electrically conductive additive

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Table 1

Samples compositions

Samples of six compositions were made to study the effect of technical soot suspension on the electrical and hydro physical properties of a fluoranhydrite-based composite. The formulation characteristics of the experimental compositions considered in this study are presented in Table 1.

The composite samples were made as follows: 2% of sodium sulfate was dissolved in water by intensive mixing and then the binder was mixed with the mixing water. A suspension with the electrically conductive additive was added to the mixture during the mixing process. The water-to-binder ratio was corrected for each composition in order to obtain equally fluidity mixtures taking into account the amount of the additive and the plasticizing effect. Mixing the components was carried out till visual homogenization of the additive in the mixture volume. The resulting mixture was poured into metal molds with geometric dimensions of 40×40×160 mm.

Hydro physical properties . The determination of water resistance was defined as the ratio of the compressive strength of a water-saturated sample to the compressive strength of a dry sample. The determination of compressive strength in a water-saturated state was carried out as follows: samples at the age of 28 days were placed in a container with water at room temperature and kept for two days. Then the samples were removed from the container, water was removed from the surface, then the samples were tested for compression.

The samples were tested for water absorption by mass as follows: the manufactured samples were dried to a constant mass in a drying cabinet at the temperature of 45–55оС. The dried samples were placed in a container filled with water so that the water level in the container was about 50 mm higher than the upper level of the stacked samples. The water temperature in the container was 21оС. The samples were weighed every 24 hours till the results of two consecutive tests differed less than 0.1%. The water absorption of the sample was calculated as a percentage by the formula:

W =

m2–m1

m 1

•100,

where, m1 – is the mass of the dried sample to a constant mass, g;

m2 – is the mass of the water-saturated sample, g.

Mechanical properties . The hydraulic press PGM-100MG4-A was used to determine the compressive and bending strength of the samples of the developed compositions. The 40×40×160 mm prism samples were tested at the age of 28 days on laboratory press with the loading speed of 1 MPa/s.

Electrical properties . The change of the specific volume resistivity was determined by means of the experimental calculation method. At the experimental stage, the resistivity of the samples was measured using the MNIPI E7-20 device and copper electrodes embedded in the prism samples at the molding stage at the distance of 120 mm from each other. At the design stage, the specific volumetric resistivity index was determined in kOm·cm (kOm, kΩ). The calculation of the specific volumetric resistivity index was carried out on the basis of the data obtained from the device and the geometric parameters of the studied samples according to the formula [33]:

ρ = R•A/L , кΩ•cm, where ρ – is the specific volume resistivity of the sample;

R – is the resistivity of the sample;

L – is the distance between the electrodes;

A – is the cross-sectional area of the sample.

SEM and IR-ray spectroscopy were used to determine the physical and chemical properties and substantiate the processes that lead to changes in technical characteristics.

SEM. The study of the microstructural features of a fluoranhydrite-based composite was carried out at the AdMaS Research Center in Brno the Czech Republic and on the basis of the Institute of Physics and Technology of the Ural Federal Research Center of the Ural Branch of the Russian Academy of Sciences on Tescan Mira 3

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

XMU and Thermo Fisher Scientific Quattro S scanning electron microscopes. Microstructure survey parameters: the vacuum chamber pressure was 50 Pa; the accelerating voltage was HV 30 kV; the beam current was 16 A (Pa).

IR-ray diffraction. Infrared spectroscopy of fine powder obtained by grinding samples of the control and modified composition was performed on the IR Fourier spectrophotometer “IRAffinity-1”.

RESULTS AND DISCUSSION

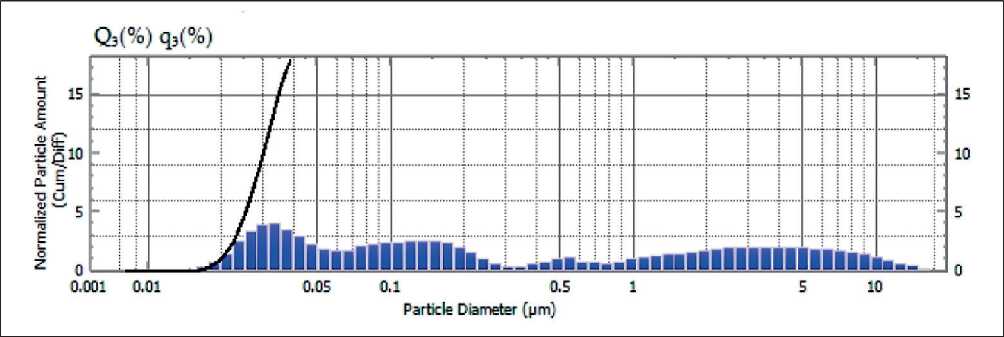

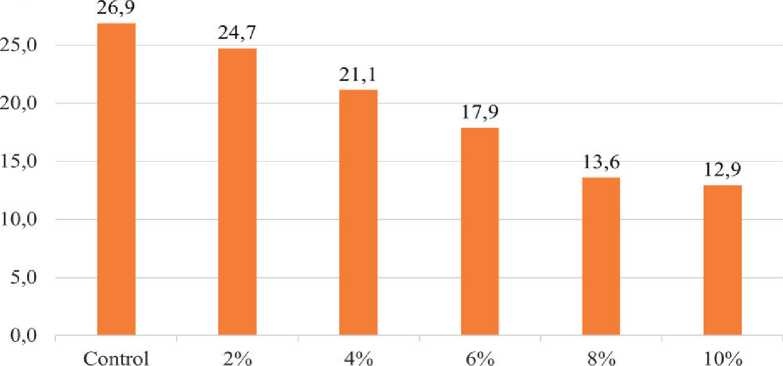

The amount of the electrically conductive additive varied in the range from 0% to 10% with a constant amount of the sodium sulfate hardening activator. This was done to determine the optimal amount of the electrically conductive additive in the composite. The results of the study of the physical, mechanical, and electrical properties of the developed composites based on fluoranhydrite are presented in Figures 2, 3, 4, and 5.

The analysis of the obtained results makes it possible to determine the optimal composition with the fluoranhydride: the electrically conductive additive in the amount of 8% and sodium sulfate in the amount of 2%.

The setting time according to the Vicat method for the control composition: the beginning of setting was after 23 minutes, and the end of setting was after 1 hour 9 minutes. The setting time according to the Vicat method for the optimal composition with 8% of the electrically conductive additive: the beginning of setting was after 1 hour 12 minutes, and the end of setting was after 1 hour 56 minutes. The increase in the setting time is due to the presence of additional components in the suspension. This increase in the setting time is preferable for the technology of self-leveling floors.

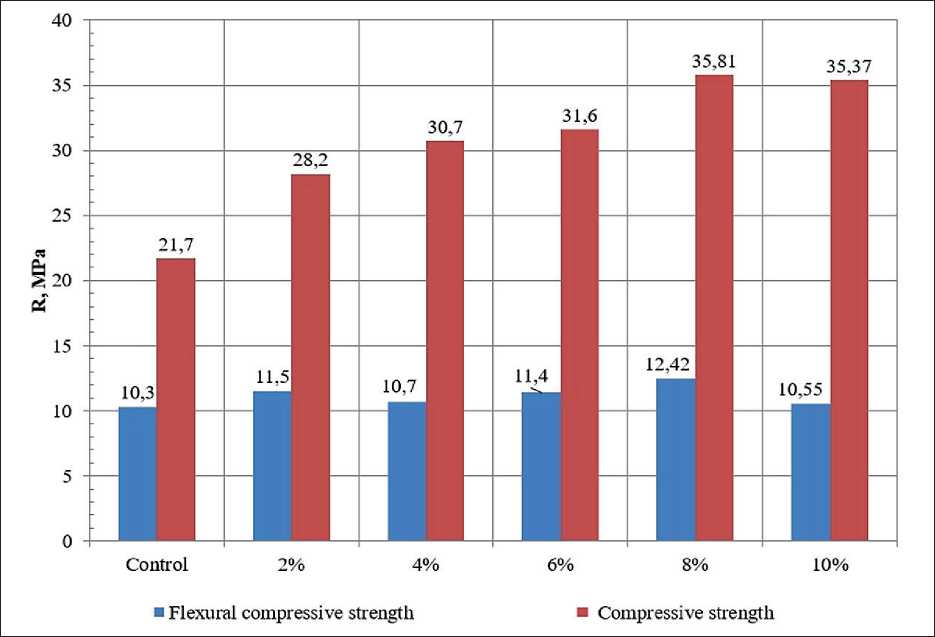

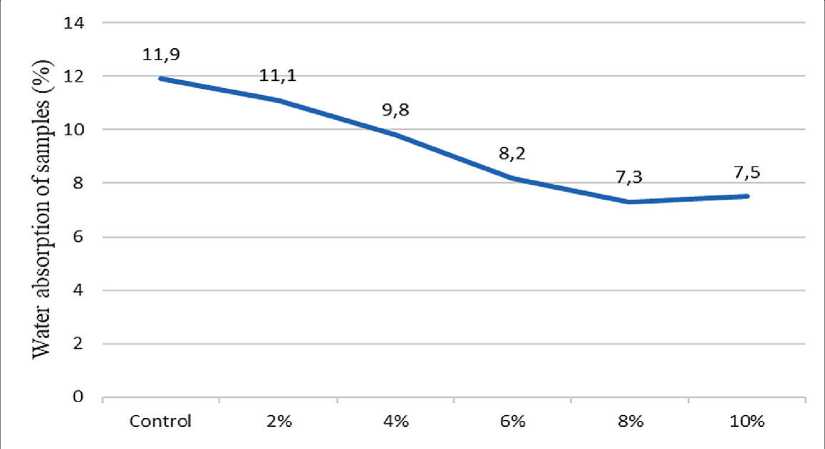

The increase of mechanical strength was obtained by increasing the percentage of the electrically conductive additive up to 8%. A further increase of the amount of the electrically conductive additive leads to a decrease of values of strength characteristics (Fig. 2). Analysis of the water-to-binder ratio, particles sizes of the dispersed phase of the additive (Fig. 1) and the increase of strength suggest a possible mechanism of action of the electrically conductive additive as a filler compacting the composite structure. This is indirectly confirmed by an increase of water resistance (Fig. 3), a decrease of water absorption (Fig. 4) and a change of samples’ microstructure (Fig. 5).

Comparing the hydro physical parameters of the samples (Fig. 3 and 4), one can conclude that the structure of the pore space of the modified compositions has changed. An increase of the coefficient of water resistance

Fig. 2. Comparison of mechanical strength of samples based on fluoranhydrite at the age of 28 days (coefficient of variation is V = 5.6%)

THE STUDY OF THE PROPERTIES OF NANOMATERIALS with a simultaneous decrease of water absorption reflects the positive effect of the additive evident in a decrease of open porosity, probably as a result of the compaction of the matrix structure.

The change of electrical conductivity at the age of 28 days depending on the amount of the electrically conductive additive is shown in Figure 6. The fluoranhydritebased composite has a high specific volume resistivity and is a dielectric that is confirmed by the characteristics of the control composition. The addition of the electrically conductive additive in the amount of up to 10% provides a reduction of resistivity by more than 2 times compared to the control sample. It should be noted that a further increase of the amount of fine particles as a filler leads to a loss of mechanical strength of samples that is consistent with similar studies performed on cement concrete [38–41].

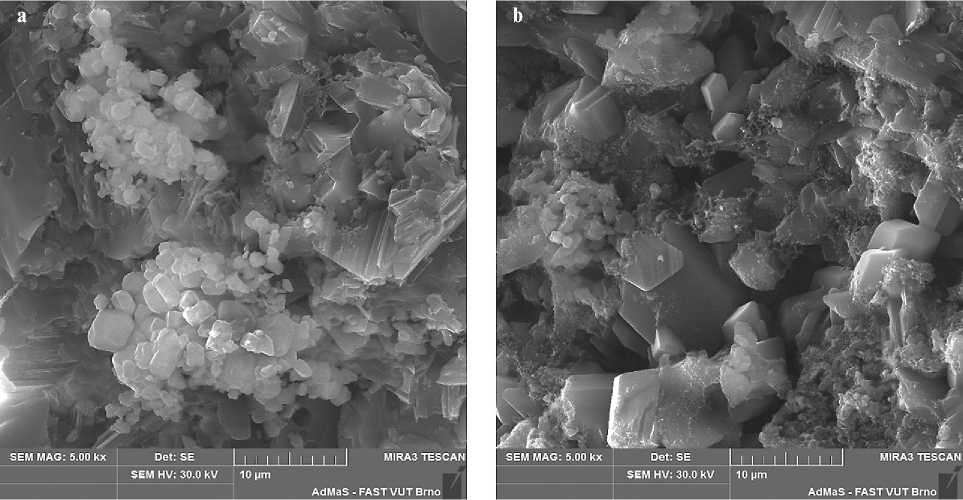

In Figure 6 the comparison of microstructures is given for the control sample (Fig. 6, a) and the modified one (Fig. 6, b). It can be seen that a denser fine-crystalline structure is formed when the electrically conductive additive is added in the amount of 8%. An increase of the number of contacts among hydration products can be observed, which leads to an increase of mechanical strength and to an improvement of the hydrophysical characteristics of the fluoranhydrite matrix.

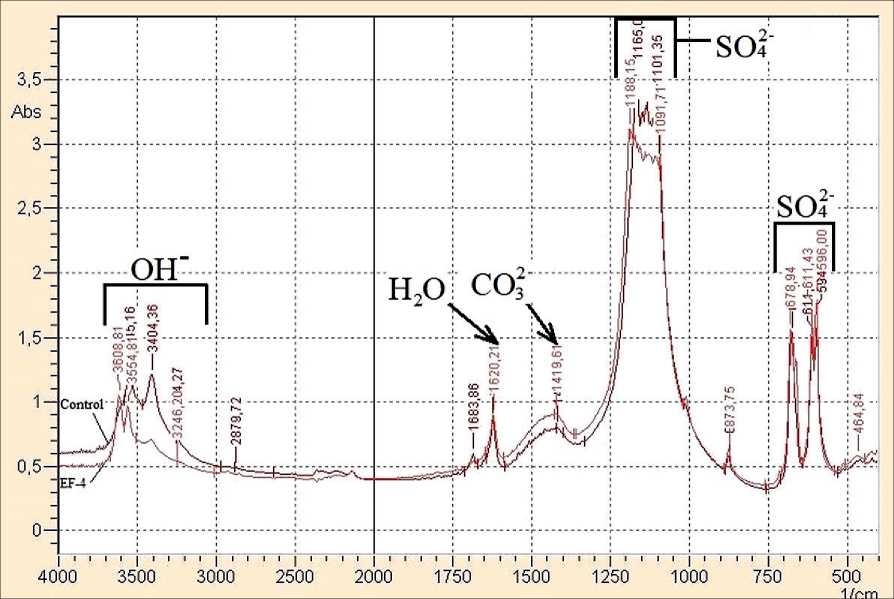

The results of a comparative analysis of microstructures are confirmed by infrared spectroscopy data in Fig-

0,8

Fig. 3. The value of the softening coefficient of te samples depending on the amount of the electrically conductive additive

Fig. 4. Water absorption of the samples depending on the amount of the electrically conductive additive

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 5. Microstructure of the control sample (a) and the modified one (8% of conductive additive) (b) at the age of 28 days at a 5000-fold increase

30,0

Fig. 6. Change of specific volume resistivity

ure 7. The electrically conductive additive in the amount of 8% changes the nature of peaks in the regions of the main functional groups; in addition, one can note the appearance of new wave numbers that are presented in Table 2. This presumably indicates a change in the crystallization conditions of technogenic anhydrite.

Thus, the optimal composition is characterized by the following indicators: the compressive and bending strengths are 35.81 and 12.42 MPa, accordingly, with the coefficient of variation equal to 5.6%; the softening coef- ficient is 0.7; the specific volumetric electrical resistivity of the composite is 13.6 kΩ•cm.

Analysis of the research literature shows that specific volume resistivity indicators in the range from 10 to 103 Ohms•cm are required for the functioning of the mineral matrix as a heating element [43]. The developed compositions cannot be used as a heating element without further optimization, while the achieved electrical conductivity is quite sufficient to neutralize the electrostatic effect in self-leveling floors.

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Fig. 7. IR spectra of a control sample and a modified sample with 8% of the electrically conductive additive

Table 2

Characteristic wave numbers of IR spectra of compositions

|

Ion |

Wave number cm–1, reference sample |

Wave numbers cm–1, modified sample |

|

SO42– |

594.08; 611.43; 673.16;1165.0; 1101.35 |

611.43;678.94;596.00;1188.15; 1091.71 |

|

CO32– |

1417.68; 873.75 |

1419.61; 873.75 |

|

OH– |

3545.16; 3404.36; 3244.27; 2879.72 |

3608.81; 3554.81; 3246.20 |

|

H 2 O |

1622.13; 1683.86 |

1620.21 |

CONCLUSION

The analysis of the effect of the electrically conductive additive on the structure formation of a mineral matrix based on fluoranhydrite has been performed. The following conclusions can be drawn:

-

1. The studied fluoranhydrite binder, when activated with sodium sulfate, has sufficient physical and mechanical characteristics to be used as an alternative to traditional gypsum binders.

-

2. Modification of the suggested composition with the electrically conductive additive increases the mechanical strength depending on its amount. Thus, the bending strength increases up to 51%, the compressive strength increases up to 65% with the addition of 8% of electrically conductive additive, the setting time increases.

-

3. The electrically conductive additive also improves the hydro physical properties of the composite. The softening coefficient of FD-4 samples increases by 39%, water absorption by mass decreases by 36%.

-

4. It was found that the addition of the electrically conductive additive significantly reduces the specific volumetric electrical resistivity by 49–52% and is 13.6 kOhm•cm for optimal composition. Analysis of the research literature has shown that specific volumetric resistivity indicators in the range from 10 to 103Ohms•cm are required for the functioning of the mineral matrix as a heating element. The developed compositions cannot be used as a heating element without further optimization, while the achieved electrical conductivity is quite enough to neutralize the electrostatic effect of self-leveling floors.

-

5. The addition of the electrically conductive additive has a significant effect on the structure of the mineral matrix based on fluoranhydrite. The traditional microstructure of the anhydrite matrix represents the formation of idiomorphic prismatic and rhomboid crystals of lamellar shape. The matrix of the modified composition is char-

- acterized by a denser structure due to the influence of the dispersed phase of suspension acting as a micro-filler and introducing the additional crystallization centers. These centers overgrown with hydration products, fill the pore space, compact and strength the matrix that explains the higher strength and water resistance of developed material.

THE STUDY OF THE PROPERTIES OF NANOMATERIALS

Список литературы Carbon-containing modifier for fluoranhydrite binder

- Azad N.M., Samarakoon S.M. Utilization of Industrial By-Products / Waste to Manufacture Geopolymer Cement / Concrete. Materials Science, Engineering. 2021, 13(2), 873. https://doi.org/10.3390/su13020873

- Joseph C.G., Taufiq-Yap Y.H., Krishnan V., Li Puma G. Application of modified red mud in environmentally-benign applications: A review paper. Environmental Engineering Research, 2022, 25(1), 795–806. https://doi.org/10.4491/eer.2019.374

- Katrijn Gijbels, Yiannis Pontikes, Pieter Samyn, Sonja Schreurs, Wouter Schroeyers Effect of NaOH content on hydration, mineralogy, porosity and strength in alkali/sulfate-activated binders from ground granulated blast furnace slag and phosphogypsum. Constructions, 2020, 10(2), 103-112. https://doi.org/10.1016/j.cemconres.2020.106054

- Arunothayan A.R., Nematollahi B., Ranade R., Khayat K.H., Sanjayan J.G. Digital fabrication of eco-friendly ultra-high-performance fiber-reinforced concrete. Cement and Concrete Composites, 2022, 125, 104281. https://doi.org/10.1016/j.cemconcomp.2021.104281

- Rosales J., Gázquez M., Cabrera M., Bolivar J.P., Francisco Agrela. 6 – Application of phosphogypsum for the improvement of eco-efficient cements / In Woodhead Publishing Series in Civil and Structural Engineering, Waste and Byproducts in Cement-Based Materials, Engineering, 2021, p. 153–189. https://doi.org/10.1016/B978-0-12-820549-5.00016-4

- Maksim Kamarou, Natalia Korob, Witold Kwapinski, Valentin Romanovski. High-quality gypsum binders based on synthetic calcium sulfate dihydrate produced from industrial waste, Journal of Industrial and Engineering Chemistry, 2021, 100, 324–332. https://doi.org/10.1016/j.jiec.2021.05.006

- Palomo A., Maltseva O., Garcia-Lodeiro I., & Fernández-Jiménez A. (2021). Portland Versus Alkaline Cement: Continuity or Clean Break: «A Key Decision for Global Sustainability». Frontiers in Chemistry, 653.

- Valentin Romanovski, Andrei Klyndyuk, Maksim Kamarou. Green approach for low-energy direct synthesis of anhydrite from industrial wastes of lime mud and spent sulfuric acid. Journal of Environmental Chemical Engineering 2021, 9, 6, 106711. https://doi.org/10.1016/j.jece.2021.106711

- Будников П.П., Зорин С.П. Ангидритовый цемент. М.: Промстройиздат, 1954. 90 c.

- Brencich A., Lątka D., Matysek P., Orban Z., Sterpi E. Compressive strength of solid clay brickwork of masonry bridges: Estimate through Schmidt Hammer tests. Construction and Building Materials, 2021, 306, 124494.

- Zhakupova G., Sadenova M.A., Varbanov P.S., Possible Alternatives for Cost-Effective Neutralisation of Fluoroanhydrite Minimising Environmental Impact. Chemical Engineering Transactions, 2019, 76, 1069-1074. https://doi.org/10.3303/CET1976179

- Rosales J., Gázquez M., Cabrera M., Bolivar J. P., Agrela F. Application of phosphogypsum for the improvement of eco-efficient cements. Waste and Byproducts in Cement-Based Materials, 2021, pp. 153-189. Woodhead Publishing. https://doi.org/10.1016/B978-0-12-820549-5.00016-4

- Kamarou M., Korob N., Kwapinski W., Romanovski V. High-quality gypsum binders based on synthetic calcium sulfate dihydrate produced from industrial waste. Journal of Industrial and Engineering Chemistry, 2021 100, 324–332. https://doi.org/10.1016/j.jiec.2021.05.006

- Rajković M., Tošković D.V. (2002). Investigation of the possibilities of phosphogypsum application for building partitioning walls-elements of a prefabricated house. Actaperiodicatechnologica, 2002, (33), 71–92. https://doi.org/10.2298/APT0233071R

- Romanovski V., Klyndyuk A., Kamarou M. Green approach for low-energy direct synthesis of anhydrite from

- industrial wastes of lime mud and spent sulfuric acid. Journal of Environmental Chemical Engineering, 2021 9(6), 106711. https://doi.org/10.1016/j.jece.2021.106711

- Gracioli B., Angulski da Luz C., Beutler C.S., Pereira Filho J.I., Frare A., Rocha J.C., Cheriaf M., Hooton R.D. Influence of the calcination temperature of phosphogypsum on the performance of supersulfated cements. Construction and Building Materials. 2020. https://doi.org/10.1016/j.conbuildmat.2020.119961

- Singh N.B. The activation effect of K2SO4 on the hydration of gypsum anhydrite, CaSO4(II). Journal of the American Ceramic Society. 2005. https://doi.org/10.1111/j.1551-2916.2004.00020.x

- Fedorchuk Y.M., Zamyatin N.V., Smirnov G.V., Rusina O.N., Sadenova M.A. (2017). Prediction of the properties anhydrite construction mixtures based on neural network approach. Journal of Physics: Conference Series. 2017. 881, 1, p. 012039. https://doi.org/10.1088/1742-6596/881/1/012039

- Zhakupova G., Sadenova M., Varbanov P.S. Possible alternatives for cost-effective neutralisation of fluoroanhydrite minimizing environmental impact. Chemical engineering, 76, 1069-1074. https://doi.org/10.3303/CET1976179

- John L. Provis, Angel Palomo, Caijun Shi. Advances in understanding alkali-activated materials. Cement and Concrete Research, 2015, 78, Part A, 110–125. https://doi.org/10.1016/j.cemconres.2015.04.013

- Liu S., Ouyang J., Ren J. Mechanism of calcination modification of phosphogypsum and its effect on the hydration properties of phosphogypsum-based supersulfated cement. Construction and Building Materials, 2020, 243, 118226. https://doi.org/10.1016/j.conbuildmat.2020.118226

- Guerra-Cossío M.A., González-López J.R., Magallanes-Rivera R.X., Zaldívar-Cadena A.A., Figueroa- Torres M.Z. Anhydrite, blast-furnace slag and silica fume composites: properties and reaction products. Advances in Cement Research, 31, 8, 2019, pp. 362-369. https://doi.org/10.1680/jadcr.17.00216

- Kamarou M., Korob N., Romanovski V. Structurally controlled synthesis of synthetic gypsum derived from industrial wastes: sustainable approach. Journal Chem Technol Biotechnol, 2021, 96, 3134-3141. https://doi.org/10.1002/jctb.6865

- Singh N.B. The activation effect of K2SO4 on the hydration of gypsum anhydrite, CaSO4 (II). Journal of the american ceramic society, 2005 88(1), 196–201. https://doi.org/10.1111/j.1551-2916.2004.00020.x

- Singh M., Garg M. Activation of fluorogypsum for building materials. Journal of Scientific and Industrial Research, 2009, 68(2), 130–134.

- Heydar Dehghanpour, Kemalettin Yilmaz, Faraz Afshari, Metin Ipek, Electrically conductive concrete: A laboratory-based investigation and numerical analysis approach, Construction and Building Materials, 2020, 260, 119948, https://doi.org/10.1016/j.conbuildmat.2020.119948

- Magallanes-Rivera R.X., Escalante-García J.I. Anhydrite/hemihydrate-blast furnace slag cementitious composites:

- Strength development and reactivity. Construction and Building Materials. 2014. https://doi.org/10.1016/j.conbuildmat.2014.04.056

- Hong S.-H., Choi J.-S., Yuan T.-F., Yoon Y.-S. Mechanical and Electrical Characteristics of Lightweight Aggregate Concrete Reinforced with Steel Fibers. Materials2021, 14, 6505. https://doi.org/10.3390/ma14216505

- Provis J.L., Palomo A., Shi C. Advances in understanding alkali-activated materials. Cement and Concrete Research, 2015, 78, 110–125. https://doi.org/10.1016/j.cemconres.2015.04.013

- Bigdeli Y., Barbato M., Gutierrez-Wing M.T., Lofton C.D., Rusch K.A., Jung J., Jang J. Development of new pH-adjusted fluorogypsum-cement-fly ash blends: Preliminary investigation of strength and durability properties. Construction and Building Materials, 2018 182, 646–656. https://doi.org/10.1016/j.conbuildmat.2018.06.086

- Xiaoli Liu, Ming Qu, Alan Phong Tran Nguyen, Neil R. Dilley, Kazuaki Yazawa, Characteristics of new cementbased thermoelectric composites for low-temperature applications. Construction and Building Materials, 2021, 304, 124635. https://doi.org/10.1016/j.conbuildmat.2021.124635

- Dehghanpour H., Yilmaz K., Afshari F., Ipek M. Electrically conductive concrete: A laboratory-based investigation and numerical analysis approach. Construction and Building Materials, 2020 260, 119948. https://doi.org/10.1016/j.conbuildmat.2020.119948

- Dehghanpour H., Yilmaz K., Ipek M. Evaluation of recycled nano carbon black and waste erosion wires in electrically conductive concretes. Construction and Building Materials, 2019, 221, 109-121. https://doi.org/10.1016/j.conbuildmat.2019.06.025

- Hong S.H., Choi J.S., Yuan T.F., Yoon Y.S. Mechanical and Electrical Characteristics of Lightweight Aggregate Concrete Reinforced with Steel Fibers. Materials, 2021, 14(21), 6505. https://doi.org/10.3390/ma14216505

- García-Macías E., Castro-Triguero R., Sáez A., Ubertini F. 3D mixed micromechanics-FEM modeling of piezoresistive carbon nanotube smart concrete. Computer Methods in Applied Mechanics and Engineering, 2018. 340, 396–423. https://doi.org/10.1016/j.cma.2018.05.037

- Al-Awsh W.A., Al-Amoudi O.S.B., Al-Osta M.A., Ahmad A., Saleh T.A. Experimental assessment of the thermal and mechanical performance of insulated concrete blocks. Journal of Cleaner Production, 2021 283, 124624. https://doi.org/10.1016/j.jclepro.2020.124624

- Liu X., Qu M., Nguyen A.P.T., Dilley N.R., Yazawa K. Characteristics of new cement-based thermoelectric composites for low-temperature applications. Construction and Building Materials, 2021, 304, 124635. https://doi.org/10.1016/j.conbuildmat.2021.124635

- Tian Z., Li Y., Zheng J., Wang S. A state-of-the-art on self-sensing concrete: Materials, fabrication and properties. Composites Part B: Engineering, 2019, 177, 107437. https://doi.org/10.1016/j.compositesb.2019.107437

- Schultz J. Conductive material prevents build-up of static electricity. AORN journal, 1970, 27(6), 1226–1228. https://doi.org/10.1016/S0001-2092(07)60644-9

- Kassebaum J.H., Kocken R.A. Controlling static electricity in hazardous (classified) locations. IEEE Transactions on Industry Applications, 1997, 33(1), 209–215.

- Garcia-Macias E., D’Alessandro A., Castro-Triguero R., Pérez-Mira D., Ubertini F. Micromechanics modeling of the electrical conductivity of carbon nanotube cement-matrix composites. Composites Part B: Engineering, 2016, 108, 451–469. https://doi.org/10.1016/j.compositesb.2016.10.025

- Marco Liebscher, Lazaros Tzounis, Dominik Junger, Tin Trong Dinh, Viktor Mechtcherine. Electrical Joule heating of cementitious nanocomposites filled with multi-walled carbon nanotubes: role of filler concentration, water content, and cement age. Smart Mater. Struct. 2020. 29. 125019. https://doi.org/10.1088/1361-665X/abc23b

- Hornbostel K., Larsen C.K., Geiker M.R. Relationship between concrete resistivity and corrosion rate – A literature review. Cem. Concr. Compos. 2013, 39, 60–72. https://doi.org/10.1016/j.cemconcomp.2013.03.019

- Hong S.-H., Choi J.-S., Yuan T.-F., Yoon Y.-S. Mechanical and Electrical Characteristics of Lightweight Aggregate Concrete Reinforced with Steel Fibers. Materials, 2021, 14, 6505. https://doi.org/10.3390/ma14216505

- Osama Zaid, Syed Roshan Zamir Hashmi, Fahid Aslam, Zain Ul Abedin, Asmat Ullah. Experimental study on the properties improvement of hybrid graphene oxide fiber-reinforced composite concrete. Diamond and Related Materials. 2022, 124, 108883. https://doi.org/10.1016/j.diamond.2022.108883