Characteristic physical–mechanical and high–temperature electric properties semicinductor ceramic based SnO2 with addition MnO2 and CuO

Автор: Dobrosmyslov Sergey S., Kirko Vladimir I., Nagibin Gennady E., Resinkina Oksana A., Popov Zahar I.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 6 т.6, 2013 года.

Бесплатный доступ

Ceramic semiconductor SnO2-based materials with MnO2 and CuO additives were synthesized at 1300 ºС and 1400 ºС. There has been carried out an investigation of the physical–mechanical and high–temperature electric properties. As a result, sintering of the material with MnO2 additive is shown to be improved at increasing firing temperature. The composition 96 % SnO2-2 % Sb2O3-2 % CuO made at the temperature 1300 ºС has the best electrophysical properties (its resistivity is 0.09 mOhm m). The resistivity of the 94 % SnO2-2 % Sb2O3-2 % CuO-2 % MnO2 composition in the high-temperature region is more by a factor of 3. The 96 % SnO2-2 % Sb2O3-2 % MnO2 composition has nonlinear voltage-currant characteristic, and hysteresis is present.

Ceramic, tin oxide, conductivity, currant – voltage characteristic

Короткий адрес: https://sciup.org/146114776

IDR: 146114776 | УДК: 666.3

Текст научной статьи Characteristic physical–mechanical and high–temperature electric properties semicinductor ceramic based SnO2 with addition MnO2 and CuO

The tin dioxide based ceramics is being used in many branches of industry – electronics, electrical engineering, electrochemistry, catalysis, biotechnology, metallurgy, atomic and chemical industries, etc. [1]. SnO2 is an n-type semiconductor having the band-gap energy 3.54 eV, whose properties basically depend on its microstructure and synthesis method. The wide range of use imposes special requirements on the material properties and thus on the synthesis method.

High-porous polycrystalline materials having a large amount of structural defects are used as catalysts and semiconductor gas sensors [2–6]. Oxygen vacancies forming in the surface active layers of the tin dioxide pores are the areas of the physical or chemical adsorption the presence of which is necessary for the gas sensing ability. On the other hand, high-density SnO2-based ceramics due to its high electro conductivity at high temperatures is used as the high temperature-electrodes [7], for instance, in the aluminum electrolysis and glass making [8]. Without glass-forming additives tin dioxide possesses a low value of sinterability which is caused by the domination of vaporization and

One of the ways to increase the ceramic material sinterability is the addition of fine-grained oxide materials such as ZnO [10], CuO [11], MnO 2 [12, 13], СоО [14], Fe 2 O 3 [13], and to improve electrical properties V2O5 [6] and Sb2O3 [15] are added. The addition of 1 mol. % CuO is especially effective because of the liquid phase formation. The Cu-O eutectic is 1080˚C [16]. A significant improvement of the electrophysical properties is provided with the Sb2O3 addition.

The aim of the paper being presented is the investigation of physical-mechanical and high-temperature electrophysical properties of a ceramics based on 96 %SnO2-2 %Sb2O3-2 %CuO with superdispersed MnO 2 .

Experimental technique

The specimens were made with the conventional ceramic technology. The initial SnO2 powder charge was prepared in the aqueous solution of Mn and Сu salts. And then it was preliminarily subjected to a thermal treatment at 1100 ºС followed by grinding. Then the charge was formed into a specimen using the 5 % polyvinyl alcohol solution as a binder. The specimen burning was carried out at 1300 ºС and 1400 ºС for 2 h . For the physical chemical tests the ceramic specimens were made in the form of cylinders 15 mm in diameter and 10 mm high, respectively. For the electro physical measurements the specimens of a rectangular shape 5×4× 50 mm were taken. The specimen’s density was measured with the hydrostatic weighing method in alcohol and the open porosity according to the State Standard 2408-95. The resistivity was measured with the four-point probe method in the temperature range 20-1000 ºС [17]. The mechanical properties were measured with the device Instron 3369. The crystalline structure of the ceramics was identified with the X-ray analysis in XRD 6000. The surface fracture pictures were taken with the scanning electron microscope (SEM) JEOL JSM-7001F (Japan).

Experimental results and discussion

In Table 1 there are presented the results of the physical-mechanical properties investigation of the ceramics and its resistivity values at T = 1000 ºС.

The experiment number is in the first column. The charge composition and final firing temperature are presented in the second and third ones, respectively. The measured values of density, open porosity, mechanical strength and resistivity are presented in columns 4 to 7.

As follows from the table a complete change of CuO for MnO2 leads to the mechanical and electrical properties degradation (experiments 1 and 2). The firing temperature increase leads to increased density and strength and decreased open porosity (№ 23 and № 45). The best composition of the investigated ones is 94 % SnO 2 -2 % Sb 2 O 3 -2 % CuO-2 % MnO 2. This ceramics has the best physical-mechanical properties (№ 7).

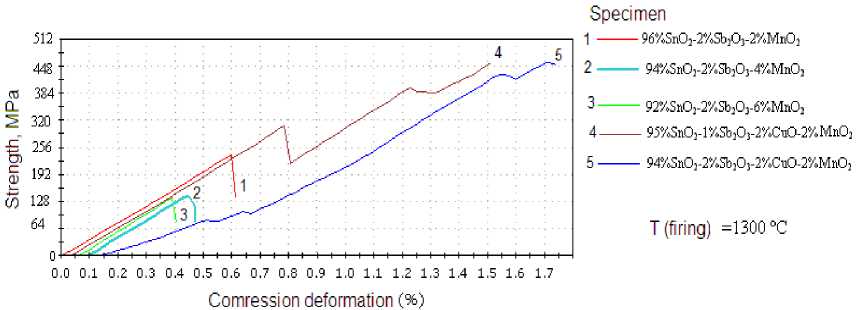

The measurement results for the ceramics strength at uniaxial compression obtained with Instron 3369 are presented in Fig. 1.

As can be seen from the figure the ceramics ultimate strength decreases with increasing MnO 2 concentration. The Young’s modulus is practically unchanged. A little addition of the glass-forming CuO phase leads to a significant ultimate strength increase and change of the deformation behavior and – 651 –

Table 1. Physical-mechanical properties and resistivity of the ceramics under investigation

|

№ |

Charge composition |

Firing temperature, ºС |

Density, g/cm 3 |

Open porosity, % |

Strengt h , MPa |

Resistivity, mOhm*m T = 1000 ºC |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

1 |

96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO |

1300 |

5.4 |

17.9 |

155.3 |

0.09 |

|

2 |

96 % SnO 2 -2 % Sb 2 O 3 -2 % MnO 2 |

1300 |

5.5 |

18.5 |

91.2 |

0.80 |

|

3 |

96 % SnO 2 -2 % Sb 2 O 3 -2 % MnO 2 |

1400 |

6.1 |

6.1 |

158.2 |

- |

|

4 |

94 % SnO 2 -2 % Sb 2 O 3 -4 % MnO 2 |

1300 |

5.5 |

17.2 |

132.5 |

0.83 |

|

5 |

94 % SnO 2 -2 % Sb 2 O 3 -4 % MnO 2 |

1400 |

6.1 |

5.1 |

257.6 |

- |

|

6 |

90 % SnO 2 -2 % Sb 2 O 3 -8 % MnO 2 |

1300 |

5.3 |

18.6 |

149.7 |

0.99 |

|

7 |

94 % SnO 2 -2 % Sb 2 O 3 -2 % CuO- 2 % MnO 2 |

1300 |

6.6 |

0.11 |

424.8 |

1.7 |

Fig. 1. Dependence of the ceramics strength on the degree of their compression deformation fracture pattern (from brittle to visco-brittle). On the curves in a number of cases an abrupt material destruction takes place that serves as evidence of deformation behavior change.

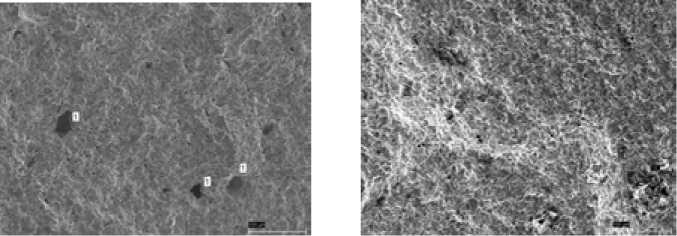

The pictures of the ceramic specimen’s surface fracture are presented in Fig. 2. The fracture structure also witnesses the change of the fracture pattern from brittle ( a ) to visco-brittle ( b ).

As can be seen from the pictures in Fig. 2 in tin dioxide with CuO or MnO 2 additives there are formed pores whose size is 20 µm in case of 2 % CuO addition (Fig. 2 (1)). In ceramics with CuO and MnO 2 the large pores are practically absent as well as the pores of a less size.

Pictures of the ceramics fractures at 5000-fold magnification are presented in Fig. 3.

The Fig. 3 shows that the destruction of the specimen 96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO occurs through particle bodies, but that of the specimen with 2 % CuO and 2 % MnO2 additives along the grain boundaries. It seems to take place through the glass-forming phase CuMn 2 O 4 , Cu1.5Mn1.5O4 [18].

It is known that when MnO 2 is added into polycrystalline tin dioxide, Mn 2 SnO 4 forms on the grains’ surfaces, which interferes with a good material sintering [19]. This does explain a high porosity of the material and its low strength. In case of MnO 2 – CuO additive combination there takes place the – 652 –

( а ) ( b )

Fig. 2. Pictures of the materials under investigation obtained with SEM JEOL JSM-7001F, x500; 1 – pores: ( а ) 96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO; ( b ) 94 % SnO 2 -2 % Sb 2 O 3 -2 % CuO-2 % MnO 2

а ) b )

Fig. 3. Pictures of the fractures, x5000; 1 – areas of particles destruction: ( а ) 96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO; ( b ) 94 % SnO 2 -2 % Sb 2 O 3 -2 % CuO-2 % MnO 2

formation of CuMnO x -phase (basically, CuMn 2 O 4 , Cu 1.5 Mn 1.5 O 4 ) [19]) that is a glass-forming one on the grains’ boundaries and promotes sintering.

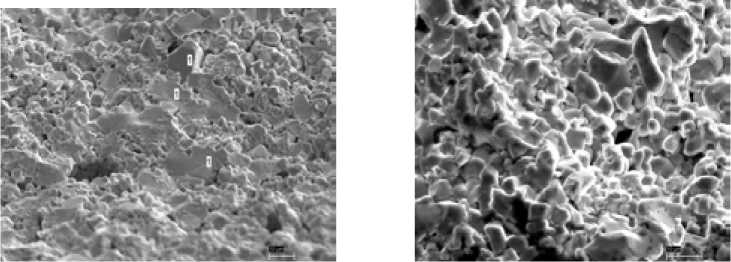

To improve the electrophysical properties Sb 2 O 3 was used. During the high-temperature sintering in the polycrystalline SnO2 lattice there takes place a substitution of the tetravalent tin atoms by pentavalent antimony ones [20] that provides the p-type conductivity and substantially decreases the energy-gap width. The ceramics receptivity measurement results versus temperature are presented in Fig. 4.

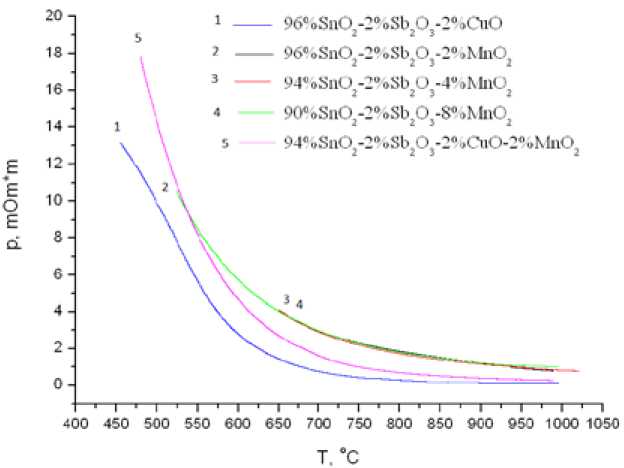

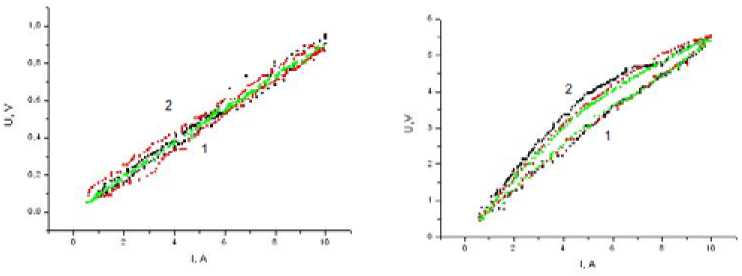

It has been mentioned above that Sb2O3 is used as an additive improving the material’s electrical conductivity. In the compositions of Fig. 4 the Sb 2 O 3 concentration (the number of the electrical charge carriers) is constant. The resistivity depends on the electrical contact between the sintered particles. The material with the CuO additive has the lowest resistivity (0.9 mOhm m, Table 1, №1). The Table 1 and Fig. 4 show that when MnO2 is used, the resistivity is independent of this phase concentration. It is possible to explain this fact by no influence of Mn 2 SnO 4 on the electrical contact between the sintered SnO2 particles. The voltage-current characteristics of the specimens are presented in Fig. 5 .

Fig. 4. T-dependencies of the resistivity of SnO 2 -based materials with different additions

а ) b )

Fig. 5. The specimens’ voltage-current characteristics obtained in 3 measurements ( Т = 1000 ºС): 1 – increasing current; 2 – decreasing current. а ) 96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO b ) 96 % SnO 2 -2 % Sb 2 O 3 -2 % MnO 2

The curves show a dependence on the material’s phase composition. In case of the 96 % SnO2-2 % Sb 2 O 3 -2 % CuO composition the voltage-current characteristics are linear which serves as an evidence of the resistivity being constant at current load increasing ( a ). In contrast to this, in specimens having CuO substituted by superdispersed MnO 2 the resistivity decreases practically by a factor of 2 with the current load increasing from 1 to 10 Å ( b ). The latter can be associated either with a generation of extra charge carriers on the interphase boundaries of the particles, or with the beginning of a flow along the boundaries because of the heat generation increased. Moreover, in case of the material with superdispersed MnO 2 voltage-current characteristic shows hysteresis (Fig.1 b ) that can be explained with a later cooling of the SnO2 particles compared to that of the interphase boundaries when decreasing the current load.

Conclusions

-

1. The specimens of the 96 % SnO 2 -2 % Sb 2 O 3 -2 % CuO composition sintered at 1300 ºС have the best electrophysical characteristics;

-

2. The substitution of CuO by MnO 2 leads to the degradation of the material’s mechanical properties;

-

3. The use of the superdispersed MnO 2 – CuO additive combination leads to a substantial increase of the mechanical strength and change of the fracture mechanism from brittle to visco-brittle;

-

4. In the compositions with MnO 2 – CuO additives there has been revealed a nonlinearity of the voltage-current characteristic. When the current load increases, the resistivity decreases. Moreover, there is revealed a hysteresis of the voltage-current characteristic.

Article was supported by RFBR № 12-03-31323

Статья выполнена при поддержке РФФИ № 12-03-31323