Characteristics research of a low thrust rocket engine manufactured using additive SLM technology

Автор: Akbulatov E.Sh., Nazarov V.P., Gerasimov E.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 4 vol.24, 2023 года.

Бесплатный доступ

The development and improvement of rocket and space technology are largely determined by the application of manufacturing technologies that enable the production of high-reliability products with energy efficiency, while simultaneously reducing material intensity and shortening the production cycle. Among these progressive technologies, additive technologies should be mentioned. The essence of these technologies lies in obtaining parts through layer-by-layer melting of material based on a computer 3D model of the product in a chamber of a specialized 3D printer equipped with a laser device. The application of additive technologies in rocket engine construction requires extensive scientific research and experimental work to confirm compliance with industry standards, rules, and mandatory certification at the state level. In accordance with the program of priority research at SibSU, in collaboration with the industrial partner “Polychrome” LLC a complex of experimental work is being carried out to test and refine the 3D printing modes of a demonstrator model of a low thrust rocket engine (LTRE). The design of the LTRE, operating on environmentally friendly gaseous fuel components, has been developed and adapted for 3D printing on the ASTRA 420 printer. The parameters and characteristics of the printer are considered, and the sequence of experimental work on selecting printing modes for the engine chamber housing and mixing head is outlined. The fundamental possibility of adjusting the modes of laser material melting and forming of the part has been established. The main technological stages of post-printing processing of LTRE chamber parts are presented. A description of the equipment for heat treatment and electrochemical polishing of parts is provided. The sequence of material structure research is outlined, and the results of metallographic and X-ray analysis of the internal state of the metal are presented. The importance of stand tests of rocket engines in the development of innovative design solutions and the implementation of innovative production technologies is demonstrated. A description and composition of the testing stand system at SibSU are presented. The results of stand firing tests indicate the fundamental possibility of manufacturing LTRE using selective laser melting of heat-resistant alloy.

Additive technologies, low thrust rocket engine, Inconel 718, post-printing processing, vibration testing, strength and tightness tests, bench fire tests

Короткий адрес: https://sciup.org/148329711

IDR: 148329711 | УДК: 621.454 | DOI: 10.31772/2712-8970-2023-24-4-682-696

Текст научной статьи Characteristics research of a low thrust rocket engine manufactured using additive SLM technology

The Russian aerospace industry has high innovative potential and is one of the main priorities of the country's economic development strategy. Its importance is currently determined by the special tasks of strengthening the defense capability of the state and the ability to ensure an accelerated pace of modernization of industrial production technological base. The practical results of space activities should be used to truly improve the quality of life of people and the development of all spheres of the economy. In the aerospace industry, extensive technical re-equipment of production, reconstruction of industrial facilities, and development of advanced world-class technologies are underway.

These include additive technologies (AF – Additive Fabrication from the term additivity – addition) [1–3], which represent a sequential layer-by-layer build-up of material and synthesis of a production object using component 3D application programs. The joining of layers of the source material can be carried out in various ways: by fusion, sintering, gluing, polymerization, depending on the physical and chemical properties of the material, the characteristics of the technological equipment and the intended purpose of the product.

The most promising type of additive technologies for use in the rocket and space industry is considered to be SLM 3D printing technology [4]. SLM (Selective laser melting) is an innovative technology for the production of complex products by laser melting of metal powder using mathematical CAD models (3D metal printing). This process consists of sequential layer-by-layer melting of powder material using powerful laser radiation. Using SLM technology, they create both precision metal parts for use as components and assemblies, as well as non-separable structures that ensure increased reliability of products.

Compared to traditional technologies currently used, selective laser melting technology has a number of advantages [5]:

– solving complex technological problems; – reduction of the cycle of research and development work, construction of complex parts without the use of equipment;

– reduction of the final mass of the product due to optimization of the design, taking into account the distribution of forces on the internal partitions and stiffeners of the product;

– lower consumption of final material through topological optimization at the product design stage.

At the same time, the use of SLM technology must be accompanied by a certain amount of postprinting processing, since the manufactured parts have increased roughness parameters, traces of technological supports, and unevenness on surfaces mating with the surfaces of other parts of the assembly unit. Porosity on the end surfaces of parts does not always provide a high-quality hermetic connection of metals by welding.

The purpose of the research

At enterprises and research organizations of the rocket and space industry, work is being carried out to create a system for the implementation and practical testing of additive technologies with their subsequent certification at the industry level. Due to this the issue of organizing advanced training of specialists in the field of additive technologies, taking into account the long-term interest and needs of enterprises of industrial partners is of relevance both for the Reshetnev Siberian State University of Science and Technology at the new stage of its development as a flagship university of the region and rocket and space engineering in general.

As part of the “Priority 2030” program, the Reshetnev Siberian State University of Science and Technology is implementing a scientific and educational project “Development, production by selective (additive) laser melting and testing of a low-thrust demonstrator rocket engine running on environmentally friendly fuel.”

A low-thrust rocket engine (LTRE) was chosen as the subject and the object of the research. Since the functional purpose of this demonstrator engine is to conduct model bench tests without simulating space conditions, the use of environmentally friendly fuel components is provided: oxygen gas О2 (oxidizer) and methane gas СН4 (fuel).

Currently, LTREs are the main executive bodies in the control system of spacecraft. They serve to orient, stabilize and correct the aircraft in space. The purpose of LTREs and the conditions of their operation impose a number of specific requirements on them, in particular the following:

– multi-mode, due to continuous operation (duration up to τв > 103 s) and various pulse modes with a minimum switching time of 0.03 s or less ;

– long service life in terms of total operating time - up to 50,000 s or more ;

– large resource in terms of total number of inclusions - up to 106.

Meeting the above requirements causes significant difficulties in the design of an LTRE, the organization of mixture formation and the working process in its combustion chamber, due to the following factors:

– low fuel consumption ;

– small number of nozzle head elements ;

– the impossibility of creating regenerative cooling;

– the difficulty of ensuring uniform distribution of mixed fuel throughout the volume of the combustion chamber.

Research object characteristics

It is known that the creation of LTRE is largely based on the results of experimental testing of prototype engines and empirical interpretation of the theoretical laws of fluid dynamics and chemical kinetics. The design, thermodynamic and gas-dynamic calculations of the demonstrator engine chamber were carried out according to the educational methods of the Department of Aircraft Engines at Re-shetnev Siberian State University of Science and Technology and the recommendations of JSC “Design Bureau of Chemical Engineering named after Alexey Mikhailovich Isaev” using SolidWorks application programs, Mathcad.

The developed demonstrator engine has the following technical characteristics:

– thrust P = 200 Н;

– oxidizer О2 (oxygen – gas , Т = 298 К);

– fuel СН 4 (methane - gas , Т = 298 К);

– oxidizer mass flow ṁо = 0,04316 kg/s;

– mass fuel consumption ṁг = 0,02439 kg/s;

– combustion chamber pressure p k = 1 MPa ;

– nozzle exit pressure pа = 0,00085 MPa ;

– engine specific impulse Jу = 2960 m/s.

The design of the engine chamber is made in the form of two monoblocks – the mixing head and the chamber body (Fig. 1), connected to each other by argon arc welding. The capabilities of SLM technology made it possible to carry out a complex design of the mixing head without making assembly units – nozzles, the topological optimization of which made it possible to additively print them in the form of holes with jet and tangential (centrifugal) supply of components to the zone of atomization and mixture formation.

Рис. 1. 3D-модели корпуса камеры и смесительной головки

Fig. 1. 3D models of the chamber body and mixing unit

3D printing equipment

The production of the engine using 3D printing technology was carried out by the industrial partner of the university, Polychrome LLC, on an ASTRA 420 printer, which was developed and manufactured at this enterprise (Fig. 2).

A special feature of the ASTRA 420 printer is the implementation of innovative solutions in dynamic modulation of the laser spot with the ability to adjust the laser power, which allows you to achieve high speeds for building parts. The ASTRA 420 3D printer can be used to solve complex production problems, in the manufacture of 3D parts and conducting research work [6; 7].

The ASTRA 420 3D printer has the following technical specifications.

Build chamber options:

– build chamber size – 420×420×280 mm;

– working stroke of the vertical movement table – 280 mm;

– table moving step – 1 mkm;

– repeatability per table stroke – ± 5 mkm;

– applying a layer of powder on the construction table – from 20 mkm (with a step 1 mkm).

Laser and optical system parameters:

– continuous IR laser, wavelength – 1080 nm;

– laser radiation power – 500 W ;

– positioning accuracy of the galvanic scanner (at the edges) – no more 10 mkm;

– exposure speed – 20–2000 m/s ;

– laser spot modulation – from 40 mkm to 2 mm ;

– laser spot modulation speed – less than 0.2 s .

Рис. 2. 3D-принтер ASTRA 420. Внешний вид

Fig. 2. 3D printer ASTRA 420. Appearance

The software includes a control program and a task preparation program. The first allows you to set technological parameters for completing a task, control all processes associated with the operation of the printer, and set movement trajectories laser spot, its modulation, control the task being performed and video record the process of building the part. The second includes software for processing STL files (geometry optimization, construction of support elements, cutting into layers).

The technical capabilities of the printer allow you to perform high-quality 3D printing CAD models using layer-by-layer selective laser melting from powders of non-ferrous metals, all types of steels, titanium, nickel, cobalt-chromium alloys and other metal materials [8].

Development of 3D printing technology

On order to increase the practical orientation of the scientific and educational project, bringing it closer to the requirements of real production, the main design, production and technological activities of the project were carried out taking into account the recommendations of the “Technological support system for the development and production of products”, which is accepted in the aerospace industry. In particular, the general methodology for technological preparation of production was used, set out in Application standard 92-4718-86 “Organization of technological development and launching of new products production” and Application standard 92-4928-90 “Basic provisions for the organization and management of technological preparation of production process”.

The SLM process belongs to the class of powder technologies [9]. The basic principle of SLM technology is to apply a thin layer of powder (20–80 microns) onto the construction table, followed by melting of a programmatically selected part of the layer of the part being built with a laser beam spot. Next, the construction table is lowered to a given height and the next layer of powder is applied to it. The selective melting process is then repeated. The process of constructing large-sized parts using SLM technology in automatic continuous printer operation mode can take up to 300 hours, depending on the size and configuration of the parts.

At the first stage of the project, in accordance with the logic of scientific research, a set of experimental work was carried out to test the manufacturing modes on an ASTRA 420 3D printer of an RDMT camera from the model powder material Silumin RS-300. The choice of this material is explained by its plasticity, low melting point and low cost. The manufactured copies of the demonstrator camera were subjected to various types of research and testing in laboratory and production conditions.

As a result, it was established that the technical characteristics of the printer ensure the implementation of innovative solutions and dynamic modulation of the laser spot with the ability to adjust the laser power, which allows you to achieve high speeds for building parts and, therefore, begin printing a chamber from the heat-resistant austenitic alloy Inconel 718.

Inconel 718 powder was selected for the chamber body and LTRE mixing head. It is known that this material was developed and patented in the USA by the author Eiselstein in 1962 [10] and is currently widely used in the aerospace and mechanical engineering industries of foreign countries. In the domestic industry, PR-08ХН53БМТУ powder is used for additive technologies Material specifica-tion(MS) 1479-704-5689-2016, which in its chemical composition is an analogue of the Inconel 718 alloy. The powder is produced by spraying the melt with an inert gas – high-pressure nitrogen. The shape of the powder particles is predominantly spherical. Manufacturer LLC "Grankom".

Previously, research work was carried out to study the melting characteristics of this powder and select printing modes. Selected modes for printing single tracks and continuous printing of samples .

The selection of modes began with a series of printing 48 samples of hollow cells in single tracks to determine the optimal combination of laser beam spot diameter, scanning speed and laser power. In the first batch of 12 samples, the spot diameter and scanning speed remained static while the laser power was varied in 15 W increments. In the second batch the speed was changed, in the third the spot diameter was changed. In the final batch, all three parameters were changed proportionally in small increments in order to determine the optimal printing mode. The results were studied using an Insein Li Fung microscope with a magnification of x10-300. The track thickness, its integrity, stability and strength were visually assessed.

The next stage of the experiments was printing three-dimensional images. The pattern (geography of filling) of the laser beam, idle speed, internal distance from the contour and step between tracks were added to the parameters established in previous experiments. The orientation of the sample in space is also important, but when working with small samples this can be neglected. The results were recorded using a microscope, and strength and porosity were assessed visually. Experiments have shown that a layer spacing of 150 µm provides the best filling and low porosity.

Balancing all of the above parameters is a primary task in SLM printing. Deviation of the mode in any direction will lead to an insufficient amount of energy supplied to the working surface and, consequently, to lack of fusion and increased porosity. The parameters can be selected based on the volume of the part: thin areas, with a small scanning area per layer, can be printed relatively quickly without the risk of porosity, and for areas of large accumulation of material, a suitable pattern is selected that will not cause overheating at the same speed. Regardless of the geometry of the part, in order to avoid the accumulation of internal residual stress, the scanning direction on each layer changes by 90° relative to the previous one.

The mixing head differs from the combustion chamber body in its massiveness and large accumulation of material throughout the entire volume. To print such a product, it was decided to manually segment it into components that would be printed sequentially in a prescribed order. This method prevents overheating on the surface while maintaining print speed. The LTRE combustion chamber was also segmented – the top and bottom of the combustion chamber were a thin-walled cylinder and cone that were printed as normal. The area that requires changing the parameters is the critical section, located at the junction of two chamber zones. This area was printed using an alternate print pattern as described above to avoid overheating. It was decided to install both models vertically, since this orientation provided the least amount of internal vertical surfaces. Supports were installed from the table to the lower surface of the parts in combination with heat sinks for reliable fixation

Thus, the parameters for printing the first LTRE sample and the mixing head were obtained, presented in the table.

Printing operating modes of LTRE combustion chamber and mixing head

|

The combustion chamber |

||||||

|

Segment |

P, W |

V, mm/s |

D, mkm |

Step, mkm |

Idle speed, mm/s |

Pattern |

|

Before the critical section |

300 |

600 |

190 |

150 |

600 |

Bidirectional optimized |

|

Critical section |

Unidirectional |

|||||

|

After the critical section |

Bidirectional optimized |

|||||

|

Mixing head |

||||||

|

Segment |

P, W |

V, mm/s |

D, mkm |

Step, mkm |

Idle speed, mm/s |

Pattern |

|

Outer layer (1.5 mm) |

300 |

600 |

190 |

150 |

600 |

Unidirectional optimized |

|

Inner layer |

Cells |

|||||

Testing of the first sample revealed the presence of porosity and leakage in the critical section area. Before printing the second sample, a series of additional experiments were undertaken to select the optimal mode for printing the critical section separately. As a result, this segment was once again divided into two equal parts, which were printed with two different patterns. The use of this approach when printing a working sample showed positive results. Porosity decreased significantly throughout the entire volume of the sample.

The above technique was applied to print the mixing head. Segmentation and delamination of the model showed a positive result; the sample had low porosity. At this stage of work, optimization of printing time was not carried out. Printing time for the camera body – 3 days, mixing head – 2 days.

Post-press technology

The shaping of chamber parts is the initial and at the same time the most critical stage of the overall technological process of manufacturing LTRE. According to some information, based on the experience of producing experimental rocket and space technology products, including the experience of the authors of this article, post-printing costs can account for more than one third of the total amount of labor costs for the production of 3D printed parts and assembly units.

Post-printing technology is developed taking into account the physico-chemical, mechanical, technological and other properties of the source material Inconel 718.

The manufacturer of the powdered material recommends heat treatment of parts made by 3D printing - hardening in a vacuum, followed by cooling in an oven while maintaining a vacuum environment and further blowing with argon. Printed chamber bodies, mixing heads and plate samples were subjected to heat treatment.

Heat treatment was carried out in a vacuum furnace SECO/WARWICK 10 VPT-4050/48 HV (Fig. 3) of the partner enterprise JSC “Krasmash”. The vacuum oven is certified to perform similar types of heat treatment.

The heat treatment modes are as follows :

– residual pressure (vacuum) in the furnace Р = 10–2 kg/sm2;

– heating speed – 20 degrees/min (~50 min);

– heat treatment temperature t = 1060 °C ;

– exposure – 60 min .

Рис. 3. Вакуумная печь SECO/WARWICK 10 VPT-4050/48 HV

Fig. 3. Vacuum furnace SECO/WARWICK 10 VPT-4050/48 HV

After cooling the parts to a standard room temperature t = 20 °C, they were subjected to abrasive treatment (sandblasting) using artificial abrasive – F-120 electrocorundum at an air-abrasive mixture pressure P = 4 kg/cm2 for 5–8 minutes.

A study was conducted of the influence of the 3D printing process on the chemical composition of the source material. Non-heat-treated and heat-treated printed samples were studied. The study was carried out in the mass spectrometry laboratory of JSC Krasmash using a 67A1053 HITACHI PMI-MASTER UVR spectrometer. As a result of the research, it was established that the chemical composition of the samples meets the requirements stated by the manufacturer in the certificate of the Inconel 718 material,

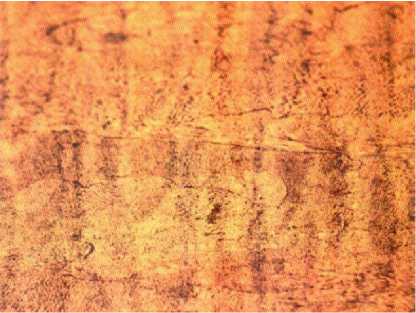

Рис. 4. Микроструктура материала без термообработки

Fig. 4. Material microstructure

without heat treatment

and also meets the requirements of the foreign standard AMS 5663M. Thus we can conclude that the process of selective laser melting and subsequent high-temperature heat treatment does not affect the chemical composition of the material and does not lead to a change in the balance of alloying elements of the alloy.

Metallographic analysis was carried out by viewing microsections of heat-treated and non-heat-treated samples after etching in a special reagent on a NICON ECLIPSE MA200 microscope at a magnification of 50 to 1000 times in a research laboratory. skom center of JSC “Krasmash”.

It was established that the structure of the micro- structure of the material without heat treatment in some areas has structural banding (Fig. 4), due to the manufacturing method by layer-by-layer laser fusion. The microstructure of the samples is austenite with precipitates of intermetallic compounds (such as the γ`-phase). In the microstructure of samples without heat treatment, grain boundaries are not detected. The grain sizes of heat-treated samples correspond to those for alloyed austenitic steels and alloys. In the non-heat-treated material, single local discontinuities with spherical particles are observed, there are defects in the form of oxide films with a length of 0.06–0.35 mm and areas of pore accumulation with a size of 0.015–0.085 mm. In heat-treated samples, such defects are not clearly visible, but microporosity is preserved (in smaller sizes). The results of metallographic analysis are in sufficient agreement with the studies of other authors [11–13].

In order to more accurately identify spatial defects in the material of printed products, radiographic inspection of engine chamber housings was carried out. The studies were carried out in areas accessible for control using a YXLON MG-103 X-ray machine. At the same time, discontinuities in the form of individual point voids with dimensions 0.3–1 mm and ring discontinuities with an intensity of 0.1– 0.2 mm elongated along the printed layers with a deterioration in print quality in the zone of the critical section of the nozzle and an increase in porosity in areas measuring 0.5–2 mm [14] .

The roughness control of the internal and external surfaces of the camera body was carried out using a Surftest SJ-201 device, which has a verification certificate from the State Regional Center for Standardization, Metrology and Testing. Due to the lack of a standard technique and special devices for measuring actual roughness values, the most characteristic areas were identified on the internal surfaces of the supersonic part of the nozzle and the cylindrical part of the combustion chamber. A total of 7 areas are allocated, accessible for control using universal means included in the device. As a result measurements, actual roughness values were obtained in the range Ra = 14.4–23.84 μkm, which significantly exceed the roughness parameters of the internal surfaces of liquid-propellant rocket engine chambers accepted in rocket engine construction (Ra = 2.5–3.6 μkm). Thus, the next task in developing the optimal finishing technology for the LTRE camera is choosing a method to improve the quality of product surfaces.

One of the effective and proven methods in the mass production of shells of rocket engine chambers is electrochemical polishing (hereinafter referred to as electropolishing), which is based on the intensive dissolution of microprotrusions of surface roughness and the slow dissolution of cavities [15; 16]. The processing process was carried out in a cathode-anode bath with a solution of sulfuric acid (H2SO4), phosphoric acid (H3PO4) and chromic anhydride (CrO3) in a certain concentration of each substance. Processing modes have been experimentally selected for chamber bodies and mixing heads:

Рис. 5. Камера РДМТ в сборе

– voltage V = 8,8 V;

– current magnitude I = 90–40 А;

– time of processing t = 4–6 min.

Next, washing operations were carried out in cascade baths with cold and hot water, clarification in a solution of nitric acid (HNO3), and neutralization in a solution of calcium carbonate (Na2CO3). Roughness control was carried out by comparison with a standard (roughness sample) and showed acceptable convergence of actual roughness parameters to the requirements of the drawing.

In accordance with the research program, the physical and mechanical parameters and characteristics of printed products were determined (breaking point σв, yield σ0,2, modulus of rigidity Е etc.), hardness measurements on samples, vibration tests, strength and tightness tests. A description of the methods and these studies results analysis is not provided in this article. Separately, it should be noted that during leak testing of the first of the printed samples of the cam-

Fig. 5. LTRE chamber assembly

era body, a leak was detected in the critical section area. This confirms the conclusions about the developed porosity of the material of this sample during X-ray inspection. As shown in one of the previous sections of the article, adjustments were made to the printing modes, ensuring the tightness of the products printed further.

At the end of the technological process of post-printing processing, mechanical preparation of the joining surfaces and manual argon arc welding of the camera body and mixing head were carried out. Welding was performed with a non-consumable tungsten electrode with a filler wire with a diameter Ø1,5 mm, printed from Inconel 718 powder on 3D printer. Due to the lack of recommendations in the industry's regulatory and technological documentation for welding printed parts made of this material, welding modes were tested on printed flat and cylindrical simulator samples.

Figure 5 shows the assembled LTRE chamber: threaded fittings for supplying fuel components are installed and welded onto the mixing head. The quality of welded joints is checked by leak testing using the “aquarium” method. A socket is installed on the lower cylindrical section of the combustion chamber to secure the thermoelectric sensor. A spark plug is installed in the central hole of the mixing head using a threaded connection with a metal seal. .

LTRE Bench Tests

When creating new designs of rocket engines, developing and implementing innovative technologies for their industrial production, bench fire tests are carried out, which are the main means of checking the validity of the adopted design and technological decisions, monitoring the specified design parameters and characteristics of the work process, assessing the performance and reliability of products [17; 18].

For this purpose, during the implementation of the project, a test bench complex was developed and manufactured on the territory of the “Ustanovo” suburban testing ground (Fig. 6). The test bench includes the following systems:

-

– fuel component supply system. It consists of two parts: an oxidizer supply system and a fuel supply system. Structurally, these systems are made separately in the oxidizer and fuel compartments. The compartments are subject to requirements for the tightness of the systems, the use of materials that do not react with fuel components and prevent sparking during the operation of the stand. The system includes two high-pressure cylinders with oxygen gas and methane gas, lines for supplying fuel components made of stainless steel, and gas reducers;

-

– ignition system of fuel components in the combustion chamber. Consists of power supply unit and spark plug 6213 NGK SILMAR9A9S;

-

– measurement system. This system is the most important when conducting bench tests, since it is from the results of measuring a wide range of parameters of the propulsion system that both the conditions for conducting bench tests and the operation of the engine are determined. It includes a draft measuring device, pressure and flow sensors of components. In this regard, the measurement system must perform the function of visual monitoring of the main parameters of the engine and the stand, remote measurement according to a given program, storing information on media, and also ensure high accuracy and safety of measuring instruments and have high noise immunity of its measuring instruments;

-

– control system. Designed for automatic starting, changing operating and stopping modes, automatic control of some basic engine parameters. When critical values are reached, it gives a signal and also provides, if necessary, an emergency stop, automatic control of pipeline valves and maintenance of specified pressures. When performing preparatory and final operations, manual control of the stand elements is used;

-

– safety system. Explosion and fire safety of the stand consists of dividing the stand into compartments of a chamber, oxygen cylinders, methane cylinders, control lines, fire extinguishing equipment, as well as emergency stop control .

Рис. 6. Общий вид рабочей зоны стендового испытательного комплекса

-

Fig. 6. General view of the bench testing complex working area

The first fire bench tests of a low-thrust rocket engine manufactured using additive technologies (code name: LTRE “Fakel-1”) took place on September 15, 2023 (Fig. 7). In accordance with the developed and approved test cyclogram, five starts were carried out with a working cycle duration of 1.5 s, followed by purging of the lines with air for 180–300 s. A stable appearance of a torch at the nozzle exit, a stable cut-off of the supply of fuel components and the cessation of combustion of the mixture of components in the combustion chamber were recorded. The thrust measuring device measured the engine thrust, which approximately corresponds to the calculated value Р = 200 Н (20 kg). In order to guarantee the safety of personnel and test bench equipment, the supply pressure of gaseous components at the engine inlet was reduced by 35–40% compared to the design pressure in the combustion chamber (рк = 1 МPa). In this case, the achieved thrust value at reduced pressure should be explained by the operation of the nozzle in the overexpansion mode, since the ambient barometric pressure (conditionally р н = 0,1 МPa) significantly exceeds the calculated pressure of the gas flow at the nozzle exit (р а = 0,00085 МPa).

Рис. 7. Огневые испытания РДМТ

-

Fig. 7. LTRE fire test

After dismantling, a visual inspection of the condition of the engine surfaces was carried out (visual defect detection of the product – according to industry terminology). During an external inspection of the external and internal surfaces of the engine (in accessible places) using local illumination and a standard technical magnifying glass of four times magnification, no surface damage was found that would prevent repeated testing.

Conclusion

In the process of implementing the scientific and educational project “Development, production by selective (additive) laser alloying and testing of a low-thrust demonstrator rocket engine operating on environmentally friendly fuel,” a significant amount of research, development, and educational and laboratory work was carried out to study and the practical application of innovative additive technologies, which have great potential for the accelerated development of the rocket and space industry.

Project participants, including students from Reshetnev University, gained new knowledge and skills in conducting practical work in the field of mechanical engineering and metallurgical production, metrology, assembly and installation operations, laser, electrochemical and other technologies used in rocket engine construction. New professional competencies were obtained that contribute to the intellectual development of Reshetnev University students – future specialists of aerospace industry enterprises.

At the same time, it should be concluded that the use of additive 3D printing technologies in the manufacture of complex and highly loaded rocket and space technology products requires a large complex of scientific research and production and technological tests to confirm the stability of characteristics and reliability indicators with subsequent certification of the innovative technology for compliance with the requirements.

Реализация научно-исследовательского проекта осуществляется при поддержке благотворительного фонда известного государственного и общественного деятеля, предпринимателя, почетного гражданина Красноярского края Х. М. Совмена.

Поддержку проекту оказывали также индустриальные партнеры СибГУ им. М. Ф. Решетнева: ООО «Полихром», АО «Красмаш», АО «КБхиммаш им. А. М. Исаева», ООО «Вариант 999», АО «ОКБ Зенит».

Acknowledgements

The implementation of the research project is carried out with the support of the charitable foundation of the famous statesman and public figure, entrepreneur, honorary citizen of the Krasnoyarsk Territory Kh. M. Sovmen.

The project was also supported by industrial partners of Siberian State University: “Polychrome” LLC, “Krasmash” JSC, “KBkhimmash named after A.M. Isaev” JSC, “Variant 999” LLC, “OKB Zenith” JSC.

Список литературы Characteristics research of a low thrust rocket engine manufactured using additive SLM technology

- Logacheva A. I. [Additive technologies for rocket and space technology products: prospects and problems of application]. Tekhnologiya legkikh splavov. 2015, No. 3, P. 39–44 (In Russ.).

- NASA tests limits of 3D-prnting with powerfull rocket engine check. Available at: http://nasa.gov (accessed: 15.11.2023).

- Belov S. V., Volkov S. A., Magerramova L. A., et. al. [Prospects for the use of additive technologies in the production of complex parts of gas turbine engines from metal materials]. Sbornik nauchnykh trudov nauchn. konf. “Addivnye tekhnologii v rossiyskoy promyshlennosti” [Сollection of scientific papers Scientific. Conf. “Additive technologies in Russian industry”]. Мoscow, 2015, P. 101–102 (In Russ.).

- Terekhov M. V., Filippova L. B., Martynenko A. A., et. al. Additivnye tekhnologii [Additive technologies]. Мoscow, FLINTA Publ., 2018, 74 p.

- GOST R 59036–2020. Additivnye tekhnologii. Proizvodstvo na osnove selektivnogo lazernogo splavleniya metallicheskikh poroshkov. Obshchie polozheniya [State Standard R 59036-2020. Additive technologies. Production based on selective laser melting of metal powders. General provisions]. Moscow, Standartinform Publ., 2020. 22 p.

- GOST R 59184–2020. Additivnye tekhnologii. Oborudovanie dlya lazernogo splavleniya. Obshchie trebovaniya [State Standard R 59184-2020. Additive technologies. Equipment for laser melting. General requirements]. Moscow, Standartinform Publ., 2020. 18 p.

- Preobrazhenskaya E. V., Borovik T. N., Baranova N. S. Tekhnologii, materialy i oborudovanie additivnykh proizvodstv [Technologies, materials and equipment for additive manufacturing]. Мoscow, RTU MIREA Publ., 2021, 173 p.

- Gu D. D., Meiners W., Wissenbach K., Poprawe R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. International Materials Reviews, 2012, No. 57 (3), P. 133–164.

- Additive Manufacturing. With Amperprint for 3D-Printing you Have the Powder to Create. Available at: https://www.hoganas.com/en/powder-technologies/additive-manufacturing/3d-printingpowders/ (accessed: 15.11.2023).

- Eiselstein H. L. Age-hardenable nickel alloy. Patent US, no. 3046108A, 1962.

- Zhigurova E. E., Mumber K. E., Kazakov R. A., et. al. [Metallographic analysis of a 3D printed chamber]. Мaterialy ХХVI Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials ХХVI Intern. Scientific. Conf “Reshetnev reading”]. Krasnoyarsk, 2022, P. 175–177 (In Russ.).

- Nazarov E. G., Maslenkov S. B. [Heat treatment of austenitic heat-resistant steels and alloys]. Metallovedenie i termicheskaya obrabotka metallov. 1970, No. 3, P. 63–72 (In Russ.).

- Pedash A. A., Lysenko N. A., et. al. [Structure and properties of samples from Inconel 718 alloy obtained using selective laser melting technology]. Aviatsionno-kosmicheskaya tekhnika i tekhnologiya. 2017, No. 8, P. 46–54 (In Russ.).

- Manokhina E. S., Shikarev M. A., Rubaylo A. P., et. al. [Analysis of the results of x-ray studies of RCT products manufactured by SLM printing]. Мaterialy ХХVI Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials ХХVI Intern. Scientific. Conf. “Reshetnev reading”]. Krasnoyarsk, 2022, P. 186–187 (In Russ.).

- Krasnova E. V., Saushkin B. P., Slyusar' I. A., Smeyan S. V. [Electrochemical processing of additive manufacturing products from metals and alloys]. Additivnye tekhnologii. 2023, No. 2, P. 49–57 (In Russ.).

- Zhao C., Qu N., Tang X. Removal of adhesive powders from additive manufactured internal surface via electrochemical machining with flexible cathode. Precision Engineering, 2021, Vol. 67, P. 438–452. DOI: 10.1016/j.precisioneng.2020.11.003.

- Yatsunenko V. G., Nazarov V. P., Kolomentsev A. I. Stendovye ispytaniya zhidkostnykh raketnykh dvigateley [Bench testing of liquid-propellant rocket engines]. Krasnoyarsk, Sib. St. Univ. Publ., 2016, 248 p.

- Nazarov V. P., Piunov V. Yu., Golikovskaya K. F., Nazarova L. P. [Simulation modeling of bench test conditions of liquid rocket engines of low-thrust]. Мaterialy ХХVI Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials ХХVI Intern. Scientific. Conf “Reshetnev reading”]. Krasnoyarsk, 2022, P. 191–192 (In Russ.).