Comparative analysis of innovative socks made from special synthetic fibers

Автор: Brner G., Arici B., Rohrbach C., Mahltig B.

Журнал: Вестник Витебского государственного технологического университета @vestnik-vstu

Рубрика: Технология материалов и изделий текстильной и легкой промышленности

Статья в выпуске: 4 (50), 2024 года.

Бесплатный доступ

Functional textiles cover a broad range of different materials and products. The term of functionality is related to properties which are typically not reached with conventional textiles. A functional property can be flame retardancy, antistatic or antimicrobial action. The addition of such functional properties is often demanded for very different types of clothes. To focus this actual report, an overview on functional socks as commercial products is given. A special view is made on the fiber composition of these socks and the thermal insulation of the product. For this, six different commercially available socks are considered which are all claimed to certain functional properties. Also, a reference material - sock without especially claimed functional property - is discussed. All socks contain at least one of the conventional fibers as polyester, polyamide and cotton. Five socks contain elastane in an amount of 2 % to 6 %, to improve the fit of the products. Claimed functional properties are achieved by a content of high - performance fibers in these knitted products. Modacrylic fibers with chlorinated co - unit are used to achieve flame - retardant properties. The use of conductive fibers, as e.g. carbon fibers, leads to antistatic properties. Only for one product a biocide application is mentioned for realization of an anti - insect effect. The socks are investigated by using scanning electron microscopy (SEM) and a test set - up for determining the thermal insulation properties by using a heat camera measuring the surface temperature. The thermal insulation properties of the socks can be clearly determined. However, the intensity of insulation strongly depends on the type of product and the area of measurement - foot ball, instep or heel. Finally, it can be stated that a broad range of different materials are used to create functional socks. For this, socks are excellent examples for textile functional products realized with special synthetic fibers.

Socks, functional textiles, high-performance fibers, thermal isolation

Короткий адрес: https://sciup.org/142244112

IDR: 142244112 | УДК: 677.017 | DOI: 10.24412/2079-7958-2024-4-59-68

Текст научной статьи Comparative analysis of innovative socks made from special synthetic fibers

УДК 677.017 DOI:

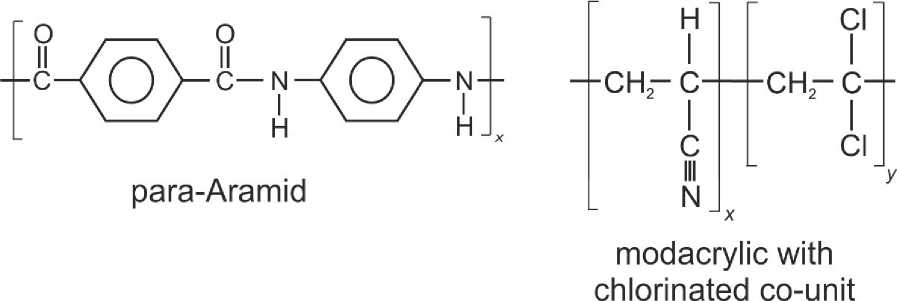

The functionalization of textiles refers to their aimed functional modification with additional or improved properties with regard to a specific application. A distinction can be made between the fiber-specific, physical properties and the, mostly superficial added properties, which are mainly realized by finishing processes. Functional fiber-specific properties can be realized by addition of high-performance fibers (Mahltig & Grethe, 2022). Prominent examples for high-performance fibers are Kevlar (para-aramid) for cut-resistance and flame-retardancy or modacrylic with chlorinated co-units (Kanecaron) for flame-retardancy (Mahltig & Grethe, 2022;

For the current overview, six different commercially available socks are considered which are all claimed to certain functional properties. Also, a reference material – sock without especially claimed functional property – is discussed. One aim of the current study is to report on the broad variation of functional properties and materials which are commercially available with textile socks. A special view is done on the used fiber materials and high-performance fibers. For evaluation of thermal insulation properties, a simple test is developed which is set in simple relation to consumer application and the textile sock as special product. The description of the testing procedure by using a heat camera can be as well used to transfer this test set-up for evaluation of other types of clothes and is by this of general interest for people, who are working in the field of functional textiles and clothing products.

Figure 1 – Chemical structures of polymers related to high-performance fibers – left: para-Aramid; right: acrylic with chlorinated co-unit for flame-retardant properties

|

No. |

Name |

Supplier |

Mentioned Labels & Standards |

|

R |

Herren Vollfrotteesocken “Men's full terry socks” |

Ronly |

Oeko Tex Standard 100 |

|

1 |

Flammschutz Arbeitssocken “2505” schwarz “Flame retardant work socks “2505” black” |

Blaklader Workwear |

EN 1149; EN 14116 |

|

2 |

Tech Summer Socks |

Diadora Utility |

ISO 9001:2015 |

|

3 |

ESD Funktionssocke-Sommer Schwarz/Grau “ESD functional socks summer black/gray” |

Runnex |

CE-Label |

|

4 |

SK24 Bamboo Hiker Socks |

Portwest |

Not mentioned |

|

5 |

BHP001 Thermoactive Workwear Socks |

Brubeck Protect |

Not mentioned |

|

6 |

Top Flame Long |

Cofra |

EN 11612A1B1C1:2008, EN1149-5:2008 |

Materials and Products

For the current overview on commercially available textile socks, seven different products are considered (Table 1). Six products are distributed by the suppliers with claimed functionals properties. These products are named as sample 1 to 6. As reference material, conventional sock is chosen, which is sold for clothing purposes without claiming further functional properties. This product is named as sample R and is the only one in this selection carrying an Oeko Tex Label (Table 1). For the two samples 1 and 6 dedicated to flame retardant properties, standards related to flame retardancy and antistatic properties are given.

An overview on functional properties and the containing fiber materials as given as supplier information is listed in Table 2. All socks contain at least one of the conventional fibers as polyester, polyamide and cotton. Five socks contain elastane in an amount of 2 % to 6 %, to improve the fit of the products. Also, for the reference sample properties as “warming” and “high wearing comfort” are mentioned. Claimed functional properties are achieved by a significant content of high-performance fibers in

Table 2 – Overview on discussed functional socks, presented are functional properties, fiber materials and further information on composition mentioned by the supplier. The sample sock R is a reference material without special promotion as functional textile material

Analytical Methods

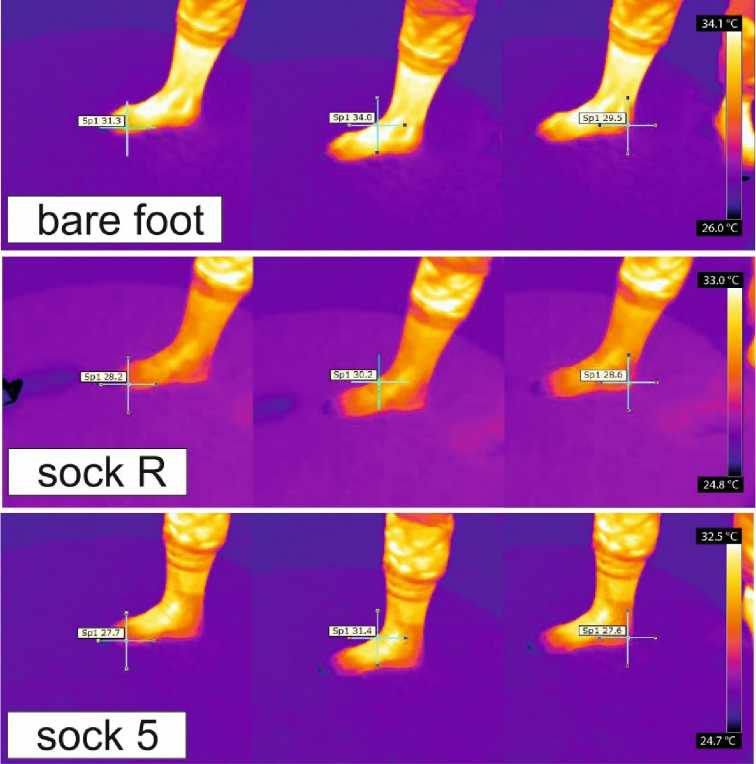

Microscopic investigations are done by scanning electron microscopy using a Tabletop microscope TM3000 from Hitachi (Japan). The samples are investigated as received and no further pretreatment is done before microscopic measurements. The thermal properties of the socks are evaluated using a heat camera type FLIR-P640 (InfrarotTec Systems, Ranstadt, Germany). For thermal insulation measurements, all socks are investigated in worn condition by using the heat camera. For reference, a measurement is done at bare feet. To ensure comparability of the results, the foot was acclimatized, by being barefoot for a minute between each measurement. By using the heat camera, a photo is recorded after wearing the sock for three minutes. Examples for such photographs are presented in Figure 2. Afterwards the camera recorded the temperature of the foot at three different points – the ball of the foot, on the instep and on the heel.

Microscopic investigations

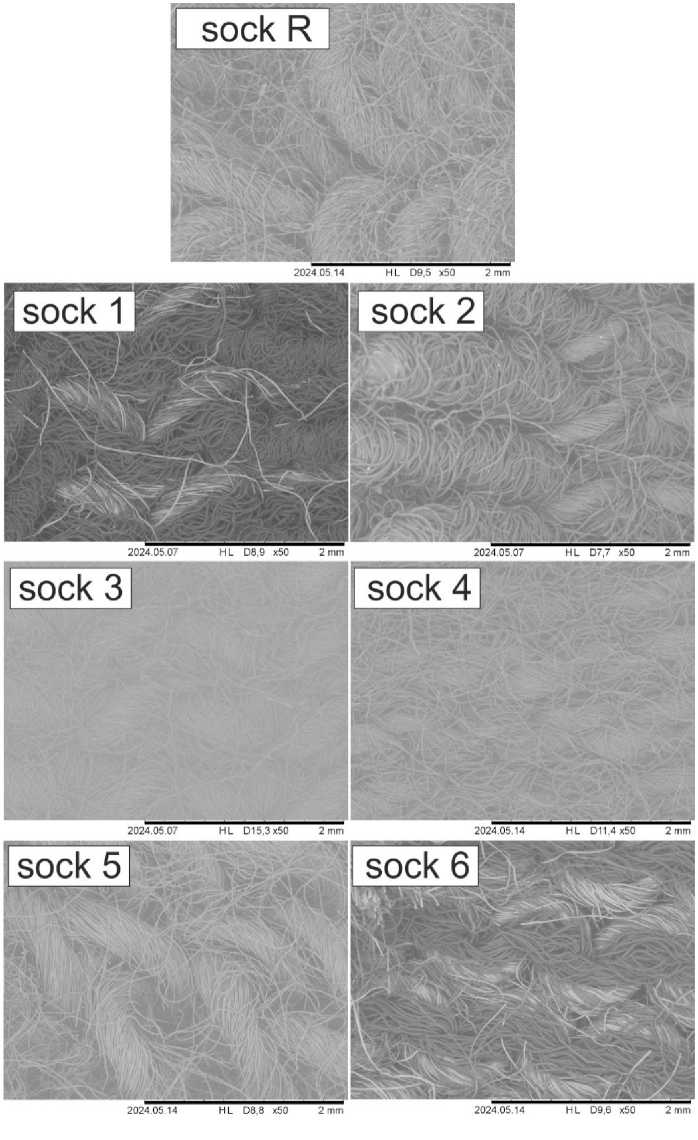

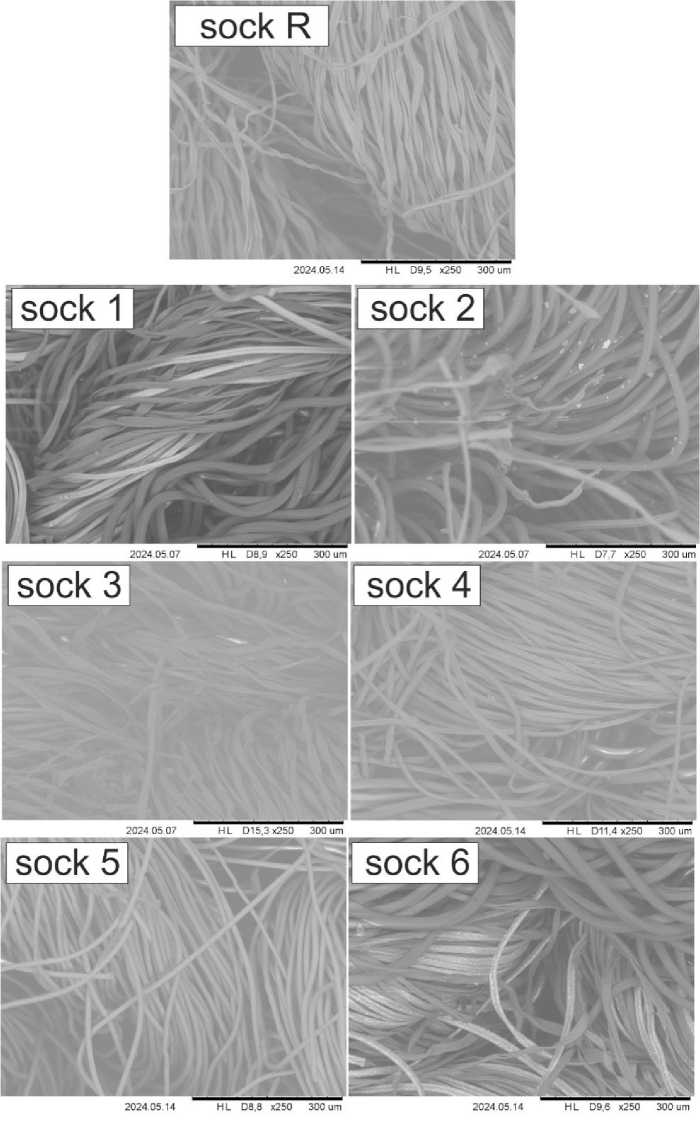

The structure of the knitted fabrics and the yarn structure of all seven products are evaluated by scanning electron microscopy (SEM). SEM images taken in low and medium magnification are presented in Figures 3 and 4.

Figure 2 – Images taken with heat camera on bare foot and foot covered by different socks. The temperatures are recorded after three minutes at three different positions of the foot (ball, instep, heel)

Thermal investigations

The investigation of thermal insulation properties, is done by determination of the surface temperature of the foot carrying the socks. The surface temperatures are determined at three different positions of the foot – the ball, instep and heel. Among these positions, for the instep the highest temperature is determined. Reference measurements are done with the bare foot. For the bare

Figure 3 – Microscopic images of the different socks recorded with scanning electron microscopy in low magnification. Samples for microscopy are taken from the shaft of the socks

Figure 4 – Microscopic images of the different socks recorded with scanning electron microscopy in medium magnification. Samples for microscopy are taken from the shaft of the socks foot, surface temperatures in the range of 29.5 to 34 °C are determined, which are below the body temperature of 36 °C for humans. A foot covered by the reference sample sock R shows a significantly decreased surface temperature. This decreased surface temperature indicates a thermal insulation caused by the sock. This effect is strongest for the measurement area of the instep. The functional socks 1 to 6 exhibit results strongly dependent on the measurement area. For the ball area, the thermal insulation of the functional socks is quite similar to the reference sock. Here, sample sock 4 exhibit the highest thermal insulation and sample sock 1 the lowest insulation (even lower than the reference sock). For the instep area, all functional socks exhibit higher surface temperatures compared to the reference sock, so a kind of cooling effect might be claimed. However, this cooling effect can be only claimed in comparison to the conventional sock and not to the bare foot. For the heel area, the functional socks 1 to 3 are quite similar to the conventional sock but the socks 4 to 6 exhibit significant lower thermal insulation properties. Based on these measurements, overall for the product samples 4 to 6 it is justified to claim a cooling effect comparable to conventional socks.

In the area of functional textiles, there are many options for equipment, properties and manufacturing processes to produce them. Combining different materials opens up additional possibilities. As well as through the use of fiber mixtures and high-performance fibers. The seven textile socks tested differ greatly in their material composition, but also have some similarities. All socks contain a certain percentage of cotton, except for the sample 4, which uses bamboo instead. In addition, the socks, with the exception of sample 6, contain elastane to increase elasticity and fit. The main properties resulting from the material compositions of the socks are clearly different, as each sock is tailored to its specific purpose. Their thermal insulation capacity fluctuates accordingly. However, the measured surface temperatures might differ from the personal impression of consumers, due to personal circumstances. Not only the insulation performance and material composition are crucial for wearing comfort, but also the surface construction of the product. All socks have heel and toe areas reinforced with terry cloth. The reference sock does not have any extra reinforced areas as it is a full terry cloth sock. In conclusion, it can be stated that the thermal insulation performance of socks is an important property contributing significantly to the wearer's subjective perception of comfort. Since every person finds a different temperature comfortable, it might be difficult to make a uniform statement about the insulation performance of socks. What counts here is not just the subjective perception of the wearer, but also the combination of the material and other functional properties of the sock. Measured values, manufacturer information and material compositions give the consumer an information as to whether the product might be suitable for their intended use and their personal body feeling. However, the consumer only gains real security

Table 3 – Temperature overview after thermal tests on the socks; the surface temperature determined at different foot positions in comparison to the bare foot and the reference sock R

Conflicts of interest

The authors declare no conflict of interest in the authorship or publication of this paper. All product and company names mentioned in this article may be trademarks of their respected owners, even without labeling.

Funding

The presented work and results are realized without special funding. All presented functional textile materials are purchased on the free market.

Список литературы Comparative analysis of innovative socks made from special synthetic fibers

- Alvarez, J., Ławińska, K. and Falkiewicz-Dulik, M. (2020). Quality assessment of viscose bamboo fabrics intended for use inside children's and special footwear. Fibres & Textiles in Eastern Europe, vol. 28, pp. 82-88. EDN: CLEDPS

- Cheng, R., Dong, K., Liu, L., Ning, C., Chen, P., Peng, X., Liu, D. and Wang, Z.L. (2020). Flame - retardant textile - based triboelectric nanogenerators for fire protection applications. ACS Nano, vol. 14, pp. 15853-15863. EDN: IRLQAA

- Kaplan, S. and Akgünoğlu, B. (2021). Transfer and friction characteristics of sports socks fabrics made of synthetic fibres in different structures. Tekstilec, vol. 64, pp. 325-337. EDN: HBDYRU

- Lam, Y.L., Kan, C.W. and Yuen, C.W.M. (2012). Developments in functional finishing of cotton fibres - wrinkle - resistant, flame - retardant and antimicrobial treatments. Textile Progress, vol. 44, pp. 175-249. EDN: RORYEN

- Mahltig, B. and Grethe, T. (2022). High - performance and functional fiber materials - a review of properties, scanning electron microscopy SEM and electron dispersive spectroscopy EDS. Textiles, vol. 2, pp. 209-251. EDN: TKSTCP

- Mahltig, B. (2021). High - performance fibres - a review of properties and IR - spectra. Tekstilec, vol. 64, no. 2, pp. 96-118. EDN: ATLLGI

- Miao, D., Wang, X., Yu, J. and Ding, B. (2022). Nanoengineered textiles for outdoor personal cooling and drying. Adv. Functional Mater., vol. 32, art. 2209029.

- Statista, (2024). Umsatz mit Outdoor-Ausrüstung weltweit in den Jahren 2019 bis 2024 mit einer Prognose bis 2029, [Online], Available from: https://de.statista.com/statistik/daten/studie/1343181/umfrage/umsatz- mit - outdoor - ausruestung - in - deutschland/ last (Accessed: 6 August 2024).

- Statista, (2024). Umsatz mit Strumpfwaren in Deutschland in den Jahren 2018 bis 2023 mit einer Prognose bis 2028, [Online], Available from: https://de.statista.com/statistik/daten/studie/672190/umfrage/umsatz-mit-strumpfwaren- in-deutschland/last (Accessed: 6 August 2024).

- Zhang, L., Chen, T., Xu, H., Liu, X., Zhang, J. and Chai, R. (2023). Simultaneously enhanced flame retardancy and smoke suppression properties of flexible polyvinyl chloride with the incorporation of modified Mg(OH)2 and Sb2O3. Materials Today Communications, vol. 34, art. 105448.