Composite binders with superabsorbent polymers

Автор: Lesovik V.S., Popov D.Yu., Fediuk R.S., Usanova K.Iu.

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 3 (108), 2023 года.

Бесплатный доступ

The object of research is a composite binder with superabsorbent polymers. The work aims to research the combined action of composite binders and superabsorbent polymers. Methods. The particle sizes distribution of the composite binder was studied by laser granulometry. The fresh properties of the mix were determined by examining the slump flow. The average density was calculated by dividing the mass of the sample by its volume. The compressive strength was studied under a static load on the press on samples with a rib of 70 mm at 3, 7, and 28 days of age. Results. Obtaining polymineral composite binders was carried out by joint grinding of Portland cement CEM I 42.5 N and wet magnetic separation (WMS) waste to a specific surface area of ≈ 550 m2/kg in a vibration mill, followed by the introduction of pre-ground Opoka-like marl (Ssp ≈ 700 m2/kg) used as a mineral modifier. Joint grinding of cement and WMS waste in different percentages and introducing the optimal amount of a mineral modifier made it possible to identify the effect of the composition on the compressive strength. When tested on the 28th day of hardening of the compositions CB-3 and CB-2, an increase in the compressive strength by 82.2 and 60.3%, respectively, was found, while in the composition of CB-1, there was a decrease in the compressive strength by 14.5%. As a result of joint grinding to an equal specific surface, despite the different ratios of components and their hardness, an almost equal grain composition of polymineral composite binders was achieved. Taking into account the increase in the strength of the developed compositions of polymineral composite binders, optimized by the chemical modifier, and the losses caused by the introduction of SAP into the cement system, the effectiveness of the use of CB-2 and CB-3, due to strength compensation, in combination with SAP modification B3 (

Concretes, composite, binder, superabsorbent, strength, polymer

Короткий адрес: https://sciup.org/143180503

IDR: 143180503 | УДК: 69 | DOI: 10.4123/CUBS.108.3

Текст научной статьи Composite binders with superabsorbent polymers

The growing potential of the global construction complex is due to the use of modern achievements in engineering and technology in construction and building materials science [1]. The development of society is associated with the creation of a comfortable human environment, including through the use of achievements in architectural materials science [2]. For this to be implemented, advanced approaches and techniques are needed in the design and synthesis of building materials, which consist of the rational choice of raw materials and a complex of chemical modifiers that allow for achieving the specified physical and mechanical characteristics of products [3]. Particular importance is given to this when creating thin-walled reinforced composites, such as textile concrete, the use of which makes it possible to reduce the energy and material consumption of structures, expand the scope of concrete and open up advanced opportunities in architecture when creating spatial and filigree forms [4,5].

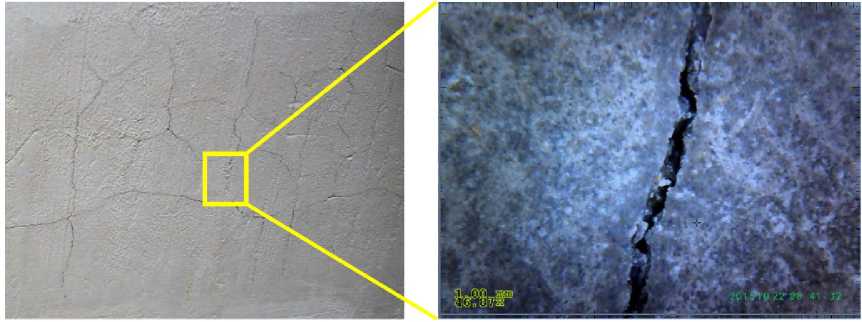

An important stage in the creation is to provide conditions for forming textile concrete [6]. As a rule, structures made of textile concrete or concrete structures reinforced with it have a large open surface area at the early stage of hardening, when the cement matrix has not yet gained the necessary strength due to the action of the environment, the influence of plastic shrinkage on the formation of a high-quality surface of the material and strength, in general, is great. Plastic shrinkage of cement materials causes the formation of cracks on the concrete surface (Figure 1), which in the case of textile concrete, due to the thinness of the composite itself, can lead to its destruction [7,8].

a) b)

Fig. 1 - Cracks in the surface of textile concrete as a result of plastic shrinkage (a) with an increase in the selected area (b)

One of the most important conditions for reducing plastic shrinkage and preventing cracking of textile concrete at an early age is proper care at the stage of hardening of the cement matrix [9–11]. To reduce shrinkage, external and internal care methods are carried out [12,13]. External care implies favorable heat and humidity conditions for hardening [14,15]. This can be achieved by using water-saturated coatings (wet burlap, sawdust, etc.), synthetic protective coatings, protecting a freshly molded structure from direct exposure to wind and solar radiation, using fogs, etc. [16,17]. Internal care involves introducing special components into the concrete mix, providing the necessary moisture balance [18]. Such agents can be either conventional aggregates introduced into the concrete mix in a wet state or additional components (for example, absorbent additives or special fillers) [19]. Internal care provided by absorbed water minimizes plastic shrinkage from rapidly drying textile-concrete surfaces exposed to unfavorable dry conditions [20,21,30,22–29].

A sharp increase in deformations falls on the period of hardening of the cement matrix in the time interval from about 4 to 10 hours [21]. These deformations are caused by plastic shrinkage of the mix that has not yet hardened, which leads to a violation of the material's structure and the formation of cracks, and in the case of thin-walled concrete products, to their destruction [22].

Plastic shrinkage results from the rapid water loss from the concrete surface because of evaporation [23]. Insufficient curing and lack of protection of the concrete surface exposed to adverse environmental conditions (strong wind, high air temperature, low humidity) are the main causes of deformation of concrete at an early stage of curing, which is still in a plastic (uncured) state [24]. The amount of water loss from the concrete surface is much greater than the amount of moisture available to replenish the lost surface moisture [25]. Accordingly, a direct consequence of this disproportion is the physical process of increasing capillary pressure in micropores, which causes compression of the system, which, in turn, can lead to the formation of cracks [26].

Despite this, there is still a lack of research on the combined action of composite binders and superabsorbent polymers, which is the goal of this article.

The tasks to achieve this goal are developing composite binders, studying the influence of binder components on strength properties, and studying the effect of superabsorbent polymers on material properties.

-

2 Materials and Methods

The production of polymineral composite binders (CB) was carried out by joint grinding of Portland cement CEM I 42.5 N and wet magnetic separation (WMS) waste to a specific surface area of ≈ 550 m2/kg by a vibration mill, followed by the introduction of pre-ground Opoka-like marl (specific surface area Ssp ≈ 700 m2/kg), used as a mineral modifier (MM). A separate introduction of MM is due to the rationality of the preparation of CB, and the choice of the value of the specific surface area is due to an increase in pozzolanic activity with an increase in fineness and a significant decrease in the grindability of marl when a given S sp is reached.

The characterization of the superabsorbent polymers used in the paper is presented in Table 1.

Table 1. SAP characterization

|

Brand |

Modification |

Partical size, µm |

Designation in the article |

|

Floset |

B3 |

<200 |

SAP B3 fine |

|

200-500 |

SAP B3 coarse |

||

|

B4 |

<200 |

SAP B4 fine |

|

|

200-500 |

SAP B4 coarse |

The superplasticizer Glenium-51 (BASF, Germany) was used to reduce a water-to-binder (W/B) ratio and increase the efficiency of polymineral composite binders and Portland cement.

At present, composite binders of a new generation are produced by joint grinding of the main hydraulic binder and mineral additives. This eliminates the drying process, which requires additional energy costs. Numerous studies have proved the effectiveness of this method. In this connection, further research aimed to develop the compositions of polymineral composite binders and determine the optimal dosage of the main components. Optimization of CB compositions was carried out using the mathematical method of experiment planning. The content of WMS waste in the composition of the composite binder (15, 30, and 45% by weight of cement) and the content of Opoka-like marl used as a mineral modifier (MM) (2, 3, and 4% by weight of CB) acted as varied factors (Tables 2 and 3). The choice of CB variation levels was carried out based on the results of preliminary studies with mineral components. The output parameter was the ultimate compressive strength. Pure Portland cement served as control samples.

Table 2. Experiment design levels

|

Factors |

Levels of variation |

Variation interval |

|||

|

natural view |

code view |

-1 |

0 |

+1 |

|

|

WMS waste by cement weight, % |

X 1 |

15 |

30 |

45 |

15 |

|

MM by CB weight, % |

X 2 |

2 |

3 |

4 |

1 |

Table 3. Experiment planning matrix

|

Plan point number |

Factors |

|||

|

X 1 |

X 2 |

|||

|

1 |

-1 |

15 |

-1 |

2 |

|

2 |

-1 |

15 |

+1 |

4 |

|

3 |

-1 |

15 |

0 |

3 |

|

4 |

0 |

30 |

-1 |

2 |

|

5 |

0 |

30 |

+1 |

4 |

|

6 |

0 |

30 |

0 |

3 |

|

7 |

+1 |

45 |

-1 |

2 |

|

8 |

+1 |

45 |

+1 |

4 |

|

9 |

+1 |

45 |

0 |

3 |

The particle sizes distribution of the composite binder was studied by laser granulometry. The granulometry of the binder systems and the raw materials was carried out using the ANALYSETTE 22 NanoTec plus laser particle size analyzer. This device performs fully automatic analysis with a clear display of the results on the screen. Repeated measurements are possible with adjustment of the

duration of dispersion by ultrasound, the number of measurements, and time intervals to obtain maximum accuracy of the results. Distilled water is used as a solvent. Measurements are made in the range from 0.01 to 2000 µm, technology using three lasers for forward and backscattering, especially high measurement accuracy due to the analysis of 165 channels.

The fresh properties of the mix were determined by examining the slump flow.

The average density was calculated by dividing the mass of the sample by its volume.

The compressive strength was studied under a static load on the press on samples with a rib of 70 mm at 3, 7, and 28 days of age.

-

3 Results and Discussion

Table 4 lists the results of composite binder optimal compositions.

Table 4. Results of composite binder optimal compositions

|

Mix ID |

Content |

W/B |

Slump flow, mm |

Density , kg/m3 |

Compressive strength, MPa, at the age |

||||

|

Binder, wt. % |

MM, wt. % of binder |

3 days |

7 days |

28 days |

|||||

|

Portland cement |

WMS |

||||||||

|

Ref |

100 |

- |

- |

0.51 |

100 |

1960 |

20.66 |

26.36 |

33.08 |

|

CB-1 |

55 |

45 |

2 |

0.51 |

100 |

1920 |

14.49 |

22.02 |

28.29 |

|

CB-2 |

70 |

30 |

3 |

0.48 |

100 |

2150 |

29.79 |

43.33 |

53.03 |

|

CB-3 |

85 |

15 |

4 |

0.46 |

100 |

2190 |

33.47 |

48.03 |

60.28 |

The joint grinding of Portland cement and WMS waste in different percentages and the introduction of the optimal amount of a mineral modifier made it possible to reveal the effect of the composition on the compressive strength. When tested on the 28th day of hardening of the compositions CB-3 and CB-2, an increase in the tensile strength by 82.2 and 60.3%, respectively, was found, while in the composition of CB-1, there was a decrease in the tensile strength by 14.5%.

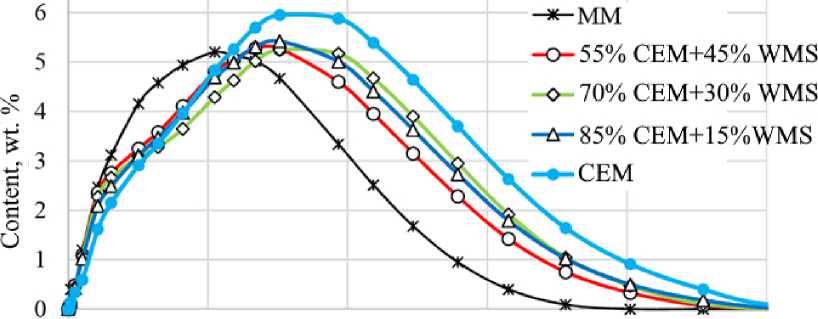

As a result of joint grinding to an equal specific surface, despite the different ratios of components and their hardness, an almost equal grain composition of polymineral composite binders was achieved (Figure 2).

О 10 20 30 40 50

Particle sizes, цт

Fig. 2 - Particle sizes distribution of the materials

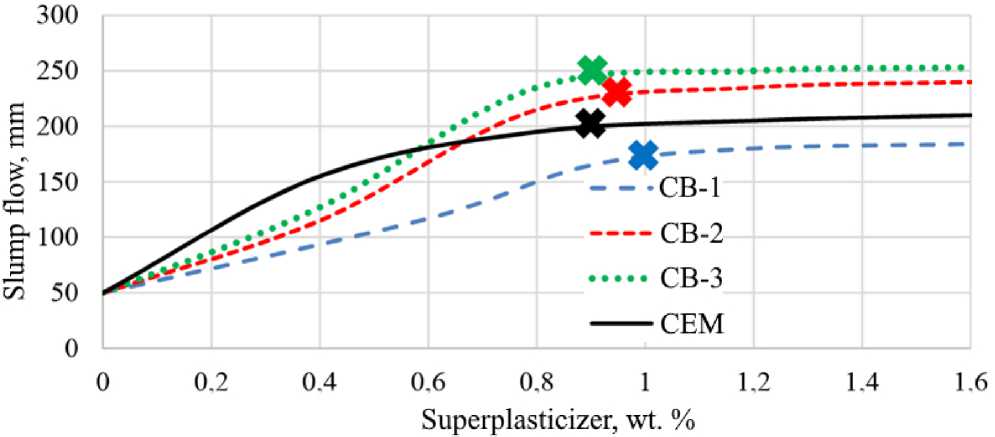

The optimal amount of the superplasticizer introduced was established by determining the effect of the additive on the slump flow using a truncated small cone (Figure 3).

Fig. 3 - Influence of Glenium-51 additive on the rheology of binders

The introduction of a chemical modifier in the CB composition significantly improved the characteristics of polymineral composite binders (Table 5).

Table 5. Results of a composite binder with SP and SAP

|

Mix ID |

Content, wt, % |

W/B |

Slump mm |

Density, kg/m3 |

Compressive strength, MPa, at the age |

|||

|

SP |

SAP |

3 days |

7 days |

28 days |

||||

|

Ref |

0.9 |

0.3 |

0.32 |

100 |

2110 |

24.08 |

38.68 |

49.53 |

|

CB-1 |

1 |

0.3 |

0.26 |

100 |

2080 |

17.29 |

27.12 |

34.79 |

|

CB-2 |

0.95 |

0.3 |

0.25 |

100 |

2210 |

43.33 |

50.19 |

63.10 |

|

CB-3 |

0.9 |

0,3 |

0.24 |

100 |

2270 |

53.52 |

64.46 |

75.64 |

When selecting the optimal dosage of the superplasticizer, a decrease in the amount of mixing water required to achieve a given CB slump flow was found compared to the reference compositions. This is due to the use of the Glenium-51 superplasticizer based on a polycarboxylate ether polymer, the effect of which is enhanced with an increase in the dispersion of the binder system. Also, the water demand for composite binders with an increase in the proportion of WMS waste in their composition was revealed. This is due to the greater grindability of WMS waste compared to cement, as a result of which, with joint grinding to a given specific surface area, with an increase in WMS content, the proportion of larger cement particles increases, which leads to a decrease in the dispersion effect caused by a combination of electrostatic and steric (spatial) affects repulsion when introducing superplasticizer. This led to an increase in the compressive strength of the tested samples at all testing periods, compared with compositions that do not contain SP and SAP (see Table 4). The increase in strength of the developed CB-2 and CB-3, containing the superplasticizer Glenium-51, on the 28th day of hardening was more than 25 and 50%, respectively, compared with the reference sample of cement paste, also containing the additive.

Taking into account the increase in strength of the developed compositions of polymineral composite binders, optimized by a chemical modifier, and the losses caused by the introduction of SAP to the cement system, the effectiveness of the use of CB-2 and CB-3, due to strength compensation, in combination with SAP modification B3 (<200 µm) is 14 and 39%, respectively, in combination with SAP modification FLOSET 129XB4N (<200 µm) - CB-2 is fully compensated by strength. At the same time, CB-3 exceeds the missing difference by 30%. Thus, compositions of polymineral composite binders were developed by joint grinding of Portland cement CEM I 42.5 N and WMS waste, followed by the introduction of ground Opoka-like marl used as a mineral modifier, and optimization due to a chemical modifier (Glenium-51) and a superabsorbent polymer, and also revealed their physical and mechanical properties.

-

4 Conclusions

The object of research is a composite binder with superabsorbent polymers. The work aims to research the combined action of composite binders and superabsorbent polymers. The particle sizes distribution of the composite binder was studied by laser granulometry. The fresh properties of the mix were determined by examining the slump flow. The average density was calculated by dividing the mass of the sample by its volume. The compressive strength was studied under a static load on the press on samples with a rib of 70 mm at 3, 7, and 28 days of age. Composite binders with superabsorbent polymers were developed. As a result, the following main results were obtained:

-

1. Obtaining polymineral composite binders was carried out by joint grinding of Portland cement CEM I 42.5 N and WMS waste to a specific surface area of ≈ 550 m2/kg in a vibration mill, followed by the introduction of pre-ground Opoka-like marl (S sp ≈ 700 m2/kg) used as a mineral modifier.

-

2. Joint grinding of cement and WMS waste in different percentages and introducing the optimal amount of a mineral modifier made it possible to identify the effect of the composition on the compressive strength. When tested on the 28th day of hardening of the compositions CB-3 and CB-2, an increase in the compressive strength by 82.2 and 60.3%, respectively, was found, while in the composition of CB-1, there was a decrease in the compressive strength by 14.5%.

-

3. As a result of joint grinding to an equal specific surface, despite the different ratios of components and their hardness, an almost equal grain composition of polymineral composite binders was achieved

-

4. Taking into account the increase in the strength of the developed compositions of polymineral composite binders, optimized by the chemical modifier, and the losses caused by the introduction of SAP into the cement system, the effectiveness of the use of CB-2 and CB-3, due to strength compensation, in combination with SAP modification B3 (<200 µm ) is 14 and 39%, respectively, in combination with SAP modification FLOSET 129XB4N (<200 µm) - CB-2 is fully compensated by strength. At the same time, CB-3 exceeds the missing difference by 30%.

-

5 Fundings

The research was partially funded by the Ministry of Science and Higher Education of the Russian Federation under the strategic academic leadership program ‘Priority 2030’ (Agreement 075-15-20211333 dated September 30, 2021).

Список литературы Composite binders with superabsorbent polymers

- Mosaberpanah, M.A. and Eren, O. (2017) Statistical Models for Mechanical Properties of UHPC Using Response Surface Methodology. Computers and Concrete. https://doi.org/10.12989/cac.2017.19.6.667.

- García Calvo, J.L., Pérez, G., Carballosa, P., Erkizia, E., Gaitero, J.J. and Guerrero, A. (2017) Development of Ultra-High Performance Concretes with Self-Healing Micro/Nano-Additions. Construction and Building Materials, 138, 306–315. https://doi.org/10.1016/j.conbuildmat.2017.02.015.

- Ganesh, P. and Murthy, A.R. (2019) Tensile Behaviour and Durability Aspects of Sustainable Ultra-High Performance Concrete Incorporated with GGBS as Cementitious Material. Construction and Building Materials. https://doi.org/10.1016/j.conbuildmat.2018.11.240.

- Azreen, N.M., Rashid, R.S.M., Mugahed Amran, Y.H., Voo, Y.L., Haniza, M., Hairie, M., Alyousef, R. and Alabduljabbar, H. (2020) Simulation of Ultra-High-Performance Concrete Mixed with Hematite and Barite Aggregates Using Monte Carlo for Dry Cask Storage. Construction and Building Materials, Elsevier Ltd, 263, 120161. https://doi.org/10.1016/j.conbuildmat.2020.120161.

- Fediuk, R. (2016) High-Strength Fibrous Concrete of Russian Far East Natural Materials. IOP Conference Series: Materials Science and Engineering. https://doi.org/10.1088/1757-899X/116/1/012020.

- Luan, C., Wang, J., Gao, J., Wang, J., Du, P., Zhou, Z., Huang, Y. and Du, S. (2022) Changes in Fractal Dimension and Durability of Ultra-High Performance Concrete (UHPC) with Silica Fume Content. Archives of Civil and Mechanical Engineering, 22, 123. https://doi.org/10.1007/s43452-022-00443-3.

- Van Tuan, N., Ye, G., Van Breugel, K., Fraaij, A.L.A. and Bui, D.D. (2011) The Study of Using Rice Husk Ash to Produce Ultra High Performance Concrete. Construction and Building Materials. https://doi.org/10.1016/j.conbuildmat.2010.11.046.

- Scrivener, K.L., Juilland, P. and Monteiro, P.J.M. (2015) Advances in Understanding Hydration of Portland Cement. Cement and Concrete Research, Elsevier Ltd, 78, 38–56. https://doi.org/10.1016/j.cemconres.2015.05.025.

- He, Z. hai, Du, S. gui and Chen, D. (2018) Microstructure of Ultra High Performance Concrete Containing Lithium Slag. Journal of Hazardous Materials, 353, 35–43. https://doi.org/10.1016/j.jhazmat.2018.03.063.

- Jung, M., Lee, Y. soon, Hong, S.G. and Moon, J. (2020) Carbon Nanotubes (CNTs) in Ultra-High Performance Concrete (UHPC): Dispersion, Mechanical Properties, and Electromagnetic Interference (EMI) Shielding Effectiveness (SE). Cement and Concrete Research, Elsevier, 131, 106017. https://doi.org/10.1016/j.cemconres.2020.106017.

- Amran, M., Al-Fakih, A., Chu, S.H., Fediuk, R., Haruna, S., Azevedo, A. and Vatin, N. (2021) Long-Term Durability Properties of Geopolymer Concrete: An in-Depth Review. Case Studies in Construction Materials, 15. https://doi.org/10.1016/j.cscm.2021.e00661.

- Xie, T., Fang, C., Mohamad Ali, M.S. and Visintin, P. (2018) Characterizations of Autogenous and Drying Shrinkage of Ultra-High Performance Concrete (UHPC): An Experimental Study. Cement and Concrete Composites, 91, 156–173. https://doi.org/10.1016/j.cemconcomp.2018.05.009.

- Fediuk, R.S., Lesovik, V.S., Liseitsev, Y.L., Timokhin, R.A., Bituyev, A.V., Zaiakhanov, M.Y. and Mochalov, A.V. (2019) Composite Binders for Concretes with Improved Shock Resistance. Magazine of Civil Engineering, 85. https://doi.org/10.18720/MCE.85.3.

- Provete Vincler, J., Sanchez, T., Turgeon, V., Conciatori, D. and Sorelli, L. (2019) A Modified Accelerated Chloride Migration Tests for UHPC and UHPFRC with PVA and Steel Fibers. Cement and Concrete Research. https://doi.org/10.1016/j.cemconres.2018.12.006.

- Fediuk, R., Pak, A. and Kuzmin, D. (2017) Fine-Grained Concrete of Composite Binder. IOP Conference Series: Materials Science and Engineering. https://doi.org/10.1088/1757-899X/262/1/012025.

- Park, S. et. al. (2021) The Role of Supplementary Cementitious Materials (SCMs) in Ultra High Performance Concrete (UHPC): A Review. Materials, 14, 1472.

- Semenov, P., Uzunian, A., Davidenko, A. and Al., E. (2007) First Study of Radiation Hardness of Lead Tungstate Crystals at Low Temperatures. Nuclear instruments & methods in physics research section A: Accelerators spectrometers detectors and associated equipment, 582, 575–580. https://doi.org/DOI: 10.1016/j.nima.2007.08.178.

- Farzad, M., Shafieifar, M. and Azizinamini, A. (2019) Experimental and Numerical Study on Bond Strength between Conventional Concrete and Ultra High-Performance Concrete (UHPC). Engineering Structures. https://doi.org/10.1016/j.engstruct.2019.02.030.

- Juenger, M.C.G., Winnefeld, F., Provis, J.L. and Ideker, J.H. (2011) Advances in Alternative Cementitious Binders. Cement and Concrete Research. https://doi.org/10.1016/j.cemconres.2010.11.012.

- Maddalena, R., Hall, C. and Hamilton, A. (2019) Effect of Silica Particle Size on the Formation of Calcium Silicate Hydrate [C-S-H] Using Thermal Analysis. Thermochimica Acta. https://doi.org/10.1016/j.tca.2018.09.003.

- Zhang, M.-H. and Islam, J. (2012) Use of Nano-Silica to Reduce Setting Time and Increase Early Strength of Concretes with High Volumes of Fly Ash or Slag. Constr. Build. Mater., 29, 573–580. https://doi.org/https://doi.org/10.1016/j.conbuildmat.2011.11.013.

- Zhang, H., Yoshino, H., Hasegawa, K. and Al, E. (2014) An Assessment of the Physical Properties of Lime-Hemp Concrete. Construction and Building Materials.

- Farzadnia, N., Noorvand, H., Yasin, A.M. and Aziz, F.N.A. (2015) The Effect of Nano Silica on Short Term Drying Shrinkage of POFA Cement Mortars. Construction and Building Materials. https://doi.org/10.1016/j.conbuildmat.2015.07.132.

- Hamada, H.M., Thomas, B.S., Yahaya, F.M., Muthusamy, K., Yang, J., Abdalla, J.A. and Hawileh, R.A. (2021) Sustainable Use of Palm Oil Fuel Ash as a Supplementary Cementitious Material: A Comprehensive Review. Journal of Building Engineering, 40. https://doi.org/10.1016/j.jobe.2021.102286.

- Jiang, D., Li, X., Lv, Y., Li, C., Jiang, W., Liu, Z., Xu, J., Zhou, Y. and Dan, J. (2021) Autogenous Shrinkage and Hydration Property of Alkali Activated Slag Pastes Containing Superabsorbent Polymer. Cement and Concrete Research, 149. https://doi.org/10.1016/j.cemconres.2021.106581.

- Almeida, F.C.R. and Klemm, A.J. (2018) Effect of GGBS on Water Absorption Capacity and Stability of Superabsorbent Polymers Partially Crosslinked with Alkalis. Journal of Materials in Civil Engineering, 30. https://doi.org/10.1061/(asce)mt.1943-5533.0002511.

- De Belie, N., Gruyaert, E., Al-Tabbaa, A., Antonaci, P., Baera, C., Bajare, D., Darquennes, A., Davies, R., Ferrara, L., Jefferson, T., Litina, C., Miljevic, B., Otlewska, A., Ranogajec, J., Roig-Flores, M., Paine, K., Lukowski, P., Serna, P., Tulliani, J.M., Vucetic, S., Wang, J. and Jonkers, H.M. (2018) A Review of Self-Healing Concrete for Damage Management of Structures. Advanced Materials Interfaces. https://doi.org/10.1002/admi.201800074.

- Sun, B., Wu, H., Song, W., Li, Z. and Yu, J. (2019) Design Methodology and Mechanical Properties of Superabsorbent Polymer (SAP) Cement-Based Materials. Construction and Building Materials, 204, 440–449. https://doi.org/10.1016/j.conbuildmat.2019.01.206.

- Liu, R., Sun, Z., Ding, Q., Chen, P. and Chen, K. (2017) Mitigation of Early-Age Cracking of Concrete Based on a New Gel-Type Superabsorbent Polymer. Journal of Materials in Civil Engineering, 29. https://doi.org/10.1061/(asce)mt.1943-5533.0001994.

- Yang, J., Liu, L., Liao, Q., Wu, J., Li, J. and Zhang, L. (2019) Effect of Superabsorbent Polymers on the Drying and Autogenous Shrinkage Properties of Self-Leveling Mortar. Construction and Building Materials, 201, 401–407. https://doi.org/10.1016/j.conbuildmat.2018.12.197.