Computing the pressure of agricultural tractors on soil and mapping its compaction

Автор: Adylin I.P., Comparetti A., Greco C., Lapik V.P., Lapik P.V., Orlando S.

Журнал: Бюллетень Почвенного института им. В.В. Докучаева @byulleten-esoil

Рубрика: Статьи

Статья в выпуске: 120, 2024 года.

Бесплатный доступ

Manufacturers of agricultural machines, when designing, pay a little attention to its impact on soil, thus producing models with high compression loads on the soil or with a small contact area between the tyres/tracks and the soil surface. Therefore, the aim of this study is to evaluate the negative impact of both wheeled and tracked agricultural tractors on the soil, in terms of soil compaction, and its causes (i. e. design features of tractor tyres/tracks), during the last six decades (i. e. from 1961 to 2021). Soil compaction is caused by the pressure applied by agricultural machines on the soil through the contact area of their tyres/tracks with the soil surface. So, the main indicator of the negative impact on the soil by the tractors manufactured during the last 60 years, i. e. the average pressure applied by the tyres or tracks of tractors manufactured in EU and in the post-Soviet cuntries from 1961 to 2021 to the soil, was computed. A general decrease of the average pressure of the tyres/tracks on the soil can be observed in 1980s and 1990s, followed by its general increase since 2000, above all for the tractors having power higher than 140 kW. Thus, there is an urgent need to assess spatial and temporal changes in soil vulnerability to compaction, that depends on weather conditions and soil properties, as well as agricultural management practices, and can only be fully assessed by means of a combination of traditional techniques (i. e. use of soil cone penetrometer followed by 2D mapping using GIS or 3D mapping through geostatistics) and mechanical approaches (i. e. computation of agricultural machine parameters - soil contact area). The results show that tractor manufacturers did not take care of reducing soil compaction during the considered period.

Soil degradation, soil compaction, tractors, tyres, tracks, spatial variability

Короткий адрес: https://sciup.org/143183570

IDR: 143183570 | DOI: 10.19047/0136-1694-2024-120-136-163

Текст научной статьи Computing the pressure of agricultural tractors on soil and mapping its compaction

Build. 4 Viale delle Scienze, 90128 Palermo, Italy, ** 0000-0002-6083-5515, e-mail: ,

Setting the goals and objectives of the study

At present, the production of foodstuff, i. e. agricultural products in the sector of crop production, can be carried out in different ways:

-

- traditional method, implying the use of soil as a fertile layer, i. e. a carrier of nutrients for plants;

-

- hydroponics method, involving the use of a nutrients-water solution;

-

- aggregation method, involving the use of a solid substrate where the plant roots are located and a nutrients-water solution periodically enters;

-

- aeroponics method, involving the use of nutrients supplied to plant roots in the form of an aerosol;

-

- others.

Despite the modern variety of ways to grow plants, the traditional method is still the main one.

Soil fertility is a limited condition, which makes humanity to think about soil health as means to achieve food security.

One of the extremely negative impacts on the soil, affecting its fertility, is its compaction.

Thus, the purpose of this article is to analyse the negative impact of agricultural tractor tyres/tracks on the soil in the context of time, as well as to determine ways to control and reduce this impact.

In order to achieve this goal, it is necessary to carry out the following tasks:

-

1) assessment of the applicability of wheeled and tracked tractors in agricultural production;

-

2) determination of indicators of the negative impact of tractor tyres/tracks on the soil;

-

3) determination of trends in the development of mechanical engineering applied to agricultural sector, by taking into account the environmental friendliness of the manufactured machines;

-

4) proposal of a protocol for monitoring and analysing the negative impact of agricultural tractor tyres/tracks on the soil.

Pressure of agricultural machines on soil

Currently, the potential serious consequences of the impact of agricultural machines on the soil are increasingly known. As the soil is and will be the main commodity for food production, the issues of prevention, conservation and restoration of the “health” of agricultural soils are extremely paramount. In fact, the “health” of a soil can be defined as a porosity of at least 10%, constituted by microporosity (consisting of pores having diameter lower than 8 μm, that should contain only water, under the optimal hydrological soil conditions) and macroporosity (consisting of pores having diameter higher than 8 μm, that should contain only air, under the optimal hydrological soil conditions), while soil compaction is the reduction of its porosity to values lower than 10%, mainly caused by the traffic of agricultural machines (Soane, Bonne, 1986; Lapik et al., 2012; Lapik, Adylin, 2013; Shah et al., 2017; Peregoodov, Novak, 2018). In fact, soil compaction is the decay of soil structure caused by the pressure applied to it, so that porosity and permeability decrease, while bulk density and cone penetrometer resistance increase (Comparetti et al., 2019).

About 30% of soils in Europe are at risk (or susceptible) to compaction (Panagos et al., 2012).

The index of soil compaction is soil cone penetrometer resistance or resistance to cut or strength, that is the resistance opposed by the soil to the cut of a slice of 1 dm 2 and is expressed as dN dm -2 or MPa. Therefore, it is the resistance to penetration in the soil by the working parts of an agricultural implement or machine and depends on the soil texture and water content: its value is lower for sandy soils and higher for clay soils, however, with reference to the optimum condition for tillage (i. e. a soil water content, expressed as percentage, slightly lower than the plastic limit, at which adhesion, external friction, cohesion and internal friction are minimum).

In order to analyse the current situation on these issues, it is needed to know the following parameters: pressure on the soil; causes of this pressure; design technical specifications of agricultural machines; pressure of agricultural machines on the soil over time; selection of tyres or tracks, aimed at minimising this pressure on the soil.

If the pressure of agricultural machines on soils is considered, together with the requirements of the various crop operations, the following negative results can be distinguished: soil compaction; disturbance of soil structure; change of the balances of soil water, air, macro-and microelements; destruction of vegetation cover and plants roots.

Studies have shown that root penetration decreases linearly with soil cone penetrometer resistance, so that the roots of most plant spe- cies are inhibited at 1.5 MPa, while the roots of many plant species stop to grow at values higher than 2.5 MPa (Kees, 2005; Raper et al., 2005).

All the above results are associated with the excessive pressure of the tyres/tracks of agricultural machines on the soil.

In the Russian Federation, the maximum allowed pressure of the tyres/tracks of agricultural machines on the soils (having a water content equal to 90% of the field capacity) is 80 kPa, according to the regulatory document, i. e. GOST R 58655-2019 “Mobile agricultural machines. Norms for determining the impact of tyres/tracks on the soil” (GOST R 58655-2019). Instead, in other developed countries, the above threshold is 60 kPa (https://ooo-kompaniya-mir- . The above difference can be explained either by different environmental policies or parameters (i. e. soil and climate ones). Moreover, some scientists reported an average pressure of agricultural machines on the soil of 15 kPa as the harmless threshold (Skuratovich, 2006). Thus, in order to achieve the ideal conditions for preventing the soil compaction caused by the traffic of agricultural machines, it is needed to highly reduce the pressure on the contact area between the tyre/track and the soil.

Technological reasons for the high pressure on the soil are incorrect methods of soil tillage and crop harvest. Thus, soil compaction highly increases with the increasing number of passes of the tyres/tracks along a trajectory (Skuratovich, 2006). In fact, the research of some scientists of Higher Institute of Agronomic Sciences “Schott-Mariem” showed, in sandy-clay soils of Tunisia, a decrease of water content by 36% and an increase of density by 70% along the tyre trajectories.

Other causes of the high pressure on the soil can be design flaws and technical specifications of agricultural machines, as well as incorrect methods of carrying out crop operations.

Therefore, the technical specifications of agricultural machines should include their operational mass. In fact, nowadays the tractor mass is higher and higher, as heavy and powerful tractors (there is a ratio mass/engine power and, therefore, weight/engine power) can de- velop higher draft force and minimise wheel slip, as well as the working capacity and, therefore, the mass of self-propelled agricultural machines (e. g. combine and grape harvesters) is increasingly higher. The higher weight of both tractors and agricultural machines causes a higher pressure on the soil.

Wheeled and tracked agricultural machines

The comparison between wheeled and tracked agricultural machines was carried out for many years.

The wheeled tractors, compared to the tracked ones, have, as disadvantages, higher slip and, therefore, destruction of the vegetation cover, plant roots and soil structure, as well as higher pressure on the soil itself, due to the smaller contact area.

Instead, the tracked tractors are worse than the wheeled ones in row fields (e. g. potato ones), cannot move on asphalt roads (although in recent years there was a trend to use elastic support materials of the tracks) and have a lower manoeuvrability, so that they are much less spread (Lapik, 2019).

Therefore, in the description of the design technical specifications of agricultural machines, it is firstly needed to take into account their tyres or tracks.

The tractor tyres are nowadays more common rather than the tracks, because the former have a higher versatility and manoeuvrability rather than the latter, as well as they fit to a wide range of crop operations (e. g. soil tillage and transportations) and have an easier maintenance.

Instead, the tracks of agricultural machines are much more massive and less manoeuvrable rather than the wheels. The tracks are less common, because they cannot be used for carrying out crop operations in row fields. Tracked tractors are often used for soil tillage, sowing and after harvest, as they can develop a higher draft force, by comparing machines having equal weight used on soils having the same adherence coefficient (Elaoud, Chehaibi, 2011). At the same time, tracked tractors have a much higher contact area rather than wheeled ones, even if the latter are equipped with twinned or triple tyres. This allows to use tracked tractors on wet soils, e. g. riсe fields with flood irrigation.

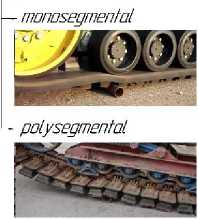

All over the world, tracked agricultural machines can be distinguished according to two features: segmentation of tracks; type of tracks.

Segmentation refers to the absence or presence of division of the track into its parts, so that it is possible to distinguish monosegmental and polysegmental tracks, respectively.

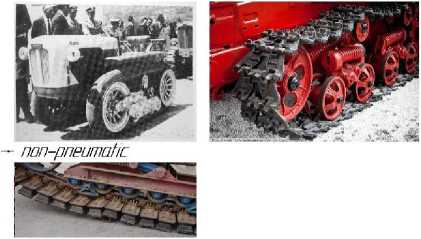

According to the type of tracks, it is possible to distinguish metal and elastic ones. Elastic tracks, in its turn, are divided into pneumatic and rubber-reinforced ones.

The classification shown in Figure 1 allows distinguishing metal, rubber-reinforced and one-piece pneumatic gas-filled tracks, as well as pneumatic and non-pneumatic ones.

Agnouttural mochihes

Segmentation

Type of propulsion organ elastin - ^ metal

- pneumatic

Fig. 1. Classification of tracks of tractors and agricultural machines.

Options for reducing the pressure of tyres/tracks on soil

In order to minimise the pressure on the soil, the tyres of wheeled agricultural machines are already modernised kolesnih-traktorov). In fact, upon further development, new tyres were manufactured, i. e. wide section and low-pressure ones, having a much higher contact area with the soil. Moreover, in some modern tractors the driver can quickly set up the inflation pressure directly from his seat. Furthermore, when the tyres are twinned or triple, both the compression effect between neighbouring wheels and the rolling resistance coefficient are lower. Figure 2 shows the different options aimed at reducing the pressure of the tyres on the soil.

a)

b)

c)

Fig. 2. Options for reducing the pressure of the tyres on the soil: a) twinned tyres; b) triple tyres; c) wide section and low-pressure tyres.

Another solution to reduce soil compaction is on-land ploughing (instead of in-furrow one), as its impact is shallower, it optimises the soil structure, by immediate loosening the soil, and it allows using a tracked tractor or a tractor equipped with twinned tyres or wide section and low-pressure ones.

However, these solutions increase the price of the tractor, so that only a few farmers can afford this supplementary cost.

According to the classification of the tracks of agricultural machines (Fig. 1), it is possible to notice that the use of metal tracks cannot preserve the surface (e. g. asphalt and concrete roads). Thus, it is necessary to mount elastic support devices. Lapik (Lapik, 2015) revealed that rubber-reinforced tracks (that are monosegmental and elastic, according to the above-mentioned classification) are the most applicable on arable lands characterized by optimal condition for tillage during summer (Lapik, 2015; .

The use of such support devices on wet soils allows avoiding the situations when tractor gets stuck in the soil, but it destroys the vegetation cover along the trajectory of the tracks. Lapik revealed that tracked tractors having rubber-reinforced metal tracks can completely destroy the plant roots, so that no plant growth along the trajectory of the tracks was observed for 30 days after their pass (Lapik, 2015).

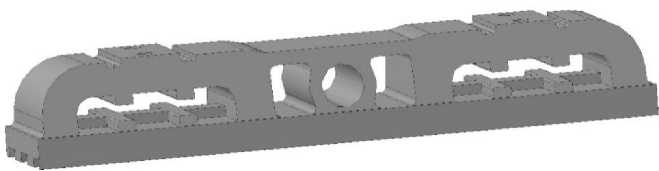

Moreover, as the not utilised agricultural area is huge in some countries, above all in the Russian Federation, the development of crop production on flood plains and soils with low bearing capacity is quite relevant (Smolsky et al., 2019; Silaev et al., 2021; Chekin et al., 2021). In order to overcome this problem, it is needed to use Rubber Cord Tracks (RCT), i. e. polysegmental elastic pneumatic tracks (Lapik, 2015; Silaev et al., 2021; Lapik, Adylin, 2011; Adylin, Lapik, 2013; Adylin, 2016) (Fig. 3), when they ensure a sufficient level of reliability.

Fig. 3. Rubber Cord Tracks (RCT) for agricultural machines (Lapik, 2019).

Knowledge gaps and hypothesis on the pressure of agricultural machines on soil

Some analyses of the average pressure on the soil of the agricultural tractors manufactured both in the periods 1970–2010 and 1979– 2014 were carried out, so that reports on the approach of agricultural tractor manufacturers to the issue of soil compaction were presented (Comparetti, 2019; Comparetti et al., 2010; Orlando, 2021). The analysis of the pressure on the soil of 783 wheeled tractors, manufactured from 1979 to 2014, showed the increased pressure on the soil, especially it concerns tractors having an engine power higher than 100 kW.

Therefore, manufacturers of agricultural machines pay a little at- tention when designing, and produce models applying high loads on the soil or having a low contact area between the tyres/tracks and the soil surface.

In order to assess the negative impact of wheeled and tracked tractors on the soil and to face the problem of declining soil fertility caused by agricultural tractors, it is proposed to study soil compaction and the causes of this phenomenon over the past six decades (i. e. from 1961 to 2021). The novelty of this study also lies in the calculation of the average pressure exerted on the soil by a sample of tractors manufactured in EU, in USA and in post-Soviet states. Finally, this study aims at deducing, for the first time, a worldwide trend in the design of wheeled and tracked agricultural machines, in terms of their pressure on the soil that can cause soil compaction .

MATERIALS AND METHODS

Soil compaction is caused by the pressure applied by agricultural machines on the soil, through the contact area of their tyres/tracks with the soil surface.

In order to compute the above pressure, the static load on the soil through a tyre or track was retrieved from the OECD test reports.

The contact area of agricultural tyres can be measured by means of the special equipment, for example, that was built up at Palermo University, in collaboration with Milan University (Febo et al., 1997).

Thus, the main indicator of the negative impact of the wheeled and tracked agricultural tractors on the soil is the average pressure applied by their tyres or tracks on the soil. Therefore, it was possible to compute the average pressure on the soil of the wheeled and tracked agricultural tractors, including some transport vehicles and some wheeled tractors equipped with twinned wheels, manufactured in EU, in the USA and in post-Soviet states during the last six decades, i. e. from 1961 to 2021.

The most widely used criterion for computing the pressure of agricultural machines on the soil is based on the following Equations (1) and (2), which allow calculating the average pressure on the soil (GOST R 58656-2019):

m • g qw = 103 • Fw

m • g

Qt = 103 • Ft (2)

where:

-

qw - average pressure of the tyre on the soil, kPa;

-

qt - average pressure of the track on the soil, kPa;

-

m - mass, determining a static load on the soil through a tyre or track, kg;

-

g = 9.81 m s -2 (gravity acceleration);

-

Fw - contact area of the tyre with the soil, m 2 ;

-

Ft - contact area of the track with the soil, m 2 .

Another commonly used criterion for computing the pressure of agricultural machines on the soil is based on the following Equations

-

(3) and (4), allowing to calculate the maximum pressure on the soil itself (GOST R 58656-2019):

qmax w qw • K 2

qmax t % ’ K 4 • qt (4)

where:

-

qmax w - maximum pressure of the tyre on the soil, kPa;

-

qw - average pressure of the tyre on the soil, kPa;

-

К 2 = 1.5 (coefficient of longitudinal unevenness of pressure distribution on the contact area between the tyre and the soil);

-

qmax t - maximum pressure of the track on the soil, kPa;

-

% - average coefficient of unevenness of stress distribution on the contact area between the track and the soil;

-

К4 - coefficient depending on the tractor weight;

-

qt - average pressure of the track on the soil, kPa.

In addition to these criteria, which determine the pressure on the soil, a criterion that shows the stresses in the soil at different depths is often used: it is recommended to determine stresses in the soil at a depth of 0.5 m, since this “has the greatest impact on the development of plants” (GOST 25954-2019). Thus, the stresses in the soil at a depth of 0.5 m for each tyre/track are determined by the following equation (5):

a • b ah = 0,637 • q • arctg —===== L hia2 + b2 + h2

h • a • b(a2 + b2 + 2h2) +(j2+h2yb2+h2yiaa^^

where:

-

oh - stresses in the soil at a depth of 0.5 m, kPa;

-

h - depth of the support base on which the tyre/track moves, m;

-

a = 0.5 contact area length, m;

b = 0.5 contact area width, m.

For a single tyre, the parameters " a " and " b " are determined by the below equations (6) and (7), respectively:

^КП a =--

2bk where:

Р КП — reduced contact area of the tyre with the soil (according to GOST 26953), m 2 .

b ^ (7)

where:

b k — tyre contact footprint width (according to GOST 26953), m.

A more universal criterion for computing the pressure of a tyre/track on the soil is based on an indicator taking into account the design technical specifications of the tyre/track itself, the effect of stress accumulation on the soil and the number of passes along a trajectory, according to the following Equation (8) (Ksenevich et al., 1985):

U = wbqmaXv(1 + xbnN) кН/м (8)

where:

U - pressure of a tyre/track on the soil;

ш - coefficient depending on the size and shape of the contact area between the tyre/track and the soil;

(for tyre: ш = 1.25;

for track if Lb < 7 ш = (0.92 + 0.3 L/b) /з;

for track if Lb > 7 ш = 2.15)

where:

L - length of the contact area between the track and the soil;

-

b - track width;

-

qmaXv - maximum pressure of the tyre/track at a constant speed;

-

X - intensity coefficient of accumulation of irreversible deformation of the soil under repeated loads;

-

^ - number of consecutive passes of the tractor along a trajectory.

The above formulas are different options for computing the pressure of tractor tyres/tracks on the soil.

As the above pressure is the ratio between the tractor weight and its contact area with the soil, the tractor load on the front and rear axles and its contact area with the soil were retrieved from manufacturers of agricultural machines or previous analyses.

In this study, among the above equations, the formulas 1 and 2 were applied to the above data for computing the pressure of wheeled and tracked agricultural tractors, respectively, on the soil.

RESULTS AND DISCUSSION

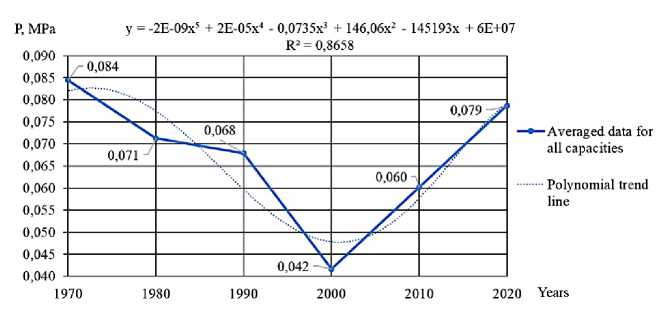

The results of the analysis on both the wheeled and tracked agricultural tractors manufactured in the EU, in the USA and in post-Soviet states during the last six decades show a high variability of the average pressure applied by them on the soil.

The average pressure on the soil of agricultural tractors having different engine power during the last six decades is shown in Figure 4.

The graph shown in Figure 4 relies on a database from the Uni- versity of Palermo and open sources, including data from agricultural tractor manufacturers; 832 tractors of various manufacturers, engine power and manufacture years, both currently commercialised and not marketed anymore, were analysed.

The above tractor manufacturers also include Massey Ferguson, John Deere, Versatile, Hesston, Kubota, Case-IH, Deutz-Allis, Agco-Allis, MTZ (Minsk Tractor Plant), New Holland, Kirovsky Zavod, Challenger, Steiger and Chelyabinsk Tractor Plant.

Of the 832 available tractors, 802 are wheeled and only 30 are tracked. Thus, there is a clear majority of wheeled tractors over tracked ones, i. e. 96.4 vs. 3.6%.

|

P, MPa A 1 AA |

|||||||

|

A 1 ЛА . |

|||||||

|

v, 14U Л TIA - |

-*-Power < 50 kW |

||||||

|

v,lZU |

-•-Power 50-80 kW |

||||||

|

л лол . |

|||||||

|

U,U5U A AAA - |

- l ow er oU-11 и к w |

||||||

|

u,uou 0 040 ■ |

Power 110-140 kW |

||||||

|

A AOA . |

—•—Power >140 kW |

||||||

|

0,000 - |

1960 1970 1980 1990 2000 2010 2020 Years

Fig. 4. Average pressure on the soil of agricultural tractors having different engine power over time.

-

Figure 4 shows a higher difference in the average pressure on the soil of tractors having different engine power during the decades 1960s, 1970s, 2000s and 2010s, rather than during the decades 1980s and 1990s. The significant differences between different power classes of tractors that are observed in 1960s and 1970s can be explained by the birth of agricultural machinery industry and the lack of strict legal frameworks for manufacturers.

Moreover, a general decrease of the average pressure of the tyres/tracks on the soil can be observed in 1980s and 1990s, i. e. 15.6% and 19.6, respectively, with reference to 1970s. This can be explained by the trend of manufacturers to adapt the contact area between the tyres/tracks and the soil to the loads on the two axles (front and rear), in order to obtain a similar pressure on the soil for all power classes of the agricultural tractors manufactured from 1980 to 2000. In the Russian Federation, the above decrease can be explained by strict state regulations for tractor manufacturers. In the decade 2000s, a different average pressure on the soil according to the tractor engine power can be observed. In fact, the lowest pressure is found for tractors having a power lower than 50 kW, while the maximum value is recorded for tractors having a power higher than 140 kW. Since 2000, a general increase of the average pressure of tractors on the soil occurred, i. e. 44.4% in 2010 with reference to 2000, above all for those having a power higher than 140 kW. This trend can be explained by the increased intensification of agriculture: tractors, having higher mass and, therefore, weight and power (as a consequence of the ratio mass/power and, therefore, weight/power), as well as able to develop higher draft force, were used.

According to the available data, the average pressure of wheeled tractors is 0.064 MPa, which is almost 22% higher than that of tracked tractors (0.050 MPa).

In order to assess the approach of agricultural tractor manufacturers towards the problem of pressure on the soil, causing its compaction, average data were computed for all engine power classes from 1961 to 2021 (Fig. 5).

The obtained polynomial trend line of the 5 th degree having a sufficient probability (higher than 86%) shows that a decrease of the soil compaction caused by tractor pressure is not expected.

Furthermore, one model of tractor was selected for each of the periods 1980–1989 (1985), 1990–1999 (1995) and 2000–2009 (2005), in order to show, in Table 1, the different average ground pressures in the various options obtained with and without the cast iron ballast suggested by the manufacturer, with single and twinned tyres having the inflation pressure also suggested by the manufacturer.

Fig. 5. Average pressure of tractors on the soil for all engine power classes from 1961 to 2021.

The results of this study suggest that the manufacturers of tractors and self-propelled agricultural machines must reverse the current trend, in order to reduce the loads on the two axles or increase the contact area, also by using tyres having wider section and lower pressure. In this way it will be possible to minimise soil compaction, that is one of the factors of soil degradation, able to reduce crop yield.

Another solution to the problem of soil compaction is Controlled Traffic Farming (CTF), implying that tractors and agricultural machines used for crop operations (e. g. sprayers) must follow the same trajectories (tramlines) (Raghavan et al., 1990, Gasso, 2013).

The efficacy of three methods for mitigating compaction damage to soil “health” was recently compared to a direct drill control. Among these methods, two improved the soil structure and mechanically reduced compaction “in situ”, while the third, that was a biological method, reduced the impact of compaction on plant growth and nutrient adsorption. Earthworm abundance, that is a key indicator of soil “health”, was significantly reduced in the mechanical mitigation treatments. This study highlighted the importance of understanding the compaction mitigation techniques, even if they differ in their efficacy and impact on soil “health” (Bussell et al., 2021).

Table 1. Average pressure exerted on the soil by three models of tractor, one for each of the periods 1980–1989 (1985), 1990–1999 (1995) and 2000–2009 (2005), in the various options obtained with and without the cast iron ballast suggested by the manufacturer, with single and twinned tyres having the inflation pressure also suggested by the one

|

Parameter |

Manufacturer (Year) |

||||

|

HESSTON (1985) |

AGCO-ALLIS (1995) |

AGCO (2005) |

|||

|

Model |

70-66DT-12 SP |

9435-PPS 32 SP |

DT220A |

||

|

Type |

MFWD |

MFWD |

MFWD |

||

|

Power |

kW |

46.77 |

101.19 |

170.40 |

|

|

Mass without ballast |

kg |

3031 |

7118 |

9302 |

|

|

Mass with ballast |

kg |

3943 |

7975 |

13216 |

|

|

Front |

Mass without ballast |

kg |

1132 |

2549 |

3581 |

|

Front |

Mass with ballast |

kg |

1547 |

2556 |

5207 |

|

Front |

N. tyres |

per axle |

2 |

2 |

2 |

|

Front |

Tyre size |

12.4-24 |

14.9-30 |

480/70R34 |

|

|

Rear |

Mass without ballast |

kg |

1898 |

4569 |

5721 |

|

Rear |

Mass with ballast |

kg |

2396 |

5420 |

8009 |

|

Rear |

N. tyres |

per axle |

2 |

4 |

4 |

|

Rear |

Tyre size |

18.4-30 |

18.4-42 |

520/85R46 |

|

|

Front |

Contact area without ballast |

cm 2 |

2115 |

3122 |

5148 |

|

Front |

Contact area with ballast |

cm 2 |

2632 |

3128 |

4992 |

|

Front |

Pressure without ballast |

kPa |

52.50 |

80.09 |

68.24 |

|

Front |

Pressure with ballast |

kPa |

57.66 |

80.15 |

102.32 |

|

Rear |

Contact area without ballast |

cm 2 |

3198 |

10037 |

15651 |

|

Rear |

Contact area with ballast |

cm 2 |

3764 |

11312 |

22545 |

|

Rear |

Pressure without ballast |

kPa |

58.23 |

44.66 |

35.86 |

|

Rear |

Pressure with ballast |

kPa |

62.44 |

47.00 |

34.85 |

|

Average pressure without ballast |

kPa |

55.36 |

62.37 |

52.05 |

|

|

Average pressure with ballast |

kPa |

60.05 |

63.58 |

68.58 |

|

The degree of soil compaction in a field can be significantly spatially variable, depending on the intensity and distribution of the traffic of agricultural machines and/or the action of tillage implements (Mouazen et al., 2001).

Therefore, a further solution to the above problem is the georeferenced measurement of soil cone penetrometer resistance (index of soil compaction), according to the principles of precision agriculture, in order to produce soil compaction maps (Carrara et al., 2005; Carrara et al., 2007; Comparetti et al., 2011; Comparetti et al., 2013). Thus, in a soil compaction map it is possible to delineate different Management Zones (MZs) (Alesso et al., 2019), where different tillage methods can be planned (Mzuku et al., 2005). As another option, a soil compaction map can be logged in the on-board PC of a tractor, linked with a tillage implement, in order to perform spatially variable depth soil tillage (Adamchuk et al., 2003; Whattoff et al., 2017).

Mapping soil compaction is paramount for delineating: compacted topsoil vulnerable to erosion and surface runoff excess; areas with compacted subsoil, e. g. plough pan, susceptible to generate subsurface runoff; vulnerable areas, e. g. chalk areas, peaty areas or wetlands and areas with drains that may be broken by the passage of heavy agricultural machines (Alaoui et al., 2018).

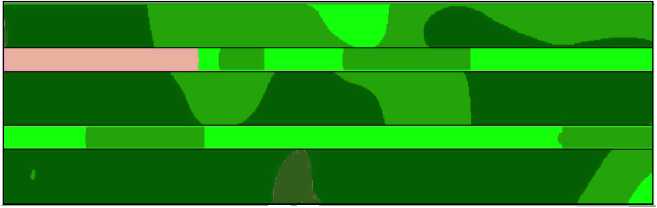

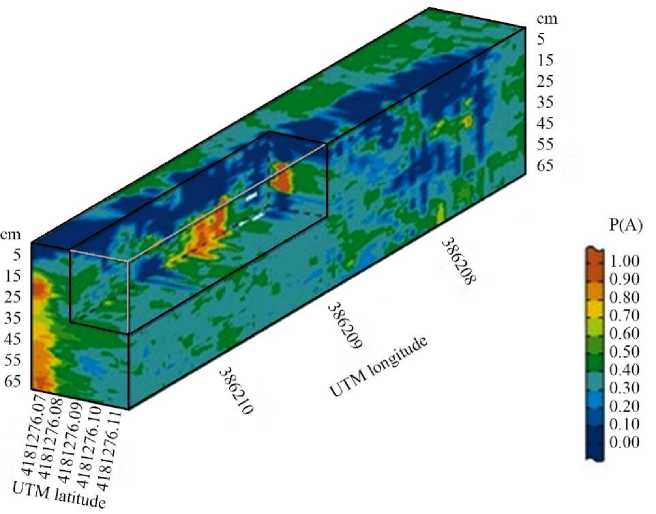

At plot or field scale, three methods can be used for mapping soil compaction: direct measurement of soil cone penetration resistance, by means of a “static” soil cone penetrometer, driven into the ground at a constant penetration speed (Vaz et al., 2011), or a “dynamic” penetrometer, driven into the ground by repeated hammering (Beckett et al., 2018), possibly together with Electrical Conductivity (EC), georeferenced data of which can be scaled up by using a GIS software (Fig. 7) (Carrara et al., 2003) or geostatistical approaches (Fig. 8) (Carrara et al., 2007); computation of the stress normal to the field plane, based on the total load of agricultural machine and contact area machine-soil or soil parameters and total load of agricultural machine; computation of the pre-consolidation stress, which can be determined based on the stress-strain relationship of soil obtained during laboratory compression, evaluated from pedo-transfer functions (based on information about pedological, mechanical and hydraulic conductivity obtained from available databases) (Alaoui, Diserens, 2018).

At larger scales, indirect relationships are used to predict the risk of soil compaction, based on measured values of soil cone penetrome- ter resistance, soil water content or organic matter, combined with a cartographic Depth-To-Water index (DTW) derived from a Light Detection And Ranging (LiDAR) sensor or a Digital Elevation Model (DEM). In fact, spatial variability may be taken into account through geostatistical methods, if data are abundant and uncertainty information can be extracted from the knowledge of the statistical distribution in the case of sparse data (Alaoui, Diserens, 2018). Campbell et al. (2013) combined soil cone penetrometer resistance measurements with within-plot measured values of soil water content, density, texture, organic matter content, soil depth, elevation, slope and a cartographic DTW, by means of multiple regression analysis. By relating the soil cone penetrometer resistance values to the DEM-derived elevation, slope and DTW variables derived from a LiDAR-generated bare ground DEM, Campbell et al. (2013) produced soil cone penetrometer resistance maps.

Cone penetro meter resistan ce (M Pa)

И 0-0.2 0.4-0.6 0.8-1.0 К 12- 1.4 ■ 1.6- 1.8

Ml 0.2-0.4 >0.6-0.8 ■ 1.0-1.2 ■ 1.4- 1.6 ■ 1.8-2.0

Fig. 7. 2D soil compaction map (3 × 15 m section parallel to the field plane) of a plot in 6–10 cm depth layer, after four passes of a tractor (the two strips are the tracks of tractor wheels).

A system for the geo-referenced measurement of soil compaction was tested during the crop season 2002–2003, in the farm of inland Sicily (Italy), located at Alia (Palermo). Three plots, that had been ploughed at 0.35 m depth and harrowed at 0.10 m depth, were selected with sandy-silty soil (clay 8%, silt 33.7% and sand 58.3%) and water content of 4.9% (Carrara et al., 2003).

Fig. 8. 3D map showing the probability P(A) of exceeding the threshold of soil cone penetrometer resistance that is critical for plant root growth (2.5 MPa), after five passes of a tractor. The probability is expressed as percentage (e. g. 1.00 = 100%), while the soil depth is expressed in cm, as well as the point positions are shown as UTM geodetic coordinates, i. e. longitude and latitude.

In July, 2003, measurement tests were carried out in a field located at Alia (Palermo, Italy), where a three-year crop rotation: durum-wheat–durum-wheat–tomato was practiced. The soil is a Vertic Xero-chrept (USDA, 1998), having a sandy-silt texture (clay 8%, silt 33.7% and sand 58.3%) and a water content of 4.9%. Before the tests the soil was ploughed at 0.35 m depth and harrowed at 0.10 m depth (Carrara M. et al., 2007).

Among the above methods, 3D mapping based on TASC (Tyres/Tracks And Soil Compaction) model is a new mapping methodology for helping practitioners, advisers and policy-makers to mitigate soil compaction (Alaoui, Diserens, 2018). In fact, Diserens et al. (2010) proposed a 3D map of compaction damage risk at 30 cm depth for a 4.5 ha plot. Geo-referenced wheel load data, acquired by means of a sensor-tyre (Cemagref patent n. 05-11455) by ploughing (furrow wheel) and soil cone penetrometer resistance values were recorded. Therefore, TASC model, combined with geo-referenced load data recorded during farming and soil parameters collected immediately prior to driving make this mapping method suitable for precision agriculture and land protection (Alaoui, Diserens, 2018).

Spatial distribution of land use is also often obtained using air-or space-borne Remote Sensing (RS) data, that provide regular spatially- and temporally-explicit data across large areas, when compared to field-based assessments (Hansen et al., 2013).

As subsoil compaction can persist over decades, indicating a long memory effect (above all, in the case of afforestation), the knowledge of previous land uses, that is owned by a range of stakeholders, must be taken into account for mapping areas subjected to soil damage (Alaoui, Diserens, 2018). Thus, in order to map soil compaction, RS cannot provide the dynamics of flow processes as related to land use effect on soil structure and the memory effect (Alaoui et al., 2018). For this purpose, mapping soil compaction should include information on both short- and long-term changes in the soil conditions, preferably also for different soil layers.

Thus, there is an urgent need to assess spatial and temporal changes in soil vulnerability to compaction, that depends on weather and soil conditions, as well as agricultural management practices. Soil compaction can only be fully assessed by means of a combination of traditional techniques (i. e. use of soil cone penetrometer followed by 2D mapping through GIS or 3D mapping through geostatistics) and mechanical approaches (i. e. computation of agricultural machine – soil contact area) (Alaoui, Diserens, 2018).

CONCLUSIONS

In agreement with a priori established aims, the conclusions of the work are the following:

-

1) wheeled tractors are more used in agricultural production, rather than tracked ones, i. e. 96 vs. 4% (according to the available data); this is justified by the higher versatility of wheeled tractors, with reference to tracked ones;

-

2) the most common indicator of the impact of tractor tyres/tracks on the soil is their average pressure on the soil; the average pressure of wheeled tractors resulted in 0.064 MPa, while that of tracked ones was 0.050 MPa, i. e. almost 22% lower than the former;

-

3) through the assessment by means of the trend line obtained from the analysis of the soil impact indicator for a high number of tractors, the environmental issue, consisting in the development of more environmentally friendly tyres/tracks for agricultural tractors, is not a priority for manufacturers, as indicated by the upward curve, after 2000, of the graph “Average pressure of tractors on the soil for all engine power classes from 1961 to 2021”;

-

4) it was possible to propose the automatic collection of soil compaction data by means of a soil cone penetrometer mounted on a tractor, to be performed during a crop operation (soil tillage), as the most innovative method for monitoring soil health;

-

5) it was possible to propose the subsequent processing of the above data, by using geostatistics software, as the most effective soil health analysis method, including planning of mitigation strategies for minimising soil compaction.

Список литературы Computing the pressure of agricultural tractors on soil and mapping its compaction

- Adamchuk V.I., Sotnikov A.V., Speichinger J.D., Kocher M.F., Instrumentation System for Variable Depth Tillage, ASAE Annual International Meeting, Paper Number 031078, Las Vegas, Nevada, 2003, pp. 1-10.

- Adylin I.P., Increasing the permeability and reducing the technogenic impact of tracked vehicles with elastic tracks by reducing the unevenness of the distribution of pressure on the soil: Cand. techn. nauk thesis, 05.20.01, Bryansk, 2016, 150 p.

- Adylin I.P., Lapik V.P., Application of rubber-cord tracks in caterpillar propulsion, Technics in agriculture, 2013, No. 1, p. 27.

- Adylin I.P., Lapik V.P., Kuznetsov A.E., Malashenko Yu. A., Lapik P.V., Elastic track of the vehicle track: pat. 196941 Russian Federation: IPC B62D 55/24: Patent holder Federal State Budgetary Educational Institution of Higher Education “Bryansk State Agrarian University”, Application No. 2019131658; declared 7.10.2019; publ. 23.3.2020, Byul. No. 9.

- Alaoui A., Diserens E., Mapping soil compaction - A review, Current Opinion in Environmental Science & Health, 2018, No. 5, pp. 60-66, https://doi.org/10.1016/j.cosh.2018.05.003.

- Alaoui A., Rogger M., Peth S., Blöschl G., Does soil compaction increase floods? A review, J Hydrol., 2018, No. 557, pp. 631-642, https://doi.org/10.1016/j.jhydrol.2017.12.052.

- Alesso C.A., Masola M.J., Carrizo M.A., Cipriotti P.A., Imhoff del S., Spatial variability of short-term effect of tillage on soil penetration resistance, Archives of Agronomy and Soil Science, 2019, No. 65(6), pp. 822-832, https://doi.org/10.1080/03650340.2018.1532076.

- Beckett C.T.S., Bewsher S., Guzzomi A.L., Lehane B.M., Fourie A.B., Riethmuller G., Evaluation of the dynamic cone penetrometer to detect compaction in ripped soils, Soil Tillage Res., 2018, No. 175, pp. 150-157, https://doi.org/10.1016/j.still.2017.09.009.

- Bussell J., Crotty F., Stoate C., Comparison of Compaction Alleviation Methods on Soil Health and Greenhouse Gas Emissions, Land, 2021, No. 10, pp. 1-10, https://doi.org/10.3390/land10121397.

- Campbell D.M.H., White B., Arp P.A., Modeling and mapping soil resistance to penetration and rutting using LiDAR-derived digital elevation data, J Soil Conserv., 2013, No. 68, pp. 460-473, https://doi.org/10.2489/jswc.68.6.460.

- Carrara M., Castrignanò A., Comparetti A., Febo P., Orlando S., Multivariate geostatistics for assessing and predicting soil compaction, Proc. of the 5th European Conf. on Precision Agriculture (5ECPA), Sweden, Uppsala, 2005, pp. 723-730.

- Carrara M., Comparetti A., Fabio P., Morello G., Orlando S., Mapping soil compaction measuring cone penetrometer resistance. Vol. Precision Agriculture, 4th European Conf. on Precision Agriculture (ECPA), Berlin, Germany, 2003.

- Carrara M., Castrignanò A., Comparetti A., Febo P., Orlando S., Mapping of penetrometer resistance in relation to tractor traffic using multivariate geostatistics, Geoderma, 2007, No. 142(3-4), pp. 294-307, https://doi.org/10.1016/j.geoderma.2007.08.020.

- Chekin G.V., Silaev A.L., Smolsky E.V., Distribution of Cu, Ni, Zn, Mn, Cr, Cd, Pb, Co, Mo, As in alluvial soils of floodplain landscapes of the Sozh river basin, Dokuchaev Soil Bulletin, 2021, Vol. 109, pp. 165-185, https://doi.org/10.19047/0136-1694-2021-109-165-185.

- Comparetti A., Febo P., Orlando S., Survey of the Mean Pressure Exerted by a Wide Range of Tractors on the Soil, Work safety and risk prevention in agro-food and forest systems: Intern. Conf., Italy, Ragusa Ibla Campus, 2010, pp. 1-5.

- Comparetti A., Febo P., Orlando S.A., System for the Real-Time Geo-Referenced Measurement of Soil Parameters, Rural Development in Global Changes, Vol. 5, Book 1, 5th International Scientific Conference “Rural Development 2011”, Akademija, Kaunas district, Lithuania, 2011, pp. 319-323.

- Comparetti A., Febo P., Orlando S., A system for the real-time geo-referenced measurement of soil parameters, Bulgarian Journal of Agricultural Science, 2013, No. 19(6), pp. 1253-1257.

- Comparetti A., Febo P., Greco C., Orlando S., Have tractor manufacturers bore in mind soil compaction over the last 40 years? Proc. of the 9th Intern. Scien. Conf. Rural Development 2019: “Research and Innovation for Bioeconomy”, Akademija, Kaunas district., Lithuania, 2019, pp. 112-118.

- Comparison of wheeled and tracked tractors, Agrovestnik, URL: https://agrovesti.net/lib/tech/machinery-and-equipment/sravnenie-kolesnykh-i-gusenichnykh-traktorov.html (accessed on 6, October ,2023).

- Diserens E., Chanet M., Marionneau A., Machine weight and soil compaction: TASC V2.0.xls - a practical tool for decision-making in farming, AgEng, Clermont-Ferrand, 2010, No. 239, pp. 10.

- Elaoud A., Chehaibi S., Soil compaction due to tractor traffic, Journal of Failure Analysis and Prevention, 2011, No. 11(5), pp. 539-545, https://doi.org/10.1007/s11668-011-9479-3.

- European Commission, Joint Research Centre, European Soil Data Centre (ESDAC). Natural susceptibility to soil compaction in Europe. URL: https://esdac.jrc.ec.europa.eu/content/natural-susceptibility-soil-compaction-europe (accessed on 6, October, 2023).

- Febo P., Pessina D., Pipitone F., Un impianto per la misura dell’area di contatto dei pneumatici agricoli: prime prove comparative, An equipment for measuring the contact area of agricultural tyres: first comparative tests: VI Convegno Nazionale di Ingegneria Agraria, Italy, Ancona, 1997.

- Gasso V., Sørensen C.A.G., Oudshoorn F.W., Green O., Controlled traffic farming: A review of the environmental impacts, European Journal of Agronomy, 2013, No. 48, pp. 66-73, https://doi.org/10.1016/j.eja.2013.02.002.

- GOST R 58656-2019. Mobile agricultural machinery. Methods for determining the impact of propulsion on the soil. Electronic fund of legal and normative-technical documents. 2021. National Standard of Russian Federation. URL: https://docs.cntd.ru/document/1200169433 (accessed on 6, October, 2023).

- GOST R 58655-2019. Mobile agricultural machinery. Norms for determining the impact of propulsion on the soil. Electronic fund of legal and normative-technical documents. National Standard of the Russian Federation. URL: https://internet-law.ru/gosts/gost/72298 (accessed on 6, October, 2023).

- Hansen M.C., Potapov P.V., Moore R., Hancher M., Turubanova S.A., Tyukavina A., Thau D., Stehman S.V., Goetz S.J., Loveland T.R., Kommareddy A., Egorov, A., Chini L., Justice C.O., Townshend J.R.G., High-resolution global maps of 21st-century forest cover change, Science, 2013, No. 342, pp. 850-853, https://doi.org/10.1126/science.1244693.

- Kees G., Hand-held electronic cone penetrometers for measuring soil strength, Technical Report 0524-2837-MTDC, U.S. Department of Agriculture Forest Service, Missoula Technology and Development Center. Missoula, 2005.

- Ksenevich I.P., Skotnikov V.A., Lyasko M.I., Running system - soil - harvest, Мoscow: Agropromizdat, 1985, 304 p.

- Lapik V.P., Mechanical and technological bases of interaction of caterpillar propulsion machines with waterlogged floodplain soil: Dr. Techn. Sci. thesis, Bryansk, 2015, 327 p.

- Lapik V.P., Adylin I.P., Reduction of negative impact on waterlogged soils of caterpillar propulsion machines by application of rubber-cord tracks, Bulletin of the Bryansk State Agricultural Academy, 2011, No. 1, pp. 28-31.

- Lapik V.P., Adylin I.P., Investigation of the impact of modern MTU on the soils of the Bryansk region, Design, use and reliability of agricultural machinery, 2013, No. 1(12), pp. 58-62.

- Lapik V.P., Adylin I.P., Kuznetsov A.E., Malashenko Yu. A., Vladimirovich L.P., Elastic track of a vehicle caterpillar: a patent for a utility model 196941 Russian Federation, IPC B62D 55/24: Patent holder Federal State Budgetary Educational Institution of Higher Education “Bryansk State Agrarian University”, Application No. 2019131658 dated 7.10.2019; publ. 23.20, Byul. No. 9.

- Lapik V.P., Frantsuzov V.S., Adylin I.P., The effect of MTU on soil compaction, Agro-consultant, 2012, No. 1, pp. 18-21.

- Lapik V.P., Frantsuzov V.S., Adylin I.P., Investigation of soil compaction MTU, Bulletin of the Bryansk State Agricultural Academy, 2012, No. 1, pp. 35-37.

- LLC Company Mir Shin. Wide-profile ultra-low pressure tires are a necessity for domestic wheeled tractors, URL: https://ooo-kompaniya-mir-shin.promportal.su/firm_news/395/shirokoprofilnie-shini-sverhnizkogo-davleniya-neobhodimost-dlya-otechestvennih-kolesnih-traktorov (accessed on 6, October, 2023).

- Mouazen A.M., Ramon H., De Baerdemaeker J., On-line detection of soil compaction distribution based on finite element modelling procedure, Proc. of the 3rd European Conference of Precision Agriculture (G. Grenier, S. Blackmore, Eds.), Vol. 1, France, Agro Montpellier, Ecole Nationale Supérieure Agronomique de Montpellier, 2001, pp. 455-460.

- Mzuku M., Khosla R., Reich R., Inman D., Smith F., MacDonald L., Spatial Variability of Measured Soil Properties across Site-Specific Management Zones, Soil Sci. Soil Fertility & Plant Nutrition, 2005, No. 69, pp. 1572-1579, https://doi.org/10.2136/sssaj2005.0062.

- Orlando S., Comparetti A., Fabio P., Greco C., The influence of tractors on soil compaction in the last four decades: Intern. Conf., Italy, Ragusa, 2021.

- Panagos P., Barcelo S., Bouraoui F., Bosco C., Dewitte O., Gardi C., Erhard M., Hervas De Diego F., Hiederer R., Jeffery S., Lükewille A., Marmo L., Montanarella L., Olazabal C., Petersen J., Penizek V., Strassburger T., Toth G., Van Den Eeckhaut M., Van Liedekerke M., Verheijen F., Viestova E., The State of Soil in Europe: A contribution of the JRC to the European Environment Agency’s Environment State and: Outlook Report - SOER 2010 EUR 25186 EN, Luxembourg: Publications Office of the European Union, 2012.

- Peregoodov N.E., Novak M.A., Practical applications analysis and economic efficiency of the method on assessment of the sealing action from the tracked mover on the soil layer, International Journal of Engineering and Technology (UAE), 2018, No. 7(2), 13, Special Issue, pp. 319-321, https://doi.org/10.14419/ijet.v7i2.13.13069.

- Raghavan G.S.V., Alvo P., McKyes E., Soil compaction in agriculture: a view toward managing the problem, Adv. Soil Sci., 1990, No. 11, pp. 1-35.

- Raper R.L., Schwab E.B., Dabney S.M., Measurement and variation of site-specific hardpans for silty upland soils in the South-eastern United States, Soil Tillage Res., 2005, No. 84, pp. 7-17, https://doi.org/10.1016/j.still.2004.08.010.

- Shah A.N., Tanveer M., Shahzad B., Yang G., Fahad S., Ali S., Bukhari M.A., Tung S.A., Hafeez A., Souliyanonh B., Soil compaction effects on soil health and crop productivity: an overview, Environ Sci Pollut Res., 2017, Vol. 24, pp. 10056-10067, https://doi.org/10.1007/s11356-017-8421-y.

- Silaev A.L., Smolsky E.V., Chekin G.V., Simonov V.Yu., Novikov A., Possibility of using technogenically polluted floodplain landscapes, Revista de la Universidad del Zulia, 2021, No. 12(32), pp. 102-113.

- Soane B.D., Bonne F.R., The effects of tillage and traffic on soil structure, Soil Tillage Res., 1986, No. 8, pp. 303-306.

- Skuratovich A., TRIZ-pros: Effective solutions in agriculture, Don't push the guys! Don't push! Moscow, 2006, pp. 87-101.

- Smolsky E.V., Silaev A.L., Dyachenko V.V., Nechaev M.M., Mameeva V.E., Green forage in radioactive flood meadows, IOP Conference Series: Earth and Environmental Science, The proceedings of the conference AgroCON-2019, article ID 012083.

- Vaz C.M.P., Manieri J.M., de Maria I.C., Tuller M., Modeling and correction of soil penetration resistance for varying soil water content, Geoderma, 2011, No. 166, pp. 92-101, https://doi.org/10.1016/j.geoderma.2011.07.016.

- Whattoff D., Mouazen A., Wayne T., A multi sensor data fusion approach for creating variable depth tillage zones, Advances in Animal Biosciences, 2017, No. 8(2), pp. 461-465, https://doi.org/10.1017/S2040470017000413.