Concentration of carbon dioxide in products of combustion of GTE NK-16ST and NK-16-18ST

Автор: Baklanov A.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 4 vol.24, 2023 года.

Бесплатный доступ

This paper considers the design of two combustion chambers of a gas turbine engine running on natural gas. One combustion chamber has 32 burners, and the other has 136 nozzles located in two rows in the flame tube head. A major contributor to global warming is considered to be the significant emissions of greenhouse gases, primarily CO2, including those emitted by gas turbine engines and power plants. The reduction of carbon dioxide levels by developing a set of structural measures in the combustion chamber is one of the urgent tasks of engine construction which requires a solution in order to meet modern environmental requirements for gas turbine engines serving as blower drives for gas compressor units. The presented research is dedicated to the analysis of influence of changes in combustion chamber design on reduction of CO2 level in exhaust gases of gas turbine engine NK-16ST. Two modifications of the combustion chamber are considered. The first one was a serial combustion chamber with diffusion combustion; the second one was a modernized combustion chamber with a modified front device. Each of the chambers considered was tested as part of the engine. During the study, combustion products were sampled directly in the exhaust tower and their concentrations, including the CO2 content, were determined. As a result of this work, it was confirmed that there is a possibility to reduce the concentration of CO2 in the engine combustion products up to 20 % without affecting the engine parameters. This reduction in carbon dioxide content was made possible by reducing the completeness of fuel combustion in the combustion chamber. The obtained data on changes in CO2 concentration can be useful in selecting the most suitable mode of engine operation, and the presented approaches to combustion processes organization can be used by developers in designing combustion chambers of natural gas-fired gas turbine engines.

Carbon dioxide emission, combustion chamber, gas turbine engine, combustion product, gas compressor unit

Короткий адрес: https://sciup.org/148329712

IDR: 148329712 | УДК: 621.43.056 | DOI: 10.31772/2712-8970-2023-24-4-697-705

Текст научной статьи Concentration of carbon dioxide in products of combustion of GTE NK-16ST and NK-16-18ST

A combustion chamber is one of the main elements that determine the reliability and efficiency of gas turbine engines (GTE). The operating process of a combustion chamber of a GTE is very complex and is determined by many factors: aerodynamics of air and gas flows, nature of fuel supply and its mixing with air and vaporisation, ignition, flame stabilisation, mass and heat exchange conditions, combustion patterns along the length of a combustion chamber. Despite significant differences in the general layout and great diversity in the design of individual elements of combustion chambers of various engines, they are based on common principles of the organisation of the working process [1].

A peculiarity of the combustion process in a gas turbine engine is that the total composition of the fuel-air mixture lies outside the flammability limits, and the cycle temperature is below the instantaneous ignition temperature of any hydrocarbon fuels. Combustion in the engine occurs in the air flow, the velocity of which is much higher than the flame propagation velocity of hydrocarbon fuels. The flow velocity in combustion chambers of stationary engines is 30-80 m/s, aviation engines is up to 50120 m/s. In addition, combustion must occur in a very limited volume, therefore with a high rate of heat release at rapid mixing and combustion processes. Irrespective of these limitations, the engine must ensure stable combustion, high combustion completeness, flammability and low toxic emissions.

At present, the issues of reducing greenhouse gases, in particular, CO2 emissions in the exhaust gases of GTEs are relevant for power engineering and gas transport industries. Of particular interest is the influence of combustion process in the combustion chamber on CO2 formation depending on GTE operation modes [2].

Modern gaseous fuels are a mixture of various hydrocarbon compounds. The conditional chemical formula of such fuels can be represented as follows: CmHn; for the methane m ~1, n ~4.

In technical calculations atmospheric air is taken as a mixture of nitrogen and oxygen, then the conventional chemical formula of air can be represented by the ratio (О2 + 3.76N2). The ratio 3.76 shows that the air contains approximately 3.76 nitrogen molecules per 1 oxygen molecule.

The chemical reaction of hydrocarbon fuel oxidation in air can be written symbolically as a stoichiometric equation

4C m H n + (4m + n)·(O 2 + 3.76N 2 ) = 4mCO 2 + 2nH 2 O + 3.76(4m + n)N 2 . (1)

The stoichiometric equation is written under the assumption of complete conversion of fuel into the main products of combustion and complete chemical inertness of atmospheric nitrogen. The stoichiometric equation provides a macroscopic description of the fuel oxidation process and makes it possible to determine such important characteristics as the stoichiometric ratio for the fuel L 0 and the composition of the products of complete combustion, namely:

L 0 =

( 4 m + n ) ( ц 0 .2 + 3.76 -ц n 2 ) 34.32(4 m + n ) kg of air

4( m -ц c + n -ц М ) 12 m + n kg of fuel

where µ is molecular weight of the respective substance,

C _ 4 m - 100 %

CO 2 4 m + 2 n + 3.76 ( 4 m + n ) ’

C h2o =

2 n - 100 %

4 m + 2 n + 3.76 ( 4 m + n ) ’

C _ 3.76(4 m + n ) - 100 %

N 2 4 m + 2 n + 3.76 ( 4 m + n )

For the methane m = 1, n = 4, then

L о * 17.2; С со2 * 9.5; С H 2 O * 19; С n2 - 71.5 %.

In the process of oxidation of carbon-containing fuels, carbon monoxide CO is formed as an intermediate substance. The conversion of CO into CO 2 is determined to a greater extent by the elementary reaction [3]

CO + ОН → CO 2 + Н.

Since this reaction is the only one that determines the conversion of CO into CO 2 , it can be concluded that all the carbon originally contained in the fuel is converted into CO 2 . It follows that the content of CO 2 in the combustion products will be determined by the completeness or incompleteness of its oxidation reaction.

Study object

To determine the influence of combustion chamber design on the CO 2 content in the combustion products, two types of combustion chambers are being considered in this paper. One is a serial one for the NK-16ST engine, the other is for the NK-16-18ST engine.

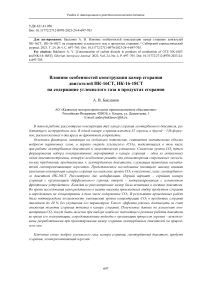

The diffusion principle of fuel combustion is organised in the serial combustion chamber of the NK-16ST GTE. The chamber (Fig. 1) consists of outer 1 and inner 2 casings, collector 3 , pipelines 4

for fuel supply from the collector to the nozzles 5 , flame tube 6 including casings 7 with applied holes 8 and mixer nozzles 9 . The annular front device 10 accommodates 32 swirl burners 11 . The flame tube (annular) consists of annular sections, between which an annular channel for supplying cooling air is formed, which provides convective-film cooling of the walls [4].

Рис. 1. Камера сгорания двигателя НК-16СТ

Fig. 1. Combustion Chamber of the Gas-turbine Engine NK-16ST

In each swirl burner, an individual fuel gas supply is carried out by means of nozzles providing a jet gas supply [5].

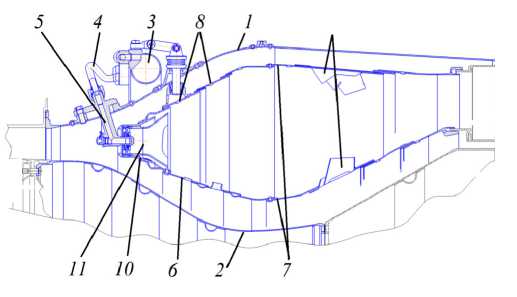

The flame tube front device of the NK-16-18ST GTE (Fig. 2) contains an annular head 1 including an outer and inner fuel manifold 2 . On the wall of the outer fuel manifold four inlets are evenly located, necessary for gas feeding into the inner cavity of the manifolds. The cavities of the manifolds are connected by means of channels 3 arranged in the front device. There are also staggered shaped windows 4 with a central hole and nozzle mounting posts 5 [6; 7].

Рис. 2. Камера сгорания двигателя НК-16-18СТ

Fig. 2. Combustion Chamber of the NK-16-18ST Gas-turbine Engine

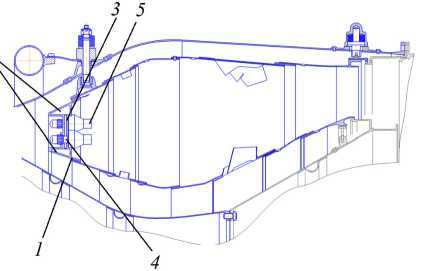

Each chamber was tested as part of a gas turbine engine. The stand (Fig. 3), where the engine was installed, consists of an air inlet equalising pipe, the inlet of which is protected by a protective mesh. It is necessary to prevent the ingress of foreign particles into the the engine block. In order to transport the exhaust gases to the exhaust tower, an exhaust unit is installed in the exhaust part of the engine. An air compressor (pneumatic brake) was used as a loading device of the free turbine [8].

Рис. 3. Схема стенда

Fig. 3. Scheme of the Stand

The stand is equipped with necessary measuring instruments. It has an oil system for lubrication of engine supports and units during testing. To ensure starting and fuel gas supply to the fuel supply elements, the stand contains a gas system. The engine parameters are monitored and its operation modes are adjusted from the control panel equipped with the monitors on which the measured parameters are displayed [9].

Test results

During the tests, the engines were started and reached the modes necessary for building the throttle characteristic. At modes higher than 10 MW, in accordance with the standard [10], combustion products were sampled in the exhaust tower and the concentrations of toxic substances in them were determined.

A gas sampling probe immersed in a special window made in the wall of the exhaust tower was used for sampling, and the Testo 350 gas analyser was used to determine the concentration of toxic components in the combustion products. The measured value of oxygen (O2) concentration in the combustion products is used to calculate the CO2 content:

c ( CO 2 )

_ c ( CO 2max ) ( 21 - c ( O 2 ) )

where c (CO2 max) is a maximum concentration value CO2, %; 21 is O2 concentration in the air, %; c (O2) is measured O2 concentration in combustion products, %.

According to the high speed of the instrument, the time of one measurement was 40 seconds. The data processed by the gas analyser were displayed on the screen and also recorded using a printing device embedded into the gas analyser [11].

To convert mass concentrations of CO 2 from % to g/m3, a number of conditions are assumed: the temperature of exhaust gases is 618.15 K, the pressure of exhaust gases is equal to atmospheric pressure under normal conditions and corresponds to 101 325 Pa.

The volume of one mole of carbon dioxide at a temperature of 618.15 K is calculated using the following formula

Vm CO2 TG

= V m CO2 T N

( T \ TG ч t n 7

and it is 50.69 litres, where T G = 618.15 K, T N = 273.15 K, Vm CO 2 TN

= 22.40 litres is the volume of

one mole of CO2 at a temperature of 273.15 K.

Since the mass of one mole of CO2 Мm CO2 is 44 grams, the mass of 1 litre will be calculated according to the ratio Мm CO2 Vm CO2 T G and it will be 0.868 g/l. The volume of 1% of 1 m3 is 10 litres. It follows that the mass of 1 % of 1 m3 is 10 litres ∙ 0.868 g/l and equals 8.68 g [12].

The data on CO 2 content in combustion products in % and g/m3 depending on the engine operation mode are summarised in the table.

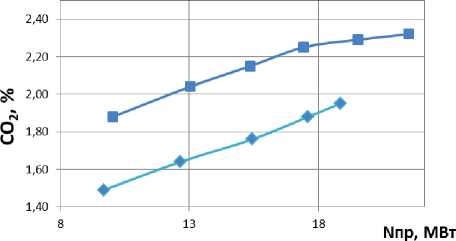

Fig. 4 shows that with increasing engine operation mode, the content of CO2 in the exhaust gases rises, which is associated with an increase in fuel and air consumption with power gain, and consequently with an increase in the consumption of combustion products.

In exhaust gases of the NK-16ST engine the level of CO 2 carbon dioxide content is lower by « 20 % compared to the NK-16-18ST engine.

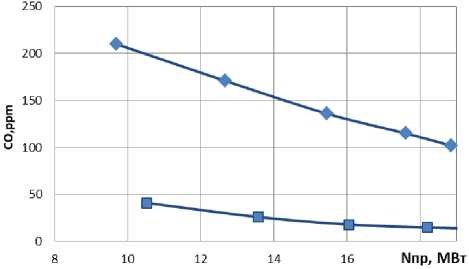

If we adhere to the earlier assumption that the only mechanism of CO2 reduction is incomplete oxidation reaction, then CO2 reduction should lead to an increase in CO emissions, which is confirmed by the measurement data (Fig. 5).

Рис. 4. Содержание углекислого газа СО2 в продуктах сгорания:

♦ – двигатель НК-16СТ и ■ – двигатель НК-16-18СТ

Рис. 5. Содержание оксидов углерода CO в продуктах сгорания:

♦ – двигатель НК-16СТ и ■ – двигатель НК-16-18СТ

Fig. 4. Content of CO2 carbon dioxide in combustion products:

♦ – engine NK-16CT and ■ – engine NK-16-18CT

Fig. 5. Content of carbon oxides in combustion products:

♦ – engine NK-16CT and ■ – engine NK-16-18CT

For the further analysis, the CO 2 mass concentrations for each operating mode of NK-16-18ST and NK-16ST engines are presented and converted into g/m3 using the previously derived ratio of 1% = 8.68 g/m3.

CO2 content depending on engine operation mode

|

NK-16-18ST |

|||||

|

n LPc |

N c |

CO, ppm |

CO 2 , % |

CO 2 , g/m3 |

|

|

1 |

4900 |

10.515 |

41 |

1.71 |

14.84 |

|

2 |

5100 |

13.577 |

26 |

1.89 |

16.41 |

|

3 |

5250 |

16.064 |

18 |

2.00 |

17.36 |

|

4 |

5350 |

18.201 |

15 |

2.10 |

18.22 |

|

5 |

5450 |

20.133 |

13 |

2.20 |

19.09 |

|

6 |

max |

22.011 |

13 |

2.25 |

19.53 |

End of Table

|

NK-16ST |

|||||

|

N LPc |

N c |

CO, ppm |

CO 2 , % |

CO 2 , g/m3 |

|

|

1 |

4900 |

9.69 |

210 |

1.49 |

12.93 |

|

2 |

5100 |

12.66 |

171 |

1.64 |

14.24 |

|

3 |

5250 |

15.451 |

136 |

1.76 |

15.28 |

|

4 |

5350 |

17.61 |

115 |

1.88 |

16.32 |

|

5 |

max |

18.864 |

102 |

1.95 |

16.93 |

From Fig. 4 and the table it can be seen that the NK-16ST engine with a commercially available combustion chamber has a lower CO2 concentration level than the NK-16-18ST engine with a combustion chamber having a multi-nozzle front device [13].

To calculate the completeness of fuel combustion the following dependence was used [14]:

η G = 1 - (0.20175 ⋅ EI CO + EI CH 4) ⋅ 10 - 3, (9)

where EI CO is a carbon monoxide emission index; EICH 4 is a methane emission index; the value 0.20175 is a coefficient that takes into account the ratio of the net calorific value of carbon monoxide QN CO to the lower calorific value of methane QN CН4 , which are QN CO = 10096 kJ/kg and QN CН 4 = 50042 kJ/kg.

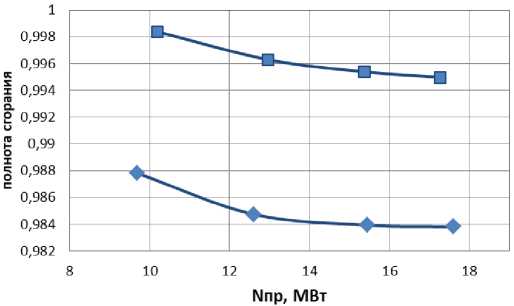

Рис. 6. Полнота сгорания топлива на различных режимах: ♦ – двигатель НК-16СТ, ■ – двигатель НК-16-18СТ

Fig. 6. Completeness of Combustion of Fuel on various power setting: ♦ – engine NK-16CT and ■ – engine NK-16-18CT

The emission indices EIi for carbon monoxide and methane are calculated using the equation

EI i = µ i (1 -α i ⋅ L 0 ) ⋅χ i ⋅ 10 - 3, µ a

where L 0 = 17.2 is a previously calculated stoichiometric methane combustion coefficient (kg of air/kg of fuel); α i is a total or local air excess ratio; µ i is a molar mass of the toxic substance to be determined (CO, CH4), g/mole; µ a is a molar mass of the air, g/mole; χ i is a volume fraction of toxic substance, ppm.

The variation of combustion completeness is characterised by insignificant decrease within 0.5 % in the power range from 10 to 17 MW, thus at the 16 MW mode the average completeness for the NK-16ST engine was ɳ = 0.985, for the NK-16-18ST engine - ɳ = 0.996 (Fig. 6).

Conclusion

The possibility of reducing the level of CO2 concentration in the engine combustion products up to 20 % by reducing the completeness of fuel combustion in the combustion chamber was confirmed.

The data obtained on the change of CO2 concentration with the change of engine operation mode can be useful in selecting the most appropriate mode to minimise CO 2 during operation.

The presented approaches to the organisation of combustion processes can be used by developers when designing combustion chambers of gas turbine engines operating on natural gas to minimise CO 2 emissions while ensuring CO optimum and combustion completeness.

Список литературы Concentration of carbon dioxide in products of combustion of GTE NK-16ST and NK-16-18ST

- Lefebvre A. H. [Fuel effects on gas turbine combustion-ignition, stability, and combustion efficiency]. Am. Soc. Mech. Eng. 1984, Vol. 84, No. CONF-840611.

- Baklanov A. V. [Impact of changing the combustion chamber design on the CO2 concentration in the exhaust gases of the NK-16ST gas turbine engine]. Gas industry. 2022, No. 6 (834), P. 80–88 (In Russ.).

- Markushin A. N., Baklanov A. V. [Investigation of the gas turbine engine combustion chamber workflow]. Bulletin of the Samara university. Space equipment, technologies and mechanical engineering. 2016, Vol. 15, No. 3, P. 81–89 (In Russ.).

- Gritsenko E. A., Danilchenko V. P., Lukachev S. V. Nekotoryye voprosy proyektirovaniya aviatsionnykh gazoturbinnykh dvigateley [Some issues of the design of aircraft gas turbine engines]. Samara, 2002, 527 p.

- Baklanov A. V. [Burner geometry impact of gas turbine engine combustion chamber characteristics]. Vestnik moskovskogo aviatsionnogo institute. 2021, Vol. 28, No. 1, P. 86–95 (In Russ.).

- Vorotyntsev I. E., Tyulkin D. D., Fedorchenko D. G., Tsybizov Yu. I. [Features of commissioning a gas turbine unit with a low-emission combustion chamber]. Journal of Physics: Conference Series. 2021, Vol. 1891, Р. 012002.

- Baklanov A. V. [Controlling fuel combustion process by burner design change in gas turbine engine combustion chamber]. Vestnik moskovskogo aviatsionnogo institute. 2018, Vol. 25, No. 2, P. 73–85 (In Russ.).

- Baklanov A. V. [Low-emission combustion chamber of diffusion type employing micro flame burning process for converted aircraft gas turbine engine]. Vestnik moskovskogo aviatsionnogo institute. 2017, Vol. 24, No. 2, P. 57–68 (In Russ.).

- STO Gazprom 2-3.5-038-2005 Instructions for conducting control measurements of harmful emissions of gas turbine plants at compressor stations. Chelyabinsk, Center for Work Safety, 2005, 13 p.

- Burrus D. L., Charour C. Α., Foltz H. L. et al. Energy Efficient Engine Combustor Test Hardware– Detailed Design Report. NASA CR-168301.

- Dodds W. J., Ekstedt E. E. Broad Specification Fuel Combustion Technology Program. Phase II, Final Report, 1989.

- Lefebvre A. H. Influence of Fuel Properties on Gas Turbine Combustion Performance. AFWAL-TR-84-2104, 1985.

- Mingazov B. G., Yavkin V. B., Sabirzyanov A. N., Baklanov A. V. [The analysis of applicability of models of burning for calculation of the GTD mnogoforsunochny combustion chamber]. Bulletin of Samara State Aerospace University of the academician S.P. Korolyov (national research university). 2011, No. 5 (29), P. 208–214 (In Russ.).

- Canilo P. M. Energeticheskiye i ekologicheskiye kharakteristiki GTD pri ispol'zovanii uglevodorodnykh topliv i vodoroda [Energy and environmental performance of gas turbine engines when using hydrocarbon fuels and hydrogen]. Kiev, Nauk. Dumka, 1987, 224 p.