Conditions for conducting experimental studies on grain drying

Автор: Rakhmankulov T., Erkinjonov A., Karimov K.A., Adilova Sh.R., Turakhodjaev N.J., Mirmuhamedov M.M., Sharipov Ja.H., Obidov Z.R., Komolov Kh.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 2 т.17, 2024 года.

Бесплатный доступ

This paper examines the effect of heater power, speed of drying agent (air), adjustable slit width and number of revolutions of drying drum on the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the chatness of rice in the rice pile. In addition, showed the changes in the value of the heating power and the drying efficiency of the device. The change of the adjustable slot size of the drying drum and the drying efficiency of the device consist of determining the effect of the moisture content of the pile of rice coming out of the drum and the effect of rice chatnash in the pile of rice. The experimental rice drying device in a stationary version was prepared at the “Andijan experimental-testing plant” JSC according to the design drawings developed by the Andijan Institute of Mechanical Engineering. Based on the results of theoretical studies, a drying drum with a diameter of 880 mm and a length of 1800 mm was adopted as the main working body.

Rice, heater, drum, experiment, diameter, moisture, size, parameters

Короткий адрес: https://sciup.org/146282846

IDR: 146282846 | УДК: 631.563.2

Текст научной статьи Conditions for conducting experimental studies on grain drying

Currently, one of the key tasks arising from production solutions is the more complete and efficient use of the manufactured product from a metal alloy or carbon steel, a reduction in loss of metal products from destruction [1–5]. Along with the intensive use of machines, mechanisms and various products, reliable protection against the aggressive effects of the media in which they are operated is required [6–10]. In addition, the savings of basic structural materials and products, their rational use is also inextricably linked with the reliable protection of their negative environmental impact [11–16].

Metal alloys play a significant role in the successful solution to improve and extend the service life of steel products or equipment [17–20]. These alloys as coatings increase the resistance and durability of products and equipment protect metal products from destruction [21–25].

Experimental part

It is desirable to carry out experimental studies using different values of heater power, speed of drying agent, adjustable slot size of drying drum. As a result of theoretical studies, it was determined that the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the chatniness of the rice in the rice pile depend on the heating power, the value of the speed of the drying agent, the drying drum, the size of the adjustable slot, and the number of revolutions of the drying drum. The tasks of experimental research are as follows:

-

– to determine the effect of the change in the value of the heater power on the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the rice chatnash in the rice pile;

-

– to determine the effect of the change in the speed of the drying agent on the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the rice chatnash in the rice pile;

-

– to determine the effect of the change in the size of the adjustable slot of the drying drum on the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the rice chatnash in the rice pile;

-

– to determine the effect of the change in the number of revolutions of the drying drum on the drying efficiency of the device, the moisture content of the rice pile coming out of the drum, and the rice chatnash in the rice pile.

For the experimental experiments, the value of the heater power is from 2 kW to 4 kW, the speed of the drying agent is from 0.25 m/s to 0.75 m/s, the adjustable slit size of the drying drum is changed from 1 sm 3 sm and the number of revolutions of the drying drum changed from 10min-1 to 22 min-1. When one parameter was changed in the experiment, the other parameters remained constant, that is, they were not changed.

The scope of experimental studies on the optimization of parameters of the drying device was carried out using the method of mathematical planning of experiments. The experiments were conducted on the basis of a four-factor plan.

Mathematical statistics methods obtained in the experiments were used, and the average arithmetic values of the indicators were determined.

Results and discussion

Changing the value of the heater power in the dryer within certain limits was carried out using switches. Fig. 1 shows a general view of the switch-wire that changes the value of the Tin barriers – 188 – were used to create different values of drying agent (air) velocity and TRO-TEC (Germany) measuring instrument was used to measure its velocity.

This picture shows an overview of the TROTEC measuring equipment (Fig. 2)

The number of rotations of the drying drum was measured using a digital tachometer (Germany) Fig. 3 shows a general view of a digital tachometer that measures the number of rotations of the drying drum

It was prepared at JSC “Andijan Pilot-Test Plant” according to the design drawings developed by the Andijan machine-building institute. Based on the results of theoretical studies, 880 mm a drying drum equal in diameter and length was adopted as the main working body1800 mm.

The influence of the change in the value of the heater power on the performance of the dryer. To conduct these experiments, the heating power value was varied from 2 kW to 4 kW in 0.5 kW increments. In this case, the value of the speed of the drying agent was 0.5 m/s, the size of the adjustable slot of the drying drum, 2 sm and the number of revolutions of the drying drum were taken as 16 min-1.

Fig. 1. Change the value of the heater power interlocked

Fig. 2. To measure the speed of the drying agent TROTEC equipment

Fig. 3. Measuring the number of rotations of the drying drum digital tachometer for experimental rice drying device in a stationary version Andi

The drying efficiency of the device was taken as the main indicator in the study of the change in the value of the heater power. In an additional study, the moisture content of the rice pile coming out of the drum and the rice chatnash in the rice pile were studied. In this case, the value of the heater power was changed in the order mentioned above and experiments were conducted.

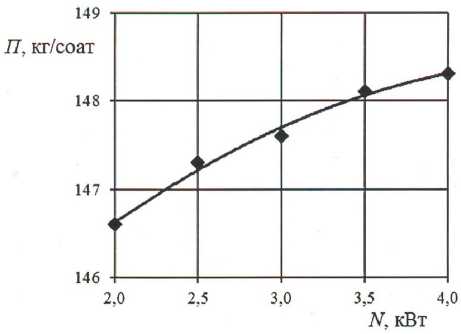

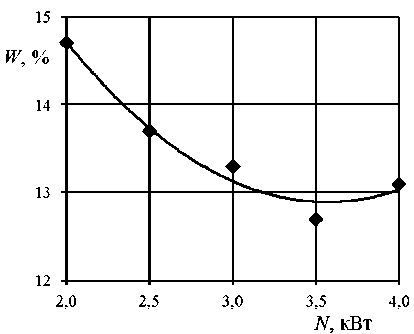

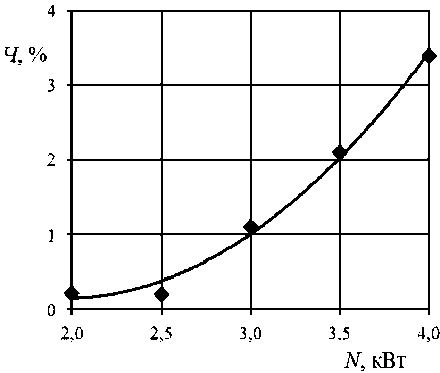

Fig. 4–5 and 6 show the results obtained in the experiments in a graphical form and presented in a tabular form.

From the connections shown in Fig. 4, 5 and 6, it can be seen that increasing the value of the heater power from 2 kW to 4 kW leads to an increase in the drying efficiency of the device and a decrease in the moisture content of the rice pile coming out of the drying drum. However, it also causes an increase in rice chatnash in the pile of rice coming out of the drying drum. Therefore, it is desirable to take the heater power less than 4 kW.

Applying the method of least squares to the graphical relationships depicted in Fig. 4, 5 and 6, they can be expressed using the following empirical formulas:

P=143.12+2.2114·N – 0.2286·N 2; (R 2 =0.99).

W=22.334– 5 .2971·N+0.7429·N 2; (R 2 =0.968).

Ch=3.1023– 3 .051N+0.7829·N 2; (R 2 =0.992).

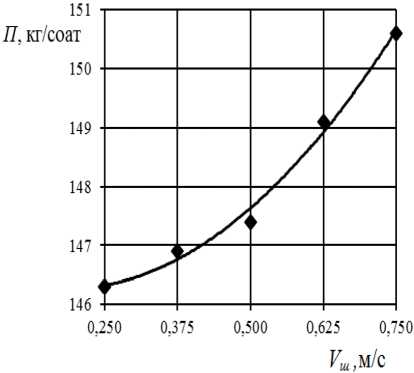

The influence of the value of drying agent speed on the performance of the device. To conduct these experiments, the drying agent velocity was varied from 0.25 m/s to 0.75 m/s with an interval of 0.125 m/s. In this case, the value of the heater power was 3 kW, the size of the adjustable slot of the drying drum 2 sm and the number of rotations of the drying drum were taken as 16 min-1.

In studying the speed of the drying agent, the drying efficiency of the device was taken as the main indicator. In addition, the moisture content of the rice pile coming out of the drum and the rice chatnash in the rice pile were studied. Experiments were carried out by changing the speed of the drying agent in the above order.

Fig. 7 shows the results obtained in the experiments in a graphical form and presented in a tabular form.

Fig. 4. It depends on the value of the heater power ( N) . change of drying efficiency ( P)

Fig. 5. I depends on the value of the power of the generator ( N). change of pile moisture ( W)

Fig. 6. I depends on the value of the power of the generator ( N). changing the rice chatnashi ( Ch) in the heap

Fig. 7. Q depends on the speed of the drying agent ( V sh ). change of drying efficiency ( P)

Conclusions

As a result of the conducted research, it can be concluded as follows: the main convenience of the experimental rice drying device is that it protects the dried grain from sunlight, which in turn has a positive effect on adding weight to the rice during the rice milling process. In the process of conducting experimental research, the theoretical difference has been significantly different, and in the current development period, conducting experimental experiments is the need of the hour.

Список литературы Conditions for conducting experimental studies on grain drying

- Shluger А.М., Аzhоgin F. F., Еfimov Е. А. Corrosion and protection of metals. Мoscow: Metallurgy. 1981, 216 (In Rus.)

- Оbidov Z.R., Ganiev I. N. Anode protective of zinc-aluminium covering with II group elements. Berlin: LAP LAMBERT Academic Publishing. 2012, 288 (In Germany)

- Оbidov Z.R., Ganiev I. N. Physicochemical of zinc-aluminium alloys with rare-earth metals. Dushanbe: ООО «Аndaleb-R». 2015, 334 (In Tajikistan)

- Amini R.N., Irani M., Ganiev I., Obidov Z. R. Galfan I and Galfan II Doped with Calcium, Corrosion Resistant Alloys. Oriental Journal оf Chemistry. 2014, 30(3), 969–973

- Obidov Z.R., Ganiev I. N., Amonov I. T., Ganieva N. I. Corrosion of Al+2.18 % Fe alloy doped with gallium. Protection of Met. and Phys. Chem. of Surfaces. 2011. 47(5), 654–657

- Obidov Z.R., Ganiev I. N., Eshov B. B., Amonov I. T. Corrosion-electrochemical and physicochemical properties of Al+2.18 % Fe alloy alloyed with indium. Russian Journal of Applied Chemistry. 2010, 83(2), 263–266. DOI: 10/1134/S 107042721002014X

- Obidov Z.R., Ganiev I. N. Anodic behavior and oxidation of the thallium alloyed Al+2.18 % Fe alloy. Russian Journal of Applied Chemistry. 2012, 85(11), 1691–1694

- Obidov Z. R. Thermophysical Properties and Thermodynamic Functions of the Beryllium, Magnesium and Praseodymium Alloyed Zn‑55Al Alloy. High Temperature. 2017, 55(1), 150–153. DOI: 10.1134/S 0018151X17010163

- Obidov Z. R. Effect of pH on the Anodic Behavior of Beryllium and Magnesium Doped Alloy Zn55Al. Russian Journal of Applied Chemistry. 2015, 88(9), 1451–1457

- Obidov Z.R., Amonova A. V., Ganiev I. N. Influence of the pH of the Medium on the Anodic Behavior of Scandium – Doped Zn55Al Alloy. Russian Journal of Non-Ferrous Metals. 2013, 54(3). 234–238. DOI: 10.3103/S 1067821213030115

- Obidov Z. R. Anodic Behavior and Oxidation of Strontium – Doped Zn5Al and Zn55Al Alloys. Protection of Metals and Physical Chemistry of Surfaces. 2012. 48(3). 352–355

- Firuzi H., Jobirov U. R., Obidov Z. R. Effect of neodymium and erbium on the kinetics oxidation of Zn0.5Al zinc alloy, in solid state. Journal of Siberian Federal University. Engineering & Technologies. 2022, 15(5), 561–568. DOI: 10.17516/1999–494X‑0417

- Obidov Z.R., Amonova A. V., Ganiev I. N. Effect of Scandium Doping on the Oxidation Resistance of Zn5Al and Zn55Al Alloys. Russian Journal of Physical Chemistry A. 2013, 87(4). 702–703. DOI: 10.1134/S 0036024413040201

- Turakhodjaev N., Shukhrat C. and at al. Ways to increase the strength of the surface of the parts. Journal of Critical Reviews. 2020, 7(11), 380–386.

- Dzhakhangirovich T.N., Makhmatmurodovich C. S., Khusniddinovich T. N. Development of Machined Durable Parts of Modified 110g13l Brand Steel. Eurasian Scientific Herald. 2023, 17, 21–24

- Karimov K., Turahodjaev N., Akhmedov A., Chorshanbiev Sh. Mathematical model for producing machine parts. E 3S Web of Conferences. 2021, 264, 40–78

- Yang W., Ruizhi Wu, Turakhodjaev N., Meiduo Liu. Microstructural evolution, precipitation behavior and mechanical properties of a novel Al–Zn–Mg–Cu–Li–Sc–Zr alloy. Journal of Materials Research. 2021, 36, 740–750

- Turakhodjaev N., Tursunbaev S., Umarova D., Kuchkorova M., Baydullaev A. Influence of alloying conditions on the properties of white cast iron. International Journal of Innovations in Engineering Research and Technology. 2020, 7(12), 1–6

- Torakhodjaev N.D., Yakubov L. E., Tursunov S. Mathematical Model of Heat Treatment to Improve TX Mechanical Properties. Composite materials. 2018, 43–52

- Joshua F. Design, construction and testing of simple solar maize dryer. Department of Mechanical Engineering, Federal University of Technology Minna. Nigeria. 2008, 3–9

- Turakhodjaeva F.N. et al. The process of developing a technology for extracting copper and other nonferrous metals from industrial slags. Corporate Governance: Theory and Practice. Collection of scientific papers on. 2019, 23, 363–364.

- Nodir T., Shukhrat C., Nargiza S. & Kulmukhammad C. Ways to increase the strength of shaftgear teeth working in a highly abrasive grinding environment. Journal of Critical Reviews. 2020, 7(7), 904–907

- Wang Y. et al. Microstructure and mechanical properties of ultra-lightweight Mg-Li-Al/Al-Li composite produced by accumulative roll bonding at ambient temperature. Materials Science and Engineering: A. 2020, 787, 13–19

- Wang Y., Zhong F., Wu R., Wu H., Turakhodjaev N., Kudratkhon B. Zhang M. High-strength, ductility and modulus Al–Li/B 4C composite with near nanostructure produced by accumulative roll bonding. Journal of Alloys and Compounds. 2020, 834, 155105

- Yang Z., Ji P., Wu R., Wang Y., Turakhodjaev N., Kudratkhon B. High-strength, ductility and modulus Al–Li/B 4C composite with near nanostructure produced by accumulative roll bonding. International Journal of Materials Research. 2023, 114(1), 65–76