Crystallization features of calcium sulfate in the process of “artificial aging”

Автор: Garkavi M., Fischer H.-B., Kolodezhnaya E.

Журнал: Вестник геонаук @vestnik-geo

Рубрика: Научные статьи

Статья в выпуске: 9 (309), 2020 года.

Бесплатный доступ

Gypsum binders are widely used in construction, mining and the oil and gas industry. The use of these binders is conditioned by stability of their technical characteristics, which is achieved by using a technological operation “artificial aging”. The features of artificial aging are: 1) hydration of calcium sulphate hemihydrate in liquid phase deficiency; 2) the resulting dihydrate gypsum crystallizes in a limited volume of micropores of the original binder. From the standpoint of the quataronic concept, the features of the crystallization of gypsum dihydrate in the micropores of the original gypsum binder are considered. The effect of artificial aging conditions and the degree of supersaturation on the growth mechanism and the morphology of gypsum dihydrate crystals was determined. The use of artificial “aging” results in healing of defects in the structure of the original binder, decreasing water demand and increasing strength.

Crystallization of quataron, calcium sulfate, artificial aging, gypsum binder

Короткий адрес: https://sciup.org/149129445

IDR: 149129445 | УДК: 548.5:666.9 | DOI: 10.19110/geov.2020.9.6

Текст краткого сообщения Crystallization features of calcium sulfate in the process of “artificial aging”

Gypsum binders have been used for many years in not only construction industry, but also in mining industry to prepare hardening backfill mixtures, building of explosionproof bridges, as well as in the oil and gas industry in drilling and grout mixes [3, 7, 11]. Regardless of the field of application of the gypsum binders, it is necessary to ensure the stability of their technical characteristics.

To improve the construction and technical properties of the gypsum binder, a technological operation of artificial “aging” is used. The essence of this process lies in keeping the gypsum binder in the environment with different relative humidity. In this case, the hydration of the gypsum binder occurs with the formation of dihydrate gypsum, which is accompanied by “self-healing” of defects. The ar- tificial “aging” results in decreasing water demand of the gypsum binder and increasing its strength.

Materials and research methods

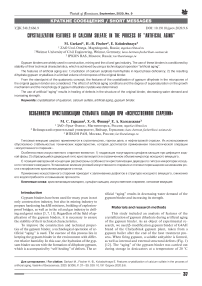

This study included an analysis of features of the crystallization of gypsum dihydrate during artificial aging of the gypsum binder. As an object of experimental research, we used β -modification gypsum binder of G4AII brand of the Chelyabinsk gypsum plant, taken from a gypsum boiler after the end of the heat treatment process. When firing gypsum, a soluble anhydrite is formed, as well as internal and external structural defects (Fig. 1) [12]. The “aging” of the gypsum binder was carried out during storage in desiccators at a temperature of 20 °C

Fig 1. Microdefects of gypsum particles

Ðèñ 1. Ìèêðîäåôåêòû ÷àñòèö ñòðîèòåëüíîãî ãèïñà

and relative humidity of 60 %, 80 % and 100 % ( ϕ = 0.6; 0.8; 1.0) for 14 days.

Results and discussion

The artificial aging process has two features:

-

— hydration of calcium sulfate hemihydrate occurs with a deficiency of the liquid phase;

-

— the resulting dihydrate gypsum crystallizes in a limited volume of micropores of the original binder.

The process of “aging” of calcium sulfate hemihydrate is conditioned by its hydration with the participation of water adsorbed on the active centers of the surface and on defects of its particles, and also by condensation of water vapor in ultrafine pores (fractures). Depending on the relative humidity of the air, liquid films of various thicknesses and structures are formed on the solid surfaces, which predetermines the possibility of changing mechanism and kinetics of hydration.

Under a high relative humidity ( ϕ = 1), liquid films about 90 µm thick are formed. Water is in a droplet-liquid state (bulk water) in such a film. At the same time, at ϕ = 0.8, the film thickness is within 5.6 ... 8.1 µm, and at ϕ = 0.6 the liquid film has a thickness of less than 3 µm. According to [4], water films that form on the surface of gypsum particles at ϕ ≤ 0.8 have anomalous properties, in particular, they have a high viscosity and a low dissolving power. As a result, the through-solution mechanism of hydration of hemihydrate calcium sulfate becomes impossible [8]; a non-traditional explanation of the hydration process is needed. This process with the participation of “anomalous” water can be considered within the quataron concept [1,2]. Its key position is the existence of specific clusters of nanometer sizes in nonequilibrium conditions –quatarons.

When liquid water is formed through quatarons, there are several ways of condensation with their merging or aggregating. The condensation of quatarons of different structure and size results in formation of different condensed phases of water. At low degrees of supersaturation ( ϕ ≤ 1) the condensation of quatarons occurs with the formation of structured water, which differs from the bulk liquid by properties [2]. Since quatarons have an increased reactivity, the participation of this water in 38

the hydration of hemihydrate calcium sulfate is carried out according to the topochemical mechanism with the formation of crystal hydrates of variable chemical composition [8]. According to I. V. Melikhov [6] at the solid-phase gypsum hydration, lamellar crystal hydrates of CaSO4∙nH2O composition are formed at n = 1.86 ± 0.05. Such variable chemical composition of hydration products predetermines their morphological heterogeneity and multistage crystallization process, which also corresponds to the quataronic concept [1].

The size of micropores in the initial gypsum binders does not exceed 1 ... 1.5 mcm, therefore, even under conditions of low supersaturation, quatarons of dihydrate gypsum appear in them, which then turn into contact nuclei. Since these quatarons are topologically and chemically close to the structure of the substrate (its role is played by the crystals of the initial binder), they are adsorbed on its surface and become sources of growth of gypsum dihydrate crystals.

In the course of growth, as noted above, the composition and structure of the crystals change. Each growing crystal captures a non-equilibrium amount of quatar-ons, and growth structural defects are formed in its volume, which can be active centers for the formation of intergrowths that bind crystals into an agglomerate (crystallization bridges) at any supersaturation of the medium. Resulted from the deposition of matter on the walls of micropores and cracks, a concentration gradient develops there, and the concentration is maximum at their entrance, where the intergrowths are formed, the adhesion of which results in a crystallization bridge [6].

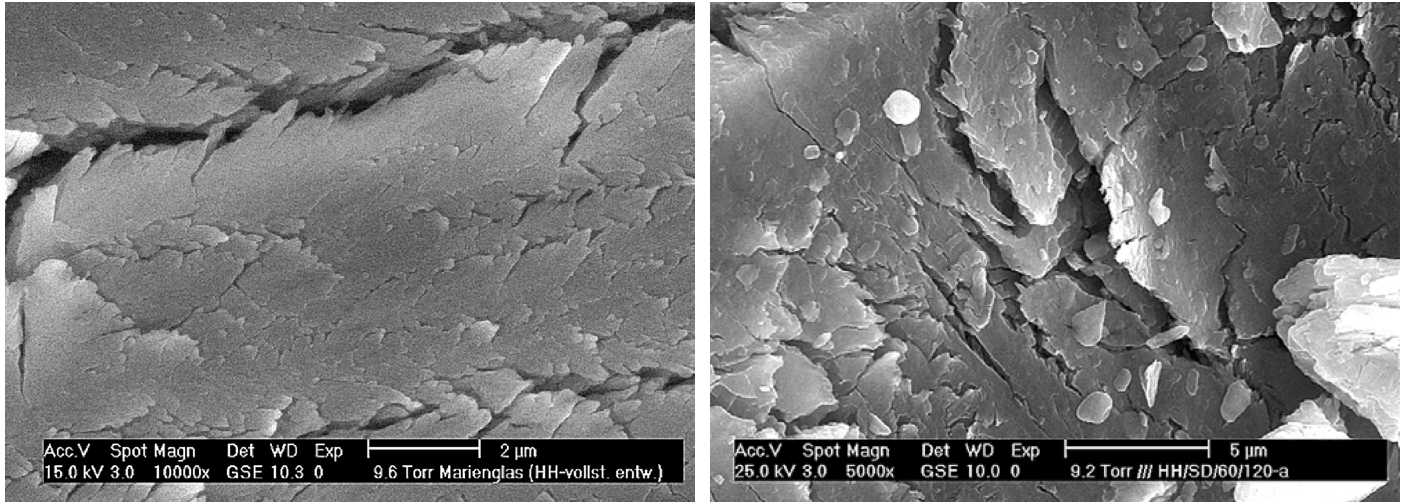

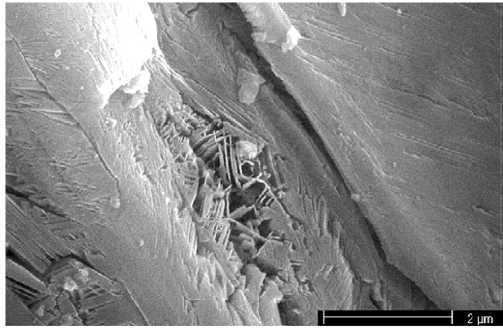

With decreasing degree of supersaturation, the growth of gypsum dihydrate crystals through the attachment of 2D nuclei becomes energetically unfavorable. In this case, crystal growth develops according to the dislocation mechanism [5, 9]. At the dislocation mechanism of growth, when particles of a crystallizing substance are embedded in the lattice of a growing crystal, several crystals are formed from one crystallization center. This phenomenon is known as crystal splitting [5]. It is connected with the fact that secondary nuclei appear on the surface of the primary nucleus of dihydrate gypsum, which formed on the walls of the microcrack, i. e. there is 2D nucleation on its own substrate. The primary nucleus of calcium sulfate crystals faces the solution with (–111) facet, because it is this facet that grows according to 2D nucleation mechanism [10]. The formation of secondary gypsum nuclei and their growth on the surface of the primary nucleus continues until they completely cover the entire surface of the microfracture and fill its volume (Fig. 2).

Fig. 2. Dihydrate gypsum crystals in the microfractures of the gypsum binder particles

Ðèñ. 2. Êðèñòàëëû äâóâîäíîãî ãèïñà â ìèêðîòðåùèíàõ ÷àñòèö ãèïñîâîãî âÿæóùåãî

Such self-healing of particle microdefects is accompanied by decreasing specific surface area of the original gypsum binder by 33 % and decreasing water demand by 14 %.

Conclusion

The conducted studies of the crystallization process of dihydrate gypsum in the micropores of a gypsum binder in the process of its artificial “aging” do not contradict the quataronic mechanism of microcrystal growth. The obtained results indicate the potential and need to use this technological conversion in the production of binders based on calcium sulfate.

Список литературы Crystallization features of calcium sulfate in the process of “artificial aging”

- Askhabov A. M. Kvataronnaia kontceptciia: osnovnye idei i nekotorye prilozheniia (The quataronic concept: basic ideas and some applications). Proceedings of Komi SC UB RAS, 2011, No. 3 (7), pp.70—77.

- Askhabov A. M. Nanoclasternaia model obrazovani-ia zhidkoi vody (Nanocluster model of liquid water formation). Proceedings of Komi SC UB RAS, 2016, No. 1 (25), pp.62—67.

- Golik V. I., Razorenov Yu. I., Polukhin O. N. Ispolzovanie kompozitnykh viazhushchikh v gornom proizvodstve (The use of composite binders in mining). Dry construction mixtures, 2014, No. 6, pp.17—20.

- Greg S., Sing K. Adsorbtciia, udelnaia poverkhnost, poristost (Adsorption, specific surface, porosity). Moscow: Mir, 1984, 306 p.

- Linnikov O. D. Mehanizm formirovaniia osadka pri spon-tannoi kristallizatcii solei iz peresyshchennykh vodnykh rastvo-rov (The mechanism of sediment formation during spontaneous crystallization of salts from supersaturated aqueous solutions). Uspekhi khimii, 2014, V.84, No. 4, pp. 343—364.

- Melikhov I. V. Fiziko-himicheskaia evoliutciia tverdo-go veshchestva (Physicochemical evolution of solids). Moscow: BINOM. Laboratory of knowledge, 2012, 309 p.

- Mayorov A. E., Paleev D. Yu. Sostoianie izoliatcii gornykh vyrabotok shakht Kuzbassa (The state of isolation of mine workings in the mines of Kuzbass). Bulletin of the Kuzbass State Technical University, 2019, No. 3, pp. 60—65.

- Polak A. F., Babkov V. V., Andreeva E. P. Tverdenie min-eralnykh viazhushchikh veshchestv (Hardening of mineral binders). Ufa: Bashk. book publishing house, 1990, 216 p.

- Rashkovich L. N. Atomno-silovaia mikroskopiia protcessov kristallizatcii v rastvore (Atomic force microscopy of crystallization processes in solution). Soros educational journal, 2001, V. 7, No.10, pp. 102—108.

- Ustinova Yu. V., Sivkov S. P., Barinova OP, Sanzharovsky A. Yu. Vliianie razlichnykh dobavok na morfologiiu kristallov dvu-vodnogo gipsa (Influence of various additives on the morphology of gypsum dihydrate crystals). Vestnik MGSU, 2012, No. 4, pp. 140—144.

- Chetvertneva I. A., Teptereva G. A., Shavshukova S. Yu., Konesev V. G. Poiavlenie, razvitie isovershenstvovanie razlichnykh tipov burovykh rastvorov v mirovoi i otechestvennoiprak-tike (Appearance, development and improvement of various types of drilling fluids in world and domestic practice). History and Pedagogy of Natural Science, 2019, No. 2, pp. 25—29.

- Garkavi M., Nekrasova S., Melchaeva O., Garkavi S., Fischer H.-B., Nowak S. Thermo-dynamic explanation of rational conditions of the «aging» of plaster binder. 18. ibausil. Internationale Baustofftagung, Weimar, 2012, pp. 1-0741-0748.