Current situation of lignite exploitation from Oltenia's mining basin and reuse solutions of remaining gaps

Автор: Nyari Apostu Izabela-Maria, Lazar Maria

Журнал: Горные науки и технологии @gornye-nauki-tekhnologii

Рубрика: Разработка месторождений полезных ископаемых

Статья в выпуске: 1, 2018 года.

Бесплатный доступ

Oltenia’s coal basin occupies an area of 4500 km2 and has the most important deposits of lignite in Romania, many of which are exploited through open-pit mining works. Open-pit lignite exploitation involves occupancy of large areas of land on long-term and considerable negative changes of physical, chemical and structural characteristics that define the regional elements, resulting in full damage of the existing landscape. Recovery and rehabilitation planning of a remaining void represents an essential step and consists into establish and implement the necessary measures of reasonable accommodation of land so that it is compatible with the environment, and aims at reintegrating degraded land in the landscape and increases its value. Choosing the final use of a remaining void is made taking into account criterias such as the climate, land morphology, slope stability conditions, regional development strategy, community requirements, financial resources, etc.

Oltenia's mining basin, remaining gaps, recovery, reuse solutions

Короткий адрес: https://sciup.org/140230100

IDR: 140230100 | DOI: 10.17073/2500-0632-2018-1-48-57

Текст научной статьи Current situation of lignite exploitation from Oltenia's mining basin and reuse solutions of remaining gaps

Following the closure of open pit mining activities, remain on the surface of land large gaps of impressive dimensions, which poses great problems considering the direct contact with environmental factors.

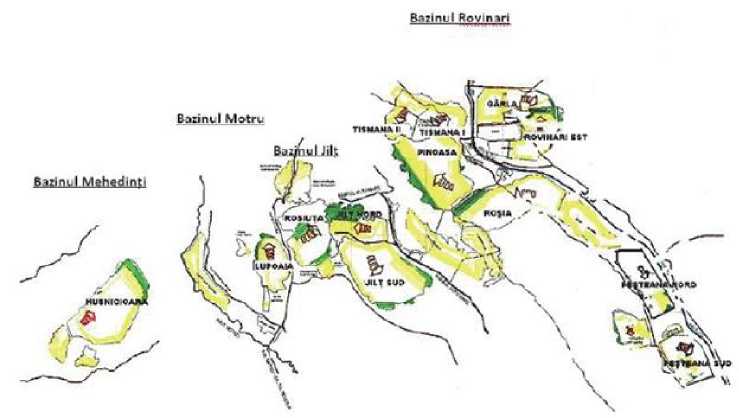

The Oltenia’s Coal Basin owns the most important lignite deposits in Romania. The basin is located within three counties, Gorj, Vâlcea and Mehedinţi, between the Danube and Olt rivers and extends on the direction of WSW-ENE, on a length of approx. 120 km.

The lignite deposits from this area are grouped according to geographic, geological and economic criteria, in 5 mining basins: Rovinari, Motru, Jilţ, Mehedinţi and

Berbeşti, each of which is delimited by several mining perimeters according to the particularities of the deposits and the possibilities of exploitation, so that a total of 19 quarries have been designed and commissioned in the course of time [5].

The organizational structure of the mining and energy of the Oltenia Basin is approved by Government decision No. 1024/2011, which provides the establishment of the Oltenia Commercial Company - S.A. The mining activity is organized in quarry mining units. At present, out of the 19 quarries, there are 10 quarries operating within the Oltenia Energy Complex (C.E.O.) (Fig. 1) [10].

6uinul Mehedmt!

BailnU Rovinari

Национальный исследовательский технологический университет

Table 1

Mining perimeters belonging to Oltenia’s Energy Company

|

Mining basin |

Mining perimeters |

Surface [ha] |

Date of closure |

|

Rovinari |

Tismana (I+II) |

1695 |

2023 (I) / 2024 (II) |

|

Rovinari (Rovinari Est+Gârla) |

1860 |

2024 |

|

|

Pinoasa |

2603 |

2027 |

|

|

Roșia de Jiu |

1738,8 |

2026 |

|

|

Peșteana Nord |

1299 |

2024 |

|

|

Motru |

Lupoaia |

1420 |

2027 |

|

Roșiuța |

1621 |

2027 |

|

|

Jilț |

Jilț Sud |

1981 |

2027 |

|

Jilț Nord |

1267 |

2026 |

|

|

Mehedinți |

Husnicioara |

936 |

2019 |

The areas occupied by open pit mining operations consist of quarry areas, surfaces of exterior dumps and utilities. Of the 19 quarries put into operation, some are already closed and others are about to cease operations in about a decade, according to the exploitation license either as a result of the depletion of reserves or as the exploitation of lignite is no longer efficient from technical and economical point of view (Tab. 1).

Over the time, 5 quarries were closed, Cicani (1974), Balta Unchiașului (1966), Beterega (1980), Urdari (2003) and Peşteana Sud (2015). The Berbeşti Quarry Mining Unit, with its 4 related quarries, was outsourced within the Govora District Heating Power Plant.

-

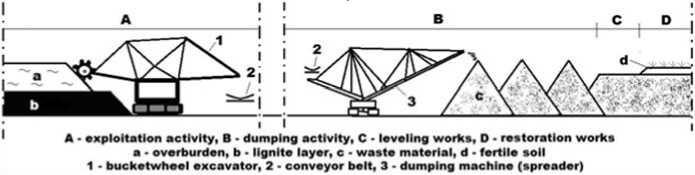

2. Actual situation of oltenia’s quarries

From the geological point of view, the Oltenia deposits belong to the Pliocene formations (Dacian, Romanian and Pontian) and consist of 21 lignite layers of different thickness ranging from centimeters to several meters and variable expansions separated by sterile rocks, soft, cohesive and noncohesive, predominantly clayey and sandy rocks (Fig. 2) [1].

Open pit exploitation presents a higher number of advantages compared to underground exploitation, such as: increased productivity as a result of complete mechanization of extraction, transportation and storage processes, lower costs, optimum working conditions and labor safety. In spite of the many advantages that exist in relation to underground exploitation, open pit operations have a direct negative impact on environmental factors. In addition, the processes of rehabilitation of degraded land are much more expensive and more complicated [9].

In Oltenia’s quarries, the exploitation of the deposits is achieved through a continuous process technology, comprising three major stages: extraction, transportation and storage.

Fig. 2. Lignite layers from Oltenia

Национальный исследовательский технологический университет

The exploitation methods have been set so that the exploitation activity is efficient from technically, economically and work safety point view. In most quarries, the combined method of operation is used to transport the tailings into the inner dump and partially transhipment into the inner dump.

The maximum production capacity is 22 million t/year for a 5 days/week program and 30.5 million t/year for a 7 days/week program, being determined by the technical endowment, the material basis, the productivity and the technological conditions, but also the demand for coal [10].

Tab. 2 presents the evolution of the main indicators for the 2012 - 2016 period, including those from Berbeşti Quarry Mining Unit, until it was outsourced within the Govora District Heating Power Plant.

The technical equipment of Târgu-Jiu Branch Mining Division consists in 559 equipments, namely: 65 bucket wheel excavators, 46 dumping machines, 366 high-capacity conveyors, 23 warehouse machines and 59 track-mounted trolleys (Tab. 3) [10].

The industrial experience gained in the field of coal exploitation extends over 50 years, during which was extracted more than 1 billion tonnes.

Table 2

Evolution of main indicators for the 2012-2016 period

|

Specification |

TOTAL |

||||

|

2012 |

2013 |

2014 |

2015 |

2016 |

|

|

Production (thousands tons) |

29690 |

22596 |

21501 |

22405 |

23000 |

|

Overburden (thousands tons) |

176741 |

149412 |

137290 |

129449 |

153000 |

|

Overburden/coal index (m3/t) |

6.0 |

6.6 |

6.4 |

5.8 |

6.7 |

|

Average productivity, exc. type 2000 (m3+tons/hour) |

1,124.0 |

1,140.0 |

1,171.0 |

1152 |

1152 |

|

Average productivity, exc. type 1400 (m3+tons/hour) |

1019 |

997 |

974 |

984 |

1016 |

|

Excavation capacity (m3/hour) |

186,183.0 |

||||

|

Dumping capacity (m3/hour) |

313,300.0 |

||||

|

Steril transport capacity (m3/hour) |

253,800.0 |

||||

|

Coal transport capacity (tone/hour) |

93,000.0 |

||||

|

Specific power consumption (kW/ m3+t) |

3.73 |

3.93 |

3.98 |

4.02 |

4 |

|

Cost unit (lei/t) |

71.89 |

68.8 |

76.51 |

52.52 |

46.29 |

Tehnical equipment

Table 3

|

Equipment Quarry |

— о S О О У 43 £ Н 5 £ 5 X о |

-В Е |

43 £ #ад о о о о н |

cd о § Е |

НМ 2 |

5 Д Е ^Е 5 •& Е 'е н 5 2 5 О-1 (D О Q. |

|

Tismana |

8 |

6 |

36 |

1 |

12 |

63 |

|

Rovinari |

5 |

5 |

23 |

- |

9 |

42 |

|

Pinoasa |

6 |

4 |

30 |

2 |

6 |

48 |

|

Roșia de Jiu |

9 |

7 |

43 |

3 |

6 |

68 |

|

Peșteana Nord |

5 |

3 |

33 |

4 |

6 |

51 |

|

Lupoaia |

5 |

3 |

27 |

2 |

3 |

40 |

|

Roșiuța |

7 |

5 |

42 |

2 |

5 |

61 |

|

Jilț Sud |

8 |

5 |

49 |

2 |

4 |

68 |

|

Jilț Nord |

6 |

5 |

48 |

1 |

5 |

65 |

|

Husnicioara |

6 |

3 |

35 |

6 |

3 |

53 |

|

Total on equipment type |

65 |

46 |

366 |

23 |

59 |

559 |

Национальный исследовательский технологический университет

-

3. Criterias for choosing the reuse type of remaining gaps

After cessation of open pit mining operations, it is important to recover the remaining gap and streaming it in the ecological or economic circuit, but unfortunately, in many cases, quarries are abandoned. With this irrational practice, there is a growing chances of security issues arising from the many risks to which the objectives and people in the areas of influence are exposed.

In case of abandonment of a remaining gap, depending on the hydrological and hydrogeological conditions in the area, a natural lake can form naturally. There is a risk of drowning because these lakes attract people swimming, the waters in the lakes are very deep, so they have a low temperature that can produce the so-called heat shock or the risk of water damage as a result of contact with non-functional abandoned machinery in the quarry. On the other hand, when the remaining gap is not flooded, it attracts off-road sports lovers, which can lead to material losses but also to human lives losses as a result of the increased risk of injury.

The environmental impact of open pits operations is greatly increased as a result of direct contact with all environmental factors. The negative visual impact resulting from the degradation of the landscape on impressive surfaces, the occurrence of gaps due to the development of the pits in deep, the appearance of the external tailings dumps, and the transporting of machines of different sizes. The degradation of aquifer systems as a result of deep excavation and their sowing resulted in the formation of a depression funnel with significant negative repercussions for households and cultures in the region. These are just a few examples that indicate that mining can not be in harmony with the environment unless it implements and applies solutions that provide for sustainable mining. It is understandable why specialists from all over the world are looking for solutions to reduce the impact of mining industry on the environment [4].

The hydrogeological conditions that characterize Oltenia's mining basin show different degrees of difficulty, ranging from easy and moderate in the Mehedinti and Jilţ basins, to heavy and very heavy, in the Motru basin and especially in Rovinari basin. The particularities of the lignite quarries in Oltenia are shown in Tab. 4 [6].

Table 4

Particularities of Oltenia’s quarries

|

Characteristics Quarry |

Overburden /coal index (m 3 /t) |

Exploitation depth (max, m) |

Hydrogeological conditions (m 3 water/t) |

|

Tismana (I/II) |

3,90/5,10 |

40/50 |

moderate, 1,55/2,60 |

|

Rovinari (Rovinari Est/Gârla) |

5,75/6,20 |

75/55 |

moderate, 2,20/difficult, 5,40 |

|

Pinoasa |

6,31 |

80 |

easy, 0,70 |

|

Roșia de Jiu |

5,14 |

120 |

difficult, 10 |

|

Peșteana Nord |

5,62 |

80 |

difficult, 9,50 |

|

Lupoaia |

4,90 |

40 |

easy, 0,20 |

|

Roșiuța |

6,80 |

60 |

easy, 0,50 |

|

Jilț Sud |

6,10 |

70 |

easy, 0,80 |

|

Jilț Nord |

6,30 |

65 |

moderate, 1,20 |

|

Husnicioara |

7,60 |

62 |

easy, 0,20 |

The hydrographic network in the Oltenia Mining Basin is rich and includes the hydrographic basins of the Jiu, Motru, Jilţ, Topolnița and Husniţa rivers. Works has been required to regularize certain rivers and their tributaries.

The overburden/coal index is on average 6:1. The average exploitation depth varies between 50 and 80 m in 16 out of 19 designed open pits. The smallest depth of exploitation can be seen in the Peșteana Sud and Urdari quarries, and the highest at the Roşia de Jiu quarry, over 120 m [6].

In the Oltenia mining region, about 2/3 of the surface is represented by hilly relief, heavily ridged hills and slopes, which is a safe premise for the state of instability of inclined surfaces, a very important source of mobile materials (alluviums). Hilly relief prevails in thirteen perimeters, meadow and hilly in four perimeters and meadow in just two perimeters located in the Rovinari Carboniferous Basin [6].

Sterile rocks consist of mixtures of clay and sands in varying proportions, and are part of the soft rock category with low resistance to compression or cutting.

-

4. Results and discussion

The physical stability of the waste dumps is an indicator of maxim importance for almost all types of redevelopment and reuse, as they involve the presence of man and equipment and equipment that can be endangered in the event of landslides [7].

Currently, in situ slopes and inner dump slopes presents relatively good stability, with a series of superficial landslides, with no serious technical and economical consequences. Regardless of whether the geometry of the final slopes of the residual void has been designed to provide stability conditions, further studies and work to increase stability are required prior to flooding.

Knowing the physical and mechanical characteristics of the rocks is necessary for slopes sizing, to combat landslides and for establish the necessary measures to increase stability [6].

There are numerous directions of reuse of the remaining gaps of open pits (Fig. 3), therefore the determination of the appropriate type of reuse depends on certain factors, such as the climate regime, the area typology and the relief, configuration of the remaining gap, specific hydrogeology of the area, stability conditions, population requirements, financial resources, regional development direction.

Lake

-

• Lake for recreation and recreation

-

• Lake for water sports

-

• Lake for fish farming

-

• Naturalistic lake

Water storage basin

Wastes deposits

Others

-

• Basin for crop irrigation

-

• Industrial water storage basin

-

• Water retention and accumulation basin as a flood protection system

-

• Household wastes deposits

-

• Industrial wastes deposits

-

• Scene for music/theater/film performances

-

• Off-road activities

Fig. 3. Directions for the reuse of the remaining pitted voids

-

Remaining gaps of quarries represent one of the toughest forms of impact under which the exploitation of minerals is manifested on the environment.

Remaining gaps of quarries can be reused for various purposes such as deposits or lakes that can take on various functions, from industrial to recreational [8].

Stage of closure and monitoring of quarry must be planned before the project starts, while ensuring the financial resources needed to achieve this stage. The common practice is to abandon the remaining gap at the end of the production cycle, thus transferring the damage to the environment and local communities, but also to future generations [3].

Except for the stabilization works of the final slopes of the remaining gaps, it is necessary to carry out the shapping works and revegetation of the surrounding lands in order to integrate them in the landscape in a most harmonious way.

Due to the location of Oltenia's Mining Basin, the aspects such as hydrological and hydrogeological conditions, the stability conditions, morphology and specific orography, the area typologies in which the mining perimeters fits, the forms of use of the surrounding lands, the distance to the residential areas, the regional development strategy and population requirements, two types of reuse of the remaining gaps of Oltenia's quarries have been established, which present a major opportunity, namely:

-

1. Open pit lake that can take different destinations;

-

2. Waste deposit.

Since the start of the mining works, the compulsory practice of proper soil recovery and management has been implemented. The soil is a vital and extremely valuable resource that contains mineral and organic elements capable to sustain plant development, but which is very hard regenerable. Its recovery allows its reuse immediately after extraction, with favorable transport to the place of use, or it can be stored and conserved for later use on a degraded surface [8].

Also, in the exploitation stage, many measures can be implemented to ensure sustainable development of the mining area after activity cessation, such as land rehabilitation at the same time as exploitation.

This practice is recommended and applied more often, lately, and involves the recovery and reuse of mining land from the stage of exploitation, so rehabilitation can be done concomitantly with the exploitation (Fig. 4), by immediately starting the process of planning and rehabilitation of the areas released by technological tasks [2].

This practice has important advantages, such as reducing the rehabilitation period after the closure of the mining area, the affected land area, the pollution degree of the environmental factors, the progressive re-integration of the land into the adjacent landscape and the possibility of reuse of land rehabilitated for other purposes [2].

Fig. 4. Restoration of land while exploiting

Национальный исследовательский технологический университет

Among the first obligations of the project owner, when the extraction works have come to an end, are to free up the land from the technological tasks and to dismantle the buildings at risk of collapse, to dispose the use of the functional equipment in other mining perimeters, to ensure Recovery, reuse and/or recycling of parts of machinery and buildings (metals, glass, etc.).

-

1. Open pit lake

Water filling of the remaining voids so that they can take over a destination that contributes to the sustainable development of mining areas is a method that is used globally, but at the national level it is not currently applied. This method has longterm benefits irrespective of the use of the lake and involves increasing the ecological, productive, cultural value of the landscape.

Water filling of the remaining voids can be done either naturally or artificially. Natural flooding occurs by the accumulation of rainwater and aquifer waters, and the artificial flooding involves the taking over and transporting water through pipelines from the place of abstraction (rivers, lakes, etc.).

Most of the time, the remaining gaps resulting from quarry exploitation are bordered on one side by the final slopes of the quarry, and on the other side by the inner dump slopes. The dams are formed by loose rocks at the first saturation and present a significant risk of sliding. Sliding can occur in the dump slope as a result of the liquefaction of the waste material or in the in situ slope, where the inflow of underground water crossing the slope can trap the particles favoring the occurrence of the sufosis phenomenon.

Depending on the area where the sliding occurs, but also the height of the water in the lake, can result waves with impressive heights and speeds, flooding and destroying the objectives from the influence zones.

The lack of a stability assessment process of the final slopes of the remaining gaps and of stabilization works to withstand the new conditions may lead to the occurrence of disastrous events such as landslides which under certain circumstances may result in material and human life losses.

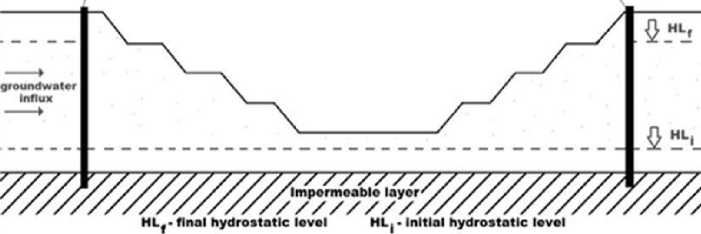

The restoration of the hydrostatic level is essential, as the households near the quarries have been affected as a result of the fountains drying up, This can be done:

-

- either by filling with water the remaining gaps, by artificial means, through adductions, at a higher level than the normal level of the phreatic to speed up the process;

-

- either by natural elevation of the hydrostatic level, if hydrological and hydrogeological conditions permit this within an acceptable period of time.

-

2. Waste deposit

The second case involves the flooding of the remaining gap by the intake of underground and pluvial water.

In this case, for restoration of the hydrostatic level in the out side of the remaining gap, it is recommended to make waterproof screens (Fig. 5) either on the whole outline of the remaining gap or just in the path of the underground water flow. If this process is lasting, it is possible to create a drilling system whereby the water taken up by the adductions from other bo-dies/watercourses is injected out of the mining perimeter, respectively out of the waterproof screens through an reverse dewatering process.

№1 ^ ГОРНЫЕ НАУКИ Россия, Москва. 2018 год МИСиС v х> И Национальный исследователь технологический университет

Fig. 5. Restoration of hydrostatic level of groundwater using waterproof screens [2]

For the setting up of a waste deposit in the remaining gap of a quarry, the following works must be carried out:

-

- leveling the remaining gap base and reducing the slopes inclination;

-

- carrying out the protection works against superficial waters;

-

- waterproofing the gap base and the slopes with natural or synthetic materials;

-

- waste depositing in compact layers separated by inert materials.

After the deposit full filling, this is covered with impermeable inert materials, a layer of vegetal soil, and areas thus recovered will be replanted for taking naturalistic, agricultural, forestry or other functions depending on the local conditions [8].

Taking into account the relatively large overburden/coal index iscovered rapports that have been recorded in Oltenia and the composition of the waste material resulting from the extraction of the lignite (clay, sand and gravel, without dangerous elements) it can be used as filling material for the construction of highways and the coarse part can be used as an embankment for protecting the banks of the water courses, for the stability of the slopes and for the consolidation of the dams (Fig. 6) [2].

The advantages consist in reducing the amount of waste material deposited in dumps and, implicitly, the amount of construction materials exploited.

Recovery and restoration of degraded land is a complex process involving the stabilization, improvement and redevelopment of degraded land so that it can be reintroduced into the natural or economic circuit. Post-closure maintenance and monitoring covers aspects such as: air quality evolution, mine water discharge and emissary quality, leakage of acidic substances, soil and vegetation quality, noise and vibration levels during closure and rehabilitation, stability and the state of waste deposits.

Land reuse is an important step towards the sustainable development of society, while ensuring economic development and rehabilitation of the affected area.

The development of sustainable activities must take into account all the possibilities offered by the land and the local communities needs.

Fig. 6. Exemples for reuse of waste materials

Национальный исследовательский технологический университет

Respecting the requirements for the harmonization of the new type of use with the surrounding landscape, it is necessary to carry out the revegetation works, using species that accept the new conditions and which also fit into the vegetation floor corresponding to the region.

Vegetation restoration also ensures that fauna is restored at a faster rate. This biological diversity of elements allows the harmonious fitting of the land into the landscape and the formation of an ecosystem that can resume its functions considerably faster.

Modeling the shores of the lake, depending on the type of use, is an important step both for the elimination of possible risks, such as accidents, and for avoiding the occurrence of regular forms by making a seemless connection with the elements of the surrounding terrain.

The infrastructure must be designed in such a way that the impact on the environment and communities of the new anthropic activity has to be minimal.

The most important aspect in the recovery and use of a remaining gap is reprezented by the stability conditions that have to be monitorized after the degraded land was bringed into use in the ecological or economic circuit. It is intended to ensure the stability reserve to avoid sliding phenomena. This practice contributes to reducing the number of accidents.

The use of available spaces has particular advantages as it supports economic reconstruction by creating new businesses, supports environmental reconstruction, economic development of the region and creates new jobs for the unemployed people.

Conclusions

Oltenia Energy Complex has in charge four mining basins: Rovinari, Motru, Jilt and Mehedinti, with a total of 10 open pits still in operation. Over the time, of 19 designed and commissioned quarries, 5 were closed and 4 quarries, belonging to the Berbeşti mining basin, were outsourced to the Govora Electric Power Plant (C.E.T.).

Peşteana Sud, Urdari, Beterega, Cicani and Balta Unchiaşului quarries were closed 2, 14, 37, 43, respectively 51 years ago, the main reason for the cessation of activity being the depletion of reserves or the inefficiency to continuate the exploitation under favorable conditions from technical and economical view. The remaining gaps of these quarries have naturally reintegrated into the landscape, some being flooded, thus becoming career lakes. The exploitation activity of the lignite in Oltenia has been going on for more than half a century and represents, for Romania, the most important energy resource. Oltenia Mining Basin has impressive amounts of lignite, enough to provide for Romania resources for the next 20-40 years. According to current operating licenses, the last of 10 functional pitches will cease activity in 2027.

After the cessation of the quarrying operation, gaps of impressive dimensions will remain on the surface of the field, which in direct connection with the environmental factors will lead to a major negative impact on the environment.

The intervention on the degraded land is essential and involves implementation and application of sustainable practices like the recovery, rehabilitation and restoration of degraded land in the shortest time as possible to eliminate or reduce the impact of anthropogenic activity.

Remaining gaps of former quarries can be reused for various purposes as deposits for certain categories of waste or open pit lakes that can take on various functions, ranging from industrial to recreational and harmoniously reintegrate into the landscape while meeting the requirements of new use.

Water filling of remaining gaps of quarries is a widely used method, but at

Национальный исследовательский технологический университет national level it is very little taken into account, although the benefits are major. It is economically advantageous and has longterm benefits regardless of the way the lake is used to increase the ecological, productive, cultural value, etc. of the landscape.

The construction of the wastes deposits in the remaining gaps is an acceptable solution as it allows the use and filling of the remaining gaps and has advantages such as: reduction of the amount of waste deposited at the surface of the land, elimination of the negative relief form, the possibility of releasing the land in the economical or ecological circuit after full filling and closing it, according to the rules in force.

Although they are less common, there are other uses of remaining gaps of quarries such as scenes for theater or music performances, film scenes, off-road activities, etc., and they have the advantage of allowing the use of degraded land which can not take up other functions, for various reasons.

After the cessation of mining operations in Oltenia's quarries, it is recommended to carry out a complex studies regarding the stability, hydrological, hydrographic and hydrogeological conditions necessary to determine the optimal use of each remaining gap. Both the requirements of local communities and the objectives of the Regional Development Strategy are considered.

The recovery and reuse of remaining gaps have numerous benefits and depend to a large extent on the choice of the most appropriate type of use with a major opportunity for the area. Among these, the most important are: the restoration of biodiversity and the reintegration of degraded land into the landscape resulting in improved environmental quality, safety and health, the possibility of creating new jobs, the development of the regional economy, which implies increasing the living standards of local communities.

Company: University of Petrosani

Address: 20, Str. Universității, Petroșani, jud. Hunedoara, Romania, 332006

Список литературы Current situation of lignite exploitation from Oltenia's mining basin and reuse solutions of remaining gaps

- Almăşan B. Exploitation of mineral deposits in Romania (in Romanian) volume I, Technical Publishing House, Bucharest, 1984.

- Apostu (Nyari) I.-M., Lazar M., Faur F. Implementation of sustainable practices in the lignite open pit Roșia de Jiu, The Mines Magazine, no.1/2017.

- Bastida A. E., Aguado A. Y. Enhancing the contribution of mining to sustainable development in Romania: a political&legal framework (in Romanian), Soros Foundation Romania, "Natural Resources Exploitation -Legal Framework" Program, 2008.

- Fodor D. The influence of the mining industry on the environment (in Romanian), AGIR Bulletin, no. 3/2006.

- Fodor D., Predoiu I. Development of the exploitation of lignite deposits in Oltenia through innovation and modernization of the working technologies (in Romanian), 2015.

- Huidu E. Exploitation through open pit mining works of coal deposits, Volume I, Măiastra Publishing House, Tg. Jiu, 2012, ISBN 9978-606-516-414-4.

- Lazăr M. Researches regarding on stability and ecological reconstruction of mines affected areas (in Romanian), Empowerment thesis, 2016;

- Lazăr M. Rehabilitation of degraded lands (in Romanian), Universitas Publishing House, Petroșani, 2010.

- Nyari (Apostu) I.-M. -Lignite mining exploitation from Rovinari Mining Basin in the context of sustainable development, Dissertation paper, 2016.

- Oltenia Energy Complex. Documents (in Romanian).