Dependence of the degree of water purification on the specific amount of electricity and the definition time

Автор: Shestakov I.Y., Khilyuk A.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.22, 2021 года.

Бесплатный доступ

The known methods of treatment of wastewater generated in rocket and space technology production using electroplating technologies do not allow to ensure the maximum permissible concentration of metal ions in treated water, or are expensive or difficult to operate. The general toxic, embryotropic and muta-genic effect of metals is well studied. These metals, getting together with water to food products in living organisms, are able to accumulate in them, causing the pathogenesis of heart diseases, brain, liver, and cancerous tumors in people. Iron ions are part of wastewater of most industries, which requires increased control and development of effective methods of wastewater treatment. The article presents a technique for conducting experiments, a method of combined water purification, including electrochemical action and adsorption, is considered. The results of studies of this method of wa-ter purification from iron ions are presented. The dependence of the degree of purification on the specific amount of electricity passing through the purified water, the strength of the electric field and the settling time is revealed. With Qav = 4.7 Kl/l, E = 1058 V/m, using quartz sand as an adsorbent and settling time for 24 hours, the concentration of iron ions decreased from 1.65 to 0, 82 mg/l. The proposed combined cleaning method requires inexpensive and affordable materials and is easy to operate.

Combined method, specific amount of electricity, electric field strength, iron, degree of puri-fication, alternating current, direct current, sorbents

Короткий адрес: https://sciup.org/148329586

IDR: 148329586 | DOI: 10.31772/2712-8970-2021-22-3-536-542

Текст научной статьи Dependence of the degree of water purification on the specific amount of electricity and the definition time

Galvanic technologies are used in the production of rocket and space technology, as a result, there is pollution of waste water with metal ions [1; 2]. The known methods of wastewater treatment do not allow to ensure the maximum permissible concentration of metal ions in the purified water or are expensive or difficult to operate in industry. One of the most common polluting components is iron ions, which is a part of wastewater in most industries, including electroplating, which requires increased control and the development of effective wastewater treatment methods. The problem of neutralization of industrial wastewater from galvanic industries is one of the most urgent, largely determining the environmental situation in the water basins of Russia [3–5] and risks to public health [6; 7], which implies the presence of not only a high cleaning result, but also optimal parameters when introduced into the technological process and includes the cost of electricity, consumables, processing time and settling time.

Methodology of conducting an experiment

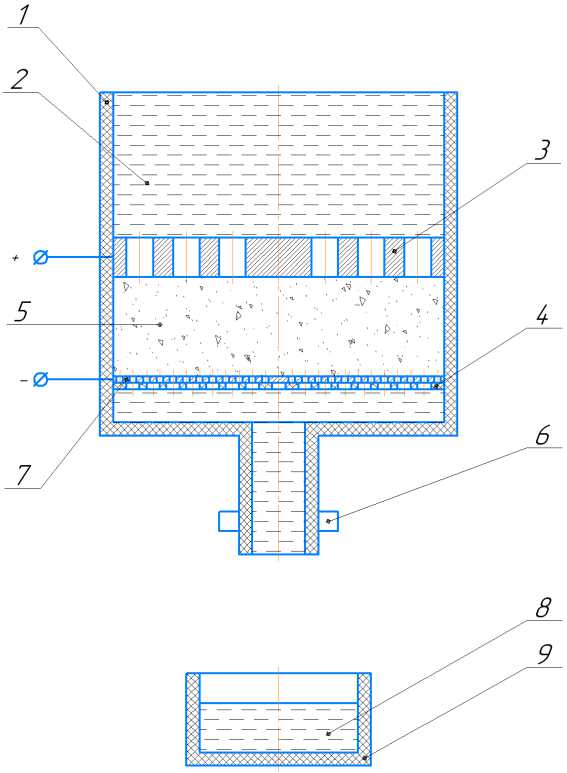

The study of the influence of a constant electric field and the specific amount of electricity on the degree of water purification from iron ions by the combined method was carried out in a cell (Fig. 1) using a graphite flat electrode with holes 3 , which plays the role of an anode (100 mm thick) and a grid of stainless steel 12X18H10T (1 mm thick) 7 , acting as a cathode, arranged in series. Cell 1 is made of a dielectric material in a form of a cylindrical tube. Sorbents (quartz sand) 5 were poured into the space between the electrodes [8–13]. The volume of treated water is 1 liter. A voltage of 18 V was applied to the electrodes, which provided a current of 0.034 A. With the help of clamp 6 , the required water flow through the adsorbent was set. Fe (III) salts were dissolved in water 2 at an average ion concentration of 1.65 mg/l. To register the process parameters, standard devices were used: a voltmeter (accuracy class 0.4), an ammeter (0.5), a portable MW14 photometer for determining the total iron content in water [14]. The degree of purification was determined by the formula,%

Y =

oк

С о

100,

where С о , С к – initial and final concentration of the removed metal ion, mg/l.

Specific energy consumption W for purification of a unit volume of water (kWh)/m3 was calculated by expression

IUτ W =---пр 10-3, V where I is electric power, А; U is voltage at the terminals of the electrodes, V; τp is time of passing electric current through purified water, h; V is volume of water to be poured, m3; 10–3 is conversion factor from W to kW.

The electric field strength E, was calculated by the expression

Е = U / L, V/m, where U is voltage at the terminals of the electrodes, V; L is interelectrode distance.

Рис. 1. Схема экспериментальной установки:

1 – корпус ячейки; 2 – вода с ионами металлов; 3 – анод; 4 – решетка;

5 – адсорбент; 6 – зажим; 7 – катод (сетка); 8 – вода; 9 – ёмкость

Fig. 1. The scheme of the experimental setup:

1 –cell body; 2 – water with metal ions; 3 – anode; 4 – grid;

5 – adsorbent; 6 – clamp; 7 – cathode (grid); 8 – water; 9 – capacity

Research results

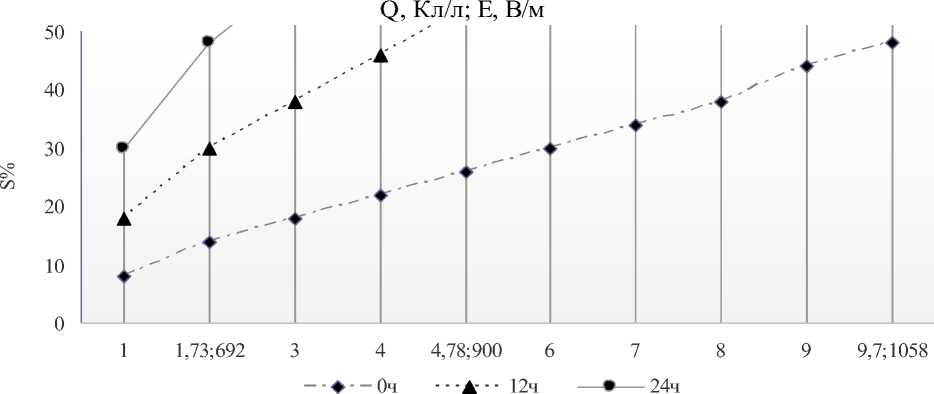

Fig. 2 shows the dependence of degree of purification on the specific amount of electricity passing through the water to be purified, the strength of the electric field and the time of melting.

Рис. 2. Зависимость степени очистки от удельного количества электричества (среднее значение), проходящего через воду, напряженности электрического поля и времени отстаивания

Fig. 2. Dependence of the degree of purification on the specific amount of electricity (average value) passing through the water, the strength of the electric field and the settling time

The analysis of the obtained experimental data showed that the effectiveness of the combined method depends on the specific amount of electricity passing through the purified water, the electric field strength and the settling time. The degree of purification improves with an increase in the settling time [5–7].

Specific energy consumption, electric field strength and degree of purification of the combined method were:

W e = 0,035 kW *h/m3,

Е = 1058 V/m,

Y = 50 %.

Conclusion

With the specific amount of electricity (Q = 9,7 Kl/l), electric field power (Е = 1058 V/m) and settling water for 24 hours, the degree of purification is 50%.

The dependence of the degree of purification on the amount of electricity is proportional to the power of the electric field. In [15], a combined method of water purification was investigated using stainless steel as an anode, which was subjected to anodic dissolution, therefore, the specific energy consumption according to the calculation is higher than in the presented method. The degree of purification in [15] was 80%, since there was a transition of dissolved iron from the anode to water into hydroxide, which acted as a coagulant.

An increase in the degree of purification is observed with an increase in the power of the electric field or the specific amount of electricity. To achieve a purification degree equal to 50%, it is necessary to settle for 24 hours, while the specific energy consumption will be 0.035 kWh/m3, which is significantly less than in the previous method (0.45 kWh / m3). The closest in terms of results were the data at 12 and 24 hours of retention time. To achieve a purification degree of more than 80%, it is nec- essary to increase the above parameters several times: the electric field strength, the specific amount of electricity and the settling time, which ultimately will affect the specific energy consumption.

Список литературы Dependence of the degree of water purification on the specific amount of electricity and the definition time

- Iskhakova I. O., Tkacheva V. E. [Innovative wastewater treatment methods for modern electroplating production]. Vestnik Kazanskogo tekhnologicheskogo universiteta. 2016, V0l. 19, No. 10, P. 143–146 (In Russ.).

- Kovalev R. A., Burdova M. G., Grishina I. V. [Comparative analysis of electroplating effluent treatment with reagent and electrochemical treatment methods]. Izvestiya TulGU. Tekhnicheskie nauki. 2018. No. 10, P. 343–346 (In Russ.).

- Zolotokopova S. V., Chan Khoan Kuok, Ngo Tkhe Kyong [Comparative analysis of the accumulation of heavy metals in the muscles of aquatic organisms of the Sherepok River (Vietnam)]. Vestnik AGTU. Seriya: Rybnoe khozyaystvo. 2018, No. 1, P. 118–123 (In Russ.).

- Bugaev L. A., Voykina A. V., Valiullin V. A., Smyr T. M., Karpushina Yu. E. [Investigation of the accumulation of pesticides in the liver of some commercial fish species of the Sea of Azov in 2009–2011]. Politematicheskiy setevoy elektronnyy nauchnyy zhurnal Kubanskogo gosudarstvennogo agrarnogo universiteta (Nauchnyy zhurnal KubGAU). 2012. No. 07 (81) (In Russ.). Available at: http://ej.kubagro.ru/2012/07/pdf/66.pdf (accessed 03.08.2021).

- Khilyuk A. V. [Study of the effect of pollutants and electroactivated water on aquatic organisms]. Reshetnevskie chteniya: materialy XXII Mezhdunar. nauch.-prakt. konf., posvyashch. Pamyati general'nogo konstruktora raketno-kosmicheskikh sistem, akademika M. F. Reshetneva. 2018, Vol. 2, P. 66–69 (In Russ.).

- Galimova A. R., Tunakova Yu. A. [Intake, content and impact of high concentrations of metals in drinking water on the body]. Vestnik Kazanskogo tekhnologicheskogo universiteta. 2013, Vol. 16, No. 20, P. 165–169 (In Russ.).

- Egorova N. A., Kanatnikova N. V. [The influence of iron in drinking water on the morbidity of the population of the city of Orel]. Gigiena i sanitariya. 2017, Vol. 96, No. 11, P. 1049–1053 (In Russ.).

- GOST R 51641–2000 Materialy fil'truyushchie zernistye. Obshchie tekhnicheskie usloviya [State Standard R 51641–2000. Granular filtering materials. General specifications ]. Moscow, IVS “URALTEST”, 2000.

- Bratilova M. M., Grechushkin A. N. [Investigation of the properties of filter media for water purification from iron]. Universum: Khimiya i biologiya : elektron. nauchn. zhurn. 2015, No. 6 (14) (In Russ.). Available at: https://cyberleninka.ru/article/n/issledovanie-svoystv-filtruyuschih-zagruzok-dlya-ochistki-vody-ot-zheleza (accessed 03.08.2021).

- Shestakov I. Ya., Raeva O. V. Sposob ochistki vody i vodnykh rastvorov ot anionov i kationov [Method for purifying water and aqueous solutions from anions and cations]. Patent RF, No. 2519383, 2014.

- Khilyuk A. V., Rogov V. A., Prusakova V. A. [Effect of an electrostatic field on adsorption in the process of natural water purification]. Vestnik KrasGAU. 2013, Vol. 12, P. 134–137 (In Russ.).

- Tagibaev D. D. [Filtration characteristics of granular filter materials]. Innovatsionnaya nauka. 2017, No. 1–2, P. 90–92 (In Russ.).

- Kuznetsov L. K., Gabitov A. I. [Filtration technology in physical and chemical processes of water treatment]. Bash. khim. zh. 2009, No. 2. P. 84–92 (In Russ.).

- GOST 4011–72 Voda pit'evaya. Metody izmereniya massovoy kontsentratsii obshchego zheleza [State Standard 4011–72. Drinking water. Methods for measuring the mass concentration of total iron]. Moscow, Izd-vo standartov Publ., 1974.

- Shestakov I. Ya., Khilyuk A. V. [Influence of a constant electric field on the adsorption purification of water from iron ions]. Siberian Journal of Science and Technology. 2020, Vol. 21, No. 1. P. 136–141. Doi: 10.31772/2587-6066-2020-21-1-136-141 (In Russ.).