Design of performance test system for water-water and carbon dioxide compressed air microchannel heat exchanger

Автор: Wan Shiqing, Qian Zhipeng, Wu Yiwei, Luo Limei

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 6 т.9, 2023 года.

Бесплатный доступ

As a new type of heat exchanger with compact structure and efficient performance, microchannel heat exchangers have good application prospects in industries with strict requirements such as energy and power, petrochemical, aerospace, and other industries. Therefore, exploring the performance and heat transfer characteristics of microchannel heat exchangers is of great significance. This article designs a performance testing system that can simultaneously explore the enhanced heat transfer inside the pipeline of water water and carbon dioxide compressed air microchannel heat exchangers. The variable working fluid circuit design is used to analyze the factors that affect the enhanced heat transfer. The Control variates is used to control the heat transfer conditions, explore the difference of heat transfer performance between different working fluids under different flow rates, inlet temperatures and other conditions, and analyze the heat transfer performance of different channel types by comparison method. The results indicate that when the hot water flow rate range is 2.063×10-5~2.556×10-5m3/s, Re-5~2.556 ×10-5m3/s, the Reynolds number and Nusselt number in the pipeline increase with the increase of inlet flow. In the carbon dioxide compressed air heat transfer experiment, when the flow rate range is 2.810×10-4~3.182×10-4m3/s, the Nusselt number and convective heat transfer coefficient of the 3.6mm inner diameter microchannel are always greater than the Nusselt number and convective heat transfer coefficient of 6.6mm. When the pipe diameter is the same, the water water microchannel heat exchanger has better heat transfer performance and smaller pressure drop compared to the carbon dioxide compressed air microchannel heat exchanger.

Microchannel heat exchanger, variable working fluid experimental system, experimental research, heat transfer and flow

Короткий адрес: https://sciup.org/14127779

IDR: 14127779 | УДК: 66.021.4 | DOI: 10.33619/2414-2948/91/42

Текст научной статьи Design of performance test system for water-water and carbon dioxide compressed air microchannel heat exchanger

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 66.021.4

With the growing energy crisis and the implementation of the sustainable development and environmental protection strategy proposed by the country, technologies and designs such as energy conservation, emission reduction, efficient cooling and heat dissipation have generally become the focus of scientific researchers and the market. The essence of microchannel heat exchangers is a three stack structure unit that can be used to transfer heat. This special three stack structure unit is manufactured using a solid substrate using special microfabrication technology. Microchannel heat exchangers play an irreplaceable role in daily life and light industrial production. However, currently, microchannel heat exchangers in the market still suffer from severe energy consumption losses. Therefore, it is necessary to conduct performance testing and research on heat transfer efficiency enhancement of microchannel heat exchangers.

Jamshidmofid Mohammad et al. [1] used graphene quantum dot nanofluid as the working fluid of microchannel heat exchanger for the first time. The results showed that when the Reynolds number was between 50-100, the use of nanofluid would significantly improve the heat transfer rate, while the increase in pressure drop was slightly lower. When the Reynolds number was between 150-200, the pressure drop was relatively high, so it was not recommended to use nanofluid.

Jie Pan et al. [2] studied the flow and heat transfer characteristics in a semicircular channel using supercritical LNG and propane as cold and heat sources, respectively, as well as the influence of channel bending angle on them. The results showed that the larger the channel bending angle, the better the heat transfer, the greater the pressure drop, and the best overall performance was achieved when the channel bending angle was 15°.

Binghuan Huang et al. [3] studied, designed and manufactured microchannel heat exchangers with and without fan accessible cavities, and analyzed the influence of the cavity entry radius and Reynolds number on heat transfer and pressure drop. The results indicate that compared to straight microchannels, microchannels with an accessible cavity can enhance heat transfer performance while also reducing pressure drop.

Fang Zhou et al. [4] conducted an experimental and numerical study on the enhanced heat transfer of micro columns with different shapes in the microchannel heat exchanger, and gave and compared Nusselt number (Nu), pressure loss and overall thermal performance parameters (TP) under different Reynolds number (Re). The experimental results show that the overall thermal performance parameters of water drop shape and irregular water drop shape are higher in the Reynolds number range than square, circular and fan shaped micro columns.

Yang Zhipeng [5] established an experimental platform to study the boiling heat transfer and pressure drop of microchannel heat exchangers, and analyzed the relationship between pressure drop and mass flow rate, pressure, and heat flux density.

Xiong Tong et al. [6] studied the influencing factors of two-phase flow distribution characteristics in microchannel heat exchangers and technical solutions to improve the uniformity of two-phase flow distribution in microchannel heat exchangers.

After conducting heat transfer experiments with water and nanofluids, Yuan Xue [7] found that if nanoparticles were present in water, the heat transfer performance of microchannels would be enhanced, and the greater the flow rate of the heat exchange medium, the more obvious the enhancement effect. Xue Yufan et al. [8] simplified the numerical simulation of rectangular parallel array microchannels by establishing a basic flow model based on the concept of porous media to address the high computational cost and long simulation time requirements of current simulation models. Wei Sheng et al. [9] compared the calculated values and experimental displacement values of four different structures of microchannel heat exchangers with slits or louvered fins. The research results showed that under given salt water flow conditions, the discharge rate of condensate water is mainly affected by wind speed. In order to further improve the thermal performance of the microchannel heat exchanger, Haiwang Li et al. [10] studied and designed a microchannel cavity with high heat transfer and low flow resistance. The results show that the side wall cavity has a relatively small expansion angle while enhancing heat transfer and reducing flow resistance, and the streamline edge cavity has a relatively large improvement in thermal performance.

Most of the existing experiments have started with different types of unit channel structures and different heat exchange working fluids. In order to meet the requirements of energy efficiency and performance testing of heat exchangers, a test bench has been built and a performance testing system for microchannel heat exchangers has been designed, but only one type of heat exchange experiment can be conducted. However, this experimental platform has designed a variable working fluid circuit and can conduct two types of heat transfer experiments to test and analyze the heat transfer performance of water water and carbon dioxide compressed air microchannel heat exchangers, exploring the optimal design that can enhance heat transfer in their flow channels.

Design of Microchannel Heat Transfer Performance Testing Experimental System

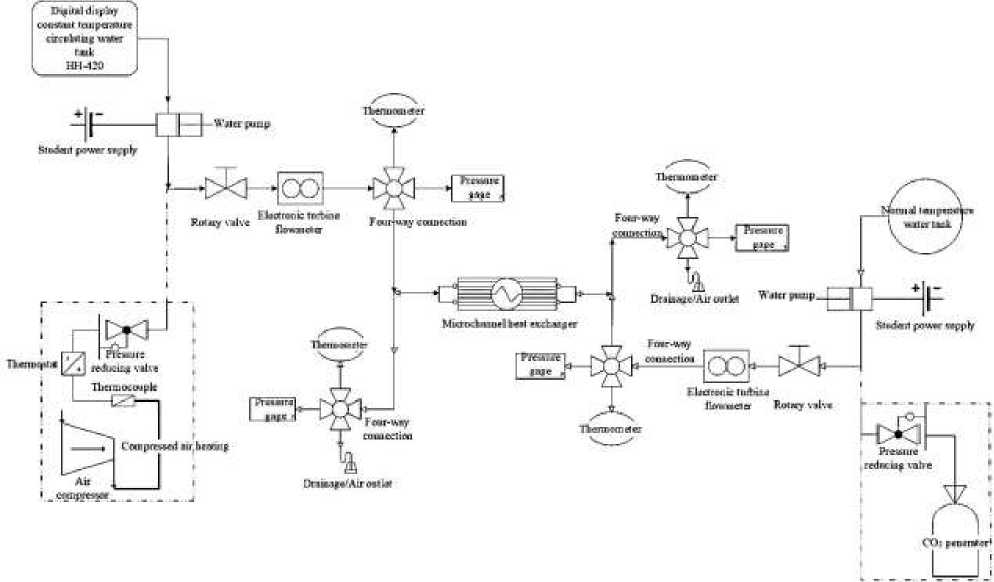

An experimental system using water, carbon dioxide, and compressed air as heat exchange working fluids was established. Based on the system diagram, a heat transfer and flow experimental platform for water and carbon dioxide compressed air microchannel heat exchangers was constructed. The experimental platform was designed for variable working fluid circuits. The core part of the microchannel heat exchanger experimental section adopts four straight microchannels, which are wrapped with high-quality insulation materials to achieve cold and heat resistance effects, effectively preventing heat loss. The microchannel material is stainless steel 304, made of 2 × Arranged in two ways, the channel has an inner diameter of 3.4 mm, a thickness of 0.2 mm, a length of 600 mm, and an inner diameter of 6.6 mm with the same material thickness and length as the control group.

Figure 1. Experimental system diagram

The specific steps of the water water experiment are as follows: (1) Add distilled water to the digital constant temperature water tank and the normal temperature water tank, set the constant temperature water tank to 50 T, and wait for the distilled water to heat to the target temperature. (2) After the target temperature is reached, without turning on the gear pump, open the rotary valves on both sides separately and wait for a few minutes to ensure that the pipeline temperature is consistent with the working fluid temperature. (3) After the readings of the thermometers on both sides remain stable and unchanged, fully open the rotary valve, connect the power supply, and start the DC gear pump. By adjusting the voltage of the DC stabilized power supply, the power of the gear pump can be changed, that is, the inlet flow rate of the working fluid can be changed. (4) Under the conditions of microchannels with inner diameters of 3.6 mm and 6.6 mm, five different flow rates qw1, qw2, qw3, qw4, and qw5 were set by adjusting the power supply voltage, and their values were read by the electronic turbine flowmeter. (5) Adjust the flow rate in order from low to high, and record 8 sets of data for each group under different flow conditions. Wait for no significant changes in the readings of the measuring instrument, and then record the inlet and outlet pressure and temperature of the hot side under three stable flow rates, and the inlet and outlet pressure and temperature under cold measurement. (6) After completing a set of experiments, close the valve of the digital display constant temperature water tank to restore the temperature of the experimental section pipeline to the value before the start of the experiment. Then, open the valve to control the flow rate, measure the next set of data, and repeat the operation of (5) under the new flow conditions to complete all preset operating conditions. (7) After the experimental work is completed, turn off the power and valves, drain the residual working fluid in the pipeline, and disassemble and organize the experimental equipment.

The steps for the carbon dioxide compressed air experiment are as follows: (1) Connect the compressed air heating belt to the power supply and temperature controller, set the heating temperature range of the temperature controller, maintain the heating belt temperature at around 50 °C, and wait for the heating belt to heat the pipeline to the target temperature. (2) After reaching the target temperature, open the valves of the air compressor and carbon dioxide cylinder and wait for a few minutes to ensure that the pipeline temperature is consistent with the working fluid temperature. (3) After the readings of the thermometers on both sides remain stable and unchanged, the inlet flow into the experimental system can be controlled by adjusting the opening of the pressure reducing valve. (4) Under the conditions of microchannels with inner diameters of 3.6 mm and 6.6 mm, five different flow rates qAir1, qAir2, qAir3, qAir4, and qAir5 were set by adjusting the pressure reducing valve, and their values were read by the electronic turbine flowmeter. Steps (5), (6), and (7) are basically consistent with the water water experiment.

The raw data obtained through testing, including temperature, pressure, flow rate, and their specific meanings are as follows: Th, in, w, Th, out, w — The inlet and outlet temperature on the hot side, in C; Tc, in, w, Tc, out, w — Cold measured inlet and outlet temperature, unit: C; Ph, in, w, Ph, out, w — Thermal measurement inlet and outlet pressure, in kPa; Pc, in, w, Pc, out, w — Cold measured inlet and outlet pressure, in kPa; Qv, w — Volume flow rate, in m3/s. The following is a calculation explanation for the microchannel core part.

(1) Geometric calculation part

Single microchannel traffic:

q v , w q s = —

n

In the formula, n - number of microchannels; Cross sectional area of microchannels:

A c = П D )2

Where D — microchannel diameter. Cross section perimeter of microchannels:

C = nD

Equivalent diameter of circular microchannels:

Dh = D

Qw: Heat transfer, the heat transferred in the water water heat transfer experiment is:

Qw p w q v , w c p (T h , in , w Th , out , w

In the equation: ρ W — density of hot water, kg/m3; Qv, w — system flow rate, m3/s; Cp — constant pressure specific heat capacity of hot water, J/kg K; Th, in, w, Th, out, w — The inlet and outlet temperature of hot water, in C.

The heat transfer on the heat side of the carbon dioxide compressed air heat transfer experiment is:

Q, = p, q , с (T —T , )

Air Air q v , Air p in , Air out , Air

In the equation: ρ Air — density of working fluid, kg/m3; q v, Air — system flow rate, m3/s; C p — constant pressure specific heat capacity, J/kg K; T in, Air 、 T out, Air — The inlet and outlet temperature of the working fluid, in °C. Calculation formula for water water convective heat transfer coefficient:

hw

Q s

A s A T m

The calculation formula for the convective heat transfer coefficient between carbon dioxide and compressed air:

h = - Q-' A . A T m

In the equation: Δ T m — Logarithmic mean temperature difference, A s — Surface area within a single microchannel, calculated as follows:

As = n Dl

A T =

m

AT -AT

max min ln max

AT

min

In the formula: l — the length of the microchannel, Δ Tmax、 Δ Tmin represents the maximum and minimum temperature differences on both sides under countercurrent conditions.

(2) Reynolds number calculation

The calculation formula for fluid qualitative temperature:

Water-Water:

_ T + T .

in out w = 2

Carbon dioxide - compressed air:

T + T .

in out

Air 2

In the formula, T in and T out respectively represent the inlet and outlet temperatures of the fluid, in °C. Based on the qualitative temperature obtained, the qualitative dynamic viscosity of the water can be obtained μ w 、 μ Air qualitative thermal conductivity λ w 、 λ Air and Qualitative Density ρ w 、

ρ Air . Qualitative flow rate:

v = -^s- Ac P

Reynolds number:

Re = P D

P

Бюллетень науки и практики / Bulletin of Science and Practice Т. 9. №6. 2023

(3) The calculation formula for Nusselt number Nu:

Nu = h ⋅ Dh λ

In the formula: h-convective heat transfer coefficient, W/(m2·K); λ-Thermal conductivity, W/(m·K).

(4) The calculation formula for pressure drop:

Water-Water:

∆P=P in,

-

P out , w

Carbon dioxide - compressed air:

∆ P = P - P (17)

in , Air out , Air

In the formula, P in and P out respectively represent the inlet and outlet pressures of the fluid, in kPa.

Results and discussion

A total of 90 raw data were measured for each experiment, and the specific data for the experimental operating points are shown in the Table 1, 2, 3.

EXPERIMENTAL DATA OF HEAT TRANSFER

IN MICROCHANNEL WITH INNER DIAMETER of 3.6 mm (WATER-WATER)

Table 1

|

q v , w ( m3/s ) |

т, . h , in , w (V) |

т, , h , out , w (V |

т c , in , w (V |

т . c , out , w (V |

р, . h , in , w (kPa) |

h , out , w (kPa) |

р . c , in , w (kPa) |

р . c , out , w (kPa) |

|

2.063×10-5 |

29.8 |

27.9 |

24.4 |

25.3 |

45.0 |

8.1 |

45.0 |

11.2 |

|

2.206×10-5 |

35.6 |

32.3 |

24.9 |

25.5 |

50.0 |

9.8 |

50.0 |

13.8 |

|

2.280×10-5 |

34.1 |

31.1 |

24.4 |

25.3 |

55.0 |

10.7 |

55.0 |

13.2 |

|

2.527×10-5 |

38.0 |

35.4 |

24.3 |

25.1 |

59.1 |

12.2 |

59.1 |

15.1 |

|

2.556×10-5 |

36.2 |

33.6 |

24.3 |

25.1 |

65.0 |

14.3 |

65.0 |

16.8 |

|

Table 2 EXPERIMENTAL DATA OF HEAT TRANSFER IN MICROCHANNEL WITH INNER DIAMETER of 6.6 mm (WATER-WATER) |

||||||||

|

q v , w ( m3/s ) |

T h , in , w (V |

T h , out , w (V |

т c , in , w (V |

т . c , out , w (V |

P h , in , w (kPa) |

P h , out , w (kPa) |

р . c , in , w (kPa) |

р . c , out , w (kPa) |

|

2.063×10-5 |

37.9 |

35.8 |

24.4 |

25.3 |

10.6 |

5.8 |

10.6 |

12.5 |

|

2.206×10-5 |

33.2 |

31.1 |

24.1 |

24.6 |

11.8 |

7.9 |

11.8 |

12.1 |

|

2.280×10-5 |

34.3 |

31.6 |

24.2 |

24.6 |

12.7 |

7.8 |

12.7 |

13.6 |

|

2.527×10-5 |

35.3 |

32.5 |

24.3 |

24.6 |

16.4 |

11.3 |

16.4 |

15.2 |

|

2.556×10-5 |

36.8 |

33.9 |

24.3 |

24.6 |

17.1 |

15.2 |

17.1 |

10.3 |

|

Table 3 GEOMETRIC CALCULATION OF MICROCHANNELS WITH DIFFERENT SIZES |

||||||||

|

Channel inner diameter |

Ac×105(m2) |

As×103(m2) |

Dh×103 ( m ) |

C× |

103 ( m ) |

|||

|

3.6 mm |

1.017 |

6.78 |

3.6 |

11.3 |

||||

|

6.6 mm |

3.419 |

12.43 |

6.6 |

20.72 |

||||

Substitute the specific data of the experimental operating points into equation (5) to obtain the heat transfer under different flow rates in the 3.6 mm and 6.6 mm inner diameter microchannels. Substituting the inlet and outlet temperatures under different flow rates into the logarithmic average temperature difference formula (10) can calculate the logarithmic average temperature difference of microchannels with different inner diameters and flow rates Δ Tm consists of ten groups, which will Δ Substituting Tm into equation (7) can obtain the convective heat transfer coefficients of each group.

Use equation (11) to obtain the qualitative temperatures of hot and cold water under different sizes of microchannels, and based on the qualitative temperature, obtain the qualitative dynamic viscosity of water μ w . Qualitative thermal conductivity λ W and qualitative density ρ w . Substitute the above data into Equation (14) to obtain the Re of the heat transfer experiment. Substitute the convective heat transfer coefficient, thermal conductivity coefficient, and hydraulic diameter into equation (15) to obtain the Nusselt number Nu under this heat transfer experiment, and obtain the pressure drop through equation (16).

With the increase of Reynolds number, the convective heat transfer coefficients of both microchannels show an upward trend, Re<2320, and the pipe flow of fluid in both circular channels is laminar flow. Nu is affected by the physical properties of the working fluid (convective heat transfer coefficient hw, thermal conductivity coefficient λ w . Density ρ w . Constant pressure specific heat capacity c p , etc.), and the size of the heat exchange surface, that is, the size of the microchannel. The larger the Nu number, the stronger the heat transfer process and the better the heat transfer performance. The Nusselt number of the microchannel with an inner diameter of 3.6 mm is generally higher than that of the channel with an inner diameter of 6.6 mm. Under the same flow rate conditions, the heat transfer performance of the 3.6 mm inner diameter microchannel heat exchanger is better than that of the 6.6 mm inner diameter microchannel heat exchanger.

Table 4

EXPERIMENTAL DATA OF HEAT TRANSFER IN MICROCHANNEL WITH INNER DIAMETER of 3.6 mm (CO 2 - compressed air)

|

q v , Air ( m3/s ) |

h , in , Air (V |

h , out , Air (V |

T . c , in , Ai (V |

c , out , Air (V |

h , in , Air (kPa) |

h , out , Air (kPa) |

p ( c , in , Air (kPa) |

p , c , out , Air (kPa) |

|

2.810×10-4 |

23.4 |

23.3 |

22.7 |

23.6 |

80 |

5.6 |

80 |

7.8 |

|

2.962×10-4 |

23.5 |

23.3 |

21.9 |

23.4 |

85 |

6.1 |

85 |

5.8 |

|

2.769×10-4 |

23.6 |

23.3 |

21.0 |

23.2 |

88 |

6.3 |

88 |

3.7 |

|

2.894×10-4 |

23.4 |

23.3 |

21.1 |

23.2 |

90 |

6.8 |

90 |

3.9 |

|

3.182×10-4 |

23.4 |

23.2 |

21.1 |

23.1 |

95 |

7.2 |

95 |

3.4 |

|

Table 5 EXPERIMENTAL DATA OF HEAT TRANSFER IN MICROCHANNEL WITH INNER DIAMETER of 6.6 mm (CO2 - compressed air) |

||||||||

|

q v , Air ( m3/s ) |

T h , in , Air (V |

T h , out , Air (V |

T c , in , Air (V) |

T c , out , Air (V) |

h , in , Air (kPa) |

P h , out , Air (kPa) |

c , in , Air (kPa) |

P c , out , Air (kPa) |

|

2.810×10-4 |

23.3 |

23.2 |

21.5 |

23.3 |

10.4 |

1.9 |

10.4 |

2.9 |

|

2.962×10-4 |

22.8 |

23.0 |

21.8 |

23.3 |

11.8 |

2.1 |

11.8 |

3.3 |

|

2.769×10-4 |

23.1 |

22.9 |

21.7 |

23.4 |

13.1 |

2.3 |

13.1 |

3.5 |

|

2.894×10-4 |

23.3 |

23.4 |

21.9 |

23.5 |

15.2 |

2.9 |

15.2 |

3.9 |

|

3.182×10-4 |

24.1 |

23.3 |

21.7 |

23.6 |

18.7 |

3.5 |

18.7 |

4.0 |

Increasing the flow rate of the heat exchanger under certain conditions has a certain effect on improving the performance of the heat exchanger. The pressure drop in microchannels with an inner diameter of 3.6 mm is relatively high. The reason for this is that as the flow rate increases, the cross-sectional area of the channel remains unchanged. Finer microchannels have higher flow rates, and the increased speed will increase the pressure drop in the microchannels and at the inlet and outlet.

The convection heat transfer coefficient hAir, the Reynolds number and Nusselt number on the hot side and the pressure drop on the hot side of the carbon dioxide compressed air heat transfer experiment are obtained through the steps similar to the water water experiment. When conducting heat transfer in a microchannel with an inner diameter of 3.6 mm, compressed air flows in the transition zone between laminar and turbulent flow, as well as in the turbulent smooth tube zone. However, when conducting heat transfer in a microchannel with an inner diameter of 6.6 mm, Re>4000, compressed air flows in turbulent flow. The changes in Nu and pressure drop are similar to the results of water water heat transfer experiments, and it can be concluded that within a certain flow rate range, the rate of improvement in heat transfer performance of microchannels with an inner diameter of 6.6 mm is more uniform.

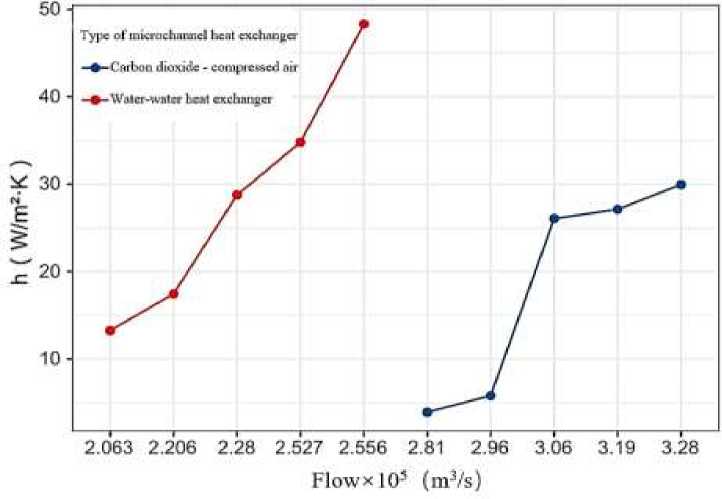

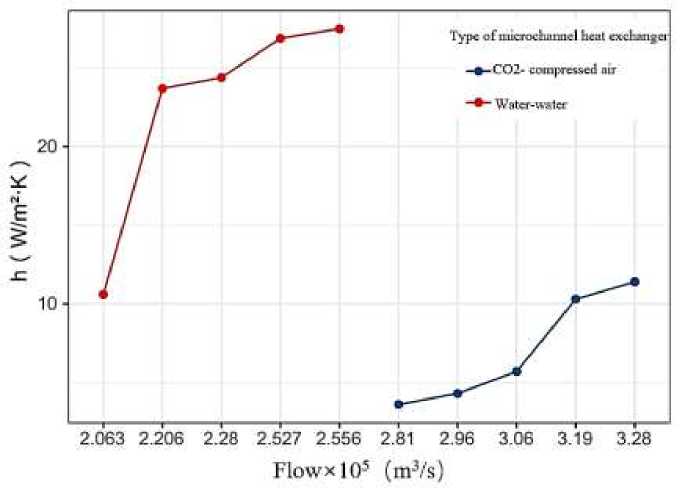

Figure 2. Comparison of two kinds of microchannel h with inner diameter of 3.6 mm

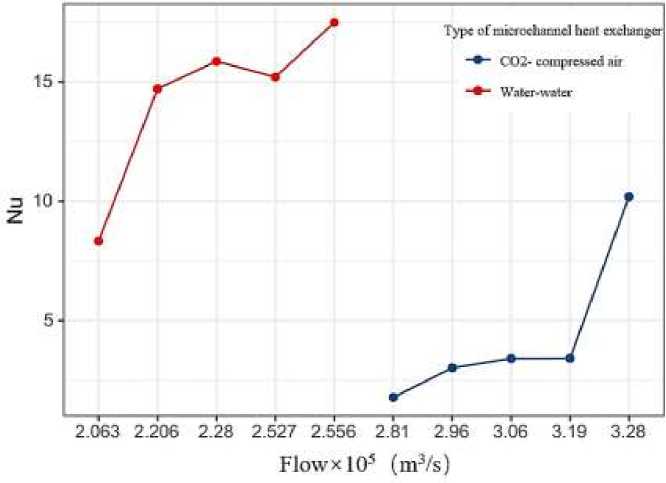

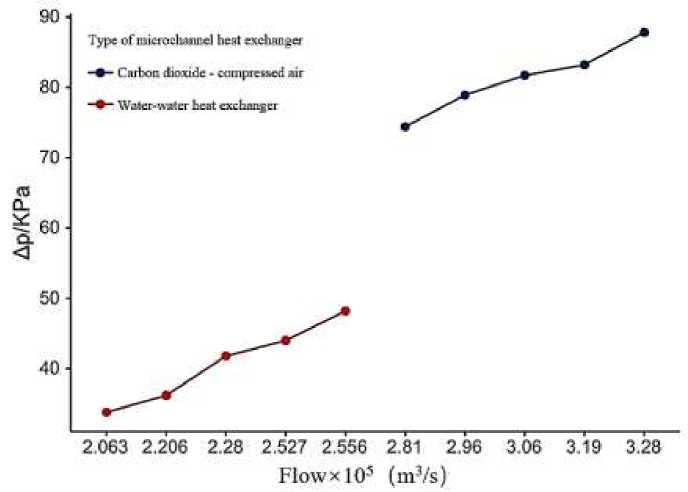

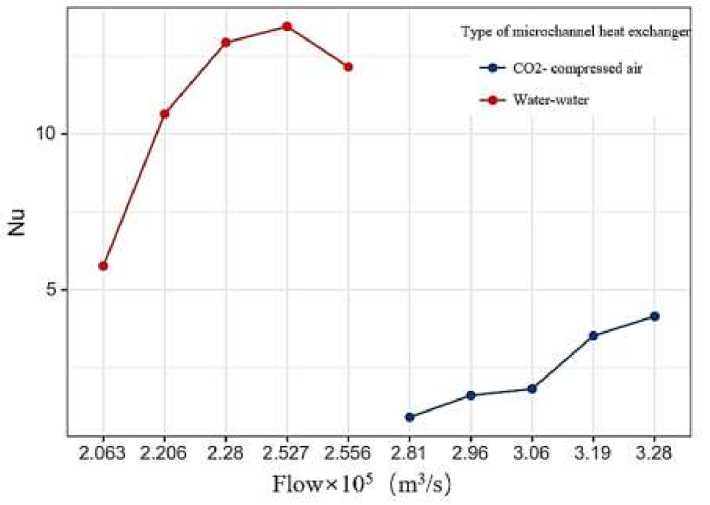

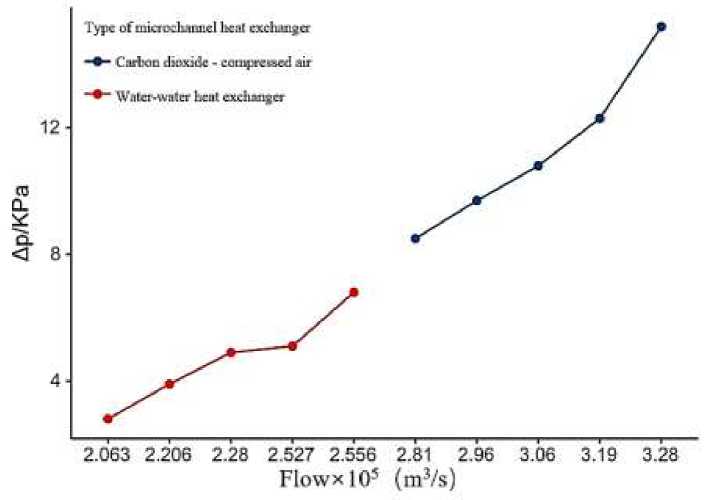

Figure 2 shows a comparison of the convective heat transfer coefficients of two types of microchannel heat exchangers, water water and carbon dioxide compressed air, when operating with a diameter of 3.6 mm. Figure 3 shows a comparison of the Nu numbers of these two types of heat exchangers when operating with a diameter of 3.6 mm. The vertical coordinates h and Nu shapes of the two figures are similar, indicating that the vertical coordinate values of the water water heat exchanger are greater than those of the carbon dioxide compressed air microchannel heat exchanger, indicating that the former has a stronger convective heat transfer intensity than the latter. When the inner diameter of the microchannel is 3.6 mm, it can be concluded that the heat transfer performance of the water water microchannel is superior to that of the carbon dioxide compressed air microchannel heat exchanger. Figure 4 shows a comparison of pressure drop between two types of microchannel heat exchangers with an inner diameter of 3.6 mm, using gas as the working fluid Δ P is larger, and it can be concluded from the meaning of pressure drop that the loss along the path of carbon dioxide compressed air microchannel heat exchangers is greater than that of water water heat exchangers.

Figure 3. Comparison of two kinds of microchannel Nu with inner diameter of 3.6 mm fluids

Figure 4. Comparison of two kinds of microchannel Δp with inner diameter of 3.6 mm fluids

Figures 5 and 6 respectively show the comparison of convective heat transfer coefficients and Nusselt numbers between the water water microchannel heat exchanger and the carbon dioxide microchannel heat exchanger when the channel inner diameter is 6.6 mm. It can be seen that the convective heat transfer coefficients and Nusselt numbers of the two microchannel heat exchangers change with the increase of flow rate. In Figure 5, the convective heat transfer coefficient of the water microchannel heat exchanger first increases sharply, and then slowly increases, The increasing form of the carbon dioxide compressed air microchannel heat exchanger tends to be flat. In Figures 5 and 6, the vertical coordinate values of the water water microchannel heat exchanger are higher. Therefore, the heat transfer effect of the water water microchannel heat exchanger with a

-

6.6 mm inner diameter is better.

Figure 5. Comparison of two kinds of microchannel h with inner diameter of 6.6 mm fluids

Figure 6. Comparison of two kinds of microchannel with Nu inner diameter of 6.6 mm fluids

Figure 7 shows a comparison of pressure drop between two types of microchannel heat exchangers when the inner diameter of the channel is 6.6 mm. The pressure drop value of the carbon dioxide compressed air microchannel heat exchanger is always greater than that of the water water microchannel heat exchanger. Therefore, in the flow range of 2.063 × 10-5~3.28 ×10-5m3/s, the carbon dioxide compressed air microchannel heat exchanger has greater loss along the path, and the water water microchannel heat exchanger has better heat transfer performance.

This experiment uses uncertainty as the evaluation standard to measure the credibility of the experimental results. The magnitude of uncertainty is inversely proportional to the quality of the measurement results, that is, the lower the uncertainty, the closer the measured values are to the true values of the experiment.

Figure 7. Comparison of two kinds of microchannel with Δp inner diameter of 6.6 mm fluids

Table 6

|

Project Symbol |

Formula Accuracy Result |

|

Temperature sensor ω |

α 0.5% 0.2887% 1 31 |

|

Pressure sensor ω |

α 2.5% 1.4434% 1 32 |

|

Turbine Flowmeter ω |

α 0.5% 0.2887 1 33 |

|

Combined uncertainty ω |

ω 2 + ω 2 + ω 3 — 1.500% |

|

Expanded uncertainty w |

k × ω k=2 3.00% |

Heat loss error of water water microchannel heat exchanger:

In the formula: Q hot, w, 3.6 - Heat dissipation capacity on the hot side of the heat exchanger with a channel inner diameter of 3.6 mm, (J); Q cold, w, 3.6 - Heat dissipation capacity on the cold side of a heat exchanger with a channel inner diameter of 3.6 mm, (J).

Substitute calculation data:

276.195 - 272.101

η = = 1.49%

1 (276.195 + 272.101)/2.

П =

Qhot , w ,6.6 Qcold , w ,6.6

= 0.72%

Qhot , w ,6.6 + Qcold , w ,6.6 ) 2

П з =

П з =

Q hot , Air ,3.6 Q cold , Air ,3.6

= 0.22%

= 0.33%

( Qhot , Air ,3.6 + Qcold , Air ,3.6 ) 2

hot , Air ,6.6 Q cold , Air ,6.6

hot , Air ,6.6 + Qcold , Air ,6.6 / 2

The statistical table of uncertainty in the measurement of this experimental system is shown in Table 6. The instruments used in the experiment, such as air compressors, constant temperature water tanks, carbon dioxide generators, and the thermometers, pressure gauges, and flow meters of the experimental measurement system, have all undergone factory calibration. The calculated values of uncertainty are truly valid, and the final expanded uncertainty ω=3.00%. The uncertainty of the pressure sensor is 1.4434%, which is slightly higher than the uncertainty of other measurement instruments, But they are all within the allowable range of experimental error, that is, the experimental measurement results of this heat exchange experimental system are all within the allowable error range.

Conclusions

This article focuses on the microchannel heat exchanger and designs a variable working fluid circuit for the experimental platform, so that one experimental platform can conduct two types of heat exchanger experiments. The heat transfer experiment was conducted using hot water and heated compressed air as heat source working fluids, and constant temperature water and carbon dioxide as cold source working fluids, respectively. The flow and heat transfer performance were studied from different unit channel structure types, different heat transfer working fluids, inlet flow rates, and other aspects. The experimental results were analyzed and the factors affecting enhanced heat transfer were studied. The following conclusions were drawn:

-

1. When the hot water flow range is 2.063 × 10-5~2.556 × 10-5m3/s, Re is less than 2320, the pipe flow in both circular microchannels is laminar flow. When the flow rate is the same, the Nu range of the 3.6 mm inner diameter microchannel is 8.33~17.49, and the Nu range of the 6.6 mm inner diameter microchannel is 5.76~12.15. Therefore, the heat transfer performance of the 3.6 mm inner diameter microchannel is better than that of the 6.6mm inner diameter microchannel.

-

2. When the inlet flow range is 2.063 × 10-5~2.556 × At 10-5m3/s, the Reynolds number and Nusselt number in the pipe increase with the increase of the inlet flow rate. Therefore, increasing the flow rate can improve the intensity of the heat transfer process of the micro heat exchanger.

-

3. In the carbon dioxide compressed air heat transfer experiment, when the flow rate range is 2.810 × 10-4~3.182 × At 10-4m3/s, by comparing the Nusselt number and convective heat transfer coefficient, it was found that the heat transfer performance of the 3.6 mm inner diameter microchannel was better than that of the 6.6 mm inner diameter microchannel.

-

4. When the microchannel diameter is 3.6 mm and 6.6 mm, the heat transfer performance of the water water microchannel heat exchanger is superior to that of the carbon dioxide compressed air microchannel heat exchanger.

-

5. Whether conducting two sets of heat transfer experiments in a 3.6 mm inner diameter microchannel or a 6.6 mm inner diameter microchannel, there is always a greater pressure drop in the carbon dioxide compressed air microchannel heat transfer experiment than in the water water microchannel heat transfer experiment. The reason for the analysis may be that during the experiment, the inlet pressure of the gaseous working fluid was higher than that of the liquid

working fluid, resulting in a pressure difference between the inlet and outlet, Δ p Air > Δ p w 。 .

Список литературы Design of performance test system for water-water and carbon dioxide compressed air microchannel heat exchanger

- Jamshidmofid M., Abbassi A., & Bahiraei M. Efficacy of a novel graphene quantum dots nanofluid in a microchannel heat exchanger // Applied Thermal Engineering. 2021. V. 189. P. 116673.

- Pan J., Wang J., Tang L., Bai J., Li R., Lu Y., & Wu G. (2020). Numerical investigation on thermal-hydraulic performance of a printed circuit LNG vaporizer // Applied Thermal Engineering. 2020. V. 165. P. 114447.

- Huang B., Li H., & Xu T. Experimental investigation of the flow and heat transfer characteristics in microchannel heat exchangers with reentrant cavities // Micromachines. 2020. V. 11. №4. P. 403.

- Zhou F., Zhou W., Zhang C., Qiu Q., Yuan D., & Chu X. Experimental and numerical studies on heat transfer enhancement of microchannel heat exchanger embedded with different shape micropillars // Applied Thermal Engineering. 2020. V. 175. P. 115296.

- Yang Z. Experimental study on flow boiling heat transfer and pressure drop characteristics in microchannel heat exchangers // Beijing University of Architecture. 2019.

- Xiong T., Yan G., Fan C., Yu J. (2021). Current Status and Prospects of Two Phase Flow Distribution in Microchannel Heat Exchangers // Journal of Refrigeration. 2021. V. 42. №1. P. 23-35.

- Yuan X. Research on Enhanced Heat Transfer Characteristics and Application of Nanofluid Microchannel Radiators // 2020.

- Xue Y., Guo C., Gu X., Xu Y., Xue L., & Lin H. Study on Flow Characteristics of Working Medium in Microchannel Simulated by Porous Media Model // Micromachines. 2020. V. 12. №1. P. 18.

- Sheng W., Li X., Wang R., Dang C., & Song M. Condensate drainage on slit or louvered fins in microchannel heat exchangers for anti-frosting // Energy and Buildings. 2020. V. 223. P. 110215.

- Li H., Li Y., Huang B., & Xu T. Numerical investigation on the optimum thermal design of the shape and geometric parameters of microchannel heat exchangers with cavities // Micromachines. 2020. V. 11. №8. P. 721.