Designing a cooler with natural cold for a 100 kW semiconductor power converter

Автор: Cheng Changshan, Golyanin Anton

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 8 т.8, 2022 года.

Бесплатный доступ

The subject of the study is the design of a cooler with natural cooling capacity for a 100 kW semiconductor power converter. The purpose of this thesis is to design a cooler with natural cooling capability for a 100 kW semiconductor power converter and to evaluate its practical effects. We summarize the demand for power semiconductor devices for new applications in power electronics in recent years. During the study and testing of the cooler for the 100 kW semiconductor power converter, the parameters that became the basis for mathematical modeling were determined. In this paper, we summarize the key issues and the current state of research on power semiconductor modules, including module thermal design and thermal modeling issues. The degree of realization is complete. In the process of developing the experimental device, reduction of energy consumption losses and reduction of explosion and fire hazards in industrial production facilities was achieved, which in turn will increase the efficiency of the invention and reduce its production costs. Development of efficiency - reduction of power consumption losses, reduction of explosion and fire hazards in industrial production facilities due to overheating of power semiconductors.

Coolers, semiconductors, heat dissipation, heat transfer, cooling efficiency, energy flow

Короткий адрес: https://sciup.org/14124774

IDR: 14124774 | УДК: 62-719 | DOI: 10.33619/2414-2948/81/34

Текст научной статьи Designing a cooler with natural cold for a 100 kW semiconductor power converter

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

UDC 62-719

The relevance of the research topic is to design a cooler with natural cooling capacity for a 100 kW semiconductor power converter.

The level of knowledge on the subject. Many scientists, such as Johann Andreas von Segner, Heron of Alexandria, Victor Schauberger, Leopold Shergyue, Richard Clem, have studied the problem of converting the energy of fluid flow into energy, but this problem has not been studied thoroughly. Some problems should be considered and decided to be eliminated.

The goal of this paper is to design a naturally cooled cooler for a 100KW semiconductor power converter. The aim of this work is to improve the energy efficiency of the cooler by using the energy of the compressed flow as a result of its periodic braking.

In this work, the following research methods were used: comparison, generalization, modeling, description, experimentation, graphical analysis. The information base of the research was literary sources and patents, such as A. P. Levtsev, A. Makeev, Ya. A. Narvatov, A. Lysyakov, S. Kudashev, V. M. Ivanov, B. V. Semkin, A. A. Blinov, T. A. Volkova.

The novelty of this research is the design of a cooler with natural cooling capacity for 100KW semiconductor power converters, which will help to reduce power consumption losses and reduce explosion and fire hazards in industrial production facilities, introducing and using this laboratory equipment in practice for facilities requiring high heat, such as industrial sites; logistics centers; all possible use in underground structures where explosive gases may leakage of semiconductor devices, such as IGBTs, etc.

In this paper, the thermal properties are considered, and the experimental characteristics are analyzed. And the model is formalized in mathematical language. A new semiconductor power cooler is developed, and a description of the theoretical calculations is considered, and the theoretical heat dissipation is calculated and simulated for different parameters and the results of the design simulations are analyzed graphically.

Material and research methods

The study was carried out under natural and laboratory conditions in 2022. Laboratory experiments were carried out in the laboratory of the Institute of Mechanical and Power Engineering of the N.P. Ogarev Mordovia State Research University.

The authors analyzed the existing articles and patents on coolers [1-4]. Articles on the subject of research work [5-7] were studied. Amplitude-frequency and phase-frequency characteristics were plotted to determine the most efficient mode of operation, and mathematical energy conversion was performed on the constructed hydraulic circuit. The development of technological solutions for power semiconductor device coolers and the transfer of cooler hydrodynamics and its heat transfer energy were studied. To be clearer the thermal design of the liquid cooler, strength, hydrodynamic calculations and calculation of economic efficiency of the semiconductor devices after their introduction into the cooler. The methodology and scheme of the experiments were developed.

Бюллетень науки и практики / Bulletin of Science and Practice Т. 8. №8. 2022

Further experiments were carried out to formalize the model in mathematical language and to process its data.

Results and discussion

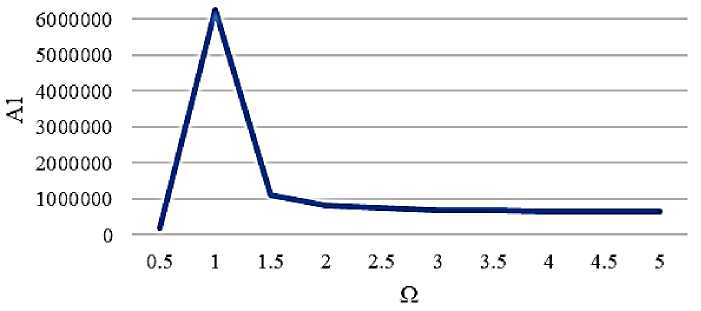

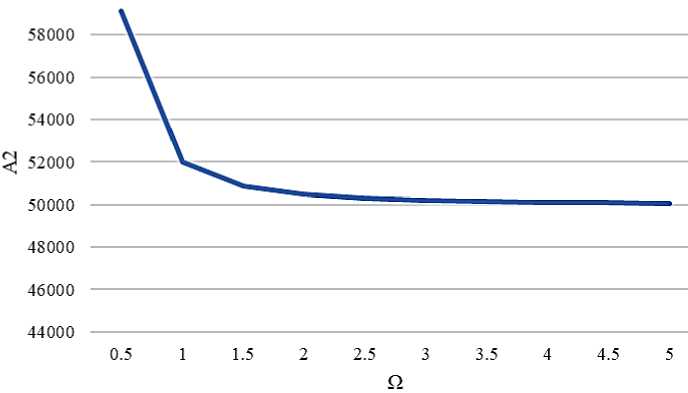

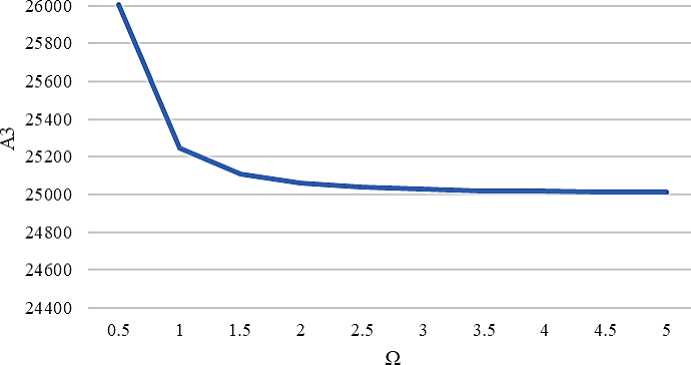

Table shows the calculated results of the amplitude-frequency and phase-frequency functions of the energy loops for three modes of operation at cooler frequencies of 0.5 to 5 Hz.

Table

VALUES OF AMPLITUDE-FREQUENCY AND PHASE-FREQUENCY FUNCTIONS OF ENERGY CIRCUITS

|

Ω |

A1(jΩ) |

A2(jΩ) |

A3(jΩ) |

|

0.5 |

207858.1079 |

207858.1079 |

207858.1079 |

|

1 |

6249900.02 |

6249900.02 |

6249900.02 |

|

1.5 |

1116978.998 |

1116978.998 |

1116978.998 |

|

2 |

831484.8052 |

831484.8052 |

831484.8052 |

|

2.5 |

743204.0568 |

743204.0568 |

743204.0568 |

|

3 |

702630.3868 |

702630.3868 |

702630.3868 |

|

3.5 |

680226.0506 |

680226.0506 |

680226.0506 |

|

4 |

666429.5895 |

666429.5895 |

666429.5895 |

|

4.5 |

657287.9447 |

657287.9447 |

657287.9447 |

|

5 |

650900.511 |

650900.511 |

650900.511 |

Based on the values obtained in Table 1, the AFC diagram was drawn.

As can be seen from the amplitude-frequency response plot (Figure 1), when the mass m is reduced to 50 kg and the softness l is reduced to 0.00008ms/N, the amplitude frequency decreases slightly compared to the reference value. When the mass m is increased to 100 kg and the compliance l is increased to 0.001 ms/N, the amplitude increases sharply by a factor of 10 or more. In this respect, this model is the best.

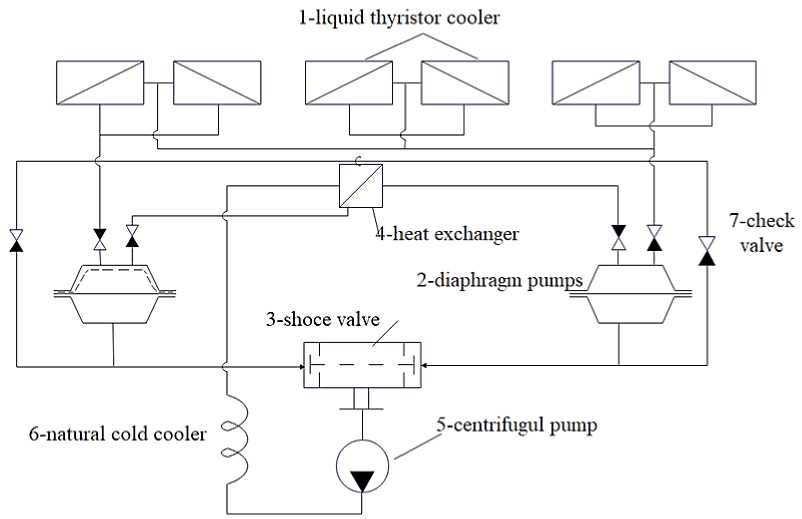

Figure 2 shows a schematic diagram of a laboratory setup with a pulsed circulating coolant.

The principle of operation of the scheme.

When the centrifugal pump 5 is turned on, it will supply the coolant through the natural cold cooler 6 to the heat exchanger 4. Then it returns back to the centrifugal pump 5 through one of the open valves of the shock valve 3. When the speed of the coolant is calculated, the valve of the shock valve 3 will quickly close. For exchange, the left valve. When the left valve is closed quickly, a hydraulic shock will occur, the revest pressure, wave of which will move the diaphragm 2. A portion of another coolant will be supplied to 7 and remove heat from the thyristor.

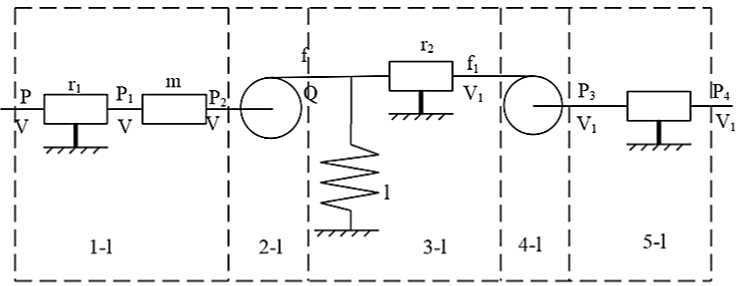

In a simplified from it includes 5 links: the first is hydraulic, take into account the friction losses of the input path with active resistance r 1 and the mass of water in the character m 1 ; the second is a convertor, converts the pressure P 2 into force, and the mass flow g into the diaphragm velocity v; the third is mechanical, takes into account the elastic properties of the diaphragm by the pliability T and the friction losses of the diaphragm about liquid active resistance r 2 ;the fourth-the converter link, converts the force f 1 into pressure P 3 , and the linear velocity V 1 into mass flow g 2 ;the fifth link is hydraulic, take into accent the losses of the loss of the output path the diaphragm pump using the active resistance r 3 . As in Figure 3:

Figure 1. The calculated results of the amplitude-frequency and phase-frequency functions of the energy loop for the three operating modes of the table cooler frequency from 0.5 to 5 Hz are shown in the graph

Figure 2. Technological scheme of the cooling unit

Figure 3. The energy circuit of the diaphragm pump link equation

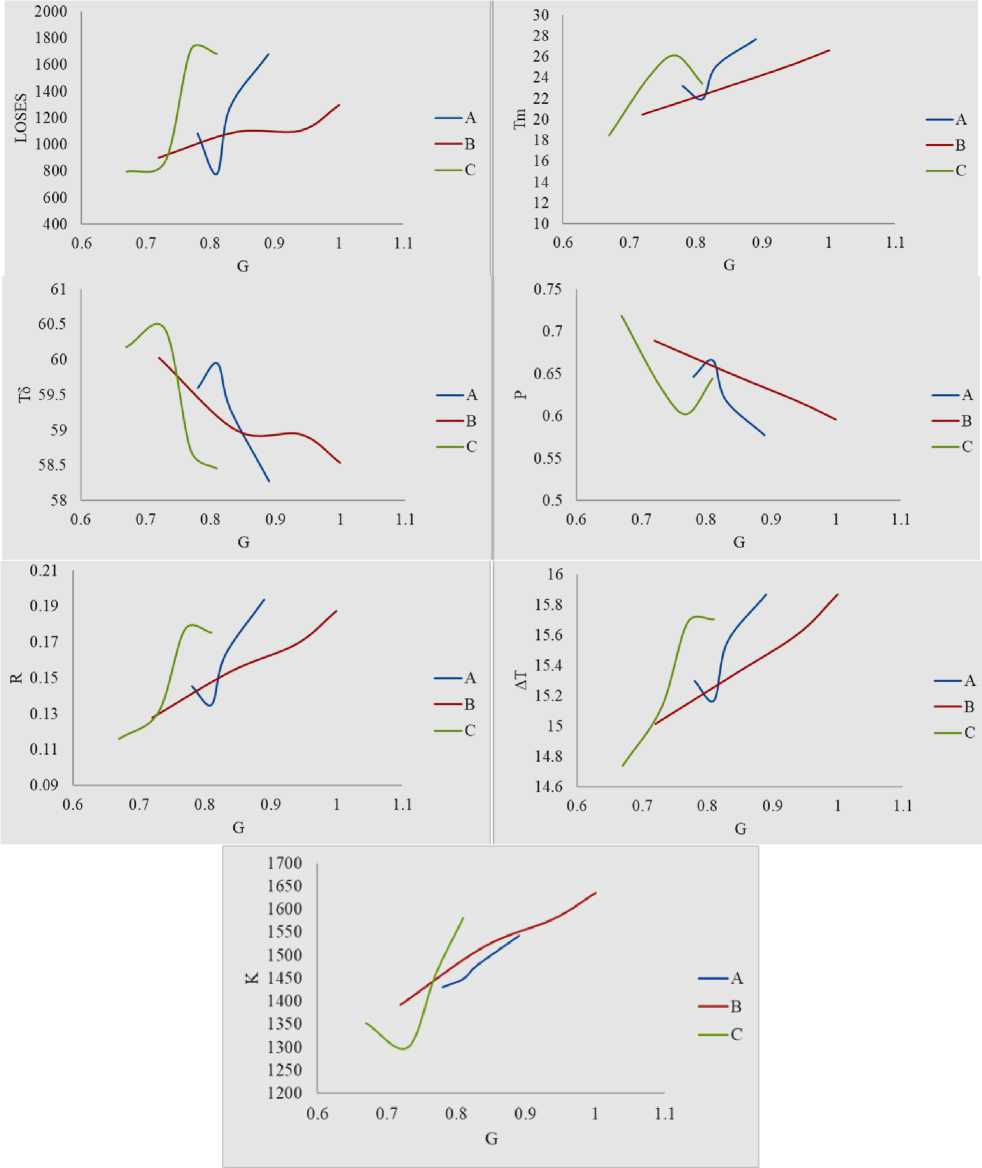

The calculation method of the micro-tank heat exchanger is studied, and the thermal efficiency is calculated to investigate the relationship between the flow rate and the input temperature, output temperature, heat loss, temperature difference and the related auxiliary quantities P, R. As in Figure 4:

We can conclude that we have obtained a peak which is equal to Ω = 4.5, which means that the design will work best under these conditions.

When considering the dependence of the third energy circuit, we can say that these indicators lead to an increase in efficiency with the growth of the parameters.

If we consider the phase-frequency characteristics, the dependence of all three energy circuits leads to a decrease of these parameters.

Moreover, in the course of this work we have a model on which we can understand which values have a greater influence on the desired value, i. e. the input temperature.

Figure 4. Plot of flow rate versus input temperature, output temperature, heat loss, temperature difference, and related auxiliary quantities P, R, etc.

Conclusions

The aim of this bachelor work is to improve the energy efficiency of 100kW semiconductor power by using the energy of the liquid cooling stream as a result of its periodic suppression.

The integrity of the solution task was evaluated.

In the process of developing the experimental device, reduction of energy consumption losses and reduction of explosion and fire hazards in industrial production facilities was achieved, which in turn will increase the efficiency of the invention and reduce its production costs.

During the study and testing of the cooler for the 100kW semiconductor power converter, the parameters that became the basis for mathematical modeling were determined.

In the simulations, the equations for the cooler of the 100kW semiconductor power converter were derived.

Based on the energy circuit dependence diagram of the second stage, we can conclude that we have obtained a peak which is equal to Ω = 4.5, which means that the design will work best under these conditions.

When considering the dependence of the energy circuit of the third stage, we can say that these indicators lead to an increase in efficiency as the parameters grow.

If we consider the phase-frequency characteristics, the dependence of all three energy circuits leads to a decrease in these parameters.

Also, in the course of this work we have a model on which we can understand which values have a greater impact on the desired value, i. e. the input temperature.

Список литературы Designing a cooler with natural cold for a 100 kW semiconductor power converter

- Haraka F., El Ouatouati A., Janan M. T. Analytical thermal resistance model for cooling high power IGBTs modules used in the arm solar converter // 2016 International Conference on Electrical Sciences and Technologies in Maghreb (CISTEM). IEEE, 2016. P. 1-4.

- Schweitzer D., Chen L. Heat spreading revisited-effective heat spreading angle // 2015 31st Thermal Measurement, Modeling & Management Symposium (SEMI-THERM). IEEE, 2015. P. 88-94.

- Van der Broeck C. H., Ruppert L. A., Hinz A., Conrad M., De Doncker R. W. Spatial electro-thermal modeling and simulation of power electronic modules // IEEE Transactions on Industry Applications. 2017. V. 54. №1. P. 404-415.

- Reichl J., Ortiz-Rodriguez J. M., Hefner A., Lai,J. S. 3-D thermal component model for electrothermal analysis of multichip power modules with experimental validation // IEEE Transactions on Power Electronics. 2014. V. 30. №6. P. 3300-3308.

- Пат. на изобретение 2423650 Российская Федерация, МПК F24D 3/00. Способ теплоснабжения / А. Н. Макеев, А. П. Левцев; заявители и патентообладатели А. Н. Макеев, А. П. Левцев. №2010112729/03; заявл. 01.04.2010; опубл. 10.07.2011, Бюл. №19.

- Макеев А. Н., Левцев А. П. Импульсные системы теплоснабжения общественных зданий // Региональная архитектура и строительство. 2010. №2 (9). C. 45-51.

- Куличихин В. В., Лазарев Л. Я., Чижов В. В., Савенков В. Ф. Методы и результаты исследования характеристик детандер-генераторной установки // Вестник МЭИ. 2001. №4. С. 19-24.

- Левцев А. П., Кудашев С. Ф., Макеев А. Н., Лысяков А. И. Влияние импульсного режима течения теплоносителя на коэффициент теплоотдачи в пластинчатом теплообменнике системы горячего водоснабжения // Современные проблемы науки и образования. 2014. №2.