Development of a Conceptual Model of Effective Management of Innovative Enterprises based on Digital Twin Technologies

Автор: Alovsat G. Aliyev, Roza Ordukhan Shahverdiyeva

Журнал: International Journal of Information Engineering and Electronic Business @ijieeb

Статья в выпуске: 4 vol.15, 2023 года.

Бесплатный доступ

The article is devoted to the development and implementation of the conceptual model of effective management of innovative enterprises based on digital twin technologies. As a result of digital transformation, the relevance of creating a digital twin of the innovative enterprise and the products/services produced there is justified. The necessity of developing the high technologies sector and the complex application of their results in relevant areas was noted. The features of the application of Industrial 4.0 platform components in the effective management processes of innovative enterprises have been studied. Organizational and technological issues of effective management of the activities of innovative enterprises were analyzed. In order to digitalize the economy on an innovative basis, directions for improving the ICT infrastructure have been proposed. The characteristics of science and technology-intensive product production in realizing and increasing the innovation potential of enterprises have been investigated. The state of the global market for the production and use of high-tech products has been analyzed. The ranking of some world countries according to the Global Innovation Index is given. Many issues related to the innovative digital development of industrial-economic systems have been revealed. A perspective conceptual development model of industrial-economic systems based on innovative digitization processes has been proposed. The stages of formation of technical and technological paradigms of development of industrial-economic systems are given. The economic-technological features of digital twin technologies in the conditions of digital transformation have been explained. The application areas and features of the digital twin technology in increasing the efficiency of the innovative activity of the enterprise were studied. The results that can be created by the application of digital twin technology in innovative industrial-economic systems have been brought to attention. A SWOT analysis of the process of using digital twins in the management of innovative industrial-economic systems was carried out. The impact of digital twin technology development on sustainable innovation processes has been investigated. The creation of digital twins for the organization and management of the activity of the innovative industrial-production enterprise and the expanded architectural system of its concept were proposed. Information about the structural subsystems of the conceptual model of innovative enterprises based on digital transformation was provided. As a result of extensive scientific analyzes and researches, a number of proposals and recommendations were developed on the effective application of digital twin technologies in the economic sphere and processes.

Innovative digitization of the economy, digital economy, digital technologies, innovative products, innovative enterprises, high-tech sector, digital twin, industrial 4.0 platform

Короткий адрес: https://sciup.org/15018879

IDR: 15018879 | DOI: 10.5815/ijieeb.2023.04.04

Текст научной статьи Development of a Conceptual Model of Effective Management of Innovative Enterprises based on Digital Twin Technologies

Published Online on August 8, 2023 by MECS Press

Advanced world countries have entered a new development environment in the direction of applying high technologies in all areas of the economy. They carry out many projects to increase the level of digitalization. The comprehensive application of rapidly developing Internet of Things (IoT), 5G, robotization, Big Data, cloud, and artificial intelligence technologies simultaneously necessitates the further development of the high-tech sector itself.

The application of the elements of the Industry 4.0 platform, "Industry, innovation and infrastructure", which is one of the 2030 Sustainable Development Goals [1] of the UN, in the activities of innovative enterprises form the basis of economic development based on new paradigms.

The fields of production of high-tech products in the ICT sphere are already considered one of the main development trends of the world economy. This requires solving the organizational and technological issues of effective management of the activities of innovative enterprises where high technologies are formed and produced. Innovative digitization of the economy requires improvement of the ICT infrastructure and capacity building of the ICT industry. In such a period, it is the main condition to achieve resistant, sustainable development of the economy. One of the main technologies and tools applied in the direction of improving economic management in the field of digital transformation is the digital twin technological concept [2].

In the 2022-2026 socio-economic development strategy, global trends, challenges, and opportunities for digital transformations are indicated in the upcoming periods [3].

Along with the development of digital technologies, the creation of a digital twin of the enterprise, process, and products is becoming an increasingly relevant area of research and application [4].

The creation of a digital twin of the enterprise implies the identification and automation of all the production, service, and all the information flow, processing, and administrative processes that take place in those areas. Currently, in the context of the transition to the digital economy, digital twin technology functions as digital copies of real physical objects (for example, manufacturing facilities, financial corporations, etc.) that help to improve the efficiency of key production-service processes [5].

The most important feature of digital twins is to have a virtual, informational, computer model of a certain physical object/process and ensure that it is constantly updated and dynamically maintained. This is mainly due to the mechanism of continuous updating of various data used to evaluate numerous properties of physical objects [6].

In order to achieve accuracy during management, it is necessary to present the studied enterprise/object as a system characterized by elements and processes. It takes a lot of time to establish the relationship between administrative processes and everything related to them. Observations show that if it takes about 2 minutes to describe one process, it will take 2 months to describe 350 processes together with others, and 5 years to describe 2000 processes. Consequently, due to the increase in the size of the system, there are limits on the control of the system that cannot be determined within the framework of a human lifetime [4].

Therefore, the task of rational management of production characteristics in a dynamically changing environment is becoming more and more important for many industrial enterprises [6].

At the same time, the complexity of production and logistics processes often does not allow enterprises to adapt quickly in the way of operational management of their resources. The reason for the problems is that the various links of the production chain are in some cases disconnected. Therefore, it is necessary to develop decision-making systems based on the creation of digital twins of enterprises. With their help, it is possible to determine the best state of the characteristics of the production process in various development options.

Innovative enterprises are considered to be the main driving force for the transition to a digital and innovative economy. For their effective activities, the improvement of regulatory mechanisms in the field of information technology development and the formation of a normal competitive environment is extremely important. Implementation of the mentioned problems is considered one of the main goals set in the respective fields [7].

In this direction, increasing the operational efficiency of innovative enterprises and science-innovation technology parks is one of the priority issues. In order to ensure sustainable economic development, it is required to further expand high-tech areas, create modern complexes in that area, to form innovative product-service production with high export potential.

There is a great need to conduct a complex analytical analysis of the problems of researching the operational efficiency of innovative enterprises and raising their level on the 4.0 Industrial platform. Modern scientific-research studies conducted at the international level directly confirm the relevance of those directions.

In the presented article attempts were made to study digital twin technologies and their application problems in the activity of innovative enterprises and to give suggestions and recommendations in the relevant field.

The main goal of the research is to determine the essential features of digital twin technology in the context of digitization of innovative enterprises and to work out the mechanisms of its application.

The main task of the research is to define the outlines of issues related to the scope of digital twin technology in the production sphere and to provide scientific support for their application in a conceptual form.

The research methodology is based on systematic analysis methods, statistical and multi-factor analysis methods, multi-criteria decision-making methods, and modern ICT systems, and tools.

The research process was approached at the micro level within certain limitations. Focused on generalized concrete object and process level. Based on the most common cases and data, innovative enterprise-level analyzes were conducted and recommendations were developed. During the research, it was preferred to refer to the most relevant scientific publications.

2. Statement of the Problem

In modern times, the economy is being transformed based on digital, innovative technologies. Economic structures are being modernized based on digital technologies. There, the formation of high-tech sectors, artificial intelligence, and robotics, bio, nano, information-communication, space, etc. development of new spheres is one of the main ways to achieve faster development of real economic sectors [8-10]. One of the main goals in building an innovation-oriented, knowledge-based economy is the introduction of high-quality and competitive information technology products to the international and local markets.

Developing a conceptual model of digital twin technologies for innovative enterprises is one of the main goals in realizing such future-focused strategic goals. In the effective management of innovative enterprises in the conditions of digital transformation, the specific characteristics, essence, purpose, structure, issues, scope, management indicators, and criteria of digital twin technologies should be studied, and in general, proposals and recommendations on its conceptual model should be developed.

In such complex problems, the recommendations of international organizations, as well as the 4.0 Industry platform [11] new management principles and models should be investigated and implemented on the basis of appropriate mechanisms, taking into account the prospects of applying new technological components. In this direction, research on digital twin technologies for innovative enterprises should be investigated and improved.

3. Research of Relevant Works

Developing a conceptual model of efficient management of innovative enterprises based on digital twin technologies is a complex issue. This is influenced by many internal and external factors. Here, attention is mainly focused on developing a conceptual model of efficient management of innovative enterprises based on digital twin technologies.

In general, although there is a certain amount of work on the development of digital twin technologies in the effective management of innovative enterprises, this area is rather poorly researched [12-21].

-

[12] is dedicated to working out the conceptual foundations of the extension of digital twin-based virtual enterprises-factory to the virtual enterprise. It was noted that production enterprises compete with each other while adapting to constantly changing conditions by establishing and strengthening their activity chains in order to survive. Therefore, enterprises are setting new goals for complex and dynamic environments to introduce, redesign, and evolve their products, processes, and system models. Enterprises are making a lot of progress, using technologies like modeling and simulation, digital twin, and virtual reality to remodel their resources, processes, and architecture. In addition, comprehensive concepts such as digital twin-based virtual factories exploit the potential of using such technological concepts in the field of application by enabling the integration of various tools, methods, and processes.

The existence of various empirical studies focusing on different uses of technologies, methods, and processes or on very general concepts and approaches is noted. Here, an attempt was made to overcome this gap by 1) compiling and discussing the conceptual and theoretical foundations of the digital twin-based virtual factory, and 2) presenting and discussing the expansion of the digital twin-based virtual factory. Systems and complexity theories, business cycle concepts, and competency-based strategic management are discussed to frame descriptive knowledge as a language for describing the internal and external nature of the operations of complex manufacturing enterprises. In addition, the design principles of the digital twin-based virtual factory concept are explored based on the framework concepts and theories to provide management guidelines for the use of such a concept, as well as its potential impacts and diversions in various application contexts.

[15] is devoted to a general approach to a sustainable intelligent manufacturing system based on digital twins. The features of intelligent production, which is a new-generation production system, provide higher quality, higher productivity, lower cost, and increased production flexibility. Development directions of sustainable production have been investigated with more attention to the concept of sustainability. The relevance of the digital twin is justified as a new digital technology used in intelligent manufacturing, capable of sensing the state of intelligent manufacturing systems in real-time and predicting system failures. It has been shown that continuous intelligent manufacturing based on digital twins has many advantages in practical applications. In this work, the essence of intelligent production based on digital twin technologies was explained and the sustainability of intelligent production was discussed. Here, the relevant content of intellectual production, including intelligent production equipment, systems, and services is analyzed. Then, along with the development of intelligent production based on digital twin technology, digital twin and its application, the current situation, and future development directions of intelligent production are presented.

4. Research Methodology

In [16], the application of digital twin technology in smart manufacturing was considered. It was noted that the new stage of the Industrial Revolution is rapidly developing with the application of new-generation information technologies. The importance of the strategic position of the manufacturing industry is shown. In recent years, the importance and relevance of the issues of forming and developing their own production development strategies, such as Germany's "Industry 4.0" and "National Industrial Strategy 2030", "Europe 2020 Strategy" of the European Union, "Advanced Manufacturing" of the United States and "Partners in China 2025" justified. The transformation of smart production into the main direction of the Industrial Revolution and industrial development was explained. In addition, the dynamic transformation of human development with sustainable development was noted. Special attention has been paid to the fact that green development is one of the most important components of the concept of sustainable development.

It is explained that the Digital Twin digitally creates a virtual model of a physical entity, promotes the interaction and integration of the physical and information worlds, and acts as a reliable bridge for industrial information integration. The rapid evolution of digital twins and the increasing application of digital twins in smart production have been noted. Here, taking into account the practical problems faced by existing smart manufacturing enterprises, the quantitative evaluation of smart manufacturing controlled by a digital twin-based industrial information integration system is performed as a set goal. Based on the object and model of smart manufacturing projects, the integration of digital twin data, and the interaction of the green performance evaluation of the smart manufacturing approach, the green performance evaluation of the smart manufacturing framework is established. Based on the approach, a green performance assessment is carried out for the smart manufacturing project of the enterprise. As a result, the digital binary controlled green performance evaluation of smart manufacturing platform is effective and can strengthen the green performance evaluation of smart manufacturing.

In [17], issues of digital twins in smart data management in a production enterprise were investigated. The main principles and stages used in the creation of Digital Twins are examined in this work. It was explained that the digital twin technology in production enterprises has special capabilities and features in increasing productivity, efficient use of resources, reducing costs at all stages of the product life cycle, creating new products, and reworking the business model of the organization. The current experience in the application of digital technologies in the management of industrial systems using digital twins has been investigated and work on the development of high-level models has been carried out.

In [19], a general approach to designing smart manufacturing systems based on digital twins in Industry 4.0 is performed. An intelligent manufacturing system is a multi-domain physical system with complex connections between various components. Usually, designers in various fields can design the subsystems of an intelligent manufacturing system based on only a limited understanding of the dynamics. Developing a single model to simultaneously implement intelligent manufacturing system designs and effectively simulate every interaction and behavior of manufacturing processes is a challenge. As an emerging technology, digital twins can achieve semi-physical simulations for early detection of design errors/defects in a smart manufacturing system, reducing physical operation/reconfiguration greatly in time and cost. However, the development of the digital twin concept in smart manufacturing system design remains uncertain. An innovative Function-Structure-Behavior-Control-Intelligence-Performance (FSBCIP) framework is proposed to review and promote how digital twin technologies are integrated into intelligent manufacturing system design based on a literature search of the Web of Science database. The architecture, basic design, new layout models, technologies, design examples, and research directions of the intelligent manufacturing system design based on digital twins are presented here. It is expected that in the era of Industry 4.0, the problems of developing new intelligent production systems will be solved and some recommendations will be given.

Although there are enough difficulties in solving the existing problems in this sphere, there are also opportunities and potential. It is very important to identify these problems and their solutions and to include them in the functional cycle.

On the basis of digital twin technologies, attempts were made to determine the problems of efficient management of innovative enterprises and prospective development directions, to investigate the technical and technological characteristics of digital twin technologies.

Digital twin technologies and applications of the main development technologies of the Industry 4.0 platform were taken into account in the activity of innovative enterprises.

It was tried to determine the application of digital twin technology to the activities of enterprises, to develop a conceptual model of efficient management of enterprises based on these technologies. Proposals and recommendations on increasing the efficiency of the sustainability level of enterprises by means of digital twin and other digital transformation technologies have been developed. International economic development trends, requirements of high and modern digital technologies, and the main trends of the Industry 4.0 platform have been taken into account in ensuring the sustainability of enterprises.

5. Science and Technology-Intensive Product Manufacturing in the Realization of Innovation Potential

The transition from traditional industrial or post-industrial industrial production to the system of knowledge economy is primarily related to the production of more products with high science and technology intensity. Currently, the global market for high-tech products is about 2 trillion dollars.

China earns about $496 billion, Germany $190 billion, and the United States $153 billion a year from the export of high-tech products [22]. As a strategic partner country, in the structure of Russian exports, mineral raw materials traditionally account for more than half, and in 2019, machinery and equipment accounted for only 6.55% of total exports. Research and development costs there are about 13 times less than in the United States, 11 times less than in China, and 4.2 times less than in Japan. Russia ranks 47th in terms of expenditures per scientist, and 34th in terms of the share of research and development expenditures in GDP [22].

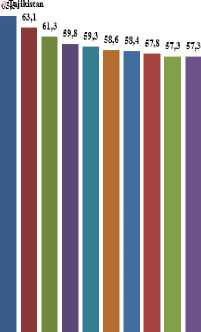

According to the "Global Innovation Index" analytical report for 2021, Russia ranked 45th in terms of innovation development among 132 countries (Switzerland was the leader). Azerbaijan ranks 80th on the [23] Global Innovation Index (Figure 1). 12% of all scientists and researchers in the world work in Russia, and 25% in the United States. It turns out that high intellectual potential is often underutilized in Russia. Only about 10% of innovative projects are implemented there (62% in the USA, 95% in Japan). In 2018, Russia was included in the list of the 25 most innovative countries.

One-third of the technologies in Russia belong to the third generation, and more than 50% belong to the fourth generation. About 10% of the technologies of highly developed industries, including the military-industrial complex and the aerospace industry, can be attributed to the fifth generation. It is too early to talk about the sixth technological generation.

This situation clearly determines the direction and structure of the tasks facing Russia and other countries with similar economies in the next decade. In order to make a strong leap towards the sixth technological regime, it is necessary to take advantage of the experience of advanced world countries. As a result, it should be noted that the scientific sphere should be separated as an independent field of the economy. Therefore, it is necessary to support the development of science and the innovative potential of the country as the basis of innovations.

In 2018, the share of high-tech products in the structure of Russian exports was 10.96%.

According to this indicator, Russia lags behind the leading countries: Israel (4.54%) and South Korea (4.55%) [22].

At the end of 2017, the total level of innovative active organizations in Russia is 9.3%. Compared to the leaders, Canada is 79.3%, Switzerland, Brazil 72.6%, Norway 71%, and China 37.1%.

|

Rating |

Name of countries (132 countries) |

Price (on a scale of 0 100) |

|

1 |

Switzerland |

65,5 |

|

2 |

Sweden |

63,1 |

|

3 |

United States of America |

61,3 |

|

4 |

United Kingdom |

59,8 |

|

о |

Republic of Korea |

59,3 |

|

6 |

Netherlands |

58,6 |

|

7 |

Finland |

58,4 |

|

8 |

Singapore |

57,8 |

|

9 |

Denmark |

57,3 |

|

10 |

Germany |

57,3 |

|

11 |

France |

00 |

|

12 |

China |

54,8 |

|

13 |

Japan |

54,5 |

|

14 |

Hong Kong, China. |

53,7 |

|

15 |

Israel |

53,4 |

|

16 |

Canada |

53,1 |

|

29 |

Italy |

45,7 |

|

41 |

Turkey |

38,3 |

|

45 |

Russian Federation |

36,6 |

|

48 |

Romania |

35,6 |

|

49 |

Ukraine |

35,6 |

|

60 |

Islamic Republic of Iran |

32,9 |

|

62 |

Belarus |

32,6 |

|

63 |

Georgia |

32,4 |

|

64 |

Republic of Moldova |

32,3 |

|

79 |

Kazakhstan |

28,6 |

|

80 |

Azerbaijan |

28,4 |

|

86 |

Uzbekistan |

27,4 |

|

98 |

Kyrgyzstan |

24,5 |

|

99 |

Pakistan |

24,4 |

|

103 |

Tajikistan |

23,9 |

Fig. 1. Ranking of some world countries according to the Global Innovation Index-2021 (proposed by the authors based on the analysis of scientific sources)

■ Sxvitzeriand

■ Sweden

i United States of Amaica

i United Kingdom

i Republic of Korea

■ Netherlands

'Finland

■Singapore

Denmark

1 Germany

1 France

China

■ Japan

■ Hong Kong. China

Israel

■ Canada

Turkey

Ukraine

i Islamic Republic of Iran

Belarus

Georgia

Azerbaijan

Uzbekistan

Kyrgyzstan

Pakistan

Russian Federation

Romania

Rqjublic of Moldova

Kazakhstan

The above analyzes confirm that, without conducting detailed research, it can be concluded that a similar situation exists in many countries, including Azerbaijan. Therefore, the development choice path of countries with the same development characteristics is almost the same. The path of scientific and technological development should be accelerated by all means.

6. Features of Digital Twin Technologies in Digital Transformation

The main informative factor of production in the digital economy is digital data. Here, the processing of large volumes of data and the use of analysis results have increased significantly compared to traditional forms of management. The digital economy is a set of economic activities that can have a guiding and developmental effect on socio-economic processes based on the latest technologies. The digital economy is a change in the form-content nature of industrial-economic relations. It is also understood as a change in their subject-object orientation.

Digital economy, in the narrow sense of the word, is the creation of information and digital platforms that enable the solution of various economic problems in a new technical and technological aspect, applied at various levels of the economy. Such an interpretation of the concept of digital economy would also be appropriate, that it is the integration of modern network software and computer resources with other relevant scientific and technological systems, which allows the increase of economic efficiency. It is an economy that thrives on digital innovation. The digital economy as a whole is also the full realization of the concept of digital twins.

In some scientific sources on the theoretical basis of the concept of digital twins [the works of M.Hindsbo, M.-T.Schmidt and M.S.Potjetra notes that industrial applications of this technology show that digital twins are the most complex models that describe the structure, context and behavior of both single industrial objects and systems composed of them. Some researchers M.Hindsbaugh and M.S.Potjetr characterize the above concept as a numerical simulation process for creating virtual prototypes. Common but essentially close interpretations of the digital twin concept allow us to generalize that this concept is distinguished by the interaction and integration of numerical simulation with the collection of data collected by sensors (devices) in real time. Digital data about the existing product from the manufacturer is constantly received and analyzed.

A number of programs and projects have been developed to develop the digital economy. Their main goals are 1) increasing the innovative activity of business, 2) increasing the efficiency of state administration; 3) development of the country's economic potential based on the use of information and telecommunication technologies. Among them, the following can be mentioned:

-

> Information society (2011-2020) Program consists of the following sub-program:

-

1) Information and telecommunication infrastructure of the information society and the services provided on its basis, 2) Information environment, 3) Security in the information society, 4) Information situation.

-

> The digital economy program includes six projects: 1) Digital environment regulation, 2) Information infrastructure, 3) Personnel for the digital economy, 4) Information security, 5) Digital technologies and 6) Digital public administration [24].

A digital prototype is a simplified implementation of a digital twin that simulates only some dynamic functions of a real object, depending on the modeling goals. Digital prototyping is typically used in the early stages of creating digital twins. It is sometimes used when it is necessary to test alternative hypotheses or to evaluate scenarios for object operation. These include, for example, the general placement of equipment in production, the calculation of several process parameters, the calculation of the rhythm and cycle of production, the calculation of other parameters at the current design stage, etc. can be shown.

The most important functional task for which digital twins are used is the 3D simulation of production and logistics processes for the purpose of their design, tuning, and optimization. This problem can be solved both at the stage of creation of new industrial areas, modernization of existing ones, and their direct operation.

Digital shadows are also digital twins that have the ability to receive digital data online from their respective digital control systems, etc. As a rule, uploading data from equipment to twins is carried out through the Internet of Things (Industrial Internet of Things). A comparison of the data of the digital twin and its digital shadow reveals discrepancies between the production processes "as it should be" (As Mast Be) and the processes "as it is". This allows for further optimization and continuous improvement. In addition, it is possible to implement operational management of production online in accordance with the digital shadow. Digital managers [25] are used for this work.

Digital managers, unlike other types of digital twins (simulators, shadow programmers, etc.) 1)receive digital data online, 2)integrate it quickly, 3)analyze and implement model-driven control, 4)optimum production is digital twins capable of choosing and implementing solutions. They download the required offline programs directly into the digital control systems of the respective equipment.

Given the basic functionality of digital twins, the benefits provided by each type have already been mentioned. The effects that a modern industrial enterprise can get from creating digital twins of its production can be summarized as follows. Thus, digital twins in the industry provide the following effects [25]:

-

> Speeding up production, technological and logistics processes and reducing costs,

-

> Reducing the share of manual labor in production,

-

> Reducing interruptions and increasing the rate of useful use of equipment,

-

> Significant reduction in equipment replacement time with digital control,

-

> Improving the quality of processes and products, reducing malfunctions,

-

> Improvement of labor safety and ergonomics in production,

-

> Reducing labor intensity and improving the quality of the production management process,

-

> Industrial equipment, industrial automation solutions, system integration, industrial engineering, etc.

Increasing the efficiency of marketing and sales,

> Creation of new industrial areas and modernization of existing areas,

> Acceleration and increase of return of investments in implementation of projects of creation of some other areas [25].

7. Application of Digital Twin Technology in Increasing the Efficiency of Innovation Activity

Currently, the application of digital technologies in various fields is complex and purposeful. The Industry 4.0 platform provides a wide range of digital technologies in these areas [11, 26]. Digital transformation, as an integral part of the 4th Industrial revolution, is being widely applied in general economic spheres, including industry, oil and non-oil industries. The digital transformation of the industrial sphere brings effective solutions to transform data into information and knowledge and then use them to improve operations. One of the core technologies of digital transformation, digital twin is a digital representation of a product, process or service. It is used to monitor, analyze and improve production and service productivity. Digital twins have been one of the top 10 strategic technology trends for recent years.

The global market for digital twins in 2018 was estimated at USD 3.76 billion. It is expected to reach USD 57.38 billion in 2027, growing at an average rate of 37.1% during the forecast period from 2019 to 2027 [27]. Although many use digital twins as a synonym for 3D models of an object, as service solutions or as their simulation models [28] there are many other successful applications of digital twins in industrial product/service production [29].

The concept of digital twin, as well as the concept of digital twin, are sometimes called "mirror model", "digital shadow", "digital lookalike", "digital model". Although these expressions have been around for a long time, they have only recently become popular with the development of artificial intelligence and the industrial Internet.

Recall that as early as 1950, NASA (National Aeronautics and Space Administration - US National Space Agency), GE (General Electric) and other industrial manufacturers were creating abstract digital models of equipment to perform equipment productivity and life cycle accounting in simulation modeling [26, 30].

The author of the first application of the digital twin concept in production (2002, University of Michigan) Dr. Michael Grieves defined it as the virtual or digital equivalent of a physical object [31]. He proposed the digital twin as the conceptual model underlying Product Lifecycle Management (PLM).

It should be noted about the types of digital twins that many researchers classify them into different types. Digital twins are divided into types such as digital twin prototype, digital twin sample and digital twin aggregate in [31].

The digital twin, which is one of the main technologies that increases the efficiency of the innovative activity of industrial-economic systems, is now recognized as the main part of Industry 4.0. This technology continues the CALS and PLM methodologies that have emerged in recent decades. The annual growth of the market in this area from 2020 to 2026 will be about 58% [22, 32]. The use of digital twin technology for innovative production processes allows to reduce the number of failures. It allows to predict the response of the equipment to operating loads with 95% accuracy. It is possible to reduce the operating costs of complex industrial complexes by 5-10%.

Currently, many large industrial enterprises are facing the problem of decreasing competitiveness. Despite a large number of applied information systems, the efficient planning of production projects remains at a low level. The digital twin plays a central role in solving these problems. Its implementation reduces the development time of prototypes, and the process of adaptation to technical tasks is accelerated. At the same time, operating costs are reduced and the speed of bringing innovative products to the market increases. These allow to quickly create and test various modifications of the digital technology product.

At this time, the number of full-scale tests is reduced, and as a result, the cost of innovations can be significantly reduced.

A digital twin allows you to quickly get information about the properties of the future innovative product. As a rapid prototyping tool, the digital twin accelerates innovation and reduces costs. Industries can test, adjust, and improve the details of a product before it is actually manufactured. In order to deeply study the process of using digital twins in the management of innovative industrial-economic systems, its strengths and weaknesses were comprehensively analyzed [22]. The results of the SWOT analysis of the process are presented in table 1.

Mathematical and simulation modeling (CAD, CAM, CAE, etc.), as well as a family of software products for computer engineering based on Product Life Cycle Management (PLM), form the methodological basis of the application of digital twin technology.

Digital twins create virtual copies of a real industrial product. They control physical processes and make decentralized decisions. Such systems can be self-learning, self-regulating and networked.

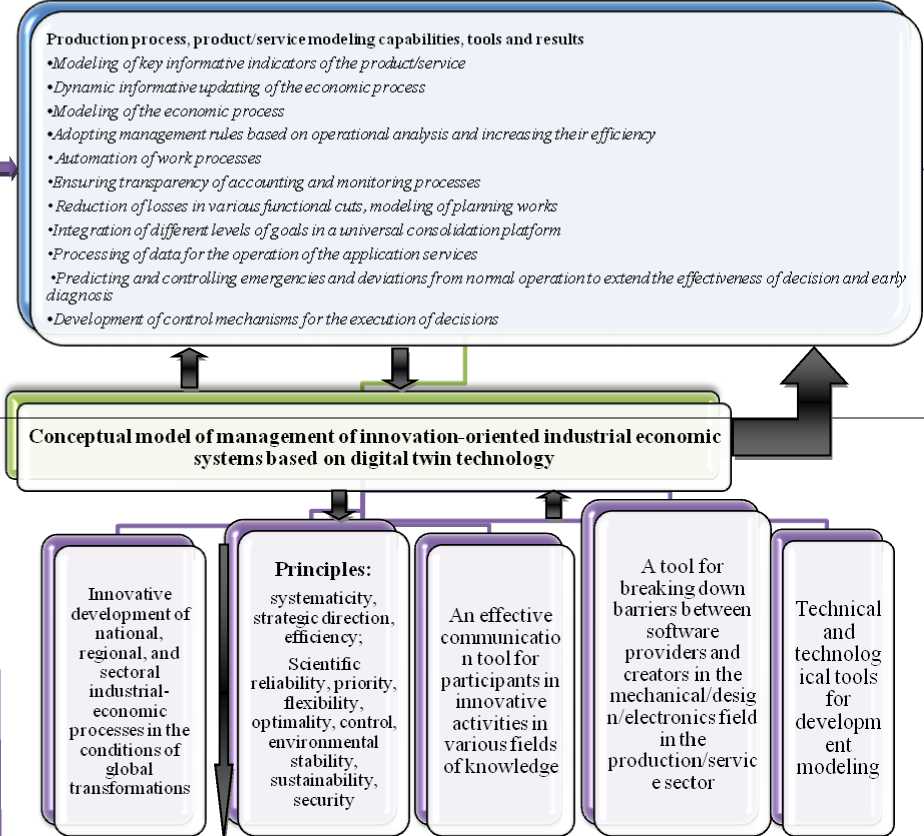

Management of innovative industrial-economic systems based on digital twin technology is influenced by production process modeling tools, production-economic systems, management principles, and certain technical and technological solutions. Taking these into account, the conceptual model of the process can be expressed as in Figure 2.

Table 1. SWOT analysis of the process of using digital twins in the management of innovative industrial-economic systems

|

Strengths |

Weaknesses |

transactions

|

|

|

Skills |

Threats, dangers |

models in the industry

implementation of digital twins

products

|

digital twins

the application of digital twins

ixtisarlarının olması

|

Digital twins

A set of mutual management and technical solutions that allow you to get the overall result and avoid mistakes

Fig. 2. Conceptual model of management of innovative industrial-economic systems based on digital twin technology (proposed by the authors based on the analysis of scientific sources)

An important issue for innovative industrial-economic systems is the use of digital twin technology in a way that ensures openness to stakeholders.

Some of its main principles that allow manufacturing companies that apply it to ensure transparency can be shown:

-

1) Transformation of workplaces,

-

2) Ensuring cyber security of the industrial-economic system,

-

3) Formation of a control and regulation system for the digital twin,

-

4) Control and audit of the digital twin,

-

5) Increasing transparency.

-

8. Methodological Foundations of the Concept of Digital Twins

In certain industrial systems, digital twins allow the simulation of various types of changes and effects. Various enterprises are building their own digital twins in the form of global platforms for modeling, simulating, and analyzing innovative production systems using key technologies for the digitization of production [22].

It should be noted that the digital twin is not limited to the collection of information obtained during the development and production stage of the product. It operates continuously in collecting and analyzing data throughout the entire life cycle of a real object [33, 34].

In terms of application, the main task of the tools of the 4.0 Industrial concept is to effectively use the technological equipment of the enterprise based on the digitization of production. The digital twin receives information (Big Data) from various sensors, controllers, and technological equipment installed in the production, processes it, analyzes it, and presents it in an acceptable form to the authorized employees of the enterprise.

Although the concept of digital twins was proposed relatively recently, researchers note that its development should be based primarily on the use of simulation methods that provide the most realistic representation of a physical object [5].

The conducted scientific analyzes also show that the concept of creating digital twins is based on specific simulation methods, optimization modules, certain classes of genetic algorithms, databases, multi-criteria decision-making, multi-dimensional data analysis, and integrated OLAP connecting their subsystems (Figure 3).

Simula tion modeling methods

Visualization and management of simulation models

Optimization modules, genetic algorithms

Multi dimensional data analysis (OLAP)

Fig. 3. Extended architectural system of the digital twin of the innovative manufacturing enterprise (proposed by the authors based on the analysis of scientific sources)

Mult idimensional data intelligent analysis subsystem

An important feature of this approach is to ensure the normal integration of subsystems working with the support of software modules in real-time.

The concept or conceptual model of the Digital factory, which is one of the implementation options of the digital twin technology, is based on the creation of a number of interconnected subsystems. Among them, we can mention the simulation subsystem, which takes into account the entire chain of creation of the final product for micro-level management, and allows for calculating of the production and financial characteristics of the enterprise. In the example of a digital plant that assembles technical equipment, the simulation model includes the following elements [6]:

-

1. Sources of supply of components necessary for the assembly of the final product entering the plant according to the given intensity;

-

2. Component warehouses designed for the temporary storage of intermediate products and their delivery to conveyor lines;

-

3. Sorting-conveyor system designed for automatic synchronization of flows with components having different technical and operational characteristics;

-

4. An assembly shop, which ensures the assembly of finished products using hired specialists;

-

5. Technical control department that ensures quality control of the final product;

-

6. A packaging workshop that performs the function of packing, assembling, and forming batches of finished products;

-

7. Warehouse of finished products intended for the temporary storage of equipment;

-

8. The shipping department, which provides the function of sending finished product batches by handing them over to the transport company;

-

9. Data warehouse intended for storage of primary data necessary for simulation modeling and processing of the results of optimization experiments;

-

10. An optimization module, which is connected to the simulation model of an enterprise and allows to search for the best values of the characteristics of the production process under various scenario conditions, etc.

Note that an important feature of the considered system is the presence of agents involved in the production process. These can include:

-

> agent-components with individual characteristics;

-

> agents-products that differ according to their functional characteristics;

-

> agent-batch of finished products, which is a grouping of agent-products (by models) for transportation;

-

> resource agents involved in various processes (eg assemblers, specialists, packers, etc.)

In addition, the automatic conversion of production system component agents into finished product agents, as well as the mechanism of grouping of product agents into finished product batches is also provided [6].

These indicate that in order to achieve optimal control of the enterprise through Digital twin technology, it is necessary to perform the following tasks [4] :

• defining the enterprise as a dynamic system;

• creating a digital twin of the enterprise;

• creation of an algorithm for optimal management of the enterprise's digital twin, etc.

9. Conclusion

Results and discussion . Ensuring the innovative development of the country's economy based on digital technologies requires the wide application of digital twin technology in the effective management of enterprises. Despite the acceptance of the results of such a development trend on a global scale, there is still a need to promote, discuss and use this problem in local conditions, at the national level, and to be believed and used by large population groups.

Digital twin, artificial intelligence, the Internet of Things, etc. on the basis of digital transformation technologies such as increasing the operational efficiency of the effective management of enterprises, and developing recommendations on strengthening the enterprise's perspective development directions, should form the basis of future discussions and research.

Development of enterprises on the basis of digital twin technology, and the development of a conceptual development model of effective management should be included among the main directions. In the development of enterprises, the application of modern ICT corresponding to the platform of Industry 4.0 should be stimulated. In order to justify the improvement of its operational efficiency through digital technologies such as the Internet of Things, artificial intelligence and machine learning, and Big Data analytics, the benefits they can bring should be the subject of a wide discussion.

Innovative enterprises are considered the main driving force for the transition to the digital economy. For their effective activities, the improvement of regulatory mechanisms in the field of information technology development and the formation of a normal competitive environment are extremely important. In this direction, increasing the operational efficiency of innovative enterprises is one of the priority directions. In order to ensure sustainable economic development, high technology areas should be further expanded. In order to create modern complexes in this field, it is required to form the production of innovative products and services with high export potential. There is a great need to conduct a complex analytical analysis of the problems of researching the operational efficiency of innovative enterprises and raising its level on the Industrial 4.0 platform.

Among the prerequisites for the formation of the innovative potential of economic subjects, its information environment should be specially mentioned. Now the countries are experiencing a period of development of the market of digital and ICT technologies. This allows us to consider the information content of socio-economic development as an innovative resource. The comprehensive application of rapidly developing Internet of Things (IoT), 5G, robotics, Big Data, cloud, and artificial intelligence technologies necessitates the parallel development of the high-tech sector.

As an integrative expression of these technologies, the concept of digital twins emerging in the production/service sector can significantly increase the efficiency of economic processes. The most important functional task for which digital twins are used is the simulation of production and logistics processes in order to tune and optimize them. This problem can be solved both at the stage of creation of new industrial areas, modernization of existing ones, and their direct exploitation. Taking into account the main functionality of digital twins, registering the benefits provided by each type can summarize the effects that a modern industrial enterprise can get from creating digital twins of its production and prepare effective development plans. Digital twins are not limited to the collection of data obtained during the development and production phase of the product, but continuously collect and analyze data throughout the life cycle of the real object.

This confirms that the main task of digital twins in terms of the application of the tools of the Industry 4.0 concept is to achieve effective use of technological equipment based on the digitization of the enterprise. As can be seen, the concept of digital twins can play an important role in increasing the efficiency of innovative enterprises in the industrial sphere in general.

The usefulness of the obtained result and application in practice. The problems of efficient management of innovative enterprises based on digital twin technologies and prospective development directions can be applied in the development of other regional enterprises and in the development of solution mechanisms and options.

The application of digital twin technologies in the efficient management of enterprises, and the analysis of the results of the application of digital innovative technologies in its formation and development can serve as a platform for a comprehensive assessment of the activities of other enterprises in general. The application of digital transformation technologies in the activities of enterprises provides a basis for making relevant management decisions.

The proposed methodological and conceptual approach to the efficient management of enterprises based on digital twin technologies can be applied in other regional and field enterprises. This can help to achieve more efficient results in that sphere and can be characterized as scientific support for management decisions in matters of economic diversification, investments in real economic sectors, and enterprises, ensuring regional technological sovereignty.

Список литературы Development of a Conceptual Model of Effective Management of Innovative Enterprises based on Digital Twin Technologies

- The Sustainable Development Goals Report. 2020. United Nations. https://unstats.un.org/sdgs/report/2020/

- Decree of the President of the Republic of Azerbaijan “On improving governance in the field of digital transformation”. Baku, April 27, 2021. https://president.az/articles/51299 (in Azerbaijani).

- Decree of the President of the Republic of Azerbaijan on the approval of the "Socio-economic Development Strategy of the Republic of Azerbaijan in 2022-2026". Baku, July 22, 2022. https://president.az/az/articles/view/56723 (in Azerbaijani).

- Masayev S.N. Algoritm vybora metoda dlya optimal'nogo upravleniya tsifrovym dvoynikom predpriyatiya. Izvestiya YUFU. Tekhnicheskiye nauki, 2021, №3(220), str.18-32.

- Makarov V.L., Bakhtizin A.R. Razrabotka tsifrovykh dvoynikov dlya proizvodstvennykh predpriyatiy. Biznes-informatika, 2019, T.13, №4, s.7-16.

- Makarov V.L., Bakhtizin A.R., Akopov A.S. Tsifrovoy zavod: metody diskretno-sobytiynogo modelirovaniya i optimizatsii proizvodstvennykh kharakteristik. Biznes-informatika, 2021, T.15, №2, s.7-20.

- Decree of the President of the Republic of Azerbaijan on some measures to improve governance in the field of digitalization, innovation, high technologies and communications in the Republic of Azerbaijan. Baku, October 11, 2021. https://president.az/articles/53407 (in Azerbaijani).

- Aliyev A.G. Shahverdiyeva R.O. Formation of ICT-based technological innovation economy sectors, and their impact aspects on socio-economic processes. Problems of Information Society, 2021, №11, pp.94-110 (in Azerbaijani).

- Strategic Roadmap for the development of telecommunications and information technologies. It was approved by the Decree of the President of the Republic of Azerbaijan dated December 6, 2016. Baku, december 30, 2016. https://president.az/az/articles/view/22382 (in Azerbaijani).

- Aliyev A.G. Development system of hierarchical indicators for analyzing and measuring the level of growth of information and knowledge economy. Management Dynamics in the Knowledge Economy, 2021, vol 9, NO 1, issue 31, pp.65-80.

- Schwab K. The Fourth Industrial Revolution. New York: Crown Business Publishing Group, 2017, 192 p.

- Emre Yildiz, Charles Møller, Arne Bilberg. Conceptual foundations and extension of digital twin-based virtual factory to virtual enterprise. The International Journal of Advanced Manufacturing Technology, 2022, volume 121, pp.2317–2333.

- Yahya Al-Samawi. Digital firm: Requirements, recommendations, and evaluation the success in digitization. I.J. Information Technology and Computer Science, 2019, №1, pp.39-49.

- Kholopov V.A., Antonov S.V., Kurnasov E.V., Kashirskaya E.N. Digital twins in manufacturing. Russian Engineering Research, 2019, volume 39, pp.1014–1020.

- Bin He, Kai-Jian Bai. Digital twin-based sustainable intelligent manufacturing: A review. Advances in Manufacturing, 2021, volume 9, pp.1–2.

- Lianhui Li, Bingbing Lei, Chunlei Mao. Digital twin in smart manufacturing. Journal of Industrial Information Integration, 2022, volume 26, pp.100-289.

- Kuftinova N.G., Ostroukh A.V., Maksimychev O.I., Yu.E.Vasil’ev, Klimenko V.A. Digital twins in smart data management at a manufacturing enterprise. Russian Engineering Research, 2022, volume 42, pp.162–164.

- Aliyev A.G. Informatsionnaya model' effektivnosti proizvodstva v promyshlennosti Narodnoye khozyaystva Azerbaydzhana, 1988, №3, s.54-58.

- Jiewu Leng, Dewen Wang, WeimingShen, Xinyu Li, Qiang Liu, Xin Chen. Digital twins-based smart manufacturing system design in Industry 4.0: A review. Journal of Manufacturing Systems, 2021, volume 60, pp.119-137.

- Lim K.Y.H., Zheng P., Chen C. A state of the art survey of Digital twin: Techniques, engineering product lifecycle management and business innovation perspectives. Journal of Intelligent Manufacturing, 2020, 31, pp.1313–1337.

- Marietheres Dietz, Gunther Pernul. Digital twin: Empowering enterprises towards a system-of systems approach. Business & Information Systems Engineering, 2020, volume 62, pp.179–184.

- Polyanin A.V., Golovina T.A. Kontseptsiya upravleniya innovatsionnoy deyatel'nost'yu promyshlennykh sistem na osnove tekhnologii tsifrovogo dvoynika. Nauchno-tekhnicheskiye vedomosti SPbGPU. Ekonomicheskiye nauki, 2021, T.14, №5, s.7-23.

- Global Innovation Index-2021. World Intellectual Property Organization. 226 p. https://www.wipo.int/edocs/pubdocs/en/wipo_pub_gii_2021.pdf.

- Shpak P.S., Sycheva Ye.G., Merinskaya Ye.Ye. Kontseptsiya tsifrovykh dvoynikov kak sovremennaya tendentsiya tsifrovoy ekonomiki. VOU. Seriya «Ekonomika», 2020, T.18, №1, s.57-68.

- Korablev A.V. Klyuchevyye funktsional'nost' i preimushchestva ispol'zovaniya tsifrovykh dvoynikov v promyshlennosti. Tsifrovaya ekonomika, 2019, 2(6), s.5-11.

- Imamverdiyev Y.N. A conceptual model of digital twin for the oil and gas industry. Problems of Information Technology, 2020, №2, səh.41-51.

- Gefen C. Digital twin market-growth, size, share, forecast, industry analysis 2019-2027. 2019. https://works.bepress.com/charlie-gefen/63/download/

- Tjønn A. Digital twin through the life of a field. Abu Dhabi International Petroleum Exhibition & Conference, 2018, pp.1–6.

- Kritzinger W., Karner M., Traar G., Henjes J., & Sihn W. Digital twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine, 2018, vol.51, no.11, pp.1016–1022.

- Lim K.Y.H., Zheng P., & Chen C.H.A state-of-the-art survey of digital twin: Techniques, engineering product lifecycle management and business innovation perspectives. Journal of Intelligent Manufacturing, 2020, vol.31, pp.1313–1337.

- Grieves M., & Vickers J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In: Kahlen FJ., Flumerfelt S., Alves A. (eds) Transdisciplinary Perspectives on Complex Systems. Springer, 2017, pp.85–113.

- Pospelova T.A., Strekalov A.V., Knyazev S.M., Kharitonov A.N. Implementation of Digital twins for gas field management. Oil Province, 2020, volume 1(21), pp.230–24.

- Ponomarev K.S., Feofanov A.N., Grishina T.G. Tsifrovoy dvoynik predpriyatiya kak instrument tsifrovoy transformatsii proizvodstv. V sbornike: Tsifrovaya ekonomika: Oborudovaniye, upravleniye, chelovecheskiy kapital. Materialy Vserossiyskoy nauchno-prakticheskoy konferentsii, 2018, s.73-76.

- Pogorelova L.A. Tsifrovyye dvoyniki v nepreryvnykh innovatsionnykh protsessakh. Vestnik YURGTU (NPI), 2018, №5, s.57-64.