Development of a model for detecting malfunctions during the maintenance of aircraft units and systems

Автор: Gusev E.V., Rodchenko V.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 4 vol.22, 2021 года.

Бесплатный доступ

Today, we can distinguish a number of promising reusable launch vehicles “SV Wing” – a reusable cruise stage of a light-class launch vehicle; “Baikal-Angara” reusable booster of the first stage of the An-gara launch vehicle; “Soyuz-7” is a reusable two-stage medium-class launch vehicle; flight design tests of “Soyuz-7” are planned for 2025. To maintain the operational characteristics of aircraft, it is necessary to develop a maintenance system that ensures the specified reliability of flying vehicle assemblies. The pur-pose of this work is to develop a model for detecting malfunctions in the process of maintenance of units and systems of aircraft. Within the framework of this work, an algorithm has been developed, which is based on the method of statistical testing, which allows, at low computer time, to analyze the maintenance process in more detail, taking into account the duration of separate operations and their effectiveness. Da-ta on the duration and efficiency of separate operations can be obtained in the process of special tests of equipment by timing and analysis of service results. For modeling it is necessary to have the following ini-tial data: the law of distribution of the duration of separate operations; the effectiveness of troubleshooting during separate operations. The algorithm implements two types of maintenance: full and reduced. Re-duced maintenance provides for operations that are most effective in terms of the number of faults to be eliminated: adjustments, regulations, search for faulty elements. The developed model makes it possible to investigate the possibility of reducing the downtime for maintenance without a significant decrease in the quality of maintenance, namely: to assess the effectiveness of maintenance when it is carried out according to the full and reduced scheme; evaluate the effectiveness of maintenance when performing maintenance in a limited time; justify the most appropriate ways to improve the quality of service, provided that the down-time for maintenance is limited and predict the likelihood of detecting malfunctions during the maintenance process. The practical significance of the results of this work can be achieved in the aerospace industry, in particular, at the design stage (testing and operation) of a maintenance system for reusable elements of launch vehicles.

Fault detection model, maintenance, recovery, technical diagnostics, fault prediction, controlled parameter

Короткий адрес: https://sciup.org/148329595

IDR: 148329595 | УДК: 629.7.083 | DOI: 10.31772/2712-8970-2021-22-4-638-648

Текст научной статьи Development of a model for detecting malfunctions during the maintenance of aircraft units and systems

Flying vehicles (FV) are subject to strict requirements for safety, reliability, economy and environmental impact. Therefore, when developing FV, they try to take into consideration all possible factors which will affect the FV, and the impact of the FV itself on the environment. It is also important to take into account the desire to increase the period of active existence due to the application of new materials and production technologies, what, in turn, increases the cost of the direct production of the aircraft and its maintenance during operation.

The development of launch vehicles (LV) with a reusable first stage is one of the urgent tasks, since competition in the market for delivering payloads to target orbits is increasing, the cost of launching of one kilogram of payload is decreasing, and some LVs, unable to withstand competition, become not actual. Restoration of the launch vehicle stage after the flight, maintenance, repair and replacement of faulty elements is the main task of the maintenance system. Design, testing and operation of the maintenance system is an integral part of the LV operation process as a whole.

Maintenance of aircraft units and systems of FV

Maintenance of FV components and systems is the main method of preventing malfunctions. During maintenance, troubleshooting and their elimination is carried out. For most types of aircraft equipment, the following characteristic stages of maintenance can be distinguished, each of which includes certain types of work [1–2].

-

1. Carrying out an external examination and checking the equipment "without current":

-

– preparation of control and measuring equipment;

-

– disassembly of the equipment, inspection of the condition (for example, fastenings, soldering or installation);

-

– checking the quality of cable installation insulation;

-

– autonomous checking of the accuracy of operation of individual devices using the simplest control and measuring equipment.

-

2. Checking and testing of nodes and blocks of equipment under current:

– regulation and adjustment of some elements and devices;

-

– checking the operability of the elements and devices of the equipment in normal and special modes;

-

– search for faulty elements and troubleshooting with or without replacement of elements.

-

3. Routine work:

– checking the status of (for example, relay contacts, mechanical components);

– cleaning of separate units and equipment as a whole;

-

4. Carrying out control of the functioning of the equipment as a whole:

-

– assembly and equipment configuration;

-

– control of equipment parameters in normal and special modes;

-

– complex debugging and tuning of equipment.

In the process of performing maintenance, at each stage, operations are carried out to identify faulty elements, replace or restore them.

At the first stage of maintenance (external inspection of the equipment “without current”), such operations are the identification and replacement of faulty elements: burnt resistances, worn out connectors, the condition of the relay contacts is checked, etc.

At the second stage tests of the equipment “under current” are carried out. At the same time, the search and restoration of faulty elements is carried out only in the case when it is not possible to establish the initial modes of operation or the limits of operation of separate devices of the equipment, with the help of adjustment organs.

At the third stage (routine maintenance), measures are carried out (cleaning, replacement of lubricants, etc.) aimed at eliminating conditions leading to malfunctions.

At the fourth stage (checking the functioning of the equipment in the whole, debugging and setting it up in accordance with the specified technical conditions), searching and eliminating of troubleshooting can also be carried out. At the same time, part of the work carried out earlier is repeated, for example, setting up separate nodes, checking installation, adjusting contacts, etc. An approximate distribution of detected faults by types of operations related to troubleshooting and maintenance stages is given in Table 1 [2–3]. From table it can be seen that at certain stages of maintenance, some operations are carried out (the “+” sign), are not carried out (the “-” sign), or are not always carried out (the “±” sign).

All maintenance operations are divided into three types:

-

– operations related to the identification of malfunctions (search for faulty elements);

-

– operations related to troubleshooting (regulation, adjustment, replacement)

-

– auxiliary operations (preparation of control and measuring equipment, disassembly, assembly, rejection of spare parts).

Based on the analysis of statistical data on the explotation of radio-electronic equipment of FV, it is possible to roughly distribute the total maintenance time by types of operations (Table 2) [2–3].

As follows from Table 1 and 2, at almost all stages of maintenance, work is carried out related to the search, identification and elimination of faults, the execution time of which is random and constitutes the bulk of the maintenance time.

Analytical method for assessing the probability of detecting faults

From the data given in Table 1, it follows that maintenance measures can prevent a significant part of the failures. At the same time, the statistical evaluation of the probability of preventing Ppp failures in the general case can be estimated by the ratio:

lip — llpp 4~ Upp

where Ppp – statistical assessment of the probability of preventing failures during maintenance;

ti p — llpp ~h tlpp – the total number of avoidable failures, which is determined by the malfunctions accumulated by the time of the maintenance; ^pp Upp – is the amount of failuers, identified and not identified in the process of maintenance, accordingly (it is assumed that all identified malfunctions could lead to the failure of flying vehicle units and systems).

So Ppp – is one of the main indicators for quantitative assessment of the effectiveness of mainte- nance.

Operations carried out at various stages of maintenance

Table 1

|

Troubleshooting Operations |

Й 4) ь |

Maintenance steps |

|||

|

3 л О |

Й ^1 ед й й и |

й й о £ S |

1 * О пз О |

||

|

Troubleshooting by replacing elements or without replacement |

20–40 |

± |

± |

± |

± |

|

Cleaning, lubrication |

10–20 |

– |

– |

+ |

– |

|

Regulation and adjustment |

40–70 |

– |

+ |

– |

+ |

Distribution of service time by types of operations

Table 2

|

Maintenance operation |

Time, spent for maintenance, % |

The law of distribution of the operation duration |

|

Searching of faults |

60–80 |

Exponential |

|

Eliminating of faults |

10–20 |

Rayleigh, normal |

|

Auxiliary operations |

10–20 |

Normal |

In the element failure prediction model, fault detection is an ordered process and Ppp mainly depends on the forecasting method and time, assigned to this process.

Assume that the probability of missing a faulty element due to inaccurate measurement of the parameter β and the probability of missing a faulty element due to lack of time Q ( TS ) are independent. Then the probability of preventing failures during maintenance can be represented as a product:

^® = (1-/?)[1-QO, (2)

Where 1 fl LTs> 0 — T$ < TSq

Where

, 1 σβ

Here L = ~ and Pso – is the average time required for service; β= β – relative error, where σ

-

- is the root-mean-square error; α ( t ) – is the parameter value α in the moment of time t.

Taking into consideration the accepted designations (2) is converted to the form

Ppp(Js) = (1-Д№ (3)

The ratio (3) can be used for an approximate assessment of the probability of detecting malfunctions during maintenance and forecasting.

Assessment of the probability of detecting a malfunction during maintenance

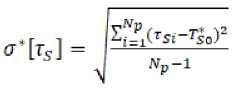

The model for detecting malfunction in the process of maintenance of aircraft units and systems is based on an algorithm that implements the method of statistical tests [4–6].

The analytical evaluation Ppp discussed above does not take into account the effectiveness of separate maintenance operations.

The method of statistical modeling allows, at a low cost of machine time, to analyze the maintenance process in more detail, taking into account the duration of separate operations and their efficiency (Tables 1 and 2). Data on the duration and effectiveness of separate operations can be obtained in the process of special testing of equipment by timing and analysis of the results of maintenance.

For modeling, it is necessary to have the following initial data:

– the law of distribution of the duration of separate operations;

– the efficiency of fault detection during separate operations (the proportion of identified faults out of the total number accumulated by the beginning of maintenance).

The algorithm implements two types of maintenance: full and reduced, the block diagram of the algorithm is shown in Fig. 1 Reduced maintenance involves carrying out operations which are most effective in terms of the number of faults to be eliminated: adjustments, substrings, and search for faulty elements (Table 1).

The process of maintenance is evaluated by: Ppp — ftTs’Tso) where Ps – is the time, spent for the maintenance; Pso — ^[Ts] – the average time of the maintenance conduction.

For evaluation Ppp N-fold modeling of the maintenance process is foreseen.

The number of realisations of the algorithm is determined by the relative error results ^R for a given confidence probability α and the dispersion of the estimated values [7–9].

One realisation of the algorithm consists in modeling, using random numbers, the durations of separate maintenance operations (Table 2) and evaluating their effectiveness. It is considered that if the total maintenance time ^S in the i- th realisation does not exceed the allotted Ps , then all the malfunctions accumulated by the beginning of maintenance are detected in this implementation.

The following designations are used in the block diagram of the algorithm:

N –amount of realization of the algorithm;

ξ –random number, uniformly distributed in the interval (0,1);

Р RA – statistical assessment of the probability that in the process of adjustments and regulations it is possible to establish the initial values of the controlled parameters and no troubleshooting is required;

Р EI – statistical assessment of the probability of detecting a malfunction during an external examination;

г^– total duration of maintenance in i -realisation;

npp , npp – the number of faults identified during full and reduced maintenance, respectively;

-

∑ τ Р – counter of the number realisation in which the total time of maintenance ^s does not exceed the allocated Ts ;

-

^s– counter of the total downtime of equipment for maintenance in N realisations [10–12].

The results of solving the problem are the following quantities:

-

1. Statistical assessment of the probability of detecting faults:

-

2. Mathematical expectation and standard deviation of the duration of maintenance:

-

3. Histogram of a random variable r^– of maintenance duration:

where r in i - realization takes the value 0 and 1. pi

,

,

N p

∑ rij

*

-

p * = i = 1 i = 1,2,... k ,

i ,, ,

p where p* – is the frequency, corresponding to the i-th discharge of the histogram; k – number of dis-

Np charges of the histogram; ∑ rij – counter of the number of discharges of a random variable Гу in the ii =1

th discharge.

To implement the considered algorithm, it is necessary to set the numerical values of the following source data:

-

– mathematical expectation and standard deviation of the duration of the execution of separate operations (auxiliary Т A , ^4; regulations and adjustments Т RA , J^ ; troubleshooting Ту , σ y ; external inspection, cleaning, lubrication Т EI , ^EI ;);

-

– average troubleshooting time TPF ~ ;

-

– Т S (maintenance time);

-

– Р RA и Р EI ;

-

– the average number of eliminated malfunctions during the reduced and complete maintenance ( npp and npp );

-

– the required error of the results ^R and the value t α .

The value can be estimated by the ratio:

S = 2 1 a

N p

S x?

( N P

S X i

, i =1

N p

*

N p ;

N p — 1

– the required number of algorithm realization (N Р E ) [13–15].

An example of assessing the probability of detecting malfunctions during maintenance

During the pilot operation, the parameters of the maintenance are determined:

-

1) according to the results of timing of separate maintenance operations:

– mathematical expectations and standard deviations of the execution time of auxiliary operations Т A = 0.2 h, , = 0.07 h; regulation and adjustment Т RA = 0.15 h, = 0.05 h; troubleshooting Т Y = 0.1

h ^y = 0.04 h; external examination Tei= 1.0 h; 'j>; =0.3 h;

– average troubleshooting time Т PF = 0.5 h;

-

2) according to the results of processing statistical data on the evaluation of the effectiveness of separate maintenance operations:

-

– the effectiveness of the regulations and adjustments provided in the equipment. Is evaluated by

the ratio: , where –is the number of faults eliminated by regulations and adjust- nRA +nRA ments – number of malfunctions that could not be eliminated by adjustments , РRA =0.3;

– service efficiency during external inspection. It is estimated by the ratio , where

"ш +"и и – the number of faults identified and missed during the inspection, respectively РEI =0.2. .

Controlled exploitation was carried out for two types of maintenance: full and reduced. The average number of faults identified during the full and reduced maintenance, respectively, are

,

Рис. 1. Блок-схема алгоритма для оценки процесса выявления неисправностей при техническом обслуживании

Fig. 1. Block diagram of the algorithm for evaluating the process of troubleshooting during maintenance

To analyze the possibility of reducing the downtime for maintenance without a significant decrease in the efficiency of maintenance means:

-

– evaluate the effectiveness of maintenance depending on the type;

-

– evaluate the effectiveness of maintenance when it is carried out in a limited time ( Ts

).

To solve these issues, it is necessary to evaluate the value of P PP when the time allotted for maintenance is changed, for cases of full and reduced maintenance.

The problem was solved using the developed algorithm with the following initial data:

N P E =200, ee = 0.1, t„ = 1.96,

Let's consider the obtained results.

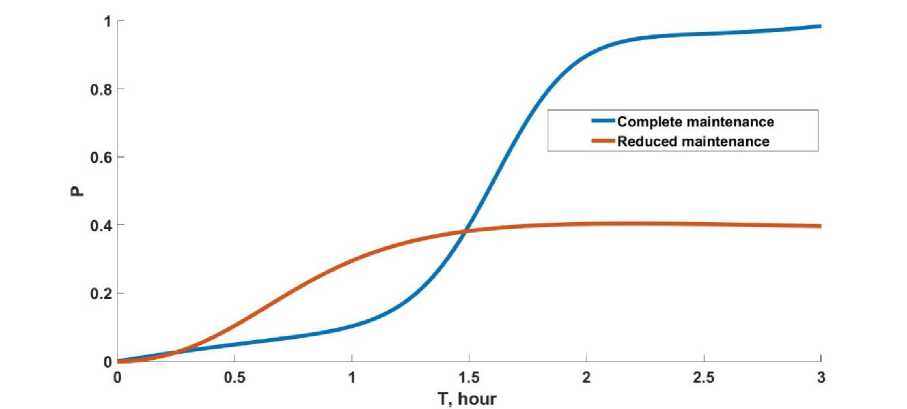

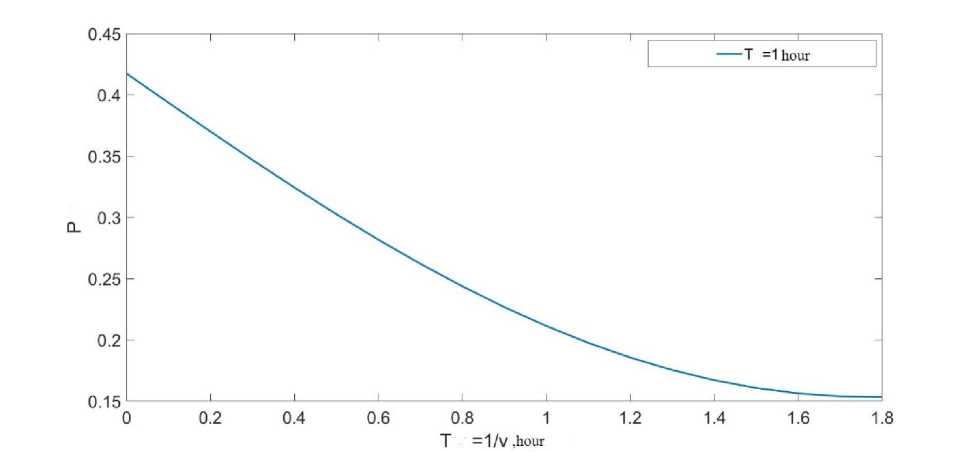

On fig. 2 and 3 there are graphs of dependence of Ppp from the time Т S , spent for maintenance, and average search time.

Analysis of the graphs in fig. 2 and 3 allows to draw the following conclusions:

-

1. Max value Ppp is achieved when carrying out a complete maintenance, under condition, that not less than Т S = 2 h ( P^p > 0.98)is allocated for carrying out maintenance.

-

2. Carrying out maintenance on a reduced schedule is impractical Ppp< 0.46. However, in case of limited maintenance time Ts = lh it is better to conduct reduced maintenance, as in this case Ppp = 0.3 and at full maintenance it is . p;P = 0.1

The considered algorithm is an integral element of the program and methodological complex (PMC) with a user interface realised in the Matlab environment [16]. PMC allows prognosing maintenance parameters for flying vehicles units and elements with various maintenance systems and optimizing these parameters in order to increase the FV readiness coefficient. In the practical application of PMC for fly- ing vehicles units and assemblies with an integrated maintenance model, by optimizing the parameters of the maintenance system, it was possible to increase the value of the availability coefficient by 2.41% [17].

Рис. 2. Графики зависимости вероятности выявления неисправностей от времени, отводимого на ТО

Fig. 2. Graphs of the dependence of the probability of detecting faults on the time allocated for maintenance

Рис. 3. График зависимости вероятности выявления неисправностей от среднего времени их поиска

Fig. 3. Graph of the dependence of the probability of detecting faults on the average time of their search

Conclusion

When carrying out maintenance during a limited time, it is necessary to provide special methods for reducing the time for troubleshooting (search systems for faulty elements, advanced training for maintenance personnel). At the same time, reducing the time from Т PF = 0.5 h to Т PF = 0.1 h increases the likelihood of fault detection by 1.5 times and reduces downtime for maintenance on average of 2 times.

Thus, it is obvious from the results of the calculation that for the considered maintenance system, it is impossible to reduce the downtime without significant reducing the quality of recovery.

Список литературы Development of a model for detecting malfunctions during the maintenance of aircraft units and systems

- Mironychev V. P. [Methods and methods of troubleshooting in radio electronic systems]. Vo-logdinskie chteniya. 2009, No. 73, P. 74–77 (In Russ.).

- Sugak E. V. et al. Nadezhnost’ tekhnicheskikh sistem [Reliability of technical systems]. Krasno-yarsk, NII SUVPT, MGP Rasko Publ., 2001, 608 p.

- Ksendz S. P. Diagnostika i remontoprigodnost’ radioelektronnykh sredstv [Diagnostics and maintainability of radio-electronic equipment]. Moscow, Radio i svyaz Publ., 1989, 248 p.

- Vyyavlenie prichin otkazov REA [Revealing the causes of REE failures]. Ed. L. G. Dubitsky, Moscow, Radio i svyaz Publ., 1983, 232 p.

- Dmitrievsky E. S. Konstruktorsko-tekhnologicheskoe obespechenie ekspluatatsionnoy nadezh-nosti aviatsionnogo radioelektronnogo oborudovaniya [Design and technological support for the oper-ational reliability of aviation radio-electronic equipment]. St. Petersburg, 2001, 88 p.

- Patraev V. E., Shangina E. A. Nadezhnost’ tekhnicheskikh sistem kosmicheskikh apparatov [Re-liability of technical systems of spacecraft: a tutorial]. Krasnoyarsk, Siberian Federal University Publ., 2019, 64 p.

- Patraev V. E. Metody obespecheniya i otsenki nadezhnosti kosmicheskikh apparatov s dlitel’nym srokom aktivnogo sushchestvovaniya [Methods for ensuring and assessing the reliability of spacecraft with a long active life]. Krasnoyarsk, Sib. state aerospace un-t Publ., 2010, 136 p.

- Zolotov A. A., Nurulaev E. D. [Methods for increasing the efficiency of control of units of rock-et and space technology]. Vestnik MAI. 2015, Vol. 22, No. 4, P. 46–52 (In Russ.).

- Galleev A. G., Zolotov A. A., Perminov A. N., Rodchenko V. V. Ekspluatatsiya ispytatel’nykh kompleksov raketno-kosmicheskikh sistem [Operation of test complexes of rocket-space systems]. Moscow, MAI Publ., 2007, 260 p.

- Gusev E. V., Zolotov A. A., Rodchenko V. V. [Technique for optimization of maintenance pa-rameters and reliability indicators of complex technical systems operating on oxygen-hydrogen fuel]. Al’ternativnaya energetika i ekologiya. 2017, No. 1–3, P. 22–33 (In Russ.).

- Aleksandrov A. I. et al. Ekspluatatsiya radiotekhnicheskikh kompleksov [Operation of radio engineering complexes]. Moscow, Soviet radio Publ., 1976, 280 p.

- Gusev E. V., Zolotov A. A., Rodchenko V. V. [Forecasting indicators of maintenance of com-plex technical systems]. Polet. 2021, No. 8, P. 37–44 (In Russ.).

- Fitch E. S. Proactive maintenance for machanical system. Amsterdam: Elsevier Science, 2013, 339 p.

- Panday B. K. Failure Spase X Falcon 9. Sps-aviation, 2015, p. 10–12.

- Nikushkin N. V., Katsura A. V. [Solution of the problem of modeling aircraft maintenance sys-tems]. Vestnik SibGAU. 2006, No. 4 (11), P. 46–49 (In Russ.).

- Gusev E. V. Svid. o gos. reg. programmy dlya EVM 2021619616 Rossiyskaya Federatsiya. Programma rascheta parametrov sistemy tekhnicheskogo obsluzhivaniya [Certificate of state registra-tion of a computer program 2021619616 Russian Federation. Program for calculating the parameters of the maintenance system]. No. 2021618549; app. 07/02/2021; publ. 07.15.2021.

- Gusev E. V. [Development of a software package for predicting the parameters of maintenance of complex systems]. Perspektivy nauki. 2021, No. 7 (142), P. 31–35 (In Russ.).