Development of combined electron-ion-plasma method for formation of multiphase submicro-nanoscale alloys based on aluminum

Автор: Ivanov Yu. F., Eresko S.P., Ahmadeev Yu. H., Lopatin I.V., Klopotov A.A.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 1 т.20, 2019 года.

Бесплатный доступ

Aluminum-based alloys are widely used in many branches of modern industry (aviation, mechanical engineer- ing, shipbuilding, instrument-making, energy and medicine, etc.). The promising method for further expanding the scope of these alloys is surface treatment based on the use of concentrated energy fluxes (laser beams, plasma flows, powerful ion beams, continuous and pulsed electron beams). The purpose of this paper is to establish the possibilities of integrated electron-ion-plasma modification of the structure and properties of the surface layer of technically pure aluminum A7. The surface alloy was formed in a single vacuum cycle using the “KOMPLEX” facility (ISE SB RAS) by spraying a titanium film with a thickness of 0.5 μm and the subsequent irradiation with an intense pulsed electron beam in the aluminum melting mode. After 20 “spraying/irradiation” cycles, nitriding (540 °C, 8 h) of the formed surface alloy was performed in a low-pressure gas discharge plasma using the plasma generator “PINK”. Surface alloy studies were carried out applying the modern materials science methods (scan- ning and transmission electron diffraction microscopy, X-ray phase analysis, determination of hardness and wear resistance). The choice of elements alloying the surface layer of aluminum was based on the analysis of binary state diagrams of Al-N, Al-Ti, Ti-N systems and the isotermal section of the ternary system Al-Ti-N. It has been shown that formation of an entire series of binary and ternary compounds, including MAX-phases of the composi- tion Ti2AlN and Ti4AlN3, is observed under equilibrium conditions in the Al-Ti-N system. The carried out research has allowed to state that an integrated method of electron-ion-plasma modification of technically pure A7 alumi- num by nitriding (540 °C, 8 h) of the surface alloy formed by pulsed melting in vacuum of the Al-Ti system (20 “spraying/irradiation” cycles with an electron beam with parameters 10 J/cm2; 50 μs; 10 pulses; the titanium film thickness in each cycle 0.5 μm) leads to formation of a multiphase multielement submicro-nanocrystalline surface layer up to 20 μm thick. It is shown that the mechanical (microhardness) and tribological (wear resistance and friction coefficient) properties of the formed surface layer exceed manifold the properties of the original commercially pure aluminum A7.

Aluminum, electron-ion-plasma processing, nitriding, structural researches, nanostructure, properties

Короткий адрес: https://sciup.org/148321901

IDR: 148321901 | УДК: 669/713-048/25 | DOI: 10.31772/2587-6066-2019-20-1-88-98

Текст обзорной статьи Development of combined electron-ion-plasma method for formation of multiphase submicro-nanoscale alloys based on aluminum

Introduction. Titanium and aluminum-based alloys are widely used in the aerospace industry, mechanical engineering and shipbuilding, medicine, etc. [1; 2]. In many cases extension of scope of these materials is based on the improvement of properties of a surface layer of a detail or product. It happens due to formation of wear resistant, hard and super hard coatings; creation of multielement multiphase sub-micro nanocrystal surface layers; and integrated processing combining formation of multipurpose coatings on preliminary modified surface of a detail [1–5]. Perspective methods of surface treatment are those based on the use of concentrated energy streams (laser beams, plasma streams, powerful ion beams, continuous and pulse electron beams) [5–12]. Employing this approach allows to drastically improve material properties connected with modifying surface layer condition

(hardness, wear resistance, resistance to the influence of hostile environment, etc.) [5–13]. One of the perspective methods of metals and alloys surface treatment is the approach based on the integrated impact of plasma streams and intensive pulse electron beams on the material surface [5; 13].

The purpose of the present research is to find opportunities for integrated electronic ion-plasma modification of the structure and properties of commercially pure aluminum surface layer.

Material and method of research. Material of research – commercially pure aluminum А7 brand (0.15Si, 0.16Fe, 0.01Cu, 0.03Mn, 0.02Mg, 0.04Zn, 0.03Ga, 0.01Ti, balance Al, weight. %) [14]. Specimen dimensions 15 x 15 x 5 mm. The surface alloy was formed in a single vacuum cycle using the “KOMPLEX” facility

(ISE SB RAS) by spraying a titanium film with a thickness of 0.5 μm and the subsequent irradiation with an intense pulsed electron beam in the aluminum melting mode. After 20 “spraying/irradiation” cycles, nitriding (540 °C, 8 h) of the formed surface alloy was performed in a low-pressure gas discharge plasma using the plasma generator “PINK”. Research into the element and phase structure, defective substructure condition was carried out applying the methods of scanning electron microscopy (Philips SEM-515 with microanalyzer EDAX ECON IV) and transmission diffraction electron microscopy (JEOL JEM-2100 F), X-ray diffraction analysis (X-ray diffractometer Shimadzu XRD 6000). Material properties were characterized by hardness (PMT 3, indentation load 0.2 Н). Tribological studies (wear resistance and friction coefficient identification) were carried out on tribometer Pin on Disc and Oscillating TRIBOtester (TRIBOtechnic, France) under the following parameters: steal ball of 6 mm diameter, track radius – 2 mm, indentation load and track length vary depending on the ware resistance factor of the material under study.

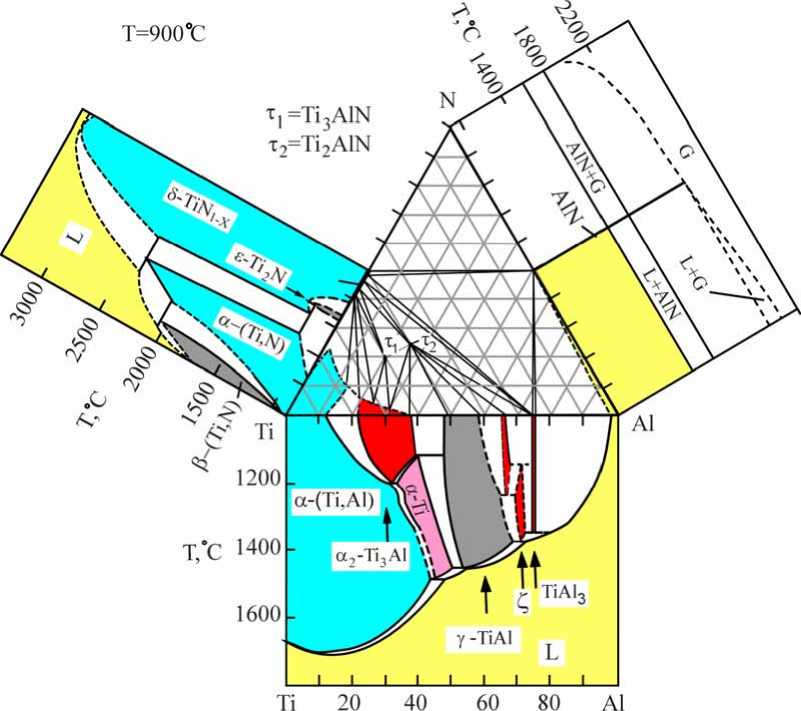

Results and discussions. Fig. 1 shows binary state diagrams Al-N, Al-Ti, Ti-N and Isothermal section of the ternary system Al-Ti-N. Two of the three alloying elements of the ternary system Al-Ti-N are metals, while the third one nitrogen is a non-metal and belongs to VВ group of the Periodic table. Nitrogen atoms possess five electrons on the outer s- and р -shells ([He]2s22p3). With such electronic structure nitrogen quite easily attaches three more electrons which is a characteristic of non-metal.

System Al-N. Nitrogen is almost insoluble in Al neither in liquid, nor in hard states [15]. In the Al-N system existence of only one connection in the field of the stoichiometric structure of AlN with hexagonal structure was found (Pearson's symbol hP 4, pr. gr. R 6 3 ts , ZnS prototype) (fig. 1).

System Ti-N. Titan possess a characteristic of activel interaction with nitrogen. It finds reflection in formation of compounds in the Ti-N system in the form of solid solutions with variable structures and with wide areas of homogeneity: P- (Ti,N), a- (Ti,N), 5- TiN X ( cF 8, NaCl) (fig. 1) [16] . In compounds 5- TiN X atoms Ti form a metal face-centered cubic sublattice, where in octahedral interstices interstitial (nitrogen) or vacancies may be present. In not stoichiometric disordered compound 5- TiN X change of structural vacancies concentration causes wide area of homogeneity. Under the temperature of ~ 1100 °С and content of N atoms ~33% from the phase 5- TiN X nitride s- Ti2N ( tP 6, anti-TiO2) with the narrow area of homogeneity is formed. Besides, in a number of studies existence of three intermediate phases was identified: Z - Ti 4 N 3-X ( hR 8) [17], nW x ( hR 6, VTa 2 C 2 ) [18; 19], Ti 4 N 3-x ( hR 2, V 4 C 3 ) [17; 18].

System Al-Ti-N. Inside isothermal triangle in the system Al - Ti - N existence of three nitride compounds of strong stoichiometric ratio was found (fig. 1): T 1 - Ti3AlN (Pearson's symbol cP 5, prototype CaTiO 3 ) [22; 23]; T 2 - Ti 2 AlN ( hP 8, Cr 2 AlC) [24]; T 3 — Ti 4 AlN 3 ( hP 16, Ti 4 AlN 3 ) [25]. Apart from that, in [26–28] metastable condition Ti1 - xAl x N (cF8, NaCl).

Out of the three compounds formed in the system Al-Ti-N, compound T 1 -Ti3AlN proves the most stable [29] and belongs to the phase group H [30]. Literature shows that there are several ways of how compounds T 1 -Ti2AlN can be prepared. Let us demonstrate the synthesis of particles with Ti 2 AlN phase. First, under exothermic reaction of powders Al and Ti in nitrogen atmosphere [31]. Second, as a result of powders Al and TIN hot pressing and subsequent homogenization of samples under the temperature 850 ° C within 200 hours [32]. Third, when sintering under above 1500 ° C from powders AlN and Ti [33; 34]. Fourth, as a result of 24 hours roasting under between 1275 ° C and 1600 ° C and 1100 MPa of powder bland Al, Ti, TiN and AlN nitrides pressed under room temperature [35]. Fifth, when nitriding Al-Ti alloys as a result of roasting under 1000 оC [36]. Sixth, when heating a powder bland consisting of two parts Ti and one part of AlN under 1400 оC for 48 hours under the pressure of ≈ 40 MPа [24]. Seventh, powder bland AlN and Ti vacuum sintering under 10 - 3 Pa for 16 hours [37].

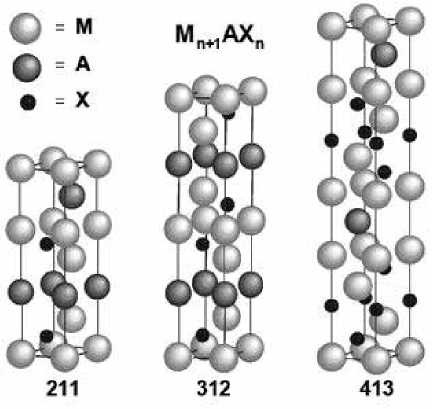

Recently great attention is drawn to perspective materials – polycrystalline nanolaminates. This class of materials represents machine processed ceramics which is stable at high temperatures [38–41]. In terms of structure nanolaminates, which are called still MAX phases, [42] represent threefold compounds with structure M n+1 AX n (M = transition metal, А = element of IIIА or IVA group of the Periodical table, X = С or N, п accepts integer values 1, 2, 3). MAX are phases representing laminated hexagonal structure with space group P 6 3 / mmc with two formula units in a space unit (fig. 2). The unique distinctive feature of these materials is a laminated crystal lattice, a natural arrangement of layers of atoms М- and А-elements.

According to literature [42], more than 70 of the popular nanolaminates are titanium nitride-based. They are phases Ti 2 AlN (211) and Ti 4 AlN 3 (413), where element X is nitrogen.

In the light of the aforesaid it is possible to assume that application of the high-energy electronic ion-plasma integrated processing of aluminum surface in a uniform vacuum cycle combining formation of “film (tita-nium)/(aluminum) substrate” system, radiation with an intensive pulse electron beam of aluminum surface in the melting mode, and subsequent saturation of the alloyed layer with nitrogen atoms of low pressure gas category plasma can lead to specific structural and phase states which will cause formation of a multiphase surface with the increased physical and mechanical properties. The research of commercially pure aluminum modified layer phase structure was conducted applying the methods of X-ray diffraction analysis. It is revealed that the surface layer is multiphase material and contains α-Ti (5.2 mass. %), Al3Ti (58.4 mass. %), AlN (24.2 mass. %) and Al (12.2 mass. %).

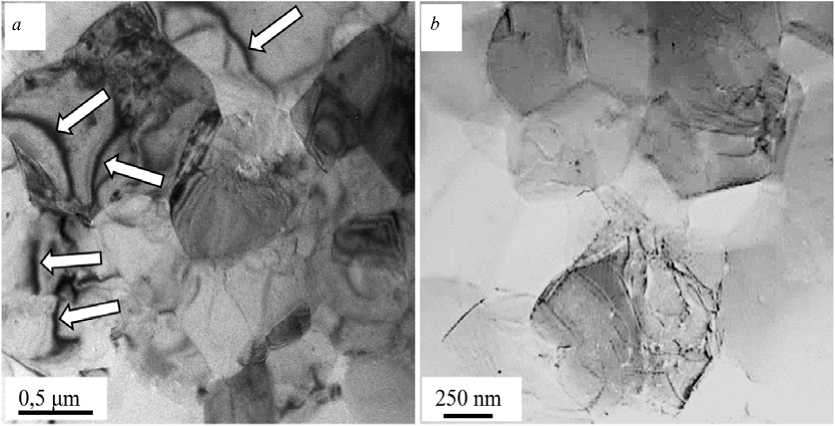

The undertaken research showed that the surface layer up to 20 microns thick has sub-microcrystalline, typical structure of which is provided in fig. 3.

at.% Al

Fig. 1. Isothermal section at 900 °C of the Al-Ti-N ternary system [20; 21] and binary state diagrams of the Al-N [15], Al-Ti [15] and Ti-N systems [16]

Рис. 1. Изотермическое сечение при 900 ° С тройной системы Al-Ti-N [20; 21] и бинарные диаграммы состояний систем Al-N [15], Al-Ti [15] и Ti-N [16]

Fig. 2. Crystal structure of MAX-phases with transition metals (M) with layers of elements A (C or N) from groups IIIA and IVA [41]

Рис. 2. Кристаллическая структура MAX-фаз с переходными металлами (M) со слоями из элементов A (C или N) из групп IIIA и IVA [41]

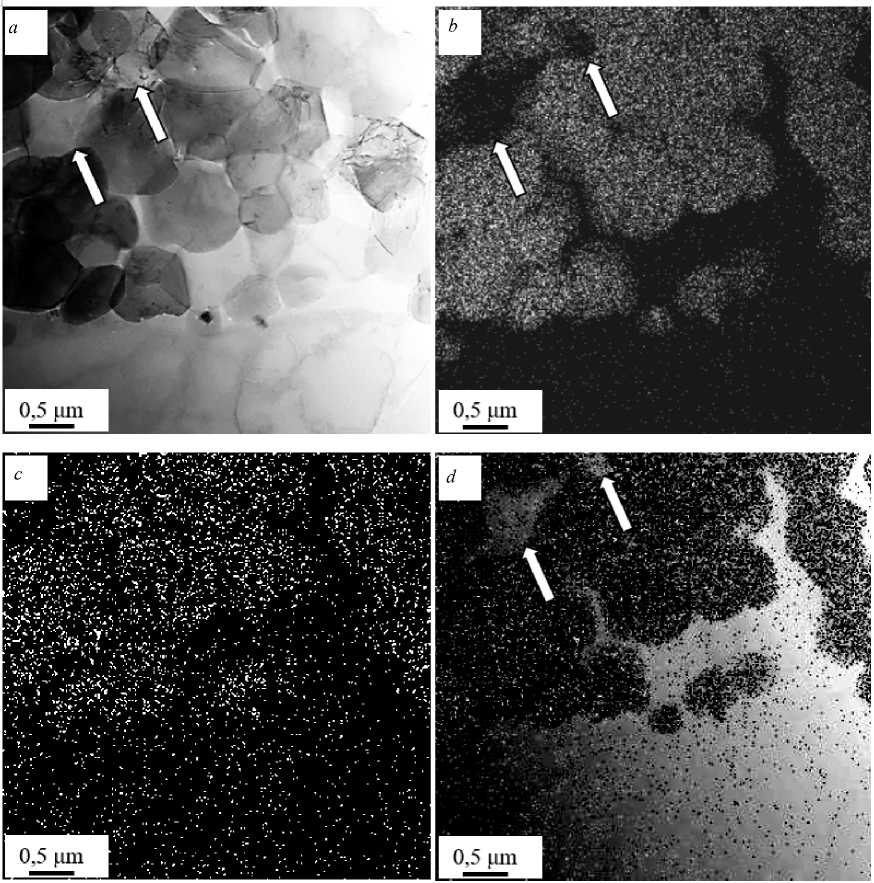

Fig. 3. Electron-microscopic image of the surface layer of commercially pure aluminum grade A7 modified by nitriding (540 °C, 8 h) of a surface alloy formed by pulsed melting in a vacuum of the Al-Ti system (20 sputtering/irradiation cycles) with an electron beam with parameters J/cm2; 50 µs; 10 imp.; titanium film thickness in each cycle 0.5 µm):

a – arrows indicate bend contours of extinctions; b – dislocational substructure of material

Рис. 3. Электронно-микроскопическое изображение поверхностного слоя технически чистого алюминия марки А7, модифицированного путем азотирования (540 °C, 8 ч) поверхностного сплава, сформированного импульсным плавлением в вакууме системы Al-Ti (20 циклов «напыле-ния/облучения» электронным пучком с параметрами 10 Дж/см2; 50 мкс; 10 имп.; толщина пленки титана в каждом цикле 0,5 мкм):

а – стрелками указаны изгибные контуры экстинкции; b – дислокационная субструктура материала

Crystallite sizes change ranging from 0.2 microns up to 0.9 microns.

Crystallites have various forms changing from globular to facetted. In crystallites volumes a dislocation substructure in the form of chaotically distributed dislocations is observed (fig. 3, b ). The scalar density of dislocations changes in limits (0.8 + 1.1) x 1010 cm-2.

Electronic and microscopic image of crystallites is characterized by a large number of flexural extiction contours (fig. 3, contours are specified by arrows). Existence on electronic and microscopic images of such contours indicates curvature torsion of a crystal lattice of the studied foil that testifies, in turn, elastic tension of the studied material layer [43]. Generally, contours start from crystallite border lines. This fact proves that the crystallite border lines are the source of material elastic tension [44]. A number of studies [45–47] shows that the cross sizes of a flexural extinction contour are inversely proportional to tension amplitude of this particular foil section. Analyzing the electronic and microscopic image of the material structure shown in fig. 3, it can be noted that the cross sizes of flexural contours are minimum at crystallites border lines and are maximum in the center of the crystallite. Therefore, amplitude of curvature torsion of a crystal lattice of material is minimal in the center of crystallites while increases as approaching the border line of the section.

Applying the methods of the micro-diffraction analysis with the subsequent indicating of micro-diffraction patterns it was found that crystallites are formed by the phases α-Ti, Al3Ti and Al that was also revealed by the methods of the X-ray phase analysis. In most cases grains of α-titanium and aluminum are located in chains parallel to the modifiable surface of a sample.

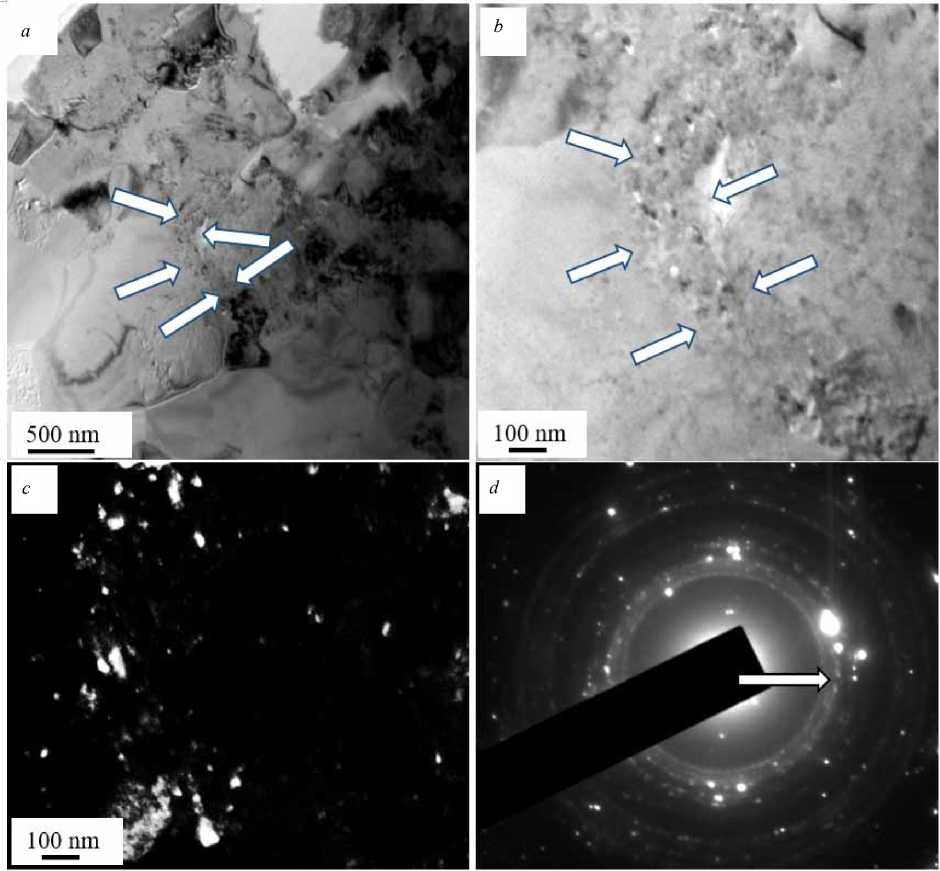

On borders of crystallites extended layers having nanocrystal structure with particles size of 10-20 nanometers are observed. A typical image of such structure is show in fig. 4. The microdiffraction patterns analysis received from similar foil sections shows that nanocrystals are aluminum nitrides. As a rule, such layers are formed along the titan aluminide Al 3 Ti grain sections borders. Nanodimensional allocations of aluminum nitride particles are found in aluminum grains volume as well.

Electronic microscope JEOL JEM-2100 F allows studies applying the methods of electron microprobe analysis, distribution of chemical elements forming the material. Results of such research of the modified layer of commercially pure aluminum are given in fig. 5. Nitrogen atoms distribution in the structure of the studied material attracts a lot of attention. It is clear that in the aluminum layer (substrate), adjacent to the modified layer (the lower part of the picture in fig. 5) atoms of nitrogen are distributed unevenly, concentrating along borders of a cellular dislocation substructure. In aluminum grains volume located in the modified layer (specified by an arrow fig. 5), atoms of nitrogen form nanodimensional objects which are obviously aluminum nitride particles.

Properties of thealuminnum modified layer was characterized by the size of microhardness and wear resistance.

As a result of the research it was revealed that modifying of commercially pure aluminum of A7 brand by nitriding (540 °C, 8 h) of the surface alloy formed by pulse melting in the system vacuum.

Al-Ti (20 cycles “dusting/radiation” via the electron beam with the parameters of 10 J/cm2; 50 microsec; 10 imp.; thickness of titan film in each cycle equals 0.5 microns) leads to formation of a surface layer which microfirmness by 9 times exceeds the hardness of the initial material, wear resistance is 400 times higher, friction coefficient is 3.5 times less than that of the initial material.

Fig. 4. Electron-microscopic image of the surface layer of technically pure aluminum grade A7, modified by nitriding (540 °C, 8 h) of a surface alloy formed by pulsed melting in a vacuum of the Al-Ti system (20 sputtering / irradiation cycles) with an electron beam with parameters 10 J / cm2; 50 µs; 10 imp; film thickness of titanium in each cycle (0.5 µm): a , b – bright-field images; c – dark field obtained in the [200] AlN reflex; d – microelectron diffraction pattern. The arrows on fig. 4, a , b indicate aluminum nitride particles located along the boundaries of titanium aluminide;

on fig. 4, g is the reflex in which the dark-field image was obtained

Рис. 4. Электронно-микроскопическое изображение поверхностного слоя технически чистого алюминия марки А7, модифицированного путем азотирования (540 °C, 8 ч) поверхностного сплава, сформированного импульсным плавлением в вакууме системы Al-Ti (20 циклов «напыления/облучения» электронным пучком с параметрами 10 Дж/см2; 50 мкс; 10 имп.; толщина пленки титана в каждом цикле 0,5 мкм):

-

а , b – светлопольные изображения; c – темное поле, полученное в рефлексе [200] AlN; d – микроэлектронограмма. Стрелками на рис. 4, а , b указаны частицы нитрида алюминия, расположенные вдоль границ алюминида титана; на рис. 4, d – рефлекс, в котором было получено темнопольное изображение

Fig. 5. Electron-microscopic image of the surface layer of technically pure aluminum grade A7 modified by nitriding (540 °C, 8 h) of a surface alloy formed by pulsed melting in a vacuum of the Al-Ti system (20 sputtering / irradiation cycles) with an electron beam with parameters 10 J / cm 2 ; 50 μ s; 10 imp.; film thickness of titanium in each cycle 0.5 μ m) ( a ); image of the foil part ( a ) obtained in the characteristic X-ray radiation of titanium atoms (Ti Kα ) ( b ) and nitrogen (NKα) ( c ); d – combined image of the foil part ( a ) obtained in the characteristic X-ray radiation of titanium atoms (Ti Kα ) and nitrogen (N Kα ); arrows indicate aluminum grains

Рис. 5. Электронно-микроскопическое изображение поверхностного слоя технически чистого алюминия марки А7, модифицированного путем азотирования (540 °C, 8 ч) поверхностного сплава, сформированного импульсным плавлением в вакууме системы Al-Ti (20 циклов «напыления/облучения» электронным пучком с параметрами 10 Дж/см2; 50 мкс; 10 имп.; толщина пленки титана в каждом цикле 0,5 мкм) ( а ); изображение участка фольги ( а ), полученное в характеристическом рентгеновском излучении атомов титана (TiKα) ( b ) и азота (NKα) ( c ); d – совмещенное изображение участка фольги ( а ), полученное в характеристическом рентгеновском излучении атомов титана (TiKα) и азота (NKα). Стрелками указаны зерна алюминия

Conclusion. The analysis of binary charts of Al-N, Al-Ti and TIN systems conditions and isothermal section of the threefold AL-TIN system is made. It is shown that under equilibrium conditions in these systems formation of double and threefold compound including the MAX phases of Ti 2 AlN и Ti 4 AlN 3 structure is observed.

It is established that a complex method of electronic ion-plasma modifying of commercially pure aluminum of A7 brand by nitriding (540 0C, 8 hours) of the surface alloy formed by pulse melting in an Al-Ti system vacuum

(20 cycles “dusting/radiation” an electron beam with the parameters of 10 J/cm2; 50 microsec; 10 imp.; thickness of a titan film in each cycle equals 0.5 microns) leads to formation of a multiphase multi-element sub-micro nanocrystal surface layer up to 20 microns thick.

Mechanical (micro-hardness) and tribological (wear resistance and friction coefficient) properties of the formed surface layer drastically surpass the properties of initial commercially pure A7 aluminum.

Acknwledgements . The authors are grateful to E. A. Petrikova and O. S. Tolkachev for their active participation in the research of the modified material. The work was partially supported by RFBR grant (project № 19-08-00248).

Список литературы Development of combined electron-ion-plasma method for formation of multiphase submicro-nanoscale alloys based on aluminum

- Белов А. Ф., Бенедиктова Г. П., Висков А. С. Строение и свойства авиационных материалов. М.: Металлургия, 1989. 368 с.

- Рахманкулов М. М. Металлургия стратегических металлов и сплавов. М.: Теплотехник, 2008. 504 с.

- Калачев Б. А., Елагин В. И., Ливанов В. А. Металловедение и термическая обработка цветных металлов и сплавов. М.: МИСиС, 2005. 432 с.

- Белецкий В. М., Кривов Г. А. Алюминиевые сплавы. Состав, свойства, технология, применение. Киев: КОМИНТЕХ, 2005. 365 с.

- Электронно-ионно-плазменная модификация поверхности цветных металлов и сплавов/под ред. Н. Н. Коваля, Ю. Ф. Иванова. Томск: НТЛ, 2016. 312 с.