Development of the two-fuel combustion chamber and calculation of processes for the theory of turbulent burning

Автор: Baklanov A.V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 3 vol.25, 2024 года.

Бесплатный доступ

In this material development stages of the two-fuel combustion chamber for the HK-16-18CT engine are presented. Calculation of processes on the basis of the theory of turbulent burning is made. One of competitive advantages of stationary gas-turbine installation is the possibility of work on two types of fuel: on diesel and on gaseous. Therefore creation of the two-fuel combustion chamber is relevant. The designing process of the two-fuel combustion chamber consists of several stages. At the first stage the nozzle is developed. It is equipped with two internal fuel channels. Then the front device is designed. in it nozzles are placed in two ranks. This device is equipped with two separate fuel collectors. It contains cavities for a fuel supply to two channels of nozzles. Such constructive decision allows to carry out switching of one type of fuel to another without stopping operation of the engine. As a prototype for distribution of air on length of a spherical pipe the combustion chamber of the NK-8-2U engine is taken. Calculation of processes in the combustion chamber was carried out on the basis of the theory of turbulent burning. During calculation such parameters as the normal speed of burning, the pulsation speed, coefficient of turbulent exchange, scale of turbulence and intensity of turbulence are determined. The equation of thermal balance for determination of temperature in the considered area at combustion of natural gas and diesel fuel is created. It is considered what in one case is spent warmly going for evaporation of liquid fuel, in other case it is not necessary. For calculation of formation of nitrogen oxides Ya. B. Zeldovich's theory of thermal oxidation of nitrogen is used by oxygen. Emissions of carbon monoxide are determined by an empirical formula From gasdynamic calculation of the HK-16-18CT engine parameters on an entrance to the combustion chamber on various operating modes at combustion of natural gas are known. Calculation for definition of a necessary consumption of diesel fuel for power setting at preservation of temperature at the exit is executed from the combustion chamber. By results of calculation the schedule of emission of harmful substances from power setting on gas and diesel fuels is constructed. The comparative schedule of dependence of completeness of combustion of fuel on power setting is constructed. Settlement emissions of harmful substances of the developed combustion chamber in the range of operation of the engine on power from 0,7Ne to 1 Ne for liquid fuel: NOx15%O2 does not exceed 250 mg/m3, СO15%О2 does not exceed 300 mg/m3; for gaseous NOx15%O2 fuel does not exceed 120 mg/m3, СO15%О2 does not exceed 150 mg/m3.

Two-fuel combustion chamber, gas-turbine engine, natural gas, diesel fuel, theory of turbulent burning, nitrogen oxides, carbon oxides

Короткий адрес: https://sciup.org/148329750

IDR: 148329750 | УДК: 621.43.056 | DOI: 10.31772/2712-8970-2024-25-3-372-383

Текст научной статьи Development of the two-fuel combustion chamber and calculation of processes for the theory of turbulent burning

Expired aircraft gas turbine engines (GTE) are increasingly used in ground conditions; they are used to drive compressors in gas pumping units and electric generators at power plants. Work is being carried out to create GTEs for automobiles, diesel locomotives and other vehicles.

Often, requirements are imposed on a gas turbine engine for use as a drive for an electric generator, which include the ability to operate the engine on liquid (diesel) and gaseous (natural gas) fuels and to switch from one type of fuel to another without stopping the engine [1].

Stationary and transport gas turbine engines are already operating on liquid fuels that are heavier than aviation fuel, using distillate medium liquid fuels (diesel fuel, diesel oil, gas oil) and the highest quality fuel oil [2].

The use of traditional heavy fuels for ground-based applications in these cases has great advantages from the operational and economic points of view.

One of the most important characteristics of fuel for gas turbine engines is its combustion heat. The effect of combustion heat on the power characteristics and efficiency of the engine is very significant. The greater the mass combustion heat, the greater the engine efficiency.

The value of the heat of combustion of fuel depends on the chemical composition or ratio of elements that make up the combustible part of the fuel. Consequently, for hydrocarbon liquid fuels it depends on their chemical structure. In practice, the net calorific value is accepted as the main thermochemical characteristic of hydrocarbon fuels [3].

The lower calorific value for natural gas is Hu = 50,000, for diesel fuel Hu = 40,000. The stoichiometric coefficient for natural gas is 17.3, and for diesel fuel 14.5 [4].

Development object

Let us consider the stages of development of a dual-fuel combustion chamber for the NK-16-18ST engine and calculation of intra-chamber processes based on the theory of turbulent combustion [5].

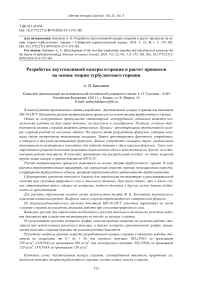

Рис. 1. Форсунка камеры сгорания

Fig. 1. Nozzle of the combustion chamber

To implement dual-fuel combustion at the first stage, a dual-fuel injector (Fig. 1) was developed, which contains a swirler body 1 , including a vane swirler 2 and a mixing sleeve 3 , as well as a nozzle body 4 , which is installed in a gas distribution device 5 . The swirler body 1 contains two fuel supply channels: for liquid fuel 6 and gas 7 . A gas distribution sleeve 8 is installed in the internal channel of the nozzle body 4 , forming a fuel channel 9 between the nozzle body 4 , and a sprayer 10 with holes 11 is installed between the nozzle body 4 and the gas distribution sleeve 8 . An elongated mesh filter 12 and a centrifugal liquid fuel sprayer 13 are installed in the center of the gas distribution sleeve 8 . To ensure tightness, the dual-fuel injector contains sealing rings 14 , a splined nut 15 , which, using a threaded connection, fixes the body of the injector 4 in the gas distribution device 5 , and to ensure a given air flow through the vane swirler 2 has a throttle plate 16 [6].

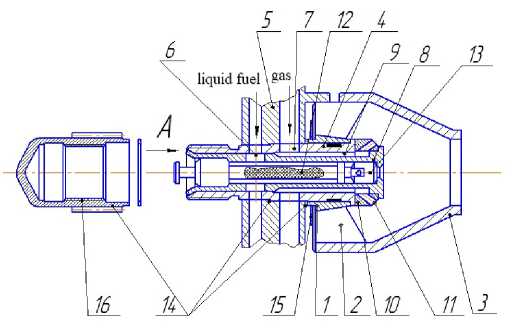

At the second stage [7] a front device was developed (Fig. 2). It contains a ring head 1 with external 2 and internal 3 fuel manifolds. On the surface of the external fuel manifold there are gas supply nozzles 4 . The supply is carried out into the internal cavity of the external manifold 2 . On the ring head between the manifolds, there are air shaped windows 5 along the circumference, necessary for the supply of air. They contain central openings 6 and racks for fastening 7 burners (nozzles) 8 to the ring head 1 . Also in the racks there are through channels for supplying fuel 9 to the nozzles 8 .

Рис. 2. Фронтовое устройство жаровой трубы

-

Fig. 2. Flame tube head

In the middle of the head of the annular 1 on the outer side there is a hollow annular collector 10 with channels for supplying fuel 11 to the injectors 8 . The hollow annular collector is placed in the diffuser 12 and has a fuel supply nipple 13 .

The injectors 8 contain two cavities 14 , 15 , one of which is connected to the outer 2 and inner 3 fuel collectors filled with gaseous fuel (gas), and the other - with channels for supplying fuel 11 from the hollow annular collector 10 filled with liquid fuel. The injector 8 is equipped with a liquid 16 atomizer and a gaseous 17 atomizer [8].

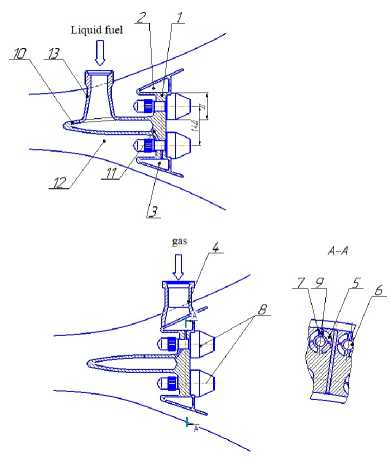

Рис. 3. Камера сгорания

-

Fig. 3. Combustion chamber

The dual-fuel chamber consists (Fig. 3) of a housing 6 , a flame tube 3 , a liquid manifold 9 and a gas manifold 1 for feeding gas to the injectors 2 . The flame tube is annular, consisting of several sections. Between the rings, when connected, spacer plates 5 or corrugated tapes 4 are installed, which serve to create film air cooling. The flame tube is suspended from the front side using clamps 7 . Rings 8 are welded to the rear part of the outer and inner casings, with which they rest on the corresponding annular surfaces of the turbine nozzle apparatus [9; 10].

Mathematical model

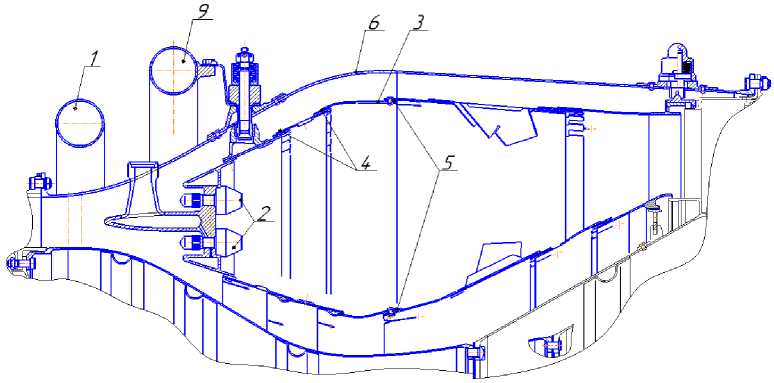

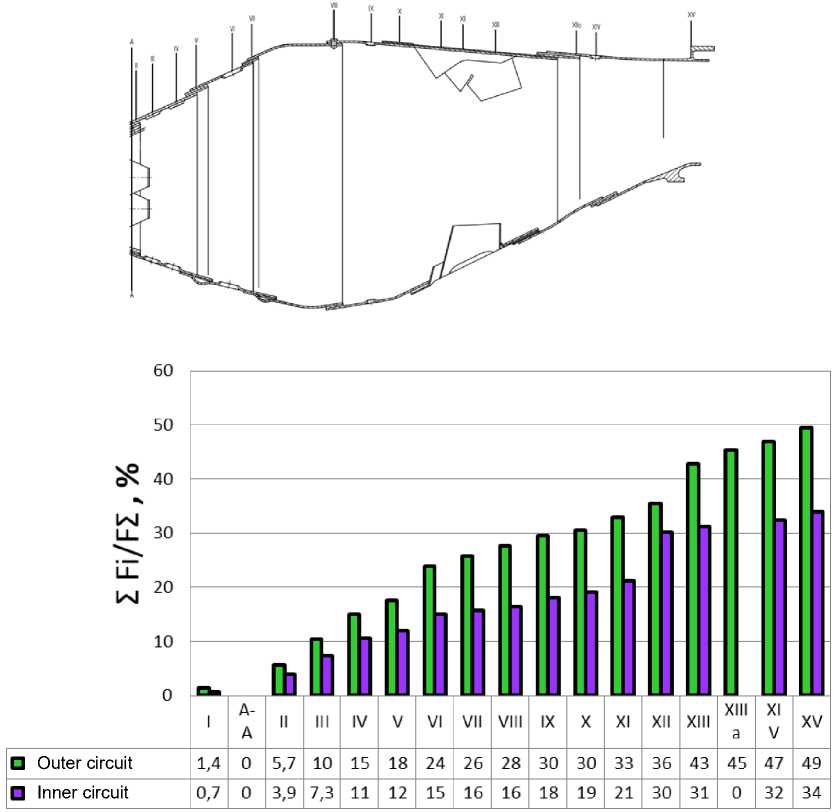

The combustion chamber of the NK-8-2U engine (Fig. 4) was taken as a prototype for air distribution (location and number of holes and slots) along the length of the combustion tube.

Рис. 4. Распределение воздуха по длине жаровой трубы

-

Fig. 4. Air Distribution on length of a flame tube

To determine the completeness of combustion, the surface theory of turbulent combustion of an average mole of the mixture is used, on the basis of which a dependence is obtained for determining the local completeness of fuel combustion in the area under consideration [11]:

n =

3 3 U м0

W,3

1 - exp

^ 3Ax -^ J

V li A

-

U n

U м0

1 - exp

^ 2 Ax-^ J

V li A

U 2

+ —n

U м0

1 - exp V

Ax e ।-—1

V li A A

This dependence allows us to determine the completeness of combustion of the average volume of a mixture with composition a i during its stay on a section of the combustion chamber of length Ax with a velocity W and burning from the surface with a turbulent velocity U n0 = U n + W' .

The normal combustion rate U n is determined by the parameters of the mixture at the entrance to the calculated section of the combustion chamber using the empirical equation:

U n = U n 0

(I Ti

I T

8 / .'i

I fP I ■

' \ P 0 J

where U n0 – normal burning rate provided P 0 = 105Pascal, Т 0 = 873К.

0.8

Exponents 5, у are calculated according to A. M. Mellor: 8 = 2.98-- a

0.22

у = -0.38 +--, accord- a

ing to V. A. Shchukin: δ = 1.8, γ = –0.2.

The pulsation speed is determined using the dependence

W’ = e W ,

where W - flow velocity behind the burner device; e - turbulence intensity.

The turbulence parameters included in the calculated dependencies can be estimated using the empirical dependence

e = 0.041 ( 1 + P 2tg2 ф ) 0.5

X

X -0.5

\ 'utt J

,

where r out - swirl outer radius; x = X + A x ( X - distance from front device; A x - distance from the mouth of the jet to the front).

To determine the scale of turbulence l 0 , it is necessary to carry out a number of transformations.

From the theory of turbulence, the dependence for determining the coefficient of turbulent exchange is:

D t = l mix W' ■ (5)

where l mix – Lagrangian scale of turbulence; W' – pulsating velocity.

The dependence for determining the coefficient of turbulent diffusion at the initial section of a swirling jet is:

Dt = 0.00294 ( 1 + p 2tg2 ф ) 0.5 WRp , (6)

where ф - swirl angle in the jet; W - average flow rate of the jet; в - coefficient taking into account the design features of the swirler; Rр – pipe radius.

By equating the right-hand sides in equations (5) and (6) and taking into account that l 0 = 0.5 l cm , we can obtain an expression for calculating the scale of turbulence in the combustion chamber flame tube:

l 0

= 0.014 Rp

0.5

x

\ 'uut J

The obtained value of local combustion completeness An i characterizes the combustion completeness in relation to the fuel at the entrance to the combustion zone under consideration. Summing up all the combustion completeness values up to the calculated cross-section allows us to obtain the change in the absolute value of combustion completeness along the length of the flame tube n i :

П / = An 1 + An 2 (1 - An 1 ) + Ап з (1 - An 1 ) (1 - An 2 ).

To calculate using the presented method, it is necessary to divide the fire tube into several sections, in each of which it is necessary to determine the necessary parameters characterizing the flow of intrachamber processes.

When burning diesel fuel, the average temperature of the gas in the i-th section can be found from the heat balance equation, which takes into account the heat Q i _ 1 brought by the gas from the previous zone; Q air i , introduced by the air entering the combustion zone from the side openings; Q air i , supplied to the gas due to the combustion of part of the fuel in the i-th zone, and the heat Qvap i used to evaporate the liquid fuel, according to the diagram in Fig. 5:

Q i = Q i _ 1 + Q ai^ +A Q g i _ Q vapc (9)

From this we get

T _ Cpg i _ 1 T gi G g _ 1 + C pair T cc A G ar + A G s ,П Hu - LV ap A zGti

Ti c G сpgi Ggi where Tgi – gas temperature in the i-th section; Tc – combustion chamber inlet air temperature; Gair i ,Ggi – air and gas consumption in the i-th section; Δz – fuel evaporation rate; GTi, Gsti – liquid and steam fuel consumption in the corresponding sections; сpg , срair – heat capacity of gas and air; Нu – calorific value of fuel; Lvap – heat of vaporization.

|

О о |

о °е |

о о |

||

|

О Q^ о ► |

о о ' |

о о |

||

Рис. 5. Схема подвода тепла в зону горения

Fig. 5. The scheme of a supply of heat in a burning zone

When burning natural gas, the average temperature of the gas in the i-th section is found from the heat balance equation, which takes into account the heat Q i _ 1 brought by the gas from the previous zone; Q air i , introduced by the air entering the combustion zone from the side openings; Q g i , supplied to the gas due to the combustion of part of the fuel in the i-th zone:

Q i = Q i _ 1 + Q air i +A Q gr

From this we get:

T _ c P gi T gi- 1G gi - 1 + c P air T c A G air i + A G ni П Hu

Tgi = cpgiGgi where Tgi – gas temperature in the i-th section; Tc – combustion chamber inlet air temperature; Gair i ,Ggi – air and gas consumption in the i-th section; cpgi – heat capacity of gas in the i-th section; cp air – heat capacity of air; Нu – calorific value of fuel.

After determining the local values of the mixture composition, combustion temperature and complete combustion, the instantaneous concentrations of О 2 and N 2 can also be calculated [12].

To calculate the formation of nitrogen oxides, it is necessary to use the theory of Ya. B. Zeldovich to determine the thermal oxidation of nitrogen by oxygen:

d NO

d т

5 - 1011 - e

O 2

86000 RТ g

- 43000

„ ,T 64 RT

ON e g 22 3

- ( NO ) 2 Г ,

where т - time, с; T g - temperature in the reaction volume, К; NO, N2, О 2 - concentrations of components of the final gas mixture, mol/l.

To do this, it is necessary to divide the entire volume of the flame tube into n zones, taking into account that in each zone the composition of the unreacted mixture of fuel and air is formed, as well as combustion products received from the previous zone. The concentration of ΔNO xi in each zone is determined by the nitrogen oxides released here and received from the previous zone.

Carbon monoxide emissions are determined by an empirical formula, the volume, % [13]:

CO =

2*

0.5

—] bb

p I cc \pccj

V exp cT * c . z st . g

10 - 4,

where f – доля воздуха, участвующего в горении proportion of air participating in combustion; let us assume f = 0.5; G air cz – air passing through the combustion zone; C , b , c – constants; C = 20, b = 1.0, c = 0.009.

Calculation results

From the thermogasdynamic calculation of the NK-16-18ST engine, the parameters at the combustion chamber inlet are known for various operating modes when burning natural gas. These parameters are taken as boundary conditions for performing the calculation within the chamber processes (Table 1).

Table 1

Parameters of the engine NK-16-18ST

|

Name |

Unit of measurement |

N = 50 % |

N = 60 % |

N = 70 % |

N = 80 % |

N = 90 % |

N = 100 % |

|

Power |

kW |

9000 |

10800 |

12600 |

14400 |

16200 |

18000 |

|

Air flow rate at the inlet to the compressor station |

kg/s |

88.5858 |

92.8724 |

96.4033 |

99.8401 |

103.05 |

106.158 |

|

Total fuel (gas) consumption per hour |

kg/h |

2740.29 |

3085.49 |

3422.71 |

3757.35 |

4088.51 |

4418.26 |

|

Braking temperature at the outlet of the com pressor |

К |

908.648 |

946.42 |

982.188 |

1015.19 |

1045.97 |

1074.79 |

|

Braking pressure at the inlet to the compressor station |

MPa |

0.791 |

0.847 |

0.896 |

0.944 |

0.990 |

1.0348 |

|

Braking temperature at the entrance to the compressor |

К |

554.716 |

566.782 |

577.242 |

587.116 |

596.163 |

604.731 |

To determine the temperature of the gas there is the following expression:

Tg = Tx + u П г where n > 1.0, g cc Cpg (1 + a • L 0 ) 1 ’

where срg – average heat capacity of gas at constant pressure; Hu – net calorific value; η – combustion efficiency; α – excess air coefficient in the calculated area; Tc*c – temperature before combustion chamber, К.

To determine the required consumption of diesel fuel while maintaining the temperature at the outlet of the combustion chamber, taking into account the excess air coefficient:

a =

G

G air

L o • G t ’

where L 0 –stoichiometric coefficient for the fuel under consideration, the following dependence was obtained.

G

G g

G air

Hu • n

Cp (Tg - Tar)

In accordance with this dependence, the required diesel fuel consumption was calculated for each engine operating mode (Table 2).

Diesel fuel consumption depending on engine modes NK-16-18ST

Table 2

|

Name |

Unit of measurement |

N = 50 % |

N = 60 % |

N = 70 % |

N = 80 % |

N = 90 % |

N = 100 % |

|

Power |

kW |

9000 |

10800 |

12600 |

14400 |

16200 |

18000 |

|

Total diesel fuel consumption per hour |

kg/h |

2740.29 |

3085.49 |

3422.71 |

3757.35 |

4088.51 |

4418.26 |

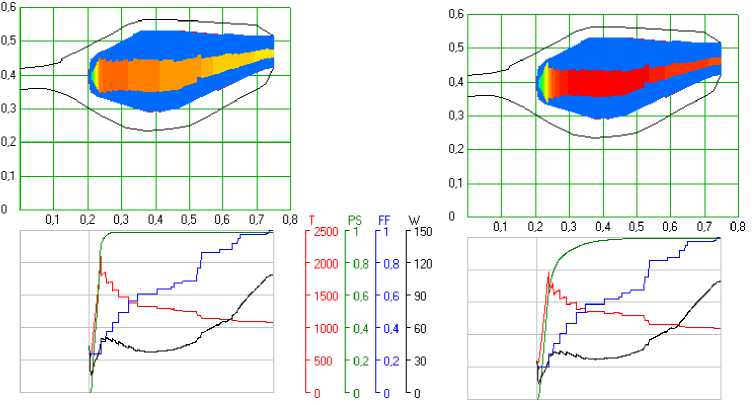

To evaluate the parameters of the combustion chamber operating on gaseous and diesel fuel, a calculation was performed in the program “CAMERA” [14]. For the calculation, the geometry of the combustion chamber, the number of nozzles, the number, diameters and coordinates of the air supply holes along the length of the combustion tube were specified. The data in Tables 1 and 2 were used as the initial data for the calculation.

а b

Рис. 6. Распределение параметров по длине жаровой трубы: а – при работе на дизельном топливе; б – при работе на природном газе

Fig. 6 Distribution of Parameters on length of a spherical pipe: a – diesel fuel; b – natural gas

Fig. 6 shows that during combustion of diesel fuel a higher flame temperature is observed in the combustion zone. The efficiency of combustion almost immediately reaches its maximum value. The distribution of velocity along the length of the flame tube is similar, since it is determined by the geometric features of the flame tube [15].

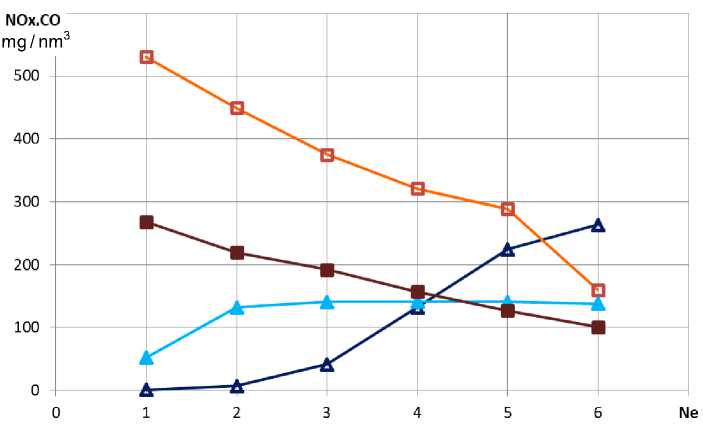

Рис. 7. Сравнительный график эмиссии вредных веществ от режима работы двигателя СО: ■ – природный газ; ϒ – дизельное топливо; NOx: ▲ – природный газ; ∆ – дизельное топливо

-

Fig. 7. Emission of harmful substances from power setting СО: ■ – natural gas; ϒ – diesel fuel; NOx: ▲ – natural gas; ∆ – diesel fuel

From the summary graph (Fig. 7) of emissions of harmful substances for two types of fuel, it is evident that the concentration of CO and NOx is lower when the engine is running on gaseous fuel.

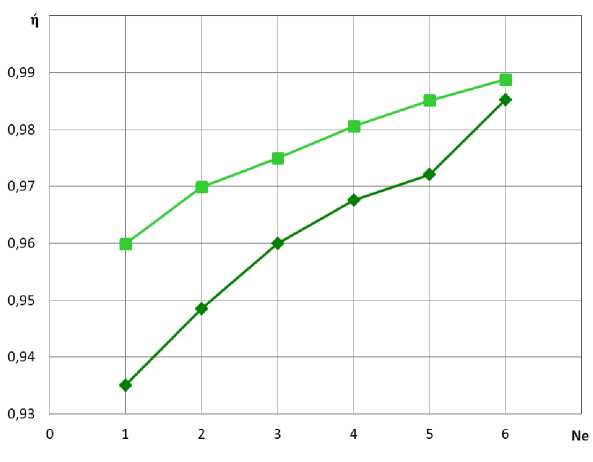

Рис. 8. Сравнительный график зависимости полноты сгорания топлива от режима работы двигателя при использовании: ♦ – дизельное топливо; ■ – природный газ

-

Fig. 8. Completeness of combustion of fuel from power setting:

♦ – diesel fuel; ■ – natural gas

The combustion efficiency is significantly higher when using natural gas (Fig. 8), and its increase is noted with an increase in the engine operating mode.

Conclusion

-

1. A combustion chamber that ensures the operation of a stationary gas turbine engine on liquid and gaseous fuels has been developed.

-

2. The calculation of intra-chamber processes was performed based on the theory of turbulent combustion for various engine operating modes when supplying liquid and gaseous fuels.

-

3. The calculated emissions of harmful substances of the developed combustion chamber in the engine operating range by power from 0.7 to 1 Ne for liquid fuel NOx15%О2 does not exceed 250 mg/m3, СO15%О2 does not exceed 300 mg/m3; for gaseous fuel NOx15%О2 does not exceed 120 mg/m3, СO15%О2 does not exceed 150 mg/m3.

Список литературы Development of the two-fuel combustion chamber and calculation of processes for the theory of turbulent burning

- Gritsenko E. A., Danilchenko V. P., Lukachev S. V. Konvertirovanie aviatsionnykh GTD v gazoturbinnye ustanovki nazemnogo primeneniya [Conversion of aviation gas turbine engines to landbased gas turbines]. Samara, 2004, P. 266.

- Lefebvre A. H., Ballal D. R. Gas Turbine Combustion: Alternative Fuels and Emissions. Third Edition, CRC Press, 2010, 560 p.

- Mingazov B. G., Yavkin V. B., Sabirzyanov A. N., Baklanov A. V. [The analysis of applicability of models of burning for calculation of the GTD mnogoforsunochny combustion chamber]. Vestnik Samarskogo gos. aerokosm. un-ta im. ak. S. P. Koroleva (natsional'nogo issledovatel'skogo universiteta). 2011, No. 5 (29), P. 208–214 (In Russ.).

- Lansky A. M. Rabochiy protsess kamer sgoraniya malorazmernykh GTD [Working process of combustion chambers of small-sized GTD]. Samara, 2009, 335 р.

- Baklanov A. V. [Concentration of carbon dioxide in products of combustion of GTE NK-16ST and NK-16-18ST]. Siberian aeroaspace journal. 2023, Vol. 24, No. 4, P. 697–705 (In Russ.).

- Baklanov A. V. Dvukhtoplivnaya forsunka [Two-fuel nozzle]. Patent RF, no. 2750402 C1, 2021.

- Danilchenko V. P., Lukachev S. V., Kovylov J. L. [Design of aircraft gas turbine engines]. Samara, SNTs RAN Publ., 2008, 620 p.

- Baklanov A. V. Frontovoe ustroystvo zharovoy truby dvukhtoplivnoy kamery sgoraniya [Front device of a spherical pipe of the two-fuel combustion chamber]. Patent RF, no. 2806420 C1, 2023.

- Zheng H., Zhang Z., Li Y., Li Z. [Feature-Parameter-Criterion for Predicting Lean Blowout Limit of Gas Turbine Combustor and Bluff Body Burner]. Mathematical Problems in Engineering. 2013, Vol. 16, Р. 1–17 (In Russ.).

- Roy G. D., Frolov S. M., Netzer D. W., Borisov A. A. High-Speed Deflagation and Detonation: Fundamentals and Control. Moscow, ELEX-KM Publishers, 2001, 384 p.

- Mingazov B. G. Kamery sgoraniya gazoturbinnykh dvigateley [Combustion chambers of gasturbine engines]. Kazan, 2006, 220 p.

- Mingazov B. G., Baklanov A. V. [Influence of constructive changes on emissions of nitrogen oxides in the GTD combustion chamber]. Vestnik Samarskogo gos. aerokosm. un-ta im. ak. S. P. Koroleva (nats. issled. un-ta). 2013, No. 3–1 (41), P. 177–182 (In Russ.).

- Lefebvre A. H. Influence of Fuel Properties on Gas Turbine Combustion Performance. AFWAL-TR-84-2104, 1985.

- Mingazov B. G., Yavkin V. B., Tokmovtsev Yu. V. Programmnyy kompleks Kamera [Program Camera complex]. Svid. 2006613901.

- Baklanov A. V. [Stage-by-stage operational development of the combustion chamber of the gas-turbine engine working in the conditions of speeding up of speed of air at an exit from the compressor]. Vestnik of the Moscow aviation institute. 2017, Vol. 24, No. 3, P. 13–22 (In Russ.).