Development of wear-resistant parts of high-manganese modified 110G13L brand steel

Автор: Chorshanbiev Sh.M., Karimov K.A., Adilova Sh.R., Turakhodjaev N., Erkinjonov A., Mirmuhamedov M.M., Sharipov Ja.H., Obidov Z.R., Komolov Kh.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Рубрика: Исследования. Проектирование. Опыт эксплуатации

Статья в выпуске: 2 т.17, 2024 года.

Бесплатный доступ

The efficient operation of the technological equipment of machinery manufacturing enterprises and heavy industry without distortion depends in many respects on the strength of their details. This requires the study of the process of operation of the details, which are mainly rubbed with each other. These methods are widely used in obtaining high-quality steel castings. The simplest method of processing steel outside the oven is modification. Modified carbon steel is much more economical in properties approaches to leached steel, while modified steel leached by saving and investigation approaches leached steel with valuable and rare additives (Ni, Mo, Ti and other). Modification with alkaline and alkaline-earth metals greatly increases the quality of steel. The quality of steel is positively influenced by nitride-forming modifiers.

Modifier, structure, ferrotitan-65, alloy, hardness, melting, steel, detail, absorbency, temperature

Короткий адрес: https://sciup.org/146282845

IDR: 146282845 | УДК: 621.882

Текст научной статьи Development of wear-resistant parts of high-manganese modified 110G13L brand steel

Despite all the research [1–5], scientific research [6–9] and experimental work [10–13] carried out by World Scientists, several disadvantages are observed in the wear resistance of steel brand 110G13L.

Mechanical engineering consists of a number of technological processes in manufacturing enterprises, forming a kind of technological chain. This chain is closely related to the working unit of each unit and the working quality of the machines before it. Taking this issue into account, it can be concluded that the influence of technological chain equipment on the quality indicators of machinery manufacturing enterprises and heavy industrial products is great.

Therefore, professor scientists of Tashkent State Technical University, together with the scientific researchers and mature and experienced specialists of the Joint Stock Company “Almalyk mining and metallurgical combine” and its affiliated Central repair mechanical plant, to improve the strength of steel parts, to increase the operational properties of cast products based on the selection of modifiers or the selection of other modifiers to form a quality structure, and to obtain quality castings from parts with high strength a number of measures have been taken to increase.

In the period of liquefaction of steels using electric arc furnaces at the enterprises of our republic, measures are being taken to obtain quality casting products. In this regard, it is becoming important to increase the priority of research on the improvement of technologies that provide resource and energy savings in the liquefaction of steels, which is widely used in the industry.

Today, machine-building is the main consumer of metals produced in our country. In the machinetool industry, the automobile and aviation industry, in electronics and radio engineering, a lot of machine and accessory details are made from metals.

Metals used in technology are mainly divided into two groups – ferrous and non-ferrous metals. Ferrous metals include iron and its compounds (cast iron, steel, ferroalloys). The remaining metals and their alloys form the group of non-ferrous metals.

Until now, iron and its alloys, considered the main machine-building material, are of particular importance among metals. Iron and its alloys make up 90 % of metals produced worldwide. This is explained by the fact that ferrous metals have important physical and mechanical properties, as well as the fact that iron ores are widely distributed in nature, and the production of cast iron and steel is cheap and uncomplicated [14].

From the beginning of the 20th century, the world scientists who contributed to the further development of the theory of selective operation of modifiers to increase the strength of steel parts include the following; English and German scientists R. Gadfield, R. Mel, E. Bain, G. Hahnemann, F. Wefer, G. Esser and others, Russian scientists P. A. Rebinder, A. A. Zhukov, Kryakovsky, Yu. V., Lipman M. S, A. A. Bochvar, N. A. Minkevich, S.S., Steinberg, N. Ya. Selyakov, N. T. The works of Gudtsov, G. V. Kurdyumov, A. P. Gulyaev and others are among such works. CIS scientists A. A. Bochvar, N. A. Minkevich, S.S., Steinberg, N. Ya. Selyakov, N. T. Gudtsov, G. V. Kurdyumov, A. P. Gulyaev, A. M. Butlerov, S. V. Lebedev, P. A. Rebinder, S. P. Korolyov and A. T. Tumanov contributed a lot. They have developed various technologies of heat treatment of machine parts obtained by cast method in order to increase their operational properties. Among other things, they have developed grinding modes, surface treatment technology of coated teeth, and methods of restoring bent teeth to increase the wear resistance of gear wheels.

Uzbek scientists have conducted a number of scientific researches on increasing the service life of mechanical engineering parts, increasing their mechanical properties, processing alloys inside and outside the furnace. Professors A. A. Mukhamedov, N. D. Turakhodjaev, S. A. Rasulov, F. R. Norkhudzhaev, Sh. A. Karimov made great contributions in this regard. In particular, they created thermocyclic and high-temperature processing methods for increasing the mechanical properties of details based on thermal processing [15, 16].

Experimental part

Induction melting of 110G13L modified steel alloy in laboratory conditions of Tashkent State Technical University, Faculty of Mechanics, “Foundry Technologies” department (INDUCTION MELTING MACHINE, Model: BF-TB 2) was carried out in the furnace.

At the first stage of the study, 1400 gr. 110G13L grade steel slag was liquefied at a temperature from 20 °С to 1250–1300 °С, and then ferrotitanium-65 in the amount of 0.5 % was loaded into the furnace and the temperature in the induction furnace was raised to 1410 °С.

To determine the hardness of the obtained sample, the liquid alloy taken from the furnace was poured into a sand-clay mold at 1390–1410 °С. The temperature of the liquid alloy was measured on a Kelvin PLTs 3000 device.

In order to determine the hardness, chemical composition and structure, the samples were prepared using the S 11MV universal lathe in the Mechanics shop of the Central Repair Mechanics Plant belonging to “Almaliq MMC” JSC [17, 18].

Results and discussion

As a result of the research carried out in an induction furnace with the addition of 0.5 % ferrotitanium-65 as a modifier to 110G13L steel, the following indicators were obtained: the hardness of the surface parts of the sample according to HRB was 96.8 and 97.1, the hardness of the central part was 99.8, according to HRB the average was 97.9, HB-217.1 according to Brinell.

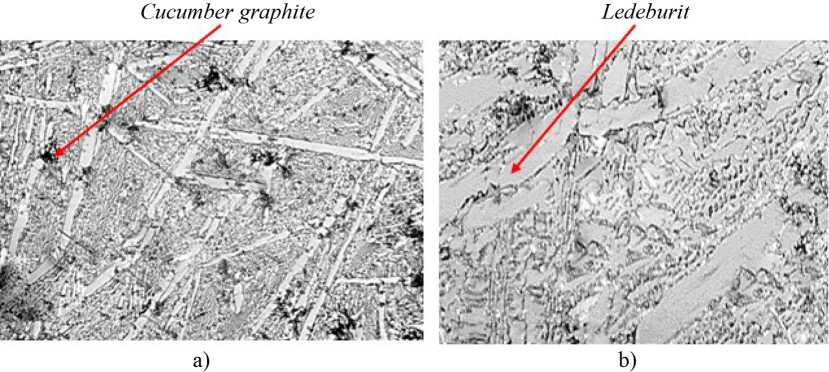

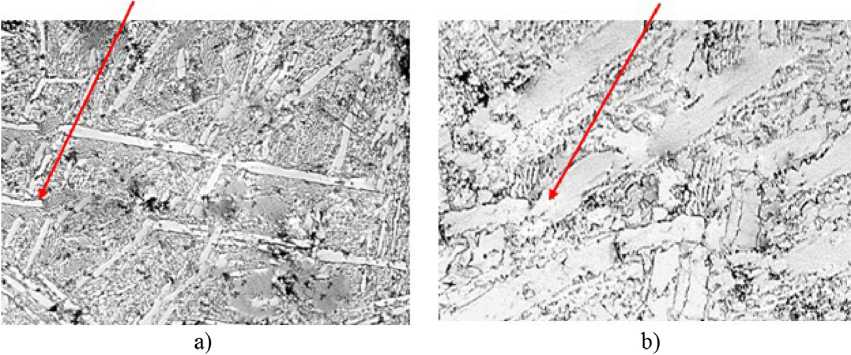

When studying the structure and chemical composition, the following results were obtained (Fig. 1a, b, Table 1).

Fig. 1. 0.5 of ferrotitanium-65 to 110G13L steel as a modifier; 1; 1.5; 2;

Application in 3 and 4 % and obtained results: a) 1x100 size view; b) 2x400 size view

Table 1. Chemical composition results obtained when 0.5 % ferrotitanium was added as a modifier to 110G13L steel

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi –65 |

0.91 |

0.68 |

11.94 |

0.051 |

0.015 |

0.61 |

0.11 |

0.022 |

0.43 |

The microstructure was manifested in the form of primary small columnar crystals of high ledeburite. Crystals are 4–5 microns wide and 50 microns long. The appearance of custard-like graphite is significant, probably due to forced redistribution under the influence of high temperature [19].

The eighth stage of the study was carried out in an induction furnace with the addition of 1 % ferrotitanium-65 as a modifier to 110G13L steel. The following indicators were obtained: the surface hardness of the sample was 99.4 and 95.2, the hardness in the central part was 101.2, HRB on average was 98.6, HB-229.2 on Brinell [20].

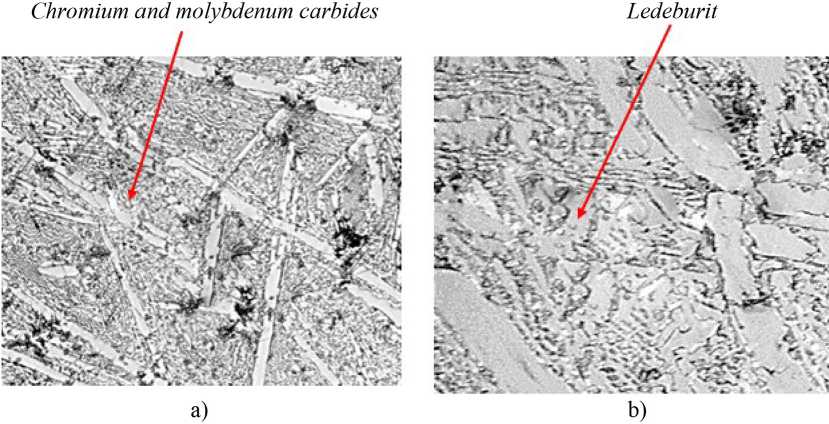

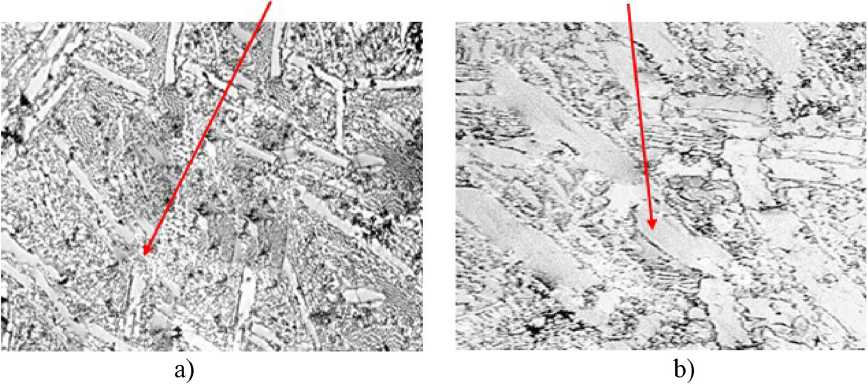

When studying the chemical composition and structure, the following results were obtained (Fig. 2a, b, Table 2).

Small carbides of chromium and molybdenum are visible in the ledeburite layers. Molybdenum reduced the grain sizes to 3–4 microns in width and 40–45 microns in length [24].

The ninth stage of the research was carried out in an induction furnace with the addition of 1.5 % of ferrotitanium-65 as a modifier to 110G13L steel, and the following indicators were obtained: the surface hardness of the sample was 99.1 and 103.7, and the hardness in the central part was 105.3, averaged 102.7 on HRB, HB-255 on Brinell.

Ledeburit

Chromium and molybdenum carbides

Fig. 2. Chemical composition results obtained when adding 1 % ferrotitanium as a modifier to 110G13L steel: a) 1x100 size view; b) 2x400 size view

Table 2. Chemical composition results obtained when adding 1 % ferrotitanium as a modifier to 110G13L steel [21–23]

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi – 1 % |

1.14 |

0.79 |

11.32 |

0.072 |

0.014 |

0.79 |

0.17 |

0.031 |

0.03 |

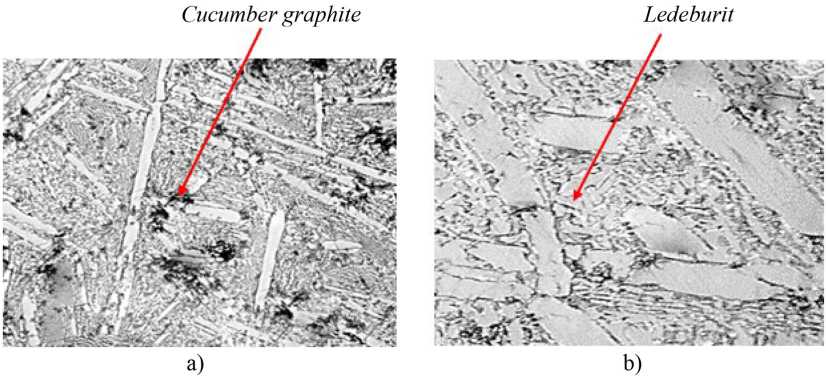

Fig. 3. Chemical composition results obtained when 1.5 % ferrotitanium was added as a modifier to 110G13L steel: a) 1x100 size view; b) 2x400 size view

Table 3. Chemical composition results obtained when 1.5 % ferrotitanium was added as a modifier to 110G13L steel

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi – 1.5 % |

1.19 |

0.86 |

11.98 |

0.059 |

0.011 |

0.81 |

0.19 |

0.046 |

0.29 |

When studying the chemical composition and structure, the following results were obtained [25] (Fig. 3a, b, Table 3).

The conclusion of the obtained results is that the microstructure of the sample (eutectic austenitic steel) was manifested in the form of small columnar crystals of high ledeburite. Crystals are 3–4 microns wide and 40 microns long [26].

The tenth stage of the study was carried out in an induction furnace with the addition of 2 % ferrotitanium-65 as a modifier to 110G13L steel. As a result of the study, the following indicators were obtained: the surface hardness of the sample was 104.6 and 105.1, the hardness in the center part was 107.2, HRB The average was 106.6, according to Brinell HB-277.

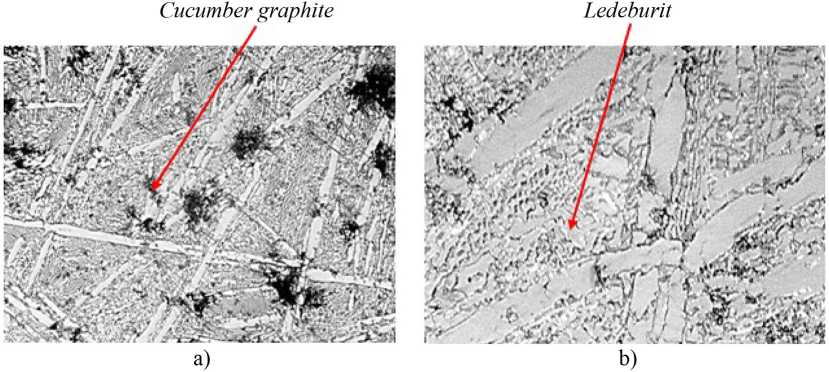

When studying the chemical composition and structure, the following results were obtained [27– 29] (Fig. 4a, b, Table 4).

The appearance of custard-like graphite is significant, probably due to forced redistribution under the influence of high temperature. The effect of titanium in this composition is manifested in reducing the size of cementite and ledeburite grains.

The eleventh stage of the study was carried out in an induction furnace with the addition of 3 % ferrotitanium-65 as a modifier to 110G13L steel. The following indicators were obtained: the surface hardness of the sample was 106.3 and 107.8, the hardness in the center part was 107.8, HRB averaged 107.3, Brinell HB-293.

When studying the chemical composition and structure, the following results were obtained [30] (Table 5, Fig. 5a, b).

Small carbides of chromium and molybdenum are visible in the ledeburite layers. Molybdenum reduced the grain sizes to 4–5 microns in width and 45–40 microns in length.

Fig. 4. Chemical composition results obtained when adding 2 % ferrotitanium as a modifier to 110G13L steel: a) 1x100 size view; b) 2x400 size view

Table 4. Chemical composition results obtained when adding 2 % ferrotitanium as a modifier to 110G13L steel

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi-65 |

1.44 |

0.68 |

11.94 |

0.061 |

0.016 |

0.61 |

0.13 |

0.022 |

0.43 |

Chromium and molybdenum carbides Ledeburit

Fig. 5. Chemical composition results obtained when 3 % ferrotitanium was added as a modifier to 110G13L steel: a) 1x100 size view; b) 2x400 size view

Table 5. Chemical composition results obtained when 3 % ferrotitanium was added as a modifier to 110G13L steel

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi –65 |

1.19 |

0.93 |

11.99 |

0.061 |

0.016 |

0.61 |

0.13 |

0.022 |

0.43 |

The twelfth stage of the study was carried out in an induction furnace with the addition of 4 % ferrotitanium-65 as a modifier to 110G13L steel. The following indicators were obtained: the surface hardness of the sample was 106.8 and 108.6, the hardness in the center part was 111.3, It averaged 108.9 on HRB and 296 on Brinell.

Chromium and molybdenum carbides Ledeburit

Fig. 6. Chemical composition results obtained when 4 % ferrotitanium was added as a modifier to 110G13L steel: a) 1x100 size view; b) 2x400 size view

Table 6. Chemical composition results obtained when 4 % ferrotitanium was added as a modifier to 110G13L steel [31]

|

Material |

C |

Si |

Mr |

P |

S |

Cr |

Ni |

Ti |

Al |

|

FeTi –65 |

1.23 |

0.91 |

11.94 |

0.058 |

0.018 |

0.62 |

0.14 |

0.021 |

0.42 |

When studying the chemical composition and structure, the following results were obtained (Table 6, Fig. 6a, b).

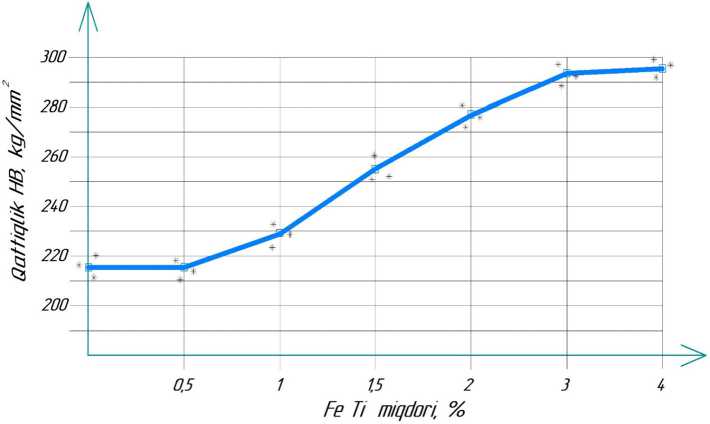

Chromium and molybdenum appear in fine carbides in ledeburite layers (Fig. 7).

According to GOST, the hardness of 110G13L steel is equal to HB-217–229. It was found that 110G13L steel is equal to HB-277–293 when 2–3 % of ferrotitanium-65 is added as a modifier (Table 7).

Fig. 7. 219 HB with the addition of 0.5 % ferrotitanium; 227 HB at 1 %; 255 HB at 1.5 %; 277 HB at 2 %; 293 HB at 3 %; 296 HB at 4 %

Table 7. A tabular view of hardness results

|

Modifier |

Hardness is a unit of measure |

% difference |

|

|

Ferrotitanium,% |

HRB |

HB |

|

|

0.5 |

97.9 |

219 |

unchanged |

|

1 |

98.6 |

227 |

unchanged |

|

1.5 |

102.7 |

255 |

10.2 |

|

2 |

106.6 |

277 |

16.3 |

|

3 |

107.3 |

293 |

21.8 |

|

4 |

108.9 |

296 |

22.6 |

Conclusions

As a result of theoretical and practical research on the development of high-strength parts from the modified 110G13L steel alloy, the following recommendations were developed:

-

– load ori musta h deficiency to the composition have the details get optimal modifiers were selected for at the MTM (TsRMZ) plant TDTU laboratory conditions tested;

-

– load ori musta h deficiency to the composition have the details get for It is recommended to add 2–3 % ferromtitanium-65 as a modifier to 110G13L steel;

-

– when 2–3 % of ferrotitanium-65 was added as a modifier to the 110G13L steel alloy, the hardness of the samples gave the above results, 0.5; 1;

-

– when adding a modifier of 1.5 and 4 %, there was almost no change, and economic efficiency was also taken into account.

Список литературы Development of wear-resistant parts of high-manganese modified 110G13L brand steel

- Shluger А.М., Аzhоgin F. F., Еfimov Е. А. Corrosion and protection of metals. Мoscow: Metallurgy. 1981, 216 (In Rus.)

- Оbidov Z.R., Ganiev I. N. Anode protective of zinc-aluminium covering with II group elements. Berlin: LAP LAMBERT Academic Publishing. 2012, 288 (In Germany)

- Оbidov Z.R., Ganiev I. N. Physicochemical of zinc-aluminium alloys with rare-earth metals. Dushanbe: ООО «Аndaleb-R». 2015, 334 (In Tajikistan)

- Amini R.N., Irani M., Ganiev I., Obidov Z. R. Galfan I and Galfan II Doped with Calcium, Corrosion Resistant Alloys. Oriental Journal оf Chemistry. 2014, 30(3), 969–973.

- Obidov Z.R., Ganiev I. N., Amonov I. T., Ganieva N. I. Corrosion of Al+2.18 % Fe alloy doped with gallium. Protection of Met. and Phys. Chem. of Surfaces. 2011, 47(5), 654–657.

- Obidov Z.R., Ganiev I. N., Eshov B. B., Amonov I. T. Corrosion-electrochemical and physicochemical properties of Al+2.18 % Fe alloy alloyed with indium. Russian Journal of Applied Chemistry. 2010, 83(2), 263–266. DOI: 10/1134/S 107042721002014X

- Obidov Z.R., Ganiev I. N. Anodic behavior and oxidation of the thallium alloyed Al+2.18 % Fe alloy. Russian Journal of Applied Chemistry. 2012, 85(11), 1691–1694.

- Obidov Z. R. Thermophysical Properties and Thermodynamic Functions of the Beryllium, Magnesium and Praseodymium Alloyed Zn‑55Al Alloy. High Temperature. 2017, 55(1), 150–153. DOI: 10.1134/S 0018151X17010163

- Obidov Z. R. Effect of pH on the Anodic Behavior of Beryllium and Magnesium Doped Alloy Zn55Al. Russian Journal of Applied Chemistry. 2015, 88(9), 1451–1457.

- Obidov Z.R., Amonova A. V., Ganiev I. N. Influence of the pH of the Medium on the Anodic Behavior of Scandium – Doped Zn55Al Alloy. Russian Journal of Non-Ferrous Metals. 2013, 54(3), 234–238. DOI: 10.3103/S 1067821213030115

- Obidov Z. R. Anodic Behavior and Oxidation of Strontium – Doped Zn5Al and Zn55Al Alloys. Protection of Metals and Physical Chemistry of Surfaces. 2012, 48(3), 352–355.

- Firuzi H., Jobirov U. R., Obidov Z. R. Effect of neodymium and erbium on the kinetics oxidation of Zn0.5Al zinc alloy, in solid state. Journal of Siberian Federal University. Engineering & Technologies. 2022, 15(5), 561–568. DOI: 10.17516/1999–494X‑0417

- Obidov Z.R., Amonova A. V., Ganiev I. N. Effect of Scandium Doping on the Oxidation Resistance of Zn5Al and Zn55Al Alloys. Russian Journal of Physical Chemistry A. 2013, 87(4), 702–703. DOI: 10.1134/S 0036024413040201

- Turakhodjaev N., Shukhrat C. and at al. Ways to increase the strength of the surface of the parts. Journal of Critical Reviews. 2020, 7(11), 380–386.

- Dzhakhangirovich T.N., Makhmatmurodovich C. S., Khusniddinovich T. N. Development of Machined Durable Parts of Modified 110g13l Brand Steel. Eurasian Scientific Herald. 2023, 17, 21–24.

- Karimov K., Turahodjaev N., Akhmedov A., Chorshanbiev Sh. Mathematical model for producing machine parts. E 3S Web of Conferences. 2021, 264, 40–78.

- Yang W. Ruizhi Wu, Turakhodjaev N., Meiduo Liu. Microstructural evolution, precipitation behavior and mechanical properties of a novel Al–Zn–Mg–Cu–Li–Sc–Zr alloy. Journal of Materials Research. 2021, 36, 740–750.

- Turakhodjaev N., Tursunbaev S., Umarova D., Kuchkorova M., Baydullaev A. Influence of alloying conditions on the properties of white cast iron. International Journal of Innovations in Engineering Research and Technology. 2020, 7(12), 1–6.

- Torakhodjaev N.D., Yakubov L. E., Tursunov S. Mathematical Model of Heat Treatment to Improve TX Mechanical Properties. Composite materials. 2018, 43–52.

- Turakhodjaeva F.N. et al. The process of developing a technology for extracting copper and other nonferrous metals from industrial slags. Corporate Governance: Theory and Practice. Collection of scientific papers on. 2019, 23, 363–364.

- Nodir T., Shukhrat C., Nargiza S. & Kulmukhammad C. Ways to increase the strength of shaftgear teeth working in a highly abrasive grinding environment. Journal of Critical Reviews. 2020, 7(7), 904–907.

- Kholmirzaev N., Turakhodjaev N., Sadikova N. Improvement of the Melting Technology of 35XГСЛ Brand Steel Alloy in An Electric ARC Furnace. Role of Exact and Natural Sciences During the Renaissance III. 2023, 60–64.

- Kholmirzaev N. et al. Technology of Processing the Liquid Steel Alloy Obtained in an Electric ARC Furnace Outside the Furnace. Central Asian Journal of Theoretical and Applied Science. 2023, 4(4), 61–64.

- Nodir T. et al. Ways to increase the strength of the surface of the parts. Journal of Critical Reviews. 2020, 7(11), 380–386.

- Turakhodjaev N. et al. Effect of metal crystallation period on product quality. Theoretical & Applied Science. 2020, 11, 23–31.

- Turakhodjaev N., Tashbulatov Sh., Zokirov R., Tursunbaev S., Baydullaev A. Studying the scientific and technological bases for the processing of dumping copper and aluminum slags. Journal of Critical Reviews. 2020, 7(11). doi.org/10.31838/jcr.07.11.79

- Wang Y. et al. Microstructure and mechanical properties of ultra-lightweight Mg-Li-Al/Al-Li composite produced by accumulative roll bonding at ambient temperature. Materials Science and Engineering: A. 2020, 787, 13–19.

- Turakhodjaev N.D. et al. Analysis of defects in white cast iron. Theoretical & Applied Science. 2020, 6, 675–682.

- Wang Y., Zhong F., Wu R., Wu H., Turakhodjaev, N., Kudratkhon, B. Zhang, M. High-strength, ductility and modulus Al–Li/B 4C composite with near nanostructure produced by accumulative roll bonding. Journal of Alloys and Compounds. 2020, 834, 155105.

- Turakhodjaev N. et al. Quality improvement of the steel melting technology in an electric arc furnace. ACADEMICIA: An Intern. Mult. Research Journal. 2021, 11(7), 48–54.

- Yang Z., Ji P., Wu R., Wang Y., Turakhodjaev, N., Kudratkhon, B. High-strength, ductility and modulus Al–Li/B 4C composite with near nanostructure produced by accumulative roll bonding. International Journal of Materials Research. 2023, 114(1), 65–76.