Development scenarios for Russia's dairy industry

Автор: Kuzin Andrei A., Medvedeva Natalya A., Zadumkin Konstantin A., Vakhrusheva Vera V.

Журнал: Economic and Social Changes: Facts, Trends, Forecast @volnc-esc-en

Рубрика: Economics of the agro-industrial complex

Статья в выпуске: 6 (60) т.11, 2018 года.

Бесплатный доступ

Innovative modernization of Russia's dairy industry is a key factor in ensuring the country's food and environmental security in the context of increasing export orientation. The goal of our research is to substantiate the concept for development of the dairy industry in Russia and to develop forecast scenarios for its functioning based on the introduction of the best available technologies. The paper reveals specific features of functioning of the industry and the contradictions they cause. We conclude that effective development of the industry is possible only under balanced state policy that takes into account international experience and the challenges that the industry has to deal with. We analyze the use of the best available technologies in the dairy industry in Russia and propose a model for development of the concept of the dairy industry on the basis of the best available technologies. Our scenarios for development of Russia's dairy industry are of practical interest, as well as our conclusion that the state policy for the development of this industry should be based on an innovative scenario involving its system modernization, which will help ensure food and environmental security of the country and promote dairy products exports...

Dairy industry, best available technologies, state policy

Короткий адрес: https://sciup.org/147224121

IDR: 147224121 | УДК: 63001 | DOI: 10.15838/esc.2018.6.60.5

Текст научной статьи Development scenarios for Russia's dairy industry

Introduction. Socio-economic changes taking place in Russia in the late 20th – early 21st century and caused by globalization make it necessary to revise the approaches to the management of the dairy industry1 as part of the agro-industrial complex of the country. Thus, it is appropriate to consider this industry on the basis of a functional approach with elements of a system approach that combines demographic, environmental, economic and institutional aspects [1]. In accordance with the decree of the President of the Russian Federation “On national goals and strategic objectives for development of the Russian Federation until 2024” dated May 7, 2018 No. 204, in order to implement scientific and technological breakthrough in the agro- industrial complex it is necessary to create a high-performance export-oriented sector that would be developing on the basis of modern technologies. According to the Concept for long-term socio-economic development of the Russian Federation for the period up to 2020, technological changes are among the main factors that determine strategic development of the economy. In European practice, ecological and environmental permits are among the key instruments that help reduce the negative impact of industry on the environment, promote compliance of industrial enterprises with environmental requirements and facilitate technological innovation [22]. The principle of BAT (best available technologies) was introduced into international practice2

in 2006 [20; 21]. Meanwhile, in Russia, the regulatory documents that determine the vector of development of the dairy industry pay little attention to the introduction of the best available technologies. In this regard, an in-depth study of the current state of the dairy industry and the development of a vision for its long-term development is important and timely.

The goal of our research is to substantiate the choice of a long-term strategy for development of the dairy industry on the basis of the best available technologies that ensure food and environmental safety of the Russian Federation. We achieve the goal by implementing the following tasks:

– we review theoretical and methodological aspects related to the elaboration of forecast scenarios for development of economic systems;

– we identify and consider the factors that affect the development of the industry;

– we define the features of introduction of the best available technologies on the basis of foreign experience;

– the forecast scenarios of development of the Russian dairy industry on the basis of introduction of the best available technologies are developed.

Our paper reveals specific features in the functioning of the dairy industry and the contradictions in its development that they cause. We analyze the application of the best available technologies in the industry and elaborate a concept for its development. This approach helps increase the reliability of industry development strategies and reduce the risks arising in the dairy industry. The scientific novelty of the research consists in the proposed model for the concept of the dairy industry development through the introduction of the best available technologies until 2030.

Classical works of the school of Professor I.V. Bestuzhev-Lada [2] contain the research on the strategies for development of economic systems since the 1950s. Global theories have been developed to support long-term forecast scenarios. The team of scientists under the leadership of the Nobel prize winner in Economics W.W. Leontief developed a longterm forecast of the world economy up to the year 2000 on the basis of a unique interregional model of input-output tables [3].

In the 1950–1970s, the Soviet Union formed a school under the leadership of academicians A.N. Efimov, A.I. Anchishkin, and V.A. Kotelnikov [4; 5]. In the 1980s, the pace of research on forecast scenarios of development decreased due to the transition from industrial to post-industrial society.

In the modern world, a developed economy is formed on the basis of forecast economic strategies and scenarios. As a rule, in most developed countries of the world, forecasting is considered to be the most important management function of the state [6; 7; 8].

The substantiation of the methodology for long-term forecasting in Russia was tested in the GOELRO plan (1920–1935); it was compiled for a number of large regions of Russia and considered sectoral and territorial aspects. The main developers of the concepts were economists N.D. Kondratiev, M.M. Sokolov, S.F. Demidov, V.S. Nemchinov. The theory of foresight, forecasting methodology and longterm planning was founded by Academician N.D. Kondratiev, a representative of Timiryazev Agricultural Academy and the author of the concept of “long waves” [9; 10]. At this stage, three mechanisms for development of the strategies have been identified: North American (Canada, USA), Asian (China, Japan, South Korea), and Western European (Sweden, France).

The second half of the 20th century witnessed a revival of research on socioeconomic forecasting and scientific substantiation of foresight methodology. The most prominent researchers of the time were M. Mesarovic and E. Pestel [11; 12]. The results achieved in this field helped outline the range of future problems in overcoming inequality between countries, protecting the environment and mitigating climate change under the influence of the human factor and the choice of alternative options for development of human civilization [13; 14; 15].

Ignoring science as a driving force of technological progress in the long term leads to the country’s lagging significantly behind economically developed countries. According to Academician A.A. Dynkin, Director of the Institute of World Economy and International Relations of the Russian Academy of Sciences, “globalization affects the quantitative parameters of growth; innovation affects the quality and the paradigm of development... Money turnover will resume only if there are products of a new quality. Innovations address these very issues [16, p. 56].

All of the above is relevant for the dairy industry in Russia. The works of many domestic and foreign scientists (S.A. Andrianov, I.M. Baynazarov, M.G. Mironov, P. Draker, B. Santo, R. Nelson) consider how to work out a strategy for its development. The scientific knowledge base that defines the features of strategic development in the conditions of mass and continuous introduction of innovations is created [17; 18]. At the same time, the issues related to the substantiation of the strategy for development of the dairy industry through the introduction of the best available technologies to guarantee the environmental safety of products remain insufficiently investigated [19]. Therefore, the goal of our study, the results of which are reflected in the present paper, is to substantiate the need to promote the development of the domestic dairy industry on the basis of the introduction of the best available technologies.

Methodology and technique. The dairy complex of Russia, which covers the entire technological cycle from the creation of raw milk to the production and sale of dairy products, includes dairy cattle breeding, feed production, dairy industry, servicing and trading organizations. The object of analysis in our article is the dairy industry as an economic system, which includes social, economic, organizational and managerial mechanisms of effective functioning and development. The subject of the analysis includes organizational, economic, social processes and relations that characterize and determine the rationale for forecasts and strategies for development of the dairy industry in Russia. The study is based on the fundamental methodological and theoretical provisions, legal documents of the public authorities of the Russian Federation. We use the following methods and approaches: a) monographic (study of the laws and trends of the dairy industry); b) abstract and logical (generalization of conceptual and methodological approaches to the substantiation of directions for development of the dairy industry); c) economic and statistical (study of the trends in the industry); d) expert assessments (development of forecasts of the industry); e) scenario forecasting (substantiation of development scenarios) and others. The application of conceptual provisions of these theories as a starting point in the substantiation of our own version allows us to show its advantages and scientific contribution due to the integration of various theoretical positions and views while maintaining the integrity of scientific approaches to the scientific problem under consideration.

The results of research into the Russian dairy industry at the present stage . There are about 20 thousand enterprises functioning in the industry; they produce about 30 million tons of milk and employ more than 1 million people. The average consumption of milk and dairy products in terms of milk in 2016 amounted to 238 kg per person per year at a rate of consumption equal to 392 kg.

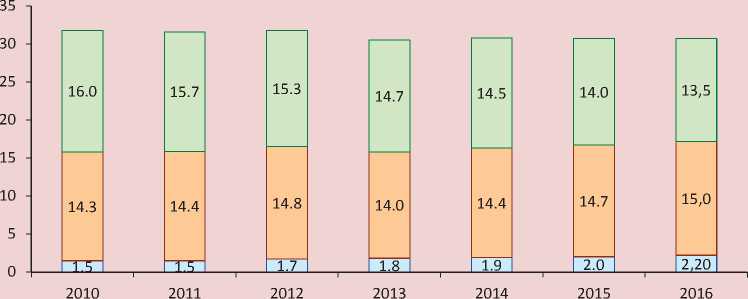

As one of the world’s largest milk producers, the Russian Federation is inferior in terms of the efficiency of its production compared to the countries with developed economies; Russia has a lower share of marketable milk in total production – 65.3%. The volume of production of raw milk in Russia is shown in Figure 1.

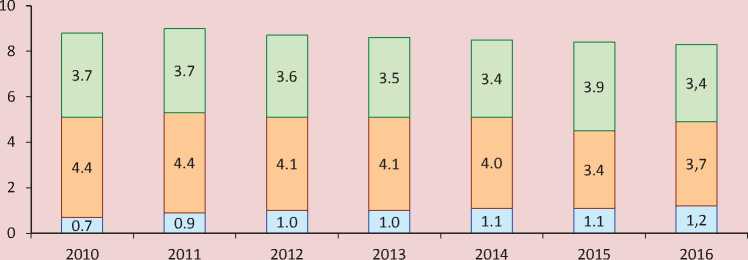

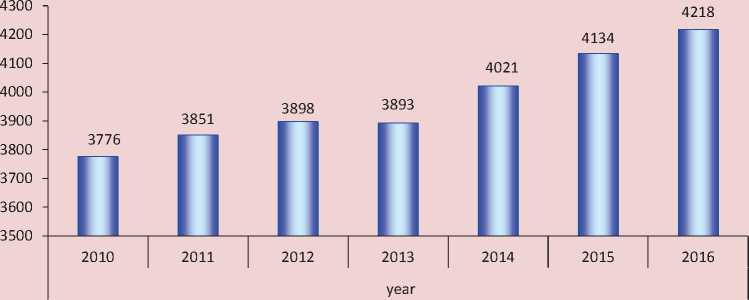

The number of cows in all types of farms during the period under consideration tends to decrease (8.8 million head in 2010 against 8.3 million head in 2016; Fig. 2 ), although their productivity is steadily increasing (Fig. 3) .

Figure 1. Milk production in Russia, million tons

□ Peasant (farmer) enterprises □ Agricultural organizations

□ People's households

Source: our compilation with the use of: Russian Statistical Yearbook: Statistics Collection. Rosstat. Moscow, 2017. 870 p.

Figure 2. Cow population in agriculture in Russia, million head

□ Peasant (farmer) enterprises □ Agricultural organizations

□ People's households

Source: our compilation with the use of: Russian Statistical Yearbook: Statistics Collection. Rosstat. Moscow, 2017. 870 p.

Table 1. Utilization of production capacities in the milk processing industry of Russia, in %

|

Indicator |

2014 |

2015 |

2016 |

2016 to 2014, in p.p. |

|

Whole milk products (in terms of milk) |

61.1 |

60.1 |

59.10 |

- 2.00 |

|

Condensed milk products |

58.2 |

58.6 |

59.76 |

1.56 |

|

Milk powder and cream powder |

42.4 |

40.3 |

39.05 |

- 3.35 |

|

Butter |

32.1 |

33.1 |

30.94 |

- 1.16 |

|

Cheese and cheese products |

62.4 |

60.9 |

59.06 |

- 3.34 |

|

Source: our compilation with the use of: Russian Statistical Yearbook: Statistics Collection. Rosstat. Moscow, 2017. 870 p. |

||||

Figure 3. Productivity of cows in Russian agriculture, kg per cow

Source: our compilation with the use of: Russian Statistical Yearbook: Statistics Collection. Rosstat. Moscow, 2017. 870 p.

The dairy industry of the country faces a number of challenges and problems. These include: a) incomplete provision of enterprises with raw milk (Tab. 1) caused, among other things, by a reduction in the number of animals3; b) lack of state support; c) flaws in the pricing policy, etc.

Despite this, in 2016, the output of most types of dairy products, especially cheese and cheese products, and the share of domestic milk and dairy products in the total volume of their resources (taking into account the structure of carry-over stocks) increased (Tab. 2) .

In addition to economic challenges, the dairy industry in the Russian Federation faces the problems of facilities and equipment upgrade and the task of reducing the negative impact on the environment. And they are no less important: the annual discharge of wastewater in the industry is 25–30 million cubic meters.

Federal Law 219-FZ “On amending Federal Law “On environmental protection” and certain legislative acts of the Russian Federation” dated July 21, 2014, which entered into force January 1, 2015, regulates the transition to the system of technological regulation of negative environmental impact on the basis of the best available technologies

Table 2. Production of the main types of dairy products in Russia, thousand tons

|

Indicator |

2014 |

2015 |

2016 |

2016 to 2014, in % |

|

Whole milk products (in terms of milk) |

11445.3 |

11625.7 |

11854.7 |

103.6 |

|

Liquid processed milk |

5317.4 |

5377.9 |

5490.5 |

103.3 |

|

Cream |

115.5 |

121.1 |

125.5 |

108.6 |

|

Curd |

382.6 |

413.3 |

405.1 |

105.9 |

|

Yogurt |

776.9 |

765.5 |

778.8 |

100.2 |

|

Kefir |

1082.8 |

1067.6 |

1068.1 |

98.6 |

|

Boiled fermented milk (“Ryazhenka”) |

216.2 |

217.2 |

221.3 |

102.3 |

|

Sour cream |

550.3 |

586.6 |

567.9 |

103.1 |

|

Cheese and cheese products |

494.3 |

581.3 |

599.7 |

121.3 |

|

Butter |

250.8 |

258.9 |

247.4 |

98.7 |

|

Source: our compilation with the use of: Russian Statistical Yearbook: Statistics Collection. Rosstat. Moscow, 2017. 870 p. |

||||

[23; 24]. The procedure for their determination is spelled out in a number of legal acts4.

In accordance with the rules, when classifying technological processes, equipment, technical methods and methods as BAT, it is necessary to take into account the following indicators:

– minimal negative impact on the environment;

– cost-effectiveness of implementation and operation;

– application of resource and energy saving methods;

– time period for implementation;

– implementation of technological processes, equipment, technical methods at facilities that have a negative impact on the environment.

In the process of research on the best available technologies used in the dairy industry, we used the information obtained from a survey of dairy enterprises, publications in the open press and information from industry experts [25; 26].

The results of the questionnaire survey5 show that large enterprises of the dairy industry of the Russian Federation actively upgrade production and reduce production costs associated with the operation of technological equipment. Thus, at present, specific energy costs (heat and electric power) are comparable with the data of European dairy producers [27] (Tab. 3) .

Water is one of the most important resources consumed in the production of dairy products. It is used for washing the equipment and production facilities, as well as for cooling the products. Specific water consumption for the production of certain types of Russian products is close to the volumes consumed by European dairy producers (Tab. 4) .

When analyzing the data, it is necessary to take into account the conversion factor that characterizes the specific consumption of milk for the production of a dairy product (for example, 10 liters of milk is spent on the production of one kilogram of cheese).

Table 3. Consumption of heat and electric power for the production of dairy products of Russian and European manufacturers

Product Specific energy consumption According to the questionnaire survey of domestic enterprises, per liter of processed milk According to foreign sources*, per liter of processed milk Electrical power, kWh Liquid milk and fermented milk products 0.02 – 0.24 0.07 – 1.1 Curd 0.14 – 0.39 No data Cheese 0.13 – 1.1 0.12 – 2.08 Butter 0.12 – 0.57 No data Condensed milk 0.02 No data Dry milk 0.177 – 0.562 0.18 – 6.47 kWh Ice cream 0.5 0.75 – 1.6 kWh Heat energy (steam), kg Liquid milk and fermented milk products 0.08 – 0.16 No data Curd 0.08 – 0.66 No data Cheese 0.02 – 0.035 No data Butter 0.06 – 0.84 No data Condensed milk 0.72 No data Dry milk 2.02 No data Ice cream No data No data * Source: Official website of the European Commission. Available at:

Table 4. Water consumption for the production of dairy products by Russian and European producers

|

Product |

Specific water consumption, liters |

|

|

According to the questionnaire survey of domestic enterprises, per liter of processed milk |

According to foreign sources*, per liter of processed milk |

|

|

Liquid milk and fermented milk products |

1.32 – 4.5 |

0.6 – 4.1 |

|

Curd |

1.46 – 3.0 |

- |

|

Cheese |

2.4 – 3.0 |

1.2 – 3.8 |

|

Butter |

1 – 2.5 |

- |

|

Condensed milk |

8 |

- |

|

Dry milk |

3.9 |

0.69 – 6.3 |

|

Ice cream |

6 |

- |

* Source: Official website of the European Commission. Available at:

Water consumption per ton of milk, which is processed at milk processing plants, varies from 4.2 to 6 cubic meters. Out of the total water consumption, most of the water, up to 85%, is sent by dairy plants to the sewerage after primary use.

About four tons of sour whey is formed during the production of one ton of curds. Waste water in the dairy industry consist mainly of milk residues, whey (one cubic meter of whey is equivalent to 100 cubic meters of domestic waste water), contain alkaline and acidic chemicals that were used for sanitation. Wastewater generated by dairy plants is characterized by high organic load, unstable pH and temperature and a significant content of nitrogen and phosphorus. As a rule, these effluents end up in urban wastewater treatment plants, only a small proportion of dairy plants have their own treatment facilities. The load on wastewater treatment facilities is quite high due to the significant amount of residual milk fat, proteins and “short” carbohydrates, as well as chemical compounds used for washing the equipment. But the main problem is the fluctuation of pH, disrupting the balance of the biological components at the treatment facilities. To avoid this, a pre-treatment area for wastewater is usually created at dairy plants.

Another equally important environmental issue related to production is air pollution by powder during the drying of dairy products. In order to clean the exhaust air in spray dryers, various aspiration devices, including cyclones, are used. However, their cleaning efficiency is insufficient, and part of the product remains in the exhaust air. For instance, when drying skim milk in the dryers with a capacity of one cubic meter of evaporated moisture per hour, the loss of product with air can reach 23 kg/h, and the exhaust air contains from 40 to 170 mg of product in one cubic meter.

Thus, wastewater treatment and air treatment seem to be the most obvious and indemand areas of BAT implementation.

The analysis and generalization of international experience in determining approaches to the selection of the best available technologies for the dairy industry and the preparation of a handbook on BAT leads to the conclusion that the integrated (environmental, environmental) permits are one of the key tools to reduce the negative impact of industry on the environment in the European practice. In addition, they ensure the compliance of the industry with environmental requirements and encourage technological innovation [28–32]. We should note that in the world practice there is no direct stimulation of the transition to the best available technologies. The costs of their implementation are partially compensated by reducing the costs associated with the implementation of the established requirements and reducing the responsibility for causing possible or real harm to the environment. At the same time, the role of market incentives such as resource saving and increasing the competitiveness of production is significantly increasing.

The idea of transition to the management of the Russian dairy industry development, which forms the environment of functioning, instead of “adaptation” to the existing circumstances, is, in our opinion, the key one in understanding the strategic goal of upgrading dairy enterprises.

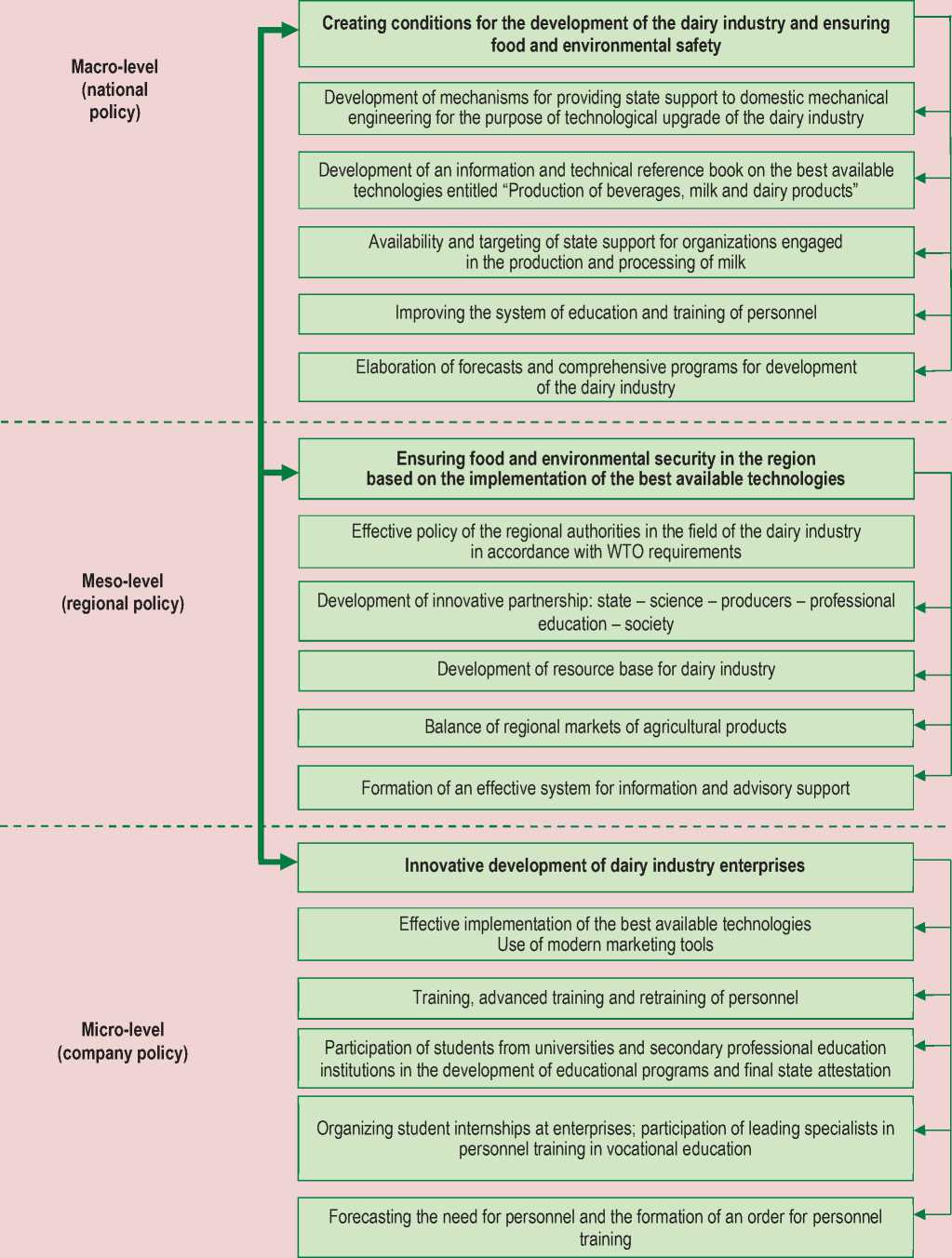

The essence of our concept consists in the formation of directions for development of the dairy industry based on the increasing role of the human factor, promotion of innovation through the introduction of the best available technologies that ensure food and environmental safety, allowing the industry to increase competitive potential.

In order to achieve the goal, a number of ideological approaches should be used constructively.

-

1. Purposeful improvement of the dairy industry in the future requires an understanding of the current changes taking place in Russia and the world in connection with the development of science and technology.

-

2. The basis for the introduction of BAT is the use of scientific achievements available in the world and in Russia. At the same time, it is necessary to provide basic research with significant state support, to organize active and systematic interaction of educational institutions and enterprises of the industry in the training of highly qualified personnel, to create motives and incentives for the environmental modernization of Russia’s dairy industry.

-

3. Pilot projects, the development of a BAT handbook and technology indicators can be effective tools for promoting the best available technologies.

-

4. It is necessary to revise the procedure of collecting and arranging the data: a) on the levels of emissions of marker substances; b) on the consumption of raw materials and energy resources; modernization of basic and environmental equipment and on the economic aspects of introduction of the best available technologies.

-

5. Energy-saving technologies should serve as the basis for practical implementation of the innovation strategy.

-

6. It is necessary to develop a system for effective use of resources and create a favorable investment climate to increase investment in the implementation of the best available technologies in the dairy industry.

Figure 4. Concept for development of the dairy industry through the introduction of the best available technologies

Source: our own compilation.

These approaches serve as the foundation for the concept that we developed on the basis of introduction of the best available technologies (Fig. 4) .

In the course of elaborating the forecast scenarios for development of the dairy industry we took into account provisions of Federal Law 172 “On strategic planning in the Russian Federation” dated June 28, 2014, the Forecast of long-term socio-economic development of the Russian Federation for the period up to 2030, the Strategy for development of the food and processing industry of the Russian Federation for the period up to 2020 (approved by Resolution 559-r of the Government of the Russian Federation dated April 17, 2012), the Concept for long-term socio-economic development of the Russian Federation for the period up to 2020 (approved by Resolution 1662-r of the Government of the Russian Federation dated November 17, 2008), the State program for agricultural development, regulation of markets for agricultural products, raw materials and food for 2013– 2020 (approved by Resolution 717 of the Government of the Russian Federation dated July 14, 2012) [34–38].

According to the results of the study, we define the following factors that should be taken into account in the long-term forecasting of trends in the development of the dairy industry:

-

* intensity of innovative renewal of production and dynamics of labor productivity;

-

* improving the quality of labor resources;

-

• level of state support;

-

* degree of importance of Russian products in the domestic and foreign markets;

-

* level of financial stability of milk processing enterprises.

Given these aspects and their impact on the development of the dairy industry in the long term, we consider it advisable to determine three scenarios of its development: 1) conservative, 2) innovative and 3) target-oriented (accelerated) (Tab. 5).

The conservative scenario implies a slow and long-term recovery of the dairy industry with the use of available resources. There will be no significant changes in the organizational and economic mechanisms of state regulation of the agro-industrial complex and in the amount of support from the budget. The concentration of capital and production capacity within large holdings and the gradual shutting down of small and medium-sized independent industries will continue. The conservative scenario does not provide competitive advantages to organizations in the conditions of functioning under the WTO and does not ensure compliance with the requirements of the Food security doctrine of the Russian Federation [39] and the federal law “On environmental protection”. The implementation of this scenario does not ensure long-term competitiveness of the dairy industry.

The innovative scenario is characterized by the strengthening of investment orientation in agriculture. It is based on the modernization of resources, facilities and equipment within the dairy industry through the introduction of

Table 5. Main characteristics of development scenarios for the dairy industry in Russia

|

Development scenario |

Criteria |

|||

|

Dairy industry development dynamics |

State support |

Educational activity |

Innovation activity in the dairy industry |

|

|

о |

The development of the dairy industry in the long term is not ensured. Available resources are used. Production tends to decrease with the growth of imports of goods and technologies. Low level of implementation of BAT. |

State policy is based on the preservation of preferential tax treatment, which is contrary to WTO requirements. |

Reduction in funding for higher education institutions, and the development of the secondary education system. |

Resource provision of innovation activities will be carried out by private investors, which will not provide the necessary amount of capital investment and will adversely affect the changes in the infrastructure of the agro-industrial complex. Labor productivity growth is 1.1 times by 2018 and 1.5 times by 2030 in relation to the level of 2016. |

|

> |

Development of the dairy industry with an annual growth of up to 2–4%, in case the state subsidies are preserved. The increase in the share of products using BAT to 35–40% relative to 2016. Twofold growth in investment by 2030 as compared to 2016. Expansion of production of dairy products in connection with the decline in the purchasing power in people’s money incomes. |

State support in accordance with WTO requirements. Improvement of the investment climate. |

Modernization of professional education with the qualitative renewal of the teaching staff. Improving the efficiency of human capital use. |

Strengthening of investment and innovation activity, modernization of fixed assets, technological re-equipment of enterprises in the agro-industrial complex in accordance with modern requirements. Labor productivity growth by 1.2% in 2018 and by 1.8 times by 2030 compared to 2016; formation of new centers of innovation development. |

|

Accelerated growth rates of the agro-industrial complex. Technological upgrade of the dairy industry. Significant inflow of foreign capital. Ensuring the requirements of the Food security doctrine of the Russian Federation and the federal law “On environmental protection”. Improving the competitiveness of the dairy industry. Increasing the share of products using BAT to 75– 80%. |

Significant state support inaccordance with WTO requirements. Improvement of the investment climate |

Increase in education costs in order to improve the quality of training of students in agricultural education institutions. Improving the quality of human capital by creating a resource center in the region. |

Shifting the agro-industrial complex to an innovative way of development. In the dairy industry – the formation of research teams together with educational institutions and the implementation of applied research for the dairy industry. |

|

|

Source: our own compilation. |

||||

BAT and involves the influence of innovative factors while improving the efficiency of human capital in 2020–2022 [39]. The scenario will help ensure food and environmental security of the country. It provides for the development of the dairy industry with an annual growth rate of 2–4% (while maintaining the provision of state support to agricultural producers in the next 10 years). Increased competition in the domestic and global markets will make it possible to attract investments in the agroindustrial complex, the volume of which will increase by 2030 by 2 times to the level of 2014, which will contribute to the strengthening of the raw material base of the dairy industry.

The implementation of this scenario will lead to an increase in the spending on education up to 6.5% of GDP by 2030. This will provide support to universities that train personnel for the dairy industry. Education reform also implies a qualitative renewal of the teaching staff – the transition to effective contracts between staff and educational institutions is inevitable. This mechanism guarantees professional development of scientific and pedagogical staff due to the fact that their responsibility for the results increases.

The innovative scenario in comparison with the conservative one has a number of advantages that will be manifested in improving the quality parameters of development of the agroindustrial complex, especially in the field of efficiency of human capital utilization, already in the medium term.

The target-oriented (accelerated) scenario is created on the platform of the innovative scenario. Accelerated growth rates of production and investment are its advantages. The scenario provides for a full-scale implementation of all tasks set out in Decrees6 596 and 204 of the President of the Russian Federation dated May 7, 2012. It is expected that the share of products produced with the use of the best available technologies and resourcesaving technologies will reach 75–80% in the industry.

The scenario assumes an increase in spending on vocational education up to 8% of GDP by 2030, which will make it possible to implement changes in the industry, to ensure the introduction of a modern education system and the achievement of the main indicators of the average values for OECD countries7. In the field of education, it provides for the increase the level of remuneration of teachers through the transition to a system of effective contract, to specialized training of high school students, which creates conditions for indepth study of certain subjects that determine the choice of future profession. The scenario also provides for the following measures: assistance to universities engaged in training personnel for the industry; modernization of resources, facilities and equipment in the sphere of education. Applied research aimed at the application of new knowledge to achieve practical goals and objectives for the dairy industry will be implemented with the involvement of budget funds by co-financing the project and creating research teams in conjunction with higher education institutions of the relevant profile.

Conclusions. Our study clearly shows that currently in Russia it is necessary to develop an effective mechanism to implement the selected priorities in the framework of the national innovation system. This mechanism should include: a) development and regular adjustment of long-term forecasts of socio-economic development of the dairy industry, taking into account global trends; b) selection of development priorities; c) development of regional strategic plans and target programs that implement the selected priorities on the basis of innovative partnership of business, government, creative individuals and society.

The results of our study will help:

-

1. Make well-founded management decisions using comprehensive forecast indicators of the dairy industry based on the use of the best available technologies in the medium and long term.

-

2. Improve the quality of the information base for analysis, forecasting and monitoring the effectiveness of the development of the dairy industry as an economic system.

-

3. Form science-based forecasts of the parameters of the effectiveness of development of the dairy industry in the medium and long term.

The results of our study can be used by legislative and executive authorities in the development of a legal framework of the state policy for the dairy industry according to the selected priorities. Some theoretical and practical recommendations can be useful in the educational process in universities, as well as to managers and specialists of the dairy industry, who are engaged in the development of the dairy industry through the use of BAT.

Список литературы Development scenarios for Russia's dairy industry

- Medvedeva N.A. Prognozirovanie razvitiya sel'skogo khozyaistva Evropeiskogo Severa Rossii . Vologda-Molochnoe: ITs VGMKhA, 2017. 181 p.

- Bestuzhev-Lada I.V. (Ed.). Mir nashego zavtra: antologiya sovremennoi klassicheskoi prognostiki . Moscow: Eksmo, 2003. 214 p.

- Kuzyk B.N., Yakovets Yu.V. Rossiya-2050: strategiya innovatsionnogo proryva . Moscow: Ekonomika, 2005. 624 p.

- Anchishkin A.I. Prognozirovanie tempov i faktorov ekonomicheskogo rosta . Moscow: MAKSPress, 2003. 300 p.

- Gulin K.A., Ermolov A.P. Strategic approaches to scientific and technological development potential in the territory. Problemy razvitiya territorii=Problems of Territory's Development, 2016, no. 1 (81), pp. 7-14..

- Zadumkin K.A., Anishchenko A.N., Vakhrusheva V.V., Konovalova N.Y. Enhancing the efficiency of dairy farming through improving the regional system of fodder production. Ekonomicheskie i sotsial'nye peremeny: fakty, tendentsii, prognoz=Economic and Social Changes: Facts, Trends, Forecast, 2017, vol. 10, no. 6, pp. 170-191. DOI: 10.15838/esc.2017.6.54.11

- Uskova T.V., Sychev M.F., Chekavinskii A.N. Monitoring funktsionirovaniya agropromyshlennogo kompleksa Vologodskoi oblasti: zaklyuchitel'nyi otchet o NIR . Vologda, 2010. 83 p.

- Medvedeva N.A. System approach to the forecasting of agriculture of the region: instruments and mechanisms. Molochnokhozyaistvennyi vestnik=Bulletin of the Dairy Industry, 2016, no. 3 (23), pp. 100-111..

- Kondratiev N., Yakovets Yu., Abalkin L. Bol'shie tsikly kon"yunktury i teoriya predvideniya . Moscow: Ekonomika, 2002. 764 p.

- Ilyin V.A., Shabunova A.A., Kalachikova O.N. et al. Natsional'naya bezopasnost' Rossii: vnutrennie ugrozy realizatsii strategii . Vologda, 2015. 218 p.

- Emel'yanov V.S. (Ed.). Mesarovich M., Takakhara Ya. Obshchaya teoriya sistem: matematicheskie osnovy . Moscow: Mir, 1978.

- Medvedeva N.A. Ways of development of regional agriculture. Vestnik Povolzhskogo gosudarstvennogo universiteta servisa. Seriya Ekonomika=Bulletin of Volga Region State University of Service. Economics Series, 2014, no. 3 (35), pp. 60-65..

- Mansfield E. Microeconomics. Theory and Applications. New York; London, 1979. Pp. 499-501.

- Nakatani T. Price competition and technical choice. Kobe University Economic Review, 1979, no. 25, pp. 68-69.

- Nelson R. Production sets, technological knowledge, and research and development: fragile and overworked constructions for analysis of productivity growth? The American Economic Review, Papers and Proceeding, 1982, vol. 70, no. 2, pp. 62-67.

- Dynkin A.A. Global crisis -an impulse for development of innovation Problemy teorii i praktiki upravleniya=Issues of Management Theory and Practice, 2009, no. 4, pp. 8-15..

- Maklakhov A.V., Tyapugin E.A., Abramova N.I. et al. Sistema razvitiya molochnogo skotovodstva na osnove sovremennykh tekhnologii proizvodstva moloka s uchetom kormoproizvodstva, kormleniya i razvedeniya krupnogo rogatogo skota v usloviyakh Evropeiskogo Severa Rossiiskoi Federatsii .Vologda-Molochnoe, 2017. 160 p.

- Maklakhov A.V., Simonov G.A., Tyapugin E.A. et al. Ot zemli do moloka: prakticheskoe posobie . Vologda-Molochnoe, 2016. 136 p.

- Kuzin A.A., Lagun A.A. et al. Organization and efficiency of the work of the dairy cluster in the Vologda Oblast. Molochnokhozyaistvennyi vestnik=Bulletin of the Dairy Industry, 2016, no. 2 (22), pp. 117-127. Available at: http://molochnoe.ru/journal..

- Dymar O.V. Energy and resource saving in the dairy industry. In: Materialy mezhdunarodnogo nauchno-prakticheskogo seminara "Innovatsionnye tekhnologii i oborudovanie dlya molochnoi promyshlennosti" . Available at: http://www.dairynews.ru/upload/iblock/05e/2016%2002%2019.pdf

- Canut A., Pascual A. Pollution prevention in food industries through both cleaning of closed equipment with ozonated water and cleaning in place (CIP) systems WATER POLLUTION IX. In: WIT Transactions on Ecology and the Environment, 2008, vol. 111, pp. 615-625.

- Evrard D., Laforest V., Villot J., Gaucher R. Best Available Techniques as a sustainability tool in manufacturing: case study in the dairy sector. 23rd CIRP Conference on Life Cycle Engineering. Procedia CIRP, 2016, no. 48, pp. 520-525.

- On amending Federal Law "On environmental protection" and some legal acts of the Russian Federation: Federal Law 219-FZ of July 21, 2014. Spravochno-pravovaya sistema "Konsul'tantPlyus" ..

- On approving the criteria for defining the objects exerting negative impact on environment as the objects of categories I, II and IV: Resolution 1029 of the Government of the Russian Federation dated September 28, 2015. Spravochno-pravovaya sistema "Konsul'tantPlyus" ..

- Agarkova E.Yu., Kruchinin A.G., Ryazantseva K.A. Optimization of the composition of emulsion and paste-like products. Molochnaya promyshlennost'=Dairy Industry, 2016, no. 8, pp. 42-44..

- Kuznetsov P.V. et al. About the choice of the equipment to dry milk and whey. Molochnaya promyshlennost'=Dairy Industry, 2015, no. 3, pp. 34-37..

- Official Website of the European Commission. Available at: http://eippcb.jrc.ec.europa.eu/reference/BREF/FDM/FDM_31-01-2017-D1_BW

- Westergaard W. Tekhnologiya proizvodstva sukhogo moloka. Vyparivanie i raspylitel'naya sushka . Copenhagen, Denmark. Available at: http://www.intent93.ru/useruploads/files/Samples/Niro_Z010_2004.pdf..

- Daddi T., De Giacomo M.R., Dils E., Polders C., Lepe G.R., Vazquez Calvo V. Transferring the integrated pollution prevention and control (ippc) approach and best available techniques (BAT) concepts to Egypt, Tunisia and Morocco. Sustainability, 2013, vol. 5, no. 7, pp. 2944-2959.

- Midzic-Kurtagic S., Silajdzic I., Kupusovic T. Mapping of environmental and technological performance of food and beverage sector in Bosnia and Herzegovina. Journal of Cleaner Production, 2010, vol. 18, no. 15, pp. 1535-1544.

- Torres Lopez E.R., Doval Leira R., Galera Martinez M., Bello Bugallo P.M. Integrated environmental permit through Best Available Techniques: Evaluation of the dairy industry. Journal of Cleaner Production, 2017, vol. 162, pp. 512-528.

- Reference Document on Best Available Techniques in the Food, Drink and Milk Industries, January 2017. 1022 p.

- On strategic planning in the Russian Federation: Federal Law 172-FZ of June 28, 2014. Spravochno-pravovaya sistema "Konsul'tantPlyus" ..

- Prognoz dolgosrochnogo sotsial'no-ekonomicheskogo razvitiya Rossiiskoi Federatsii na period do 2030 goda (razrabotan Minekonomrazvitiya Rossii . Available at: http://www.consultant.ru/document/cons_doc_LAW_144190/

- Ob utverzhdenii Strategii razvitiya pishchevoi i pererabatyvayushchei promyshlennosti Rossiiskoi Federatsii na period do 2020 goda: rasporyazhenie Pravitel'stva RF ot 17.04.2012 № 559-r (red. ot 13.01.2017). Available at: http://www.consultant.ru/document/cons_doc_LAW_128940/

- O Kontseptsii dolgosrochnogo sotsial'no-ekonomicheskogo razvitiya Rossiiskoi Federatsii na period do 2020 goda: rasporyazhenie Pravitel'stva RF ot 17.11.2008 № 1662-r (red. ot 10.02.2017) (vmeste s Kontseptsiei dolgosrochnogo sotsial'no-ekonomicheskogo razvitiya Rossiiskoi Federatsii na period do 2020 goda) . Available at: http://www.consultant.ru/document/cons_doc_LAW_82134/

- O Gosudarstvennoi programme razvitiya sel'skogo khozyaistva i regulirovaniya rynkov sel'skokhozyaistvennoi produktsii, syr'ya i prodovol'stviya na 2013-2020 gody: postanovlenie Pravitel'stva RF ot 14.07.2012 № 717 (red. ot 06.09.2018). Available at: http://www.consultant.ru/document/cons_doc_LAW_133795/

- Ob utverzhdenii Doktriny prodovol'stvennoi bezopasnosti Rossiiskoi Federatsii: Ukaz Prezidenta RF ot 30.01.2010 № 120 . Spravochno-pravovaya sistema "Konsul'tantPlyus" .

- Lachuga Yu.F. Scientific and methodological support for the development of basic and exploratory research in the field of agriculture within the agro-industrial complex. Ekonomika, upravlenie=Economics, Management, 2015, no. 2, pp. 3-11..