Digital twin for combined casting and rolling line control

Автор: Yakivyuk P.N., Piskazhova T.V., Salnikov A.V., Gofman P.M.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.23, 2022 года.

Бесплатный доступ

Aluminum alloys of all kinds are widely used in rocket and other space vehicles construction and operation - in structural elements, communication lines and power supply units. The parameters of alloys processing operations must be strictly maintained in order to exclude de-fects and obtain products of the required quality. Technologies of metal processing in space engineer-ing include such operations as casting, rolling and forming; continuous melt-crystallization-forming lines can also be used, which imposes additional requirements on the integrated control of such a line. The article is focused on the design of a digital twin to be used for controlling a combined casting and rolling complex. Basing on the previously worked-out mathematical models of the units and com-ponents of the complex (furnace, tray, mold, forming unit, rectifying and cooling assembly, spools), a special program has been designed in the TIA Portal software environment using the S7-1200 micro-processor controller, which simulates the parameter changes of both rolled metal and casting and rolling line units. The article also presents the structure and the user interface of the specified pro-gram. There are calculations of the technological cycle parameters for processing of three alloys - that gives an understanding of temperatures and speeds distribution in the rolled metal at each unit of the line. The program can be used for production lines and complexes both in preliminary processing calcu-lations for various alloys (to select the necessary control options) and during the process itself as part of the applied process control system (to confirm the cooling parameters and casting speed).

Digital twin, casting and rolling line, TIA Portal software environment, aluminum alloys processing

Короткий адрес: https://sciup.org/148329632

IDR: 148329632 | УДК: 65.011.56 | DOI: 10.31772/2712-8970-2022-23-2-347-356

Текст научной статьи Digital twin for combined casting and rolling line control

The technology of processing metals to finished products, especially long ones, features a multicycle process and includes a number of intermediate technological operations. These factors lead to high production costs and, consequently, to lower competitive ability of the product. The recent world practice of metalworking is mostly focused on building smaller integrated production lines applying technologies of making non-ferrous metal and alloy products, the processing of which is performed on one continuous production melting – molding – forming line [1]. The processing is mostly a combination of casting, metal forming and heat treatment, making it all one production line. The continuous process allows elimination of large-sized billet casting, heating and hot rolling, which reduces capital costs and significantly increases product yield. At the same time, this production technique imposes additional demands on control algorithms.

For effective and up-to-date metal processing technologies control, there arises a demand for working out special computer simulation software. These may be tools such as calculating programs displaying interrelated changes of technological parameters for varied processing conditions. Simulated calculations are performed by the in-buit process-modelling dynamic mathematical program. The experience of applying such programs in raw aluminum production are described in [2–4].

Models of casting and rolling facilities able to solve control problems is not fully described in special literature; more detailes can be found only on controlling parameters of separately taken units (modelling tension between mill stands, rolled product width regulation, etc.) [5]. There are models that describe thermal and stress-strain states of forming and molding units [1; 6]. These models were developed for stating the technological and power supply parameters of formation assemblies used in making aluminum and aluminium alloys semi-finished products with specified quality parameters.

The mathematical model that comprehensively describes the interrelated parameter changes of the units of an integrated metal processing line makes it possible to calculate and visualize the process at each location of the line. Software based on such a model is a virtual twin of a casting and rolling line and allows adjustment of control algorithms before their practical application for a specified technological cycle.

Therefore, the design of models and programs of this type is a complex scientific and technological problem, which has not been fully solved so far - this is the main factor that makes the current research applicable.

Subject of research

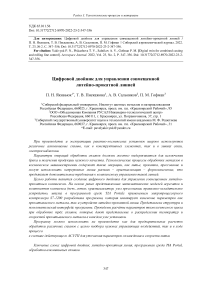

The subject is the casting and rolling complex shown in the diagram below (fig. 1). It comprises: a tray for metal tapping (1), a rotary mold (2), an induction furnace for heating the billet before rolling (3), a roll mill stand (4), a cooling-rectifying unit (5), winding spools (6).

Fig. 1. Complectation of casting and rolling line Рис. 1. Состав литейно-прокатной линии

From the furnace the metal flows to the tray that directs the molten metal into the rotary mold. The mold wheel rotates, cooling and crystallizing the metal. At the outlet of the rotary mold we get a trapezoidal billet, which is directed either to the induction furnace for additional heating, or immediately to the roll mill stand, depending on the requirements of the technological process and on the alloy type. The rolling forms a billet of the specified diameter, which is fed to the winding spools through a cooling-rectifying unit. The winding unit employs two spools that replace one another when one of them takes up the maximum number of wound wire rod layers. The rod is loaded and the spool is changed automatically.

Design of digital twing for casting and rolling line

The authors had already designed and tested models of separate units of integrated casting and rolling lines. Publications [7–8] were focused on models of production processes for combined casting— rolling-extrusion lines (CREP), metal crystallization in rotors, bar cooling and spooling. Article [9] presents a virtual CREP - a program for controlling that type of equipment. Publications [10–11] display models of billet forming in a round-shape mould, rational rate of cooling water flow to support the specified billet temperatures and prevent the mould wheel overheating.

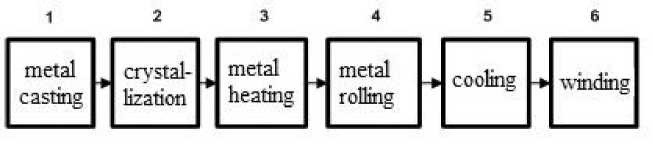

Using the above-mentioned programs in the TIA Portal software environment [12], another program was designed on the basis of S7-1200 series controller, one that provides metal temperature calculations, evaluates metal speeds along with the speeds of each complectation unit rotation (see block diagram of the program, fig. 2).

Calculation of metal temperature and billet speed at the end of the cooling section

Calculation of the time of filling the bar with one layer of the store

Calculation of the radius of the store, taking into account the already wound layers of the bar

Calculation of the angular velocity of rotation of the store

/ Output of calculation results

Fig. 2. Block diagram of the program Рис. 2. Блок-схема работы программы

The library of structures and alloys includes all thermophysical constants and structural parameters used in the model calculation.

The parameters selected are: metal density (in liquid and solid state); metal heat capacity (in liquid and solid states); density and thermal conductivity of the metal the mold is made of; heat transfer coefficients (water-metal, air-metal); structural parameters of the mold, roll mill stand and spool; distance between the units of the line; step along the x coordinate; number of calculation iterations; crystallization temperature; medium thermal conductivity coefficient; coefficient of kinematic viscosity; medium thermal diffusivity coefficient.

Metal flow rate, metal tapping temperature, temperature of cooling water, cooling water supply rate, set-point for metal temperature at the outlet of the crystallization unit, cooling water rate for the pillet as it comes out of the rolling stand, angular rotation velocity of the line units – all these are control actions that are set by the user of the program and can subsequently be changed.

Metal temperature, its flow speed and the unit angular velocity are calculated for each unit of the line. For the rotary mold, calculation of the temperature of the mould wheel proper is also made. Temperature indications are calculated step after step, as product of the numerical solution of differential equations. In the spooling unit the time of filling one layer of the accumulator with the rod is calculated continuously in order to register diameter changes and correct the angular speed of the accumulator rotation as it is filled with wire rod.

Before the calculation, the type of casting and rolling line and its complete equipment are selected. Then we preset the type of alloy chosen for the calculation. As the program starts, the library of thermophysical parameters and type sizes is accessed to acquire the data for the calculation. The next step directs the user to specify the required data of control actions for the program, or confirm the choice of values assumed by default. Metal flow rate and angular rotation velocity are interrelated, so if the metal flow gets changed, the program recalculates the angular velocities, and vice versa. Depending on the design characteristics of the line assemblies, and also on the parameters specified by the user, the feeding and temperature of metal are recalculated for each unit of the casting and rolling line. The program interface is shown in fig. 3.

The interface displays all the complectation units processing the metal in the line. For each unit there is a separate output window displaying the current technological process data calculated by the program. For the mold, these are the temperatures of the metal and the mold wheel proper at a number of locations, and of the flow rate specified by the user. For the roll mill stand, the parameters are the rod temperature, the speed of the rod feeding, the angular rotation speed of the roll stand; for the cooling section, the temperature of the rod at the output is displayed.

In the upper right corner of the screen, the user is given the options for selecting the type of casting and rolling complex, in the lower right corner of the screen - the units that will be part of the line. The program provides an option for switching on and off the water cooling of the rod after the billet exits the roll mill stand. For the winding unit, there are the program output data of the angular velocity and the number of wound layers. In the window on the right, there is a menu for managing technological processes, where the operator can change the metal flow, the amount of water for cooling, the initial tapping temperature, and also select the type of alloy. The user interface allows setting the desired temperature of the billet at the outlet of the rotary mold. As this option is activated by the corresponding key, the program changes, within the given limits, the flow rate of water for cooling the mold to the point of bringing the current temperature of the billet at the outlet closer to that specified by the user.

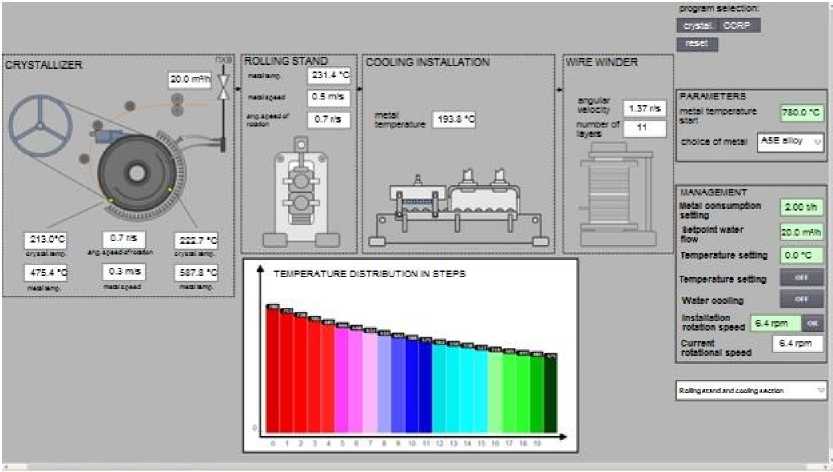

Fig. 3.Program interface with parameters for alloy A5E

Рис. 3. Интерфейс программы с расчетом сплава А5Е

The temperature histogram below the interface central field shows the calculated values of the metal temperature in the mold.

Simulation of the rolling line performance

With the help of the given program, the parameters of the entire line were calculated for three different aluminum-based alloys (see Table 1).

Table1.

Thermophysical constants of the alloys

|

Alloy |

Density, kg/m3 |

Heat capacity, J/(kg·K) |

|

А5Е |

2700 |

880 |

|

АК4 |

2770 |

797 |

|

АД33 |

2710 |

920 |

The calculations were made for the ready set casting speed and water cooling flow. The results of the calculations are shown in Figs. 3–5.

Fig. 3 presents the calculated data of the A5E alloy. The metal tapping temperature is 780 °C, the metal flow is 2 tons per hour. The metal is fed into the mold (the temperature of the billet at the outlet is 475.4 °C), then to the roll mill stand (the temperature of the rod at the outlet is 231.4 °C) and through the water and air cooling sections (the temperature of the outcoming rod is 193.8 °C) to the accumulator. The calculation was made for the water flow rate for cooling the rollers equal to 20 m3/h.

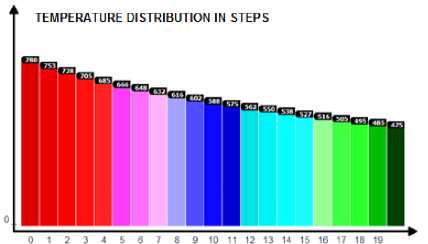

Technologists thoroughly control the metal temperature changes as it goes through the length of the mold wheel, so Fig. 4 shows these temperatures distribution diagram, step length 0.1 m. Steps from 5 to 7 refer to crystallization process, and the calculation diagram specifically points out the corresponding temperature.

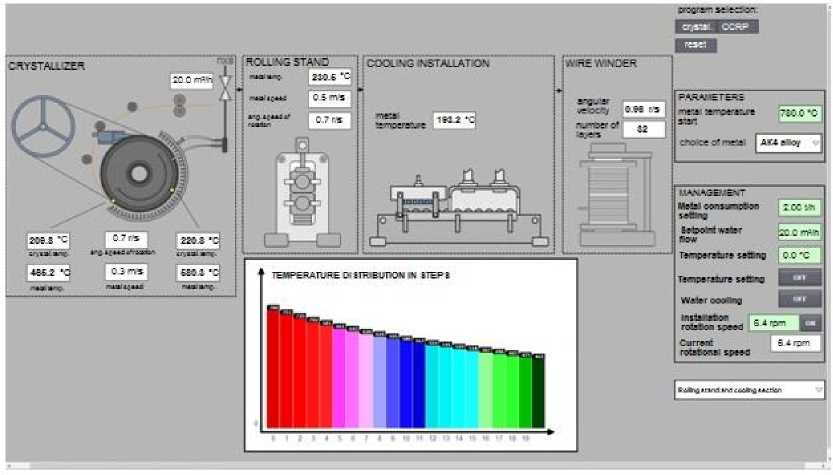

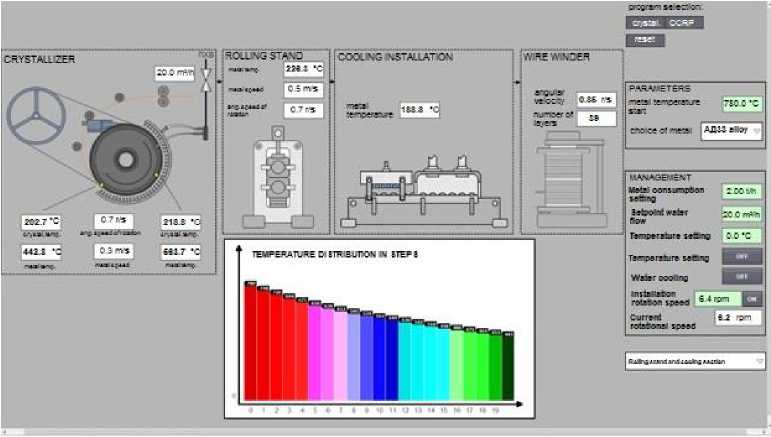

Figures 5 and 6 show the results of parameter calculations simulation for AK4 and AD33 alloys casting and rolling, at the same casting and cooling system speed as in Fig. 3 with A5E alloy parameters. The illustrations show that AD33 alloy cools faster.

Fig. 4. Program calculation of the temperature distribution in A5E alloy mold

Рис. 4. Программный расчёт распределения температуры в кристаллизаторесплава А5Е

Fig. 5. Program calculation for AK4 alloy

Рис. 5. Программный расчёт сплава АК4

Fig. 6. Program calculation for AD33 alloy

Рис. 6. Программный расчёт сплава АД33

Table 2 presents the program calculation results for three different alloys at 780 °С tapping temperature and metal flow of 2 t per hour.

Table 2

Metal temperature parameters at the unit outlets

|

Alloy |

Furnace, °С |

Mold, °С |

Roll stand, °С |

Cooling section, °С |

|

А5Е |

780 |

503,3 |

417,3 |

224,8 |

|

АК4 |

780 |

493,9 |

409,8 |

224,2 |

|

АД33 |

780 |

474,3 |

391,8 |

220,7 |

Table 3 presents the results of simulated parameter calculations for A5E alloy casting and rolling at tapping temperature of 780 °C and varied metal flow figures.

Metal temperature parameters at the unit outlets for А5Е alloy

Table 3

|

Vetal flow, ton/h |

Furnace, °С |

Mold, °С |

Roll stand, °С |

Cooling section, °С |

|

2 |

780 |

503,3 |

417,3 |

224,8 |

|

3 |

780 |

559,7 |

493,7 |

272,9 |

|

1 |

780 |

389 |

266,8 |

200,5 |

Conclusion

The program performing as a digital twin of the casting and rolling line was devised on the basis of mathematical models designed in the TIA Portal software environment. The program interface allows switching of several units on and off operation, thereby forming the sequence of the pillet processing. It also allows switching on and off the water cooling system, varying the metal flow rate, as well as the flow of water for cooling the rollers. The article presents the parameter calculations of the technological cycles for processing three types of alloys; that outlines the temperatures and speeds distribution of the rolled metal processed in sequence by each unit of the production complex. The program can be used at production lines both in preliminary processing calculations for various alloys in order to select the necessary control options, and during the process itself for confirming the cooling parameters and casting speed.

Список литературы Digital twin for combined casting and rolling line control

- Sidelnikov S. B., Dovzhenko N. N, Zagirov N. N. Kombinirovannye i sovmeshchennye metody obrabotki tsvetnykh metallov i splavov: monografiya [Combined and integrated methods of non-ferrous metals and alloys processing: a monograph]. Moscow, MAKSPress Publ., 2005, 344 p.

- Piskazhova T. V., Mann V. C. The Use of a Dynamic Aluminum Cell Model // JOM. 2006, Vol. 58, No. 2, P. 48–52.

- Piskazhova T. V. [Simulator program to support the adoption of technological decisions in the production of aluminum]. Automation in industry. 2010, No. 7, P. 41–44 (In Russ.).

- Fradet C., Bouchard B., Lapointe J., Rivard G. Multimedia for Training Cell Operators. Light Metals. 2001. P. 387–391.

- Voskan'yants A. A. Avtomatizirovannoe upravlenie protsessami prokatki [Automated control of processes of rolling]. Moscow, MGTU im. N. E. Baumana Publ., 2010, 85 p.

- Dovzhenko N. N., Belyaev S. V., Sidelnikova S. B. et al. Pressovanie alyuminievykh splavov: modelirovanie i upravlenie teplovymi protsessami [Forming of aluminum alloys: modeling and control of thermal processes]. Krasnoyarsk, SibFU Publ., 2009, 256 p.

- Sidelnikov S. B., Piskazhova T. V., Belolipetskii V. M., Yakiv'yuk P. N. [Development of a mathematical model of the CCRP casting unit, applying the method of combined casting - rolling-extrusion for making formed products from non-ferrous metals and alloys]. Metallurgiya: tekhnologii, upravlenie, innovatsii, kachestvo: sbornik trudov 17 Vseross. nauch.-prakt. konf. [Metallurgy: tech-nology, management, innovation, quality: Proceedings of the 17th All-Russian Scientific and Practical Conference]. Novokuznetsk, 2013, P. 174–178 (In Russ.).

- Sidelnikov S. B., Piskazhova T. V., Belolipetskii V. M., Yakiv'yuk P. N. [Mathematical model of the process of combined casting- rolling- extrusion to control the operation of the unit of CCRP]. Tsvetnye metally i mineraly: sbornik dokladov VI mezhdunarodnogo kongressa [Non-ferrous metals and minerals: proceedings of VI International Congress]. Krasnoyarsk, 2014, P. 1167–1170 (In Russ.).

- Sidelnikov S. B., Piskazhova T. V., Belolipetskii V. M., Yakiv'yukand P. N. et al. Virtual CCRP – a mathematical model for controlling the CCRP unit and its visualization using Wincc 7.0 and Step 7 software products. Vestnik SibGAU. 2015, Vol. 16, No. 2, P. 470–477 (In Russ.).

- Yakiv'yuk P. N., Piskazhova T. V., Belolipetskii V. M. [Mathematical model for controlling the cooling of a rotary mold]. VestnikIrGTU. 2017, Vol. 21, No. 9, P. 104–113 (In Russ.).

- Yakiv'yuk P. N., Piskazhova T. V., Belolipetskii V. M., Nesterov G. A. Virtual casting and roll-ing lines development. Mechanical and Automation Engineering for Industry 4.0: IOP Conference Series: Materials Science and Engineering, 2019. Vol. 537, No. 3. Available at: https://iopscience.iop.org/article/10.1088/1757-899X/537/3/032094/pdf (accessed: 27.12.2021).

- Siemens. Available at: https://new.siemens.com/ru/ru/produkty/avtomatizacia/industry-software/automation-software/tia-portal/programmnoe-obespechenie.html (accessed: 27.12.2021).