Dynamic stability of a straight pipe conveying pulsatile flow under thermal loads

Автор: Lolov D.S., Lilkova-markova Sv.V.

Статья в выпуске: 2, 2023 года.

Бесплатный доступ

Pipes conveying fluid are considered as a fundamental dynamical problem in the field of fluid-structure interaction. They are widely used in the petroleum industry, in nuclear engineering, aviation and aerospace, in nanostructures. This article investigates the effect of temperature load on the dynamic stability of a straight pipe conveying pulsatile flow. The fluid velocity is a harmonic function of time. The Galerkin method is applied for the solution of the differential equation of the transverse vibrations of the pipe. The differential equation is reduced to a first-order differential equation system. The system of differential equations is transformed and rewritten in a matrix form. The harmonic function of the fluid velocity allows the Floquet theory to be applied in order to investigate the dynamic stability of the system. The static scheme of the investigated pipe is a beam with restricted horizontal and vertical displacements at both of its ends. A numerical solution for a straight pipe conveying fluid with specified geometric and physical characteristics has been carried out. The temperature load and the constant fluid rate are considered as parameters of the problem. The results show that the temperature load affects the vibrational characteristics of the pipe, as well as its critical velocity.

Pipe, fluid, dynamic stability, thermal load, pulsatile flow

Короткий адрес: https://sciup.org/146282667

IDR: 146282667 | УДК: 539.3 | DOI: 10.15593/perm.mech/2023.2.01

Текст научной статьи Dynamic stability of a straight pipe conveying pulsatile flow under thermal loads

PNRPU MECHANICS BULLETIN

Fluid conveying pipes find applications in a number of areas of engineering. They are widely used in the petroleum industry for transportation of oil and gas. Another broad use of them is in the transport of water. Pipelines are also primary structural parts in power plants, hydraulic systems, air-conditioners, refrigerators etc.

Nanoscale tubes find application in nanophysics, nanobiology and nanomechanics as nanofluidic devices in nanocontainers for gas storage and nanopipes conveying fluid. The experiments at the nanoscale are difficult and expensive. That is why the continuum elastic models have been used to study the fluid-structure interaction. The carbon nanotubes are considered with Euler- and Timoshenko-beam models [1–9].

The flow of the fluid in the tube causes oscillations in it. The dynamic characteristics of the pipe’s oscillations depend on the velocity and the mass of the conveyed fluid. For pipes conveying fluid with a constant velocity it is known that the natural frequency of the pipe becomes lower when the velocity of the transported fluid increases. The velocity of the fluid corresponding to a natural frequency equal to zero is called critical velocity. At that point the system is at the edge of loss of stability. When the pipe conveys pulsatile flow, the pipe loses stability even though the mean velocity of the fluid is smaller than the critical velocity [10].

The research of the dynamic stability of pipes conveying fluid is branched into two directions: a) dynamic stability of pipes with a rectilinear axis [11–25] and b) dynamic stability of curved pipes [27–32].

The oscillations of a pipe with a flowing fluid, supported at both ends, were investigated in [36]. The global properties of the spectrum in dependence on fluid velocity, tube and fluid material densities, magnitude and direction of longitudinal force are established.

In [37] the linear stability of elastic collapsible pipes with flowing fluid is investigated, in the case when the equilibrium configuration of the pipe is helical. The geometric-variational approach was applied to study the 3D dynamics of collapsible pipes.

The dynamic stability of elastic membrane axisymmetric tubes filled with fluid was investigated in [38]. The considered fluid is non-viscous and incompressible.

Thermal loads may induce excessive vibration in the system, leading to loss of stability. Therefore, analysis of the dynamic stability due to thermal loading is essential for the safe operation of the pipeline.

The most common methods used for dynamic analysis of the pipes conveying fluid are the Transfer matrix method (TMM) and the Generalized differential quadrature method (GDQM). The both methods have significant advantage from the Finite element method (FEM). The conventional FEM can be very time consuming when it comes to investigation of a pipeline with a high number of spans. The order of the overall property matrices for the whole multispan pipeline increases with the number of spans. This is unlike the TMM in which the order of the overall transfer matrix is independent on number of spans and is kept unchanged.

The GDQM approximates a derivative of a function in the partial differential equation of the lateral vibration of the pipe at any discrete point as a weighted sum of the function values at all discrete value at the domain. The main advantage of the method is its high convergence with a small number of grid points.

The paper is structured as follows. First, it is presented the model of the pipe and the governing differential equation of its transverse vibration. The Galerkin method is employed to approach the solution of the problem. The Floquet theorem is applied to investigate the stability of the trivial solution. Finally, the obtained results from the numerical solution are presented and several important conclusions are summarized.

1. Problem formulation

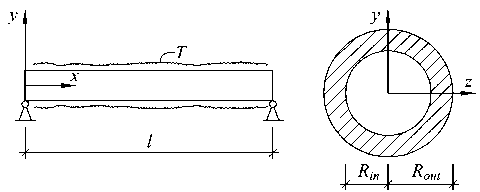

The present paper uses the Euler-Bernoulli beam theory to investigate the dynamic stability of a pipe of length l , conveying fluid and and subjected to thermal load T . The pipe, shown in Fig. 1, is hinged at its both ends.

Fig. 1. Static scheme and cross-section of the investigated pipe

The transverse vibration of a straight pipe conveying pulsatile inviscid fluid and under thermal load is governed by the following differential equation

4 22

EI— + mV2 + EAa T)+ 2mV---+ d x4 v f ’X x2 f d x d t dV d w d2 w A

+ m,+ m, + m„ = o 0, f dt dx v f p) dt2

where t is the time, w ( x , t ) is the lateral displacement of the pipe axis, x is the coordinate along the axis, EI is the rigidity of the pipe. The mass of the pipe per unit length is denoted by m p and the mass of the fluid per unit length of the pipe by m f . V is the flow velocity of the fluid in the pipe. A is the area of the cross-section of the pipe. α is the coefficient of linear thermal expansion of the material of the pipe.

The fluid velocity is the following harmonic function of the time t

V = V 0 ( 1 + 5 cos ( to f t ) ) ,

where V 0 is the constant fluid rate, 5 is the excitation coefficient and co f is the fluid pulsation frequency.

The spectral Galerkin method is applied to approximate the solution of the boundary value problem (1). According to this method, an approximate solution is sought in the form [33]:

nl

EJ { ( m f + m ) yz + 2 mV ( 1 + 5 cos ( o t ) ) yz + i = 1 0

+ [ EI ?4 y +

m f V ( 1 + 5 cos ( o ft ) ) + EA a T

— m f V 0 5 co f sin ( o f t ) y I J z i } yk dx = 0.

yi II

—

n w (x, t )=E yi(x) zi( t). (3)

i = 1

In this expression z i ( t ) are unknown functions. y i ( x ) are basic functions satisfying the boundary conditions of the tube. The eigenfunctions for the pipe with stationary fluid ( V = 0 ) are used as basic functions in the present paper.

For a Bernoulli-Euler tubular beam filled with stationary fluid, one has

5 4 w / \ 5 2 w

EI +(mf+ mp) = 0.

d xd

Free vibration of the beam has the form w (x, t ) = y (x) e o 1,(5)

where ю is the natural frequency of the beam and i = V— 1.

The substitution of (5) in (4) yields

У" ( x ) = Y 4 y i ( x ) ,

where

( m f + m p ) o 2

EI

Substituting (3) in equation (1) one obtains the residual function, which does not vanish identically since w ( x , t ) is not exact solution of equation (1). Here, and in the sequel, dots denote derivatives with respect to t and primes denote derivatives with respect to x .

For the solution of system (10) is employed the described in [33] method. The beam is divided to sections with length of A x . The integrals in (10) are expressed in the following form

Jyypdx = { y} T {у. }A x(11)

l

J yIykdx = { yI}T {Ук }A x(12)

l 1

J y"ykdx = —{Mi}T {yk }Ax(13)

In equations (11), (12) and (13):

{ y i } is a column vector of the lateral displacements of the nodes on the axis of the pipe, corresponding to the i -th eigenform of a pipe with stationary fluid;

{ y I } is a column vector of the rotations of the nodes on the axis of the pipe, corresponding to the i -th eigenform of a pipe with stationary fluid;

{ M i } is the vector of the bending moments associated with the i -th mode shape { y i } .

The substitution of (11), (12) and (13) in (10) yields

n

£ { ( m f + m p ){ y i } T { y k } z i + i = 1

+ 2 m f V ( 1 + 5 cos ( m fl ) ) { y i } T { y k } z +

R (x,t) = E {(mf + mP) УЛ + i=1

+ 2 mfV0 ( 1 + 5 cos ( o ft ) ) y I z i + EIy"z i +

+[ Ell * { y } T { y' . } +

1 г

+--

EI [

mfy0 0 ( 1 + 5 cos ( o ft ) ) 2 + EA a T { M i } T { yk }

—

+

m f V ( 1 + 5 cos ( o f t ) ) + EA a T

yi II zi

—

— mfV0 5o f

sin ( o f t ) y ' z, } .

— m f У o 5o} sin ( o t ){ y ' } T { у . } J z } A x = 0 (14)

Writing equation (14) in matrix form gives:

According to the standard Galerkin procedure, the residual function R ( x , t ) should be orthogonal to the basic functions in the area x e [ 0; l ] :

|M| z + | C ( t )| z + | K ( t )| q = 0 (15)

The equation (15) could be transformed in the following form

l

J R ( x , t ) y k ( x ) dx = 0, for k = 1,..., n (9)

The result of the application of (9) is a system of n differential equations about the unknown functions z i ( t ) . This system for the differential equation (1) is:

where

I 0

0 M

{ q } +

0 — I

K ( t ) C ( t )

{ q } = 0,

{ q } T = { q 1 = z i ;...; q n = z n ; q n + 1 = z i ;...; q 2 n = z n } (17)

After some transformations for equation (16) one obtains

{ q } = A ( t ){ q } = 0 (18) where the coefficient matrix | A ( t )| is periodic with period T , that is | A ( t + T )| = A ( t )| .

The Floquet theorem is applied to investigate the stability of the trivial solution { q } = 0 . According to the theorem the solution of the system (18) has the following form

{ q ( t ) } =Ф ( t ) { q ( 0 ) } (19) where |ф( t )| is the fundamental matrix, solution of the T – periodic system (18). The funda-mental matrix has the following form [34]

| Ф( t )A L (t) eB (20)

In (20) L (t) is a periodic matrix that has an initial val ue L (0) = I. B is a constant matrix.

The matrix |ф( T )|

is known as monodromy matrix.

p = 7800 kg / m 3 . The density of the flowing fluid is p = 1000 kg / m 3.

The finite element method was used to obtain the basic functions y, ( x ) . The eigenfunctions for the pipe with stationary fluid ( V = 0 ) are used as basic functions in the present paper. The first 14 modes were used in the present calculations.

The stability of the system is determined by the modules of the eigenvalues of the monodromy matrix (characteristic multipliers).

If all of the characteristic multipliers have modulus less than one, then the zero solution is asymptotically stable.

If all of the characteristic multipliers have modulus less than one or equal to one, and if the algebraic multiplicity equals the geometric multiplicity of each characteristic multiplier with modulus one, then the zero solution is Lyapunov stable.

If one or more of the characteristic multipliers has modulus greater than one, then the zero solution is unstable.

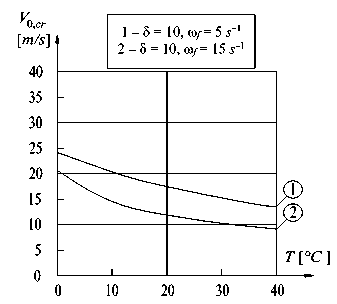

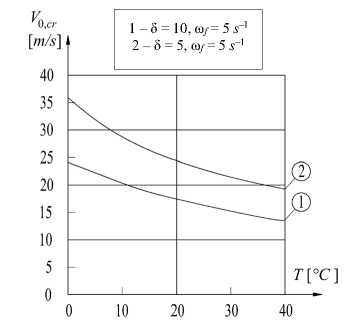

For the pipe in Fig.1 is obtained the critical value of the constant fluid rate V 0, cr for different values of the thermal load T , excitation coefficient 5 and the fluid pulsation frequency co f . The results are shown in Fig. 2 and Fig. 3.

The eigenvalues of |ф( T )| are known as characteristic multipliers. The stability of the system is determined by the modules of the characteristic multipliers of the periodic system (18) [34].

In principal the fundamental matrix is difficult to be determined in an analytic way, but there are methods to approximate it [35]. The period T is divided into k subintervals A t . For each time interval is calculated the matrix

I A ( t ) .

A = A

Fig. 2. Critical value of the constant fluid rate versus the thermal load for 5 = 10

Then the monodromy matrix |ф( T )| is calculated on the following formula

Ф( T ) = 1ПеАА '

i = 1

2. Numerical results

Numerical studies have been carried out for the system in Fig. 1.

The geometric and the material characteristics of the pipe are: the inner and the outer radii of the cross-section of the pipe are R in = 0.012 m and R out = 0.014 m , Young’s modulus E = 210 GPa , coefficient of linear thermal expansion a = 10 - 5 C - 1, the density of the material of the pipe

Fig. 3. Critical value of the constant fluid rate versus the thermal load for co , = 5 s - 1

The obtained results show that the temperature load has a destabilizing effect on the pipe – with increasing the temperature the critical velocity decreases.

Conclusion

Thermal loads on a structure could affect its integrity if they are not taken into account in the design process. The structures are subject to daily and seasonal temperature changes due to their exposure to outdoor air temperature, solar radiation or underground temperature. In the past thermal stresses have caused failures in the structures. Understanding the effect of the thermal loads on the structures, and how to minimize them, significantly reduces the risks of failure or serious damages and prevents from high repair costs.

In the present paper is studied the influence of the temperature on the stability of a pipe conveying pulsatile flow.

The employed Floquet theory, in the case when the fluid velocity is a harmonic function of the time t , allows the

Список литературы Dynamic stability of a straight pipe conveying pulsatile flow under thermal loads

- Belhadi A., Boukhalfa A., Belalia S.A. Free vibration modeling of single-walled carbon nanotubes using the differential quadrature method. Mathematical modeling of engineering problems. 2017, Vol. 4 (1), pp. 33-37.

- Reddy, C.D., Lu C., Rajendran S., Liew K.M. Free vibration analysis of fluid conveying single-walled carbon nanotubes. Applied Physics Letters. 2007, Vol. 90, pp. 133122.

- Yoon, J., Ru C., Mioduchowski A. Vibration and instability of carbon nanotubes conveying fluid. Composites Science and Technology. 2005, Vol.65 - pp. 1326 - 1336.

- Lolov D.S., Lilkova-Markova Sv. V. Dynamic stability of double-walled carbon nanotubes. Journal of the Serbian Society for Computational Mechanics. 2018, Vol.12(1), pp.1-8.

- Yoon J., Ru C.Q., Mioduchowski A, Flow-induced flutter instability of cantilever CNTs. Int. J. Solids Struct. 2006, Vol.43, pp. 3337-3349.

- Yoon J., Ru C.Q., Mioduchowski A, Vibration and instability of CNTs conveying fluid. Compos. Sci. Technol. 2005, Vol. 65, pp. 1326-1336.

- Wang X.Y., Wang X., Sheng G.G. The coupling vibration of fluid-filled carbon nanotubes. J. Phys. D: Appl. Phys. 2007, Vol.40, pp.2563-2572.

- Dong K., Wang X. Wave propagation in carbon nanotubes under shear deformation. Nanotechnology. 2006, Vol. 17, pp. 2773-2782.

- Dong K., Wang X., Sheng G.G. Wave dispersion characteristics in fluid-filled carbon nanotubes embedded in an elastic medium. Model. Simul. Mater. Sci. Eng. 2007, Vol.15, pp. 427-439.

- Jeong W., Soo Y., Jeong S.,Lee S., Yoo W. Stability Analysis of a pipe conveying periodically pulsating fluid using finite element method. JSME International Journal. 2006, Vol. 49, pp. 1116-1122.

- Paidoussis M. Fluid-structure interactions: Slender Structures and Axial flow, Academic Press, London, 1998.

- Paidoussis M., Issid N. Dynamic stability of pipes conveying fluid. Journal of Sound and Vibration. 1974, Vol. 33(3), pp. 267-284.

- Deng Q., Yang Z. Wave propagation in submerged pipe conveying fluid. Acta Mechanica Solida Sinica. 2019, Vol.32(4), pp. 483-498.

- Lolov D. S., Lilkova-Markova Sv. Dynamic stability of a fluid-immersed pipe conveying fluid and resting on a damped Winkler elastic foundation. Proceedings of XI International Conference Industrial Engineering and Environment Protection 2021 (IIZS 2021), October 7-8th, 2021, Zrenjanin, Serbia. pp.49-55.

- Hellum A., Mukherjee R., Hull A. Flutter instability of a fluid-conveying fluid-immerced pipe affixed to a rigid body. Journal of Fluids and Structures. 2011, Vol.27, pp. 1086-1096.

- Lin W., Qiao N. Vibration and stability of an axially moving beam immersed in fluid. International Journal of Solids and Structures. 2008, Vol. 45, pp. 1445-1457.

- Huang Q., Lin T., Safarpour M. Flow-induced vibration attenuation of a viscoelastic pipe conveying fluid under sinusoidal flow, using a nonlinear absorber. Mechanics Based design of Structures and Machines. 2020, Vol. 50, pp. 1673-1703.

- Liang F., Gao A., Yang X.D. Dynamical analysis of spinning functionally graded pipes conveying fluid with multiple spans. Applied Mathematical Modeling. 2020, Vol. 83, pp. 454-469.

- Askarian A.R., Permoon M.R., Shakouri M. Vibration analysis of pipes conveying fluid resting on a fractional KelvinVoigt viscoelastic foundation with general boundary conditions. International Journal of Mechanical Sciences. 2020. Vol. 179, pp. 105702.

- Cao J., Liu Y., Liu W. The effect of two cases of temperature distributions on vibration of fluid-conveying functionally graded thin-walled pipes. Journal of Strain Analysis. 2018, Vol. 53(5), pp. 324-331.

- Ameen K.A., Al-Dulaimi M.J., Hatem A.A. Experimental study of vibration on pipe conveying fluid at different end conditions for different fluid temperatures. Engineering and Technology Journal. 2019, Vol. 37, pp. 512-515.

- Li B., Wang Z., Jing L. Dynamic response of pipe conveying fluid with lateral moving supports. Shoc, and Vibration. 2018, Vol. 2018, pp. 1-17.

- Al-Waily M., Al-Baghdadi M., Al-Khayat R. Flow Velocity and Crack Angle Effect on Vibration and Flow Characterization for Pipe Induced Vibration. International Journal of Mechanical & Mechatronics Engineering. 2017, Vol. 17(5), pp. 19-27.

- Siba M., Wahmahmood W., Zakinuaw M., Rasani R., Nassir M. Flow-induced vibrations in pipes: challengess and solutions - a review. Journal of Engineering Science and Technology. 2016, Vol. 11(3), pp. 362-382.

- Faal R., Derakhshan D. Flow-Induced Vibration of Pipeline on Elastic Support. Procedia Engineering. 2022, Vol. 14, pp. 2986-2993.

- Shiwen L., Ronghui H., Zhao Y., Jiarui W., Shuang C., Jianyong L., Yi L. Numerical Simulation Research on Flow-Induced Vibration Characteristics of Fluid-Conveying Pipe Network. Nuclear Power Engineering. 2022, Vol. 43(1), pp. 187-191.

- Jung D, Chung J. In-plane and out-of-plane motions of an extensible semi- circular pipe conveying fluid. Journal of Sound and Vibration, 2008, Vol.311(1), pp.408-420.

- Liu G., Li S., Karney B.Y. Vibration analysis of curved pipes conveying fluid. Proceedings of the ASME 2014 Pressure Vessels & Piping Conference, Anaheim, California, USA. 2014, Vol.3.

- Lolov D., Lilkova-Markova Sv. Free vibrations out-of-plane of curved planar pipe conveying fluid in two cases of supporting. Annual of UACEG, Mathematics. Mechanics. 2006, Vol. 72(2), pp.123-128.

- Liang F., Yang X.-D., Bao R.-D., Zhang W. Frequency Analysis of Functionally Graded Curved Pipes Conveying Fluid. Advances in Materials Science and Engineering. 2016, Vol.2016, Article ID 7574216.

- Zhao Q., Sun Z. Flow-induced vibration of curved pipe conveying fluid by a new transfer matrix method. Engineering applications of computational applied mechanics. 2018, Vol. 12(1), pp. 780-790.

- Zhao Q., Sun Z. In-plane forced vibration of curved pipe conveying fluid by Green function method. Applied Mathematics and Mechanics (English Edition). 2017, Vol.38(10), pp. 1397-1414.

- Wu J., Shih P. The dynamic analysis of a multispan fluid-conveying pipe subjected to external load. Journal of sound and vibration. 2001, Vol.239(2), pp. 201-215.

- Chicone C. Ordinary Differential Equations with applications, Springer Science+ Business, 1999

- Inspeger T., Horvath R. Pendulum with harmonic variation of the suspension point. Periodica Polytechnica. 2000, Vol. 44, pp. 39-46.

- Akulenko L.D., Georgievskii D.V., Nesterov S.V. Spectrum of Transverse Vibrations of a Pipeline Element under Longitudinal Load. Doklady Physics. 2016, Vol. 61 (3), pp. 129-132.

- Gay-Balmaz F., Georgievskii D., Putkaradze V. Stability of Helical Tubes Conveying Fluid. Journal of Fluids and Structtures. 2018. Vol 78 (2), pp. 146-174.

- Il'ichev A.T. Dynamics and spectral stability of soliton-like structures in fluid-filled membrane tubes. Russian Math. Surveys. 2020. Vol 75 (5), pp. 843-882