Effect of copper particles shape on the heat transfer characteristics of porous microchannels during boiling of working fluid

Автор: Jiang Weiyu, Sun Lili, Mao Jijin, Zhang Donghui, Levtsev Aleksei

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 4 т.7, 2021 года.

Бесплатный доступ

In this paper, the heat transfer performance of porous microchannels sintered with spherical and dendritic copper particle is compared. The working fluid is deionized water. For uniform particle size sample, the dendritic-particle microchannel presents better boiling heat transfer performance than the spherical-particle one. It includes higher critical heat flux (CHF), which was related to the connected pore structure of the dendritic copper powder. For mixed particle size sample, the dendritic-particle microchannel also shows higher heat transfer coefficient and CHF. At high heat flux, the dendritic-particle microchannel can effectively suppress the pressure pulsation and maintain a relatively stable flow boiling state in the microchannel.

Porous microchannels, flow boiling, heat transfer performance, copper powder particles shape

Короткий адрес: https://sciup.org/14120503

IDR: 14120503 | УДК: 621.78 | DOI: 10.33619/2414-2948/65/32

Текст научной статьи Effect of copper particles shape on the heat transfer characteristics of porous microchannels during boiling of working fluid

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 621.78

Research Background and Theoretical Research

In response to high heat flux difficulty of electronic devices, new type of cooling method is required. The microchannel has arouse extensive attention in recent years because of its compaction and high heat transfer performance. The two-phase microchannel heat sink has many advantages over the single-phase microchannel heat sink. It can obtain greater heat transfer coefficient through the latent heat of the coolant and provide better temperature uniformity.

Lee and Law of the National University of Singapore [1] proposed the method of transverse slotting of parallel microchannels (Oblique-finned channels), so that the adjacent microchannels can be horizontally connected, so that the coalescence bubbles have the space of transverse expansion, rather than the expansion to the upstream and downstream. Boiling CHF (critical heat flux) can be increased to 150 W/cm2. Kandlikar [2] proposed an open microchannel in the vertical direction to ensure the vapor expansion space in the latter half of the microchannel. Because the vapor density is far less than the liquid, once the space in the vertical direction is sufficient, it will achieve good vapor-liquid separation due to the density difference effect, which can greatly improve the CHF value. Yang [3] studied the effect of copper powder coating on the heat transfer coefficient (HFC) and critical heat flux (CHF) of boiling in narrow space. Compared with ordinary surface, microporous coating can increase HTC by 4.5 times. The optimum thickness is determined by the combination of three effects: bubble separation resistance, coating additional thermal resistance and nucleation site density. Zhang Donghui [4] sintered porous microchannels with different particle sizes with dendritic and inhomogeneous copper powders, respectively, using deionized water as working fluid. It was found that compared with the single particle size, the CHF value of the microchannel sintered with mixed particle size powder increased from 90 W/cm2 to 130 W/cm2, and the heat transfer coefficient increased by about two times at high heat flux, reaching 50 kW/m2·K. For mixed particle size, the performance of large particle size copper powder is better.

In this paper, the boiling heat transfer characteristics in porous microchannels with deionized water were studied. The heat transfer and pressure drop characteristics of porous microchannels sintered with different shapes of copper powder were studied by open system.

Porous Microchannel Experimental System

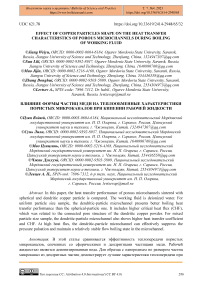

The performance test system for microchannels in this experiment is shown in Figure 1. The deionized water in the constant temperature water tank was heated to the setted temperature. Under the power provided by the micro magnetic driven gear pump, the deionized water entered the heat sink through the rotor flowmeter and the inlet throttle valve. The flow boiling phenomenon is generated by heating in the microchannel. After leaving the heat sink, the heat is exchanged with the cooling water through the plate condenser. The steam is condensed into liquid water, and finally collected into the liquid storage container. The electric heating rod is simulated as the heat source, and the input power is adjusted by the regulator. The system pressure of the heat sink is controlled by the throttle valve.

Figure 1. Porous microchannel experimental testing system: 1. Constant temperature water tank 2. Control valve 3. Micro magnetic driven gear pump 4. Pressure sensor 5. Flow meter 6. throttle valve 7. Plate heat exchangers 8. Water storage devices 9. Microchannel test room 10. Computer 11. High speed camera 12. Data acquisition system

Fabrication Method and Sample Characterization of Porous Microchannels

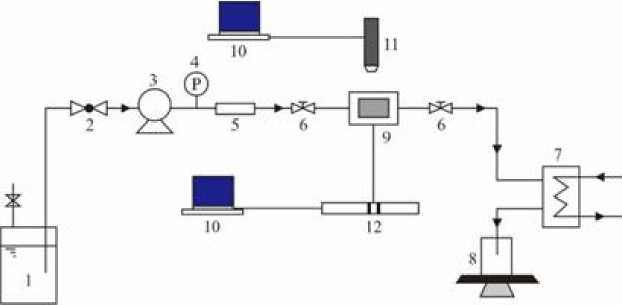

The porous microchannel was made by the powder sintering method. The structural parameters of the porous microchannel were found to be greatly influenced by the particle shape, particle size and sintering temperature. The higher sintering temperature would result in low porosity of the sample while lower temperature would lead to poor mechanical strength. If the sintering temperature is lower than 850 °C, the poor mechanical strength may lead to the collapse of porous sample. However, too high sintering temperature may lower the pore porosity of porous microchannels. After repeated attempts, the sintering temperature 900 °C was selected to ensure both appropriate structure parameters and enough mechanical strength. The manufacturing process was as follows: Firstly, the graphite mold was manufactured by the wire-electrode cutting method; secondly, the copper powders were evenly filled into the graphite mold; Then, the graphite mold was placed in a sintering furnace for about 60 minutes at 900 °C under the hydrogen-reducing atmosphere to prevent oxidation; Finally, the sintered porous microchannel was demolded very carefully. The made-up porous microchannel is shown in Figure 2.

(a) Wire processing map

Figure 2. Graphite mold finished product

(b) Graphite mould products

In order to study the effect of copper powder shape on the performance of porous microchannels, two shapes of copper powder were selected: dendritic-like and spherical-like. The particle size is 30 μm, 50 μm, 90 μm. There are two kinds of bottom thicknesses of sintering: 200 μm and 400 μm. The mixed particle size is obtained by mixing three kinds of particle size according to the mass ratio of 1: 1, and the bottom thickness is 200μm and 400μm respectively. As shown in Table 1.

Table 1.

SINGLE/MIXED PARTICLE SIZE POROUS MICROCHANNEL COPPER POWDER PARAMETERS

|

Parameter |

Single |

Single |

Single |

Mixed |

|

Particle size ( μm ) |

30 |

50 |

90 |

30-90 |

|

Bottom thickness ( μm ) |

200 |

200 |

200 |

200 |

Combined with the porosity measurement method of porous microchannel, the porosity of copper powder with dendritic shape is measured as shown in Table 2. The porosity of spherical samples with copper powder shape is shown in Table 3.

Table 2.

POROUS MICROCHANNEL POROSITY OF DENDRITIC COPPER POWDER

|

Particle size ( μm ) |

30 |

90 |

30-90 |

||

|

Bottom thickness ( μm ) Porosity ( % ) |

400 30.56 |

400 59.44 |

400 47.25 |

||

|

POROUS MICROCHANNEL POROSITY OF SPHERICAL COPPER POWDER |

Table 3. |

||||

|

Particle size ( μm ) |

30 |

90 |

|||

|

Bottom thickness ( μm ) Porosity ( % ) |

200 43.18 |

200 36.56 |

|||

Results and Analysis

Effect of Copper Powder Shape on Properties of Porous Microchannels with Single Particle Size

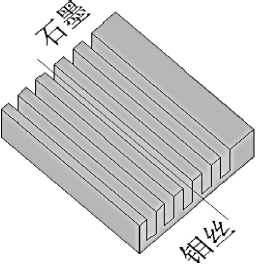

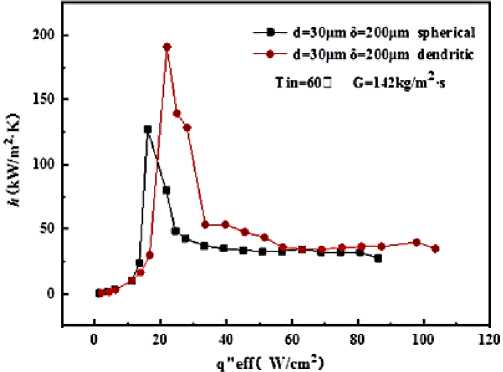

Figure 3 shows the boiling curve of porous microchannel sintered with 30 μm copper powder. The inlet subcooling is 40 °C, the mass flow rate is 142 kg/m2×s, and the bottom thickness is 200 μm. In the low heat flux region (q≤20W/cm2), the wall superheat of both kinds of particle-shape samples is very close. For the boiling starting point, the superheat of the dendritic-particle sample is slightly lower than that of the spherical-particle sample. At medium and high heat flux, the wall superheat of dendritic-shape sample is relatively low, which means that the boiling heat transfer performance is better. Figure 4 shows the variation trend of heat transfer coefficient with heat flux of two kinds of copper powder sintered samples. With the increase of heat flux, the heat transfer coefficient of both kinds of samples increases first and then decreases to a certain value. The dendritic-particle sample presents better heat transfer performance, and its maximum heat transfer coefficient reaches 190 W/m2×K in the medium and high heat flux, while the spherical-particle sample is only 126 W/m2×K, which should be related to the pore structure. The dendritic-particle microchannel includes a quantity of connected pore channels after sintered and could provide enough liquid under medium and high heat flux. The spherical-particle sample is easy to form a closed pore structure after sintering, and it is difficult to fill the liquid. Fig. 5 is the boiling curve of porous microchannel with 90 μm. The dendritic-particle porous microchannel presents lower wall superheat and higher CHF than the spherical-particle one.

Figure 3. Boiling curves of porous microchannel of both particle-shape samples

Figure 4. Heat transfer coefficient of porous microchannel with single particle size

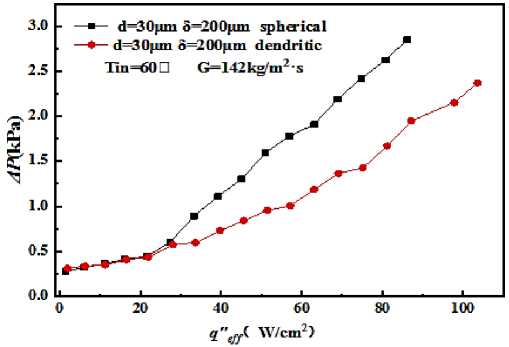

Figure 6 shows the variation trend of the heat transfer coefficients with the heat flux for both particle-shape samples. Both samples were sintered with 90 μm copper powder. The inlet subcooling degree was 40 °C, the mass flow rate was 142 kg/m2×s, and the sintering bottom thickness was 200 μm. The heat transfer coefficients of the two microchannels increase to a peak and then decrease to a certain value with the increase in heat flux. Overall, the heat transfer coefficient of dendritic copper powder microchannel is still the best. Compared with Figure 4, the heat transfer performance of 90 μm dendritic copper powder sample is better than that of 30 μm sample.

Figure 6. Variation of heat transfer coefficient microchannel with single particle size for porous microchannel with particle size

Figure 5. Boiling curves of porous

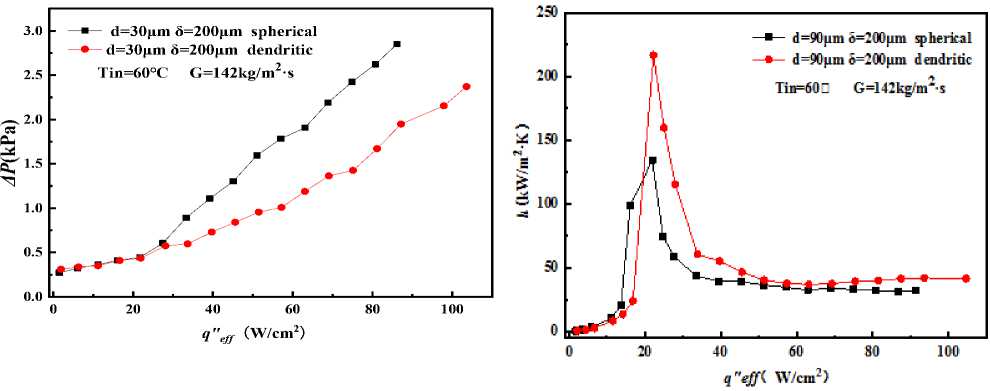

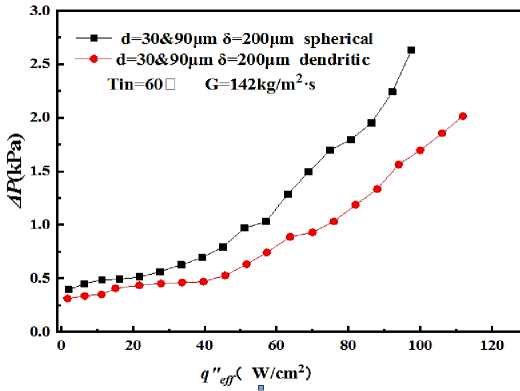

The average pressure drop of both kinds of samples is compared in Figure 7. The particle size is 30 μm and the bottom thickness is 200 μm. It can be seen from the figure that the average pressure drops increase with the increase of heat flux. In the region of low heat flux, the boiling curves of both almost coincide. The average pressure drop of spherical copper powder sample is higher than that of dendritic copper powder sample. For parallel porous microchannels, the pressure drops in flow boiling process is the sum of acceleration pressure drop and friction pressure drop (gravity pressure drop is not considered for the horizontal placement). With the increase in heat flux, the vapor content in the channel increases continuously, and the frictional resistance and acceleration pressure drop of vaporliquid two-phase slip increase continuously. However, the reason for the lower average pressure drop of dendritic copper powder needs further study.

Figure 7. The pressure drops of porous microchannel with different copper particle shapes

Figure 8. Boiling curves of mixed particle size porous microchannel

Effect of Copper Particle Shape on Properties of Porous Microchannels With Mixed Particle Size

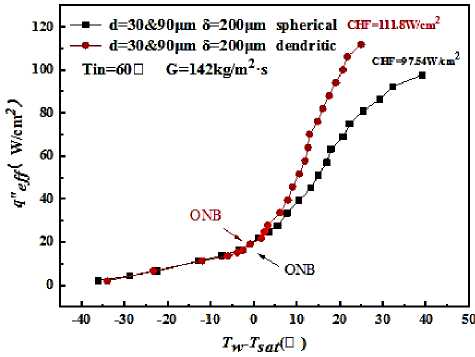

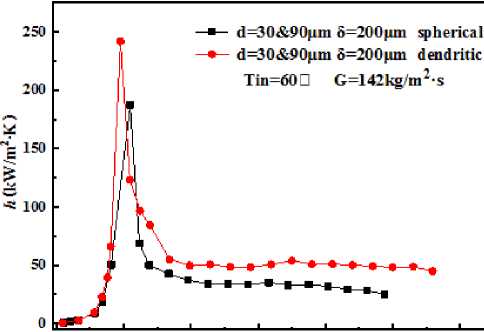

At the inlet temperature of 60 °C and the mass flow rate of 142 kg/m2×s, the boiling curve of mixed-size porous microchannels (90 μm and 30 μm copper powder mixed by mass ratio of 1:1) is shown in figure 8. It can be found that for dendritic copper powder, the CHF of mixed-particles microchannels is about 1.3 times higher than that of single-particle samples. Since the pores in the microchannels with mixed particles are the combination of large and small pores, large pores can facility the smooth discharge of large vapor bubbles while small pores provide sufficient capillary force, which is helpful to promote the CHF value. In the region of medium and high heat flux, the wall superheat of the mixed-size copper powder microchannel is lower. Figure 9 is the corresponding heat transfer performance curve of porous microchannel with mixed particle size. At low heat flux, the two curves are almost coincident, and the difference in heat transfer coefficient is small. When bubbles are generated by boiling in the channel, the peak value of heat transfer coefficient of the mixed particle size sample sintered by dendritic copper powder is higher than that of the other copper powder microchannel. The maximum heat transfer coefficients of the dendritic and spherical particle samples are 241.9 kW/m2×K and 187.4 kW/m2×K, respectively. When the heat flux is higher than 45 W/m2, the dominant boiling mechanism in the microchannel is change to convective boiling, and the flow pattern is annular flow. The heat transfer coefficient of the dendritic-type microchannel with mixed particle reaches 50 W/m2×K, while the average heat transfer coefficient of the spherical-type sample with mixed particle size is only 30 W/m2×K.

Figure 10 is a comparison of changes in average pressure drop of spherical and dendritic copper powder sintered samples, mixed particles the diameter is 30–90 μm, and the bottom thickness is 200 μm to 400 μm. It can be seen from the figure that in the single-phase region (q< 20 W/m2), the pressure drop curves are nearly horizontal. With the increase of heat flux, the slope of the pressure drop curves begins to increase. The slope of spherical-particle microchannel is greater than that of the dendritic-particle microchannel.

О 20 40 «О 80 100 120

q 'eff^ W’™^

Figure 9. Heat transfer performance curves

Figure 10. The pressure drop of microchannels with different shapes varies with heat flux

of mixed particle size porous microchannel

Effect of Particle Shape on Pressure Fluctuation

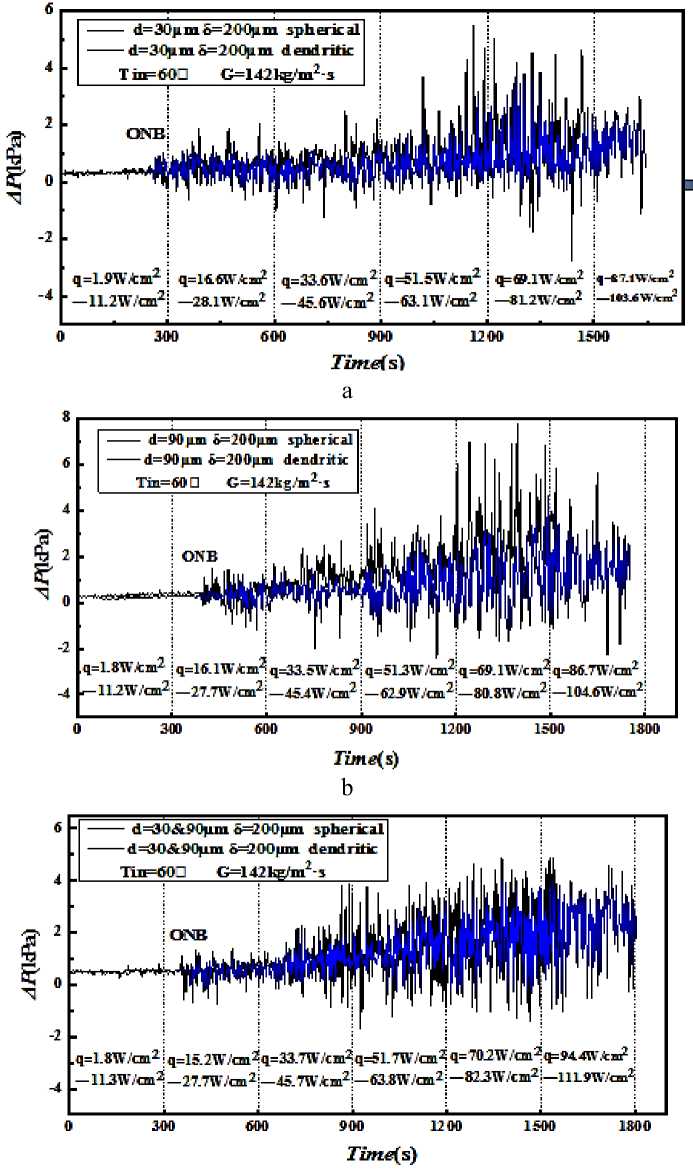

The pressure drop fluctuation is shown in Figure 11 a at T in = 60 °C and m = 142 kg/m2×s. The particle size is 30 μm and the bottom thickness is 200 μm. It can be found that at the boiling incipience point, that is, at low heat flux, the fluctuation magnitude is similar, because the working fluid in the channel is mostly liquid, and the pressure fluctuation caused by bubble formation is small. In the high heat flux region, the dendritic particle microchannel shows the small pressure fluctuation amplitude than the spherical-particle one. The maximum amplitude of the dendritic-particle sample is only about 3.5 kPa, while the pressure fluctuation amplitude of the spherical-particle one reaches about 4.1 kPa, which indicates that the porous microchannel sintered by dendritic copper powder helps to suppress the pressure fluctuation, and its heat transfer performance is also improved. For the sample with a particle size of 90 μm, the pressure fluctuation of the porous microchannel is shown in Figure 11b. In the high heat flux region, the pressure fluctuation curve of dendritic copper powder tends to be flat. Compared with the spherical and dendritic copper powder samples, it can be found that the maximum pressure difference of the spherical copper powder microchannel reaches 7.8 kPa, and its pulsation amplitude is large. The dendritic copper powder porous microchannel is better in alleviating boiling instability.

For the samples with mixed particle sizes of 30–90 μm, the pressure fluctuation of the porous microchannel is shown in Figure 11 c. At high heat flux, the maximum pressure drops of dendritic-particle microchannel is 4.1 kPa, while the maximum pressure drops of spherical-particle one is 4.8 kPa. Compared with the two samples, the dendritic-particle microchannel is beneficial to the growth and detachment of bubbles and to the suppression of boiling instability.

Conclusion

In this paper, the flow boiling heat transfer experiment of single / mixed porous microchannels sintered was carried out, using deionized water as working fluid. The effects of different inlet flow rates, copper particle sizes on the heat transfer performance and pressure drop were mainly studied. The following conclusions were reached:

-

1. For single-size porous microchannels, the wall little difference in the wall temperature between the two in the low heat flux region. However, in the medium and high heat flux region, the wall superheat of the dendritic copper powder sample is lower than that of the spherical copper powder sample, and its critical heat flux and maximum heat transfer coefficient are higher than those of the spherical sample. For the average pressure drop, the growth trend of dendritic copper powder sample is

-

2. For mixed-size porous microchannels, dendritic copper powder samples have lower wall superheat and higher critical heat flux and maximum heat transfer coefficient than spherical copper powder samples. Compared with single particle size, the boiling heat transfer performance (HTC and CHF) of mixed particle size is better.

-

3. The pressure fluctuation of each sample increases with the increase of heat flux. and the pressure fluctuation of dendritic copper powder porous microchannel is smaller than that of spherical

gentler than that of spherical copper powder sample.

c

Figure11. Pressure drop pulsation diagram

copper powder sample, which can more effectively suppress the boiling instability.

Список литературы Effect of copper particles shape on the heat transfer characteristics of porous microchannels during boiling of working fluid

- Law M., Lee P. S. A comparative study of experimental flow boiling heat transfer and pressure characteristics in straight-and oblique-finned microchannels // International Journal of Heat and Mass Transfer. 2015. V. 85. P.797-810. DOI: 10.1016/j.ijheatmasstransfer.2015.01.137

- Kalani A., Kandlikar S. G. Evaluation of pressure drop performance during enhanced flow boiling in open microchannels with tapered manifolds // Journal of heat transfer. 2014. V. 136. №5. DOI: 10.1115/1.4026306

- Yang C. Y., Liu C. F. Effect of coating layer thickness for boiling heat transfer on micro porous coated surface in confined and unconfined spaces // Experimental thermal and fluid science. 2013. V. 47. P. 40-47. DOI: 10.1016/j.expthermflusci.2013.01.001

- Wu Mingfa, Study on Flow Boiling Characteristics of Porous Microchannels [D], Master's degree thesis, Jiangsu University of Science and Technology, 2015.