Effect of different materials and additives on concrete durability

Автор: Obeid Mahmoud Abdelsalam, Aref Abu-Mahadi Mohammed Ibrahim, Nasrat Nasratullah Abdul Ghafoor

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 3 (117), 2025 года.

Бесплатный доступ

The object of research is the durability of concrete in construction, particularly in environments with high sulfate level attack, chloride exposure, or elevated CO₂ reasons. This work aims to examine how specific additives will perform a durability of concrete under these conditions. Experiments assessed concrete samples with varying compositions, focusing on additives that enhance strength and resistance and highlighted the need for specific additives to optimize concrete structure and to mitigate the environmental effects. Method. To evaluate the impact of these materials and additives on concrete's durability and strength, a series of laboratory experiments were conducted. Concrete samples were prepared with varying percentages of the following additives: Plasticizers, Superplasticizers, Air-Entraining Agents, Silica Fume, Fly Ash, Ground Granulated Blast Furnace Slag (GGBFS), Metakaolin, Limestone Powder, Nanomaterials, Zeolites, Polypropylene Fibers, Steel Fibers, Chloride-Resistant Admixtures, Corrosion Inhibitors, High-Performance Concrete (HPC) Admixtures, Activated Fly Ash or Metakaolin, and Bio-based Admixtures. Results. The incorporation of various additives generally enhanced the concrete's strength, with the extent of improvement highly dependent on the additive type and its concentration. While silica fume and GGBFS stood out for their superior performance, other materials like fly ash, nano-additives, and bio-based admixtures also demonstrated significant potential for improving concrete strength under diverse conditions. Overall, this study systematically evaluated 16 concrete additives (SCMs, fibers, chemical/bio-admixtures) through laboratory experiments (w/b = 0.35−0.45) under sulfate/chloride/CO₂ exposures. © The Author (s) 2025.

Concrete Durability, Aggressive Environments, Additives in Concrete, Fly Ash, Silica Fume, Superplasticizers, Ground Granulated Blast Furnace Slag (GGBFS), Metakaolin, Sulfate Resistance

Короткий адрес: https://sciup.org/143184930

IDR: 143184930 | УДК: 69 | DOI: 10.4123/CUBS.117.6

Текст научной статьи Effect of different materials and additives on concrete durability

Concrete is the mainstay of modern construction, famous for its versatility, strength, and wide-ranging applications. However, its durability is often cooperated when exposed to aggressive environments or cold clime. These conditions accelerate deterioration mechanisms, including sulfate attack, chloride-induced reinforcement corrosion, and carbonation, posing significant challenges to the longevity and structural integrity of concrete.

To address these issues, [1] Infrared radiation was used to cure the concrete, achieving a strength of 20 MPa. The same materials, without curing, reached only 16 MPa. [2] using SRC-artificial seawater concrete mixes, the mix with 10% Silica fume shows the best strength outcomes i.e., 28.84, 36.22, and 37.54 MPa at 7, 28, and 56 days respectively, which is an average of 12.5% higher than the mix with 20% Silica fume. Pre-cast application of hydrophobic admixtures (alkyltrialkoxysilane or triacylglycerol) in fresh concrete slightly reduces chloride diffusion (8–17% at 1 wt%) but lowers compressive strength, with triacylglycerol performing better at higher dosages (3 wt%) in low w/c (0.45) mixes, while alkyltrialkoxysilane increased chloride ingress [3], [4] develops a high-volume mineral admixture cementitious material (HMAC) using superfine cement as a reverse filler, enhancing slag and fly ash activity via grinding and chemical activation, enabling up to 90% mineral admixture content while maintaining compressive strength through improved microstructure density. The use of supplementary cementitious materials (SCMs) in cement-based composites enhances performance, durability, and sustainability, enabling the development of eco-friendly construction materials with reduced CO2 and NOx emissions, often improved further by fiber reinforcement [5].

While the incorporation of metakaolin (up to 20%) in concrete significantly enhances durability by reducing penetrability (sorptivity, permeability, conductivity, and diffusion), effectively mitigating alkalisilica reaction (ASR) without worsening carbonation, while also decreasing chloride ingress due to microstructural refinement and pozzolanic activity, outperforming other SCMs like GGCS in key durability metrics[6].

Shekarchi and his group of researchers demonstrate that natural zeolite effectively reduces cement usage (by 20-25%) and associated CO 2 emissions while enhancing concrete strength and durability, with additional benefits including humidity regulation for heritage preservation and potential applications in lightweight and specialty concretes due to its unique physicochemical properties [7].

On another hand, the authors found that complete replacement of natural coarse aggregates with recycled concrete aggregates (RCA) in self-compacting recycled concrete aggregates (SCRC) maintained fresh density and 28-day compressive strength within 5% of reference values. Rheological analysis showed reduced shear-thickening behavior in medium-strength mixes containing silica fume or metakaolin. Additionally, the study demonstrated a strong correlation between Herschel-Bulkley and Modified Bingham models for characterizing flow properties, despite increased interparticulate friction at higher RCA replacement levels [8].

The effective use of supplementary cementitious materials (SCMs) has been highlighted in this study [9] like fly ash (25–30%), GGBS (50–55%), RHA (15–20%), and sugarcane bagasse ash (15%) as sustainable cement replacements, alongside chemical additives for rebar corrosion protection, while also exploring advanced concretes with self-healing, superhydrophobic, and electromagnetic shielding properties for innovative applications.

This experimental study demonstrates that while superplasticizer (SP) dosage (400-1200 ml/100kg cement) improves workability and setting time in hot weather concrete. However, overdosing (>800 ml) reduces compressive strength and increases porosity. In contrast, controlled SP addition below saturation point enhances concrete performance by optimizing fresh properties (slump, setting) and hardened characteristics (strength, permeability, absorption) [10].

The authors found that silica fume generally reduces workability, it significantly enhances compressive strength (6-57% increase depending on dosage) and bond strength, while maintaining comparable tensile strength, flexural strength, and modulus of elasticity relative to conventional concrete [11]. Nano-silica enhances concrete strength and durability by improving microstructure and ITZ density, but its widespread use is limited by agglomeration, dispersion challenges, and cost, with optimal performance achieved at 2-3% dosage alongside plasticizers [12].

This study demonstrates that a ternary blend of 90% cement, 7.5% silica fume (SF), and 2.5% waste glass powder (WGP) achieved optimal 90-day compressive strength (55.5 MPa) and improved elastic/shear moduli compared to binary blends, while SF reduced response frequencies and specimen geometry (diameter/aspect ratio) influenced transverse frequency measurements [13]. Utilization of high-volume fly-ash concrete (HVFAC) with 50–60% fly ash, demonstrating that reduced water-to-binder ratios (0.26–0.50) and steam curing enhance workability and late-age strength (56 days), while achieving excellent chloride/carbonation resistance, despite lower early strength due to delayed pozzolanic reactivity [14].

This study evaluated fly ash and GGBS as cement replacements (0-70%) in concrete with 0.3-0.5 water-binder ratios. Compressive strength, chloride permeability (RCPT), and microstructural properties (SEM/XRD) were tested at 28, 56, and 90 days to assess mechanical and durability performance [15].

This study developed ANN and EPR models to predict 12 concrete properties (strengths, workability, permeability, environmental impact) based mix ratios (C/B, Ag/B, PL/B). Results showed ANN's superior accuracy (92.3% average), despite its complexity, while EPR provided simpler but less precise (89.4%) alternatives. Derived mix-design charts optimizing 28-day strength (20-105 MPa) within specified ranges for binder content (340-630 kg/m³), water-binder ratio (31-54%), and SCM replacement (0-40%). However, these models were limited to conventional concrete applications[16].

This review synthesizes current research on nanomaterials (1-100 nm) in cementitious composites, highlighting their dual role as micro-fillers (densifying matrix) and reactive agents (enhancing strength), Obeid, M.A.A.; Abu-Mahadi, M.I.; Nasrat, N.A.G.

Effect of different materials and additives on concrete durability;

while summarizing their effects on microstructure, mechanical properties, and durability, and identifying key research gaps for future nanoparticle applications in construction materials [17].

This review highlights natural zeolite's potential as a cement alternative in construction materials, showing that while its incorporation reduces workability and accelerates setting time due to its porous structure, blending it with other SCMs can mitigate early strength deficits and enhance durability, though conflicting findings underscore the need for further comprehensive research [18].

This study explores waste eggshell as a sustainable limestone substitute in Portland cement, investigating 15-35% replacements in mortars through comparative analysis of hydration heat, phase evolution, and electrical resistivity to assess decarbonization potential while maintaining performance [19].

This study demonstrates that UV-grafted polypropylene fibers with amide surface groups significantly enhance fiber-matrix bonding in cement composites, reducing hydrophobicity (contact angle from 106.3° to 39.9°) and improving mechanical performance (6.56% higher compressive strength, 25.55% lower drying shrinkage) compared to conventional fibers [20].

This study demonstrates that polypropylene fiber (PF) content significantly influences concrete strength, with optimal performance at 0.2% PF for compressive strength (+improvement) and 0.3% PF for flexural strength (+improvement), beyond which (up to 0.5%) both properties decline compared to control mixes, while mix type and reinforcement presence showed lesser effects [21].

This study demonstrates that steel fiber reinforcement (0.5-1.5%) significantly enhances concrete's mechanical properties: compressive strength increased by 29.3%, tensile strength by 83.7% and water absorption decreased by 50.1% at 1.5% dosage. Although electrical resistivity initially declined at lower fiber contents, the 1.5% addition rate emerged as the optimal for balanced mechanical and durability enhancements [22].

This study demonstrates that steel fiber-reinforced concrete (SFRC) with a 70-aspect ratio and 45 kg/m³ dosage significantly enhances fire resistance, achieving 56.8% higher initial crack flexural strength under ISO 834 fire exposure while reducing post-fire toughness loss (13.6%) and thermal stress, with a proposed thermal conductivity formula for temperature field modeling [23].

This review highlights bio-based admixtures as sustainable alternatives to conventional additives, demonstrating their ability to enhance concrete's mechanical/durability properties (optimal 1% dosage), enable self-healing (via bacteria/EPS), and reduce environmental impact, while calling for updated standards and further durability research to advance green construction practices [24].

This study demonstrates that a blend of 5% Natural Zeolite and 10% Metakaolin optimally enhances high-strength concrete durability (0.35 w/c ratio), showing superior acid resistance, chloride impermeability, and mechanical performance versus Silica Fume/Fly Ash, with statistical validation (R², p<0.005) confirming model reliability for strength prediction [25].[26] reported (using Air-Entraining Agents) strengths of 28.5 MPa and 23.5 MPa for 0.06% and 0.12% concentrations, respectively [27] recorded a slightly lower strength of 39.8 MPa for 5% nano-silica.

This experimental investigation systematically evaluates 16 concrete additives (including SCMs, fibers, and chemical admixtures) to determine their synergistic effects on durability enhancement in aggressive environments. The study aims to identify optimal additive combinations that maximize resistance to sulfate attack, chloride penetration, and carbonation while maintaining mechanical performance. Three primary objectives guide the research: (1) quantify the individual and combined effects of additives on compressive strength and transport properties, (2) establish performance rankings under simulated sulfate/chloride/CO 2 exposures, and (3) develop mix design guidelines for durable concrete in chemically challenging settings. The experimental matrix examines 48 mix designs with controlled variables of w/b ratio (0.35-0.45), additive dosages (5-20% for SCMs, 0.1-2% for fibers/admixtures), and exposure regimes (ASTM C1012, ASTM C1202, and accelerated carbonation tests).

-

2 Materials and Methods

Cement Types

-

• Ordinary Portland Cement (OPC)

-

• Blended Cement

-

• Pozzolanic Cement

Aggregates

Natural Aggregates (Sand, Gravel)

Recycled Aggregates

Water

-

• Potable Water

-

• Recycled Water

Admixtures

-

1. Plasticizers 2. Superplasticizers 3. Air-Entraining Agents 4. Silica Fume 5. Fly Ash 6. Ground Granulated Blast Furnace Slag (GGBFS) 7. Metakaolin 8. Limestone Powder 9. Nanomaterials 10. Zeolites 11. Polypropylene Fibers 12. Steel Fibers 13. Chloride-Resistant Admixtures 14. Corrosion Inhibitors 15. High-Performance Concrete (HPC) Admixtures 16. Activated Fly Ash or Metakaolin 17. Biobased Admixtures.

The target strength and workability can be inferred as follows:

Target Strength:

With a water-cement ratio (w/c) of 0.5, the mix likely aims for a 28-day compressive strength of 25– 35 MPa, depending on cement grade, aggregate quality, and curing conditions.

Workability:

A water content of 197 L/m³ and a well-graded aggregate mix suggest moderate workability with a likely slump of 75–125 mm, suitable for general-purpose reinforced concrete applications

Fig. 1 shows how creating a concrete mix requires several meticulously carried out procedures to guarantee the finished product satisfies the required standards for strength, durability, and quality for use in building. The first step is choosing the necessary ingredients, which include cement, sand, gravel, and water, in the amounts specified by the mix design, which takes durability, workability, and strength needs into account. Before water is progressively added to create a cohesive paste, the dry components are well combined to ensure even distribution. To balance workability and strength, the water-to-cement ratio must be precisely controlled. After that, the wet and dry ingredients are combined until a homogeneous consistency is reached, guaranteeing adequate bonding and consistent strength. To guarantee a thick construction and remove air pockets, the mixed concrete is then delivered to the location, poured into molds, and compressed. To promote hydration and avoid shrinkage fractures, the concrete is kept moist and allowed to set under regulated circumstances for a predetermined amount of time. This process is known as curing. Slump and strength tests are among the quality control procedures used during the process to make sure the concrete satisfies performance requirements and is appropriate for its intended structural or non-structural use.

Fig. 1 - Flowchart illustrating the process of making a concrete mix

Table 1. Composition of the concrete mix

|

Raw material |

Weight / m3 |

|

Portland cement Type 1 |

394 kg |

|

Sand 2.00 mm |

732 kg |

|

Crushed stone 10–20 mm |

604 kg |

|

Crushed stone 5–10 mm |

535 kg |

|

Water |

197 L |

|

Water-cement ratio |

0.5 |

Table 2. Plasticizers (0.1% to 0.5% by weight of cement)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

394 kg |

|

Plasticizer (0.1% - 0.5%) |

0.394 to 1.97 kg |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

118.2-177.3 L |

|

Water-Cement Ratio (W/C) |

0.30 to 0.45 |

Table 3. Superplasticizers (0.2% to 2% by weight of cement)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

394 kg |

|

Superplasticizer (0.2% - 2%) |

0.788 to 7.88 kg |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

98.5-157.6 L |

|

Water-Cement Ratio (W/C) |

0.25 to 0.40 |

Table 4. Air-Entraining Agents (0.05% to 0.2% by weight of cement)

|

Material |

Weight/ m³ |

|

Portland cement Type 1 |

394 kg |

|

Air-Entraining Agent (0.05% - 0.2%) |

0.197 to 0.788 kg |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

177.3-216.7 L |

|

Water-Cement Ratio (W/C) |

0.45 to 0.55 |

Table 5. Silica Fume (5% to 15% by weight of cement)

|

Material |

Weight /m³ |

|

Portland cement Type 1 |

Reduce to 335 - 375 kg. |

|

Silica Fume (5% to 15%) |

Add 19.7 - 59.1 kg. |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

173.36 L |

|

Water-Cement Ratio (W/C) |

0.44 |

Table 6. Fly Ash (15% to 40% by weight of cement)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

Reduce to 236 - 335 kg. |

|

Fly Ash (15% to 40%) |

Add 59.1 - 157.6 kg. |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

197 L |

|

Water-Cement Ratio (W/C) |

0.5 or adjust as needed. |

Table 7. Ground Granulated Blast Furnace Slag (GGBFS, 20% to 70%)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

Reduce to 118 - 315 kg. |

|

GGBFS (20% to 70%) |

Add 78.8 - 276 kg. |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

197 L |

|

Water-Cement Ratio (W/C) |

0.5 or adjust as needed. |

Table 8. Metakaolin (5% to 20%)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

Reduce to 315 - 375 kg. |

|

Metakaolin (5% to 20%) |

Add 19.7 - 78.8 kg. |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

197 L |

|

Water-Cement Ratio (W/C) |

0.5 or adjust as needed. |

Table 9. Polypropylene Fibers (0.1% to 0.3% by volume of concrete)

|

Material |

Weight / m³ |

|

Portland cement Type 1 |

394 kg |

|

Polypropylene Fibers (0.1% - 0.3% by volume) |

1 to 3 kg/m³ |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

197 L |

|

Water-Cement Ratio (W/C) |

0.5 |

Table 10. Steel Fibers (0.5% to 2% by volume of concrete)

|

Material |

Weight /m³ |

|

Portland cement Type 1 |

394 kg |

|

Steel Fibers (0.5% - 2%) |

39.4 to 157.6 kg |

|

Sand (2.00 mm) |

732 kg |

|

Crushed stone (10–20 mm) |

604 kg |

|

Crushed stone (5–10 mm) |

535 kg |

|

Water |

177.3 L |

|

Water-Cement Ratio (W/C) |

0.45 |

The first table (Table 1) presents the composition of the control concrete mix without additives, listing the quantities of each raw material required to prepare 1 cubic meter of concrete. This mix is designed to meet standard performance criteria without the influence of additives. Tables 2 through 11 display the composition of concrete mixes with various additives, outlining the quantities of each raw material used to prepare 1 cubic meter of concrete. These mixes are designed to meet standard performance criteria while incorporating the effects of additives.

Behavior of Concrete in Aggressive Environments.

Sulfate Attack

-

• Reaction: Sulfates react with calcium aluminates in the cement paste, forming expansive products like ettringite.

-

• Equation: 3CaO ⋅ Al 2 O 3 +3CaSO 4 ⋅ 2H 2 O+26H 2 O→3CaO ⋅ Al 2 O 3 ⋅ 3CaSO 4 ⋅ 32H 2 O

(Calcium Aluminate + Gypsum + Water → Ettringite)

Chloride Ingress

-

• Reaction: Chlorides penetrate concrete, leading to corrosion of steel reinforcement.

-

• Equation: Fe+2Cl-+(1/2)O2+H 2 O→Fe(OH) 2 +2Cl-

- (Iron + Chloride + Oxygen + Water → Iron Hydroxide)

Carbonation

-

• Reaction: Carbon dioxide reacts with calcium hydroxide in the concrete, forming calcium carbonate.

-

• Equation: Ca(OH) 2 +CO 2 →CaCO 3 +H 2 O

(Calcium Hydroxide + Carbon Dioxide → Calcium Carbonate)

Comparison of Materials and Additives

Table 12. Effect of Different Materials and Additives on Concrete Durability

|

Additive |

Usage Percentage |

Compressive Strength (MPa) |

Durability |

Chemical Compounds |

|

Plasticizers |

0.1% to 0.5% by weight of cement |

Typically no significant change; slight increase by 25% |

Improves workability, indirectly enhances durability |

Calcium lignosulfonate (e.g., lignosulfonates) |

|

Superplasticizers |

0.2% to 2% by weight of cement |

Increase by 5-20 MPa (10-30% over control) |

Improves workability; can indirectly improve durability |

Sulfonated melamine formaldehyde or sulfonated naphthalene formaldehyde |

|

Air-Entraining Agents |

0.05% to 0.2% by weight of cement |

Typically reduces strength by 5-10 MPa |

Enhances freezethaw resistance; improves durability in freeze-thaw conditions |

Synthetic detergents, vinsol resin |

|

Silica Fume |

5% to 15% by weight of cement |

Increase by 10-25 MPa (up to 50% over control) |

Significantly enhances resistance to chemical attack and reduces permeability |

Amorphous silicon dioxide (SiO 2 ) |

|

Fly Ash |

15% to 40% by weight of cement |

Initial strength gain may be slower; increase by 5-15 MPa (up to 25% over time) |

Improves resistance to chemical attack and reduces permeability |

Silicon dioxide (SiO 2 ), aluminum oxide (AI 2 O 3 ) |

|

Ground Granulated Blast Furnace Slag (GGBFS) |

20% to 70% by weight of cement |

Increase by 5-20 MPa over time |

Excellent long-term durability, including resistance to sulfates and chlorides |

Calcium silicate (CaSiO 3 ), silicon dioxide (SiO 2 ), aluminum oxide (Al 2 O 3 ) |

|

Metakaolin |

5% to 20% by weight of cement |

Increase by 5-15 MPa (up to 30% over control) |

Improves resistance to chemical attack and reduces permeability |

Dehydroxylated kaolinite (Al 2 Si 2 O 7 ) |

|

Limestone Powder |

5% to 20% by weight of cement |

Can increase early strength by 5-10 MPa; minor reduction in long-term strength |

Improves workability; durability effects are moderate |

Calcium carbonate (CaCO 3 ) |

|

Nanomaterials |

0.1% to 5% by weight of cement |

Can increase by 5-20 MPa (10-30% or more) |

Significantly enhances durability by reducing permeability and increasing resistance to chemical attack |

Nano-silica (SiO 2 ), nanotitania (TiO 2 ) |

|

Zeolites |

5% to 15% by weight of cement |

Increase by 5-10 MPa (up to 20% over time) |

Enhances long-term durability, including resistance to sulfates and chlorides |

Aluminosilicate minerals (e.g., clinoptilolite) |

|

Polypropylene Fibers |

0.1% to 0.3% by volume of concrete |

Typically no significant direct increase in strength; can indirectly enhance by 2-5 MPa |

Enhances toughness and impact resistance; reduces cracking |

Polypropylene (C 3 H 6 )n |

|

Steel Fibers |

0.5% to 2% by volume of concrete |

Typically no significant direct increase in strength; can indirectly enhance by 5-10 MPa |

Significantly enhances toughness, impact resistance, and durability |

Steel (iron-carbon alloy) |

|

ChlorideResistant Admixtures |

0.5% to 1% by weight of cement |

Typically no significant direct effect on strength |

Improves durability in chloride environments, reducing corrosion |

Calcium nitrite (Ca(NO 2 ) 2 ) |

|

Corrosion Inhibitors |

1% to 5% by weight of cement |

Typically no significant direct effect on strength |

Enhances durability by protecting reinforcement from corrosion |

Amine carboxylates, calcium nitrite (Ca(NO 2 ) 2 ) |

|

Bio-based Admixtures |

1% to 10% by weight of cement |

Varies; often minor increase or neutral effect |

Improves sustainability; durability effects vary |

Derived from natural sources, e.g., lignin, polysaccharides |

The table 12 above presents the comparison of various concrete materials and additives can significantly impact both compressive strength and durability. Plasticizers, typically used at 0.1% to 0.5% by weight of cement, offer a slight increase in compressive strength (2-5%) and enhance workability, indirectly benefiting durability. Superplasticizers, at 0.2% to 2% by weight of cement, can boost compressive strength by 5-20 MPa (10-30%) and also improve workability, which indirectly enhances durability.

Air-entraining agents, used at 0.05% to 0.2% by weight of cement, tend to reduce compressive strength by 5-10 MPa but significantly enhance freeze-thaw resistance, improving durability in such conditions. Silica fume, at 5% to 15% by weight of cement, can increase compressive strength by up to 50% (10-25 MPa) and significantly improve resistance to chemical attacks, thereby reducing permeability and enhancing durability.

Fly ash, which is used at 15% to 40% by weight of cement, may show slower initial strength gain but can increase compressive strength by up to 25% (5-15 MPa) over time. It also improves resistance to chemical attacks and reduces permeability. Ground Granulated Blast Furnace Slag (GGBFS), used at 20% to 70% by weight of cement, can increase compressive strength by 5-20 MPa over time and offers excellent long-term durability with resistance to sulfates and chlorides.

Metakaolin, at 5% to 20% by weight of cement, can enhance compressive strength by up to 30% (5-15 MPa) and improve resistance to chemical attacks, thus reducing permeability. Limestone powder, typically used at 5% to 20% by weight of cement, can increase early strength by 5-10 MPa but may lead to a minor reduction in long-term strength. Its main benefit lies in improving workability.

Nanomaterials, used at 0.1% to 5% by weight of cement, can significantly increase compressive strength by 10-30% (5-20 MPa or more) and greatly enhance durability by reducing permeability and improving chemical resistance. Zeolites, at 5% to 15% by weight of cement, can increase compressive strength by 5-20% (5-10 MPa) and enhance long-term durability with improved resistance to sulfates and chlorides.

Polypropylene fibers, used at 0.1% to 0.3% by volume of concrete, typically do not directly affect compressive strength but can enhance it indirectly by 2-5 MPa. They improve toughness, impact resistance, and reduce cracking. Steel fibers, at 0.5% to 2% by volume of concrete, also show minimal direct impact on compressive strength but can enhance it indirectly by 5-10 MPa, significantly improving toughness, impact resistance, and overall durability.

Chloride-resistant admixtures, used at 0.5% to 1% by weight of cement, generally do not impact compressive strength but enhance durability in chloride-rich environments by reducing corrosion. Similarly, corrosion inhibitors, at 1% to 5% by weight of cement, do not significantly affect compressive strength but protect reinforcement from corrosion, thus improving durability.

Bio-based admixtures, typically used at 1% to 10% by weight of cement, often show variable effects on compressive strength, usually minor or neutral, and improve sustainability, with varying durability effects depending on the specific additive.

Table 13. Effect of Different Materials and Additives on Concrete Durability

|

Additive |

Permeability |

Absorption |

Sulfate Resistance |

Chloride Ion Penetration |

Chemical Resistance |

|

Plasticizers |

Slight improvement (5-10%) |

Slight improvement (510%) |

No significant change |

No significant change |

No significant change |

|

Superplasticizers |

Improved (10-30%) |

Improved (10-30%) |

No significant change |

No significant change |

No significant change |

|

Air-Entraining Agents |

Higher permeability (10-30%) |

Higher absorption (1030%) |

Reduced resistance (1030% less) |

Increased (10-30%) |

Reduced (10-30%) |

|

Silica Fume |

Very low permeability (30-50% reduction) |

Low absorption (2030% reduction) |

Excellent resistance (up to 50% better) |

Very low chloride penetration (5070% reduction) |

Excellent resistance (up to 50% better) |

|

Fly Ash |

Lower permeability (10-30% reduction) |

Lower absorption (1020% reduction) |

Good resistance (up to 30% better) |

Lower chloride penetration (1030% reduction) |

Good resistance (1020% better) |

|

Ground Granulated Blast Furnace Slag (GGBFS) |

Low permeability (30-50% reduction) |

Low absorption (2030% reduction) |

Excellent resistance (up to 50% better) |

Low chloride penetration (3050% reduction) |

Excellent resistance (up to 50% better) |

|

Metakaolin |

Low permeability (20-30% reduction) |

Low absorption (2030% reduction) |

Excellent resistance (up to 30% better) |

Low chloride penetration (2030% reduction) |

Excellent resistance (up to 30% better) |

|

Limestone Powder |

Slightly higher permeability (5-15%) |

Slightly higher absorption (510%) |

Moderate resistance (1020% less) |

Slightly higher chloride penetration (5 10%) |

Moderate resistance (1015% less) |

|

Nanomaterials |

Very low permeability (50-70% reduction) |

Very low absorption (3050% reduction) |

Excellent resistance (up to 50% better) |

Very low chloride penetration (5070% reduction) |

Excellent resistance (up to 50% better) |

|

Zeolites |

Low permeability (20-30% reduction) |

Low absorption (2030% reduction) |

Good resistance (up to 20% better) |

Low chloride penetration (2030% reduction) |

Good resistance (1020% better) |

|

Polypropylene Fibers |

Slight improvement (5-10%) |

Slight improvement (510%) |

No significant change |

No significant change |

Improved resistance to cracking (1020% better) |

|

Steel Fibers |

Slight improvement (5-10%) |

Slight improvement (510%) |

No significant change |

No significant change |

Improved resistance to cracking (1020% better) |

|

Chloride Resistant Admixtures |

No significant change |

No significant change |

Improved (10-30% better) |

Significantly reduced (30-50% reduction) |

Improved resistance (2030% better) |

|

Corrosion Inhibitors |

No significant change |

No significant change |

Improved (10-30% better) |

Significantly reduced (30-50% reduction) |

Improved resistance (2030% better) |

|

Bio-based Admixtures |

Variable; generally improved (5 20%) |

Variable; generally improved (5 20%) |

Variable; generally improved (1020% better) |

Variable; generally improved (5-20%) |

Variable; generally improved (5 20%) |

The table above (Table 13) illustrates how concrete additives significantly influence various aspects of the material's durability. Plasticizers and superplasticizers primarily enhance workability, with superplasticizers notably reducing permeability and absorption by 10-30%. However, their effect on sulfate resistance, chloride ion penetration, and chemical resistance is minimal.

Silica fume, fly ash, and ground granulated blast furnace slag (GGBFS) are highly effective in reducing permeability (by 30-50%) and absorption (by 20-30%), which enhances sulfate and chemical resistance. These additives also considerably decrease chloride ion penetration (by 30-70%). Metakaolin provides similar benefits with reductions in permeability and absorption by 20-30% and offers excellent resistance to sulfates and chemicals. Limestone powder, although it slightly increases permeability and absorption, provides moderate improvements in overall durability.

Nanomaterials excel in enhancing durability, offering very low permeability (50-70% reduction) and absorption (30-50% reduction), and providing excellent resistance to sulfates, chemicals, and chlorides. Zeolites also improve concrete durability by reducing permeability and absorption by 20-30% and offer good resistance to chemicals and chlorides. Polypropylene and steel fibers improve crack resistance and slightly enhance permeability and absorption but have limited impact on other durability aspects.

Chloride-resistant admixtures and corrosion inhibitors are particularly effective in mitigating chloride-induced corrosion, reducing chloride ion penetration by 30-50% and enhancing chemical resistance by 20-30%. Bio-based admixtures show variable improvements in permeability, absorption, and other durability characteristics, depending on the specific formulation.

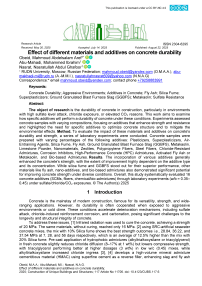

Fig. 2 - Illustrating the Compressive Strength of concrete with different percentage of additive (Plasticizers)

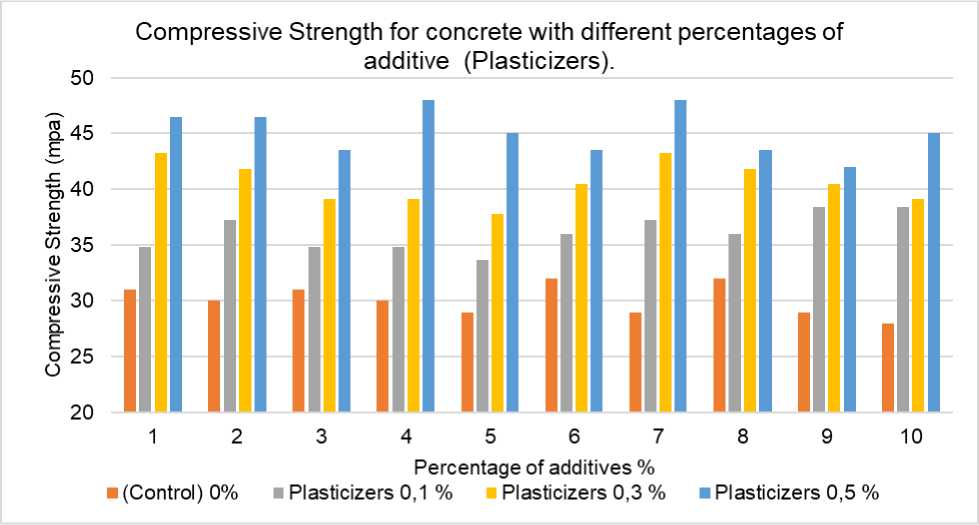

Compressive Strength for concrete with different percentages of additive (Superplasticizers).

«45.00

lllllllll

1 23456789 10

Percentage of additives %

-

■ (Control) 0% ■ Superplasticizers 0,2 % ■ Superplasticizers 1 % ■ Superplasticizers 2 %

Fig. 3 - Illustrating the Compressive Strength of concrete with different percentage of additive (Superplasticizers)

Compressive Strength for concrete with different percentages of additive (Air-EntrainingAgents).

1 23456789 10

Percentage of additives %

-

■ (Control) 0% ■ Air-Entraining Agents 0,05 %

-

■ Air-Entraining Agents 0,1 % i Air-Entraining Agents 0,2 %

Fig. 4 - Illustrating the Compressive Strength of concrete with different percentage of additive (AirEntraining Agents)

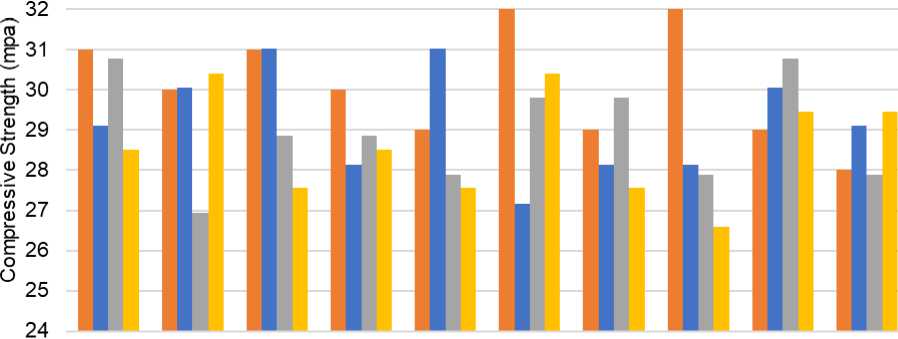

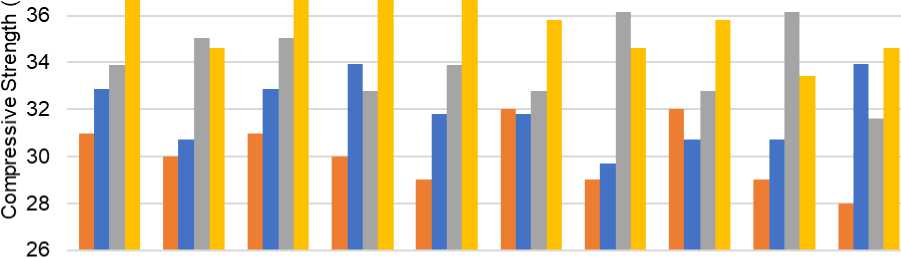

Fig. 5 - Illustrating the Compressive Strength of concrete with different percentage of additive (Silica Fume)

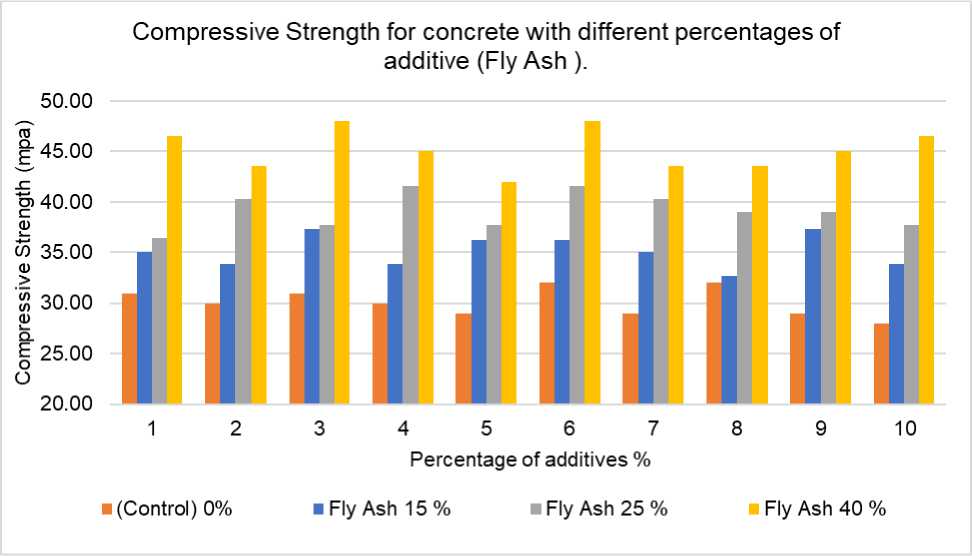

Fig. 6 - Illustrating the Compressive Strength of concrete with different percentage of additive (Fly Ash)

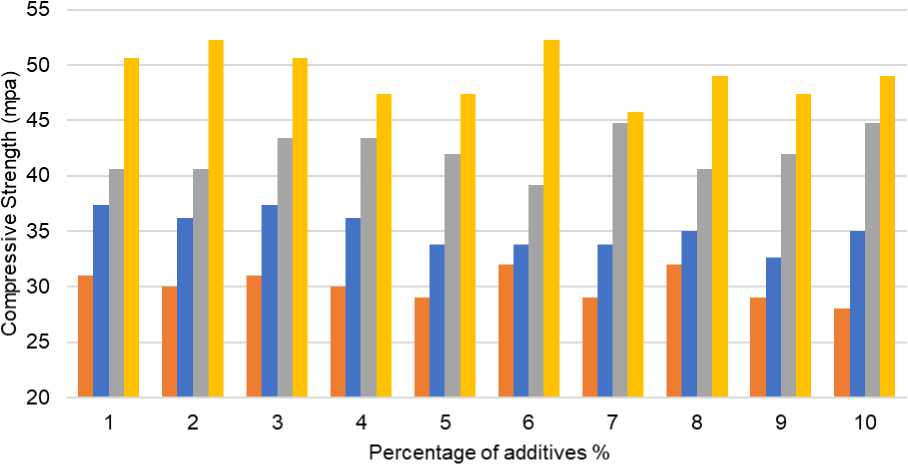

Compressive Strength for concrete with different percentages of additive (Ground Granulated Blast Furnace Slag (GGBFS)).

-

■ (Control) o%

-

■ Ground Granulated Blast Furnace Slag (GGBFS) 20 %

-

■ Ground Granulated Blast Furnace Slag (GGBFS) 45 %

8.40 E

Ground Granulated Blast Furnace Slag (GGBFS) 70 %

Fig. 7 - Illustrating the Compressive Strength for concrete with different percentages of additive (Ground Granulated Blast Furnace Slag (GGBFS))

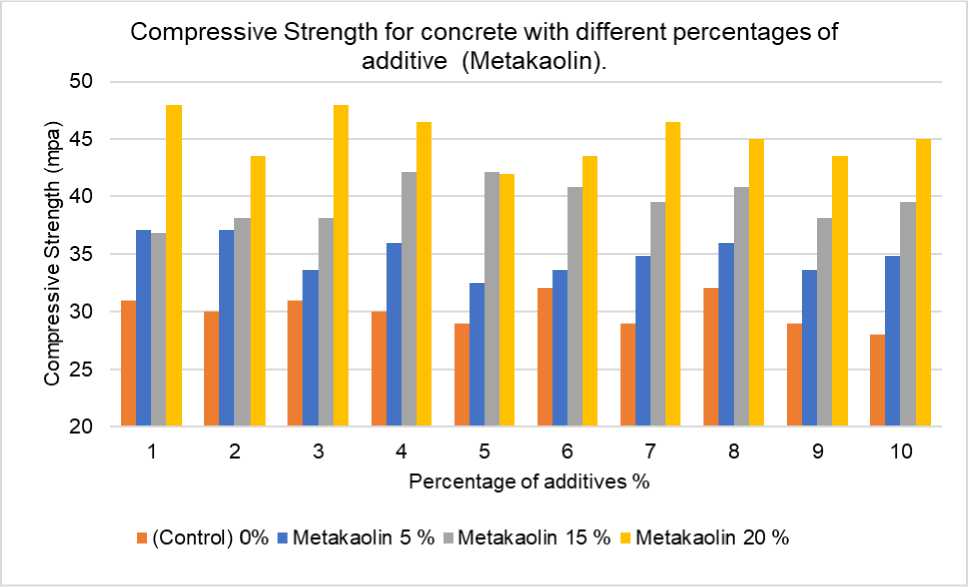

Fig. 8 - Illustrating the Compressive Strength for concrete with different percentages of additive (Metakaolin)

Compressive Strength for concrete with different percentages of additive (Limestone Powder).

1 23456789 10

Percentage of additives %

-

■ (Control) 0% ■ Limestone Powder 5 %

-

■ Limestone Powder 15 % i Limestone Powder 20 %

Fig. 9 - Illustrating the Compressive Strength for concrete with different percentages of additive (Limestone Powder)

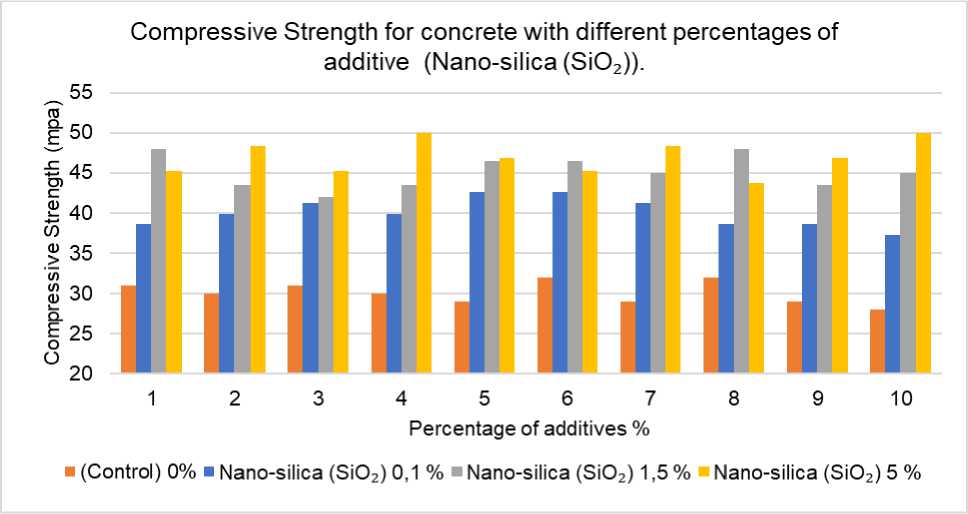

Fig. 10 - Illustrating the Compressive Strength for concrete with different percentages of additive (Nano-silica (SiO 2 ))

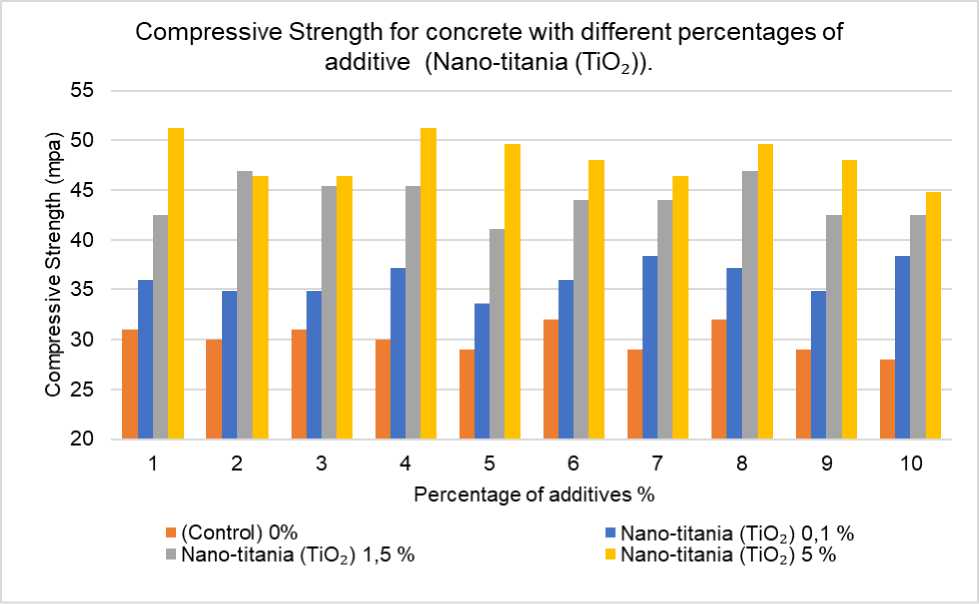

Fig. 11 - Illustrating the Compressive Strength for concrete with different percentages of additive (Nano-titania (TiO 2 ))

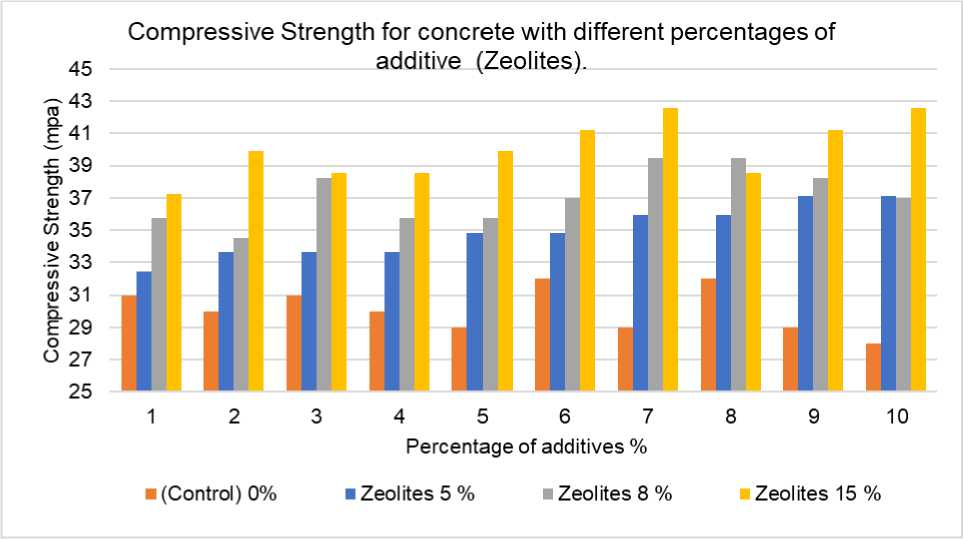

Fig. 12 - Illustrating the Compressive Strength for concrete with different percentages of additive (Zeolites)

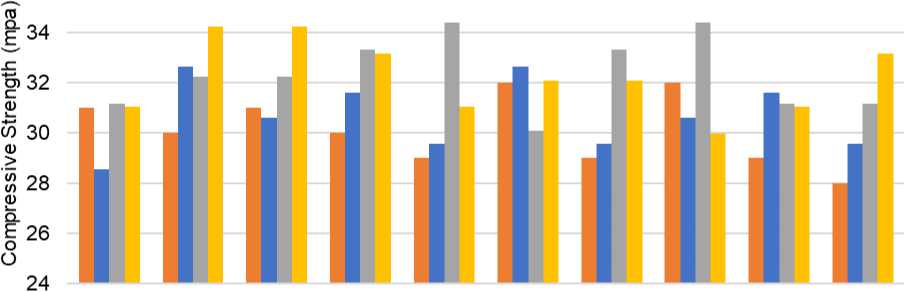

Compressive Strength for concrete with different percentages of additive (Polypropylene Fibers).

1 23456789 10

Percentage of additives %

-

■ (Control) 0% ■ Polypropylene Fibers 0,1 %

-

■ Polypropylene Fibers 0,2 % ■ Polypropylene Fibers 0,3 %

Fig. 13 - Illustrating the Compressive Strength for concrete with different percentages of additive (Polypropylene Fibers)

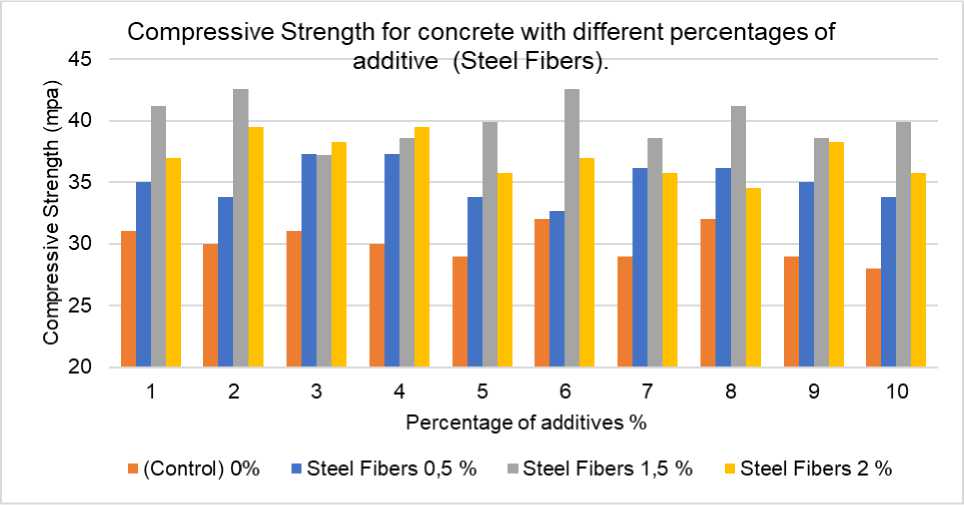

Fig. 14 - Illustrating the Compressive Strength for concrete with different percentages of additive (Steel Fibers)

Compressive Strength for concrete with different percentages of additive (Chloride-ResistantAdmixtures).

HHidHi о 123456789 10

Percentage of additives %

-

■ (Control) 0% ■ Chloride-Resistant Admixtures 0,5 %

-

■ Chloride-ResistantAdmixtures 0,75 % ■ Chloride-ResistantAdmixtures 1 %

Fig. 15 - Illustrating the Compressive Strength for concrete with different percentages of additive (Steel Fibers)

Compressive Strength for concrete with different percentages of additive (Corrosion Inhibitors).

123456789 10

Percentage of additives %

■ (Control) 0% ■ Corrosion Inhibitors 1 % ■ Corrosion Inhibitors 3 % Corrosion Inhibitors 5 %

Fig. 16 - Illustrating the Compressive Strength for concrete with different percentages of additive (Corrosion Inhibitors)

Compressive Strength for concrete with different percentages of additive (Bio-based Admixtures).

£38 E

1 23456789 10

Percentage of additives %

-

■ (Control) 0% «Bio-based Admixtures 1 %

-

■ Bio-based Admixtures 5 % i Bio-based Admixtures 10 %

Fig. 17 - Illustrating the Compressive Strength for concrete with different percentages of additive (Bio-based Admixtures)

3 Results and Discussion

Fig. (2-17): Compressive Strengths of Concrete Mixes with Additives

The Compressive Strengths of various concrete mixes incorporating different additives was evaluated across ten test cubes, revealing distinct performance trends based on additive type and concentration.

-

• Control Group: The baseline concrete mix without additives demonstrated an average compressive strength of approximately 30.10 MPa.

Material

Weight / m³

Portland cement Type 1

394 kg

Nanomaterials (0.1% to 5%)

Add 0.39 - 19.7 kg.

Sand (2.00 mm)

732 kg

Crushed stone (10–20 mm)

604 kg

Crushed stone (5–10 mm)

535 kg

Water

177.3 L

Water-Cement Ratio (W/C)

0.45

Table 11. Nanomaterials (0.1% to 5%)

-

• Plasticizers: The use of plasticizers resulted in a notable increase in compressive strength. Strengths of 36.12 MPa, 40.64 MPa, and 45.15 MPa were recorded at 0.1%, 0.3%, and 0.5% dosages, respectively.

-

• Superplasticizers: Superplasticizers enhanced compressive strength, with our results showing strengths of 33.11 MPa, 37.32 MPa, and 38.83 MPa at 0.2%, 1%, and 2% dosages, respectively. In comparison, Alsadey et al. 2016 reported strengths of 44.61 MPa, 46.79 MPa, 44.21 MPa, and 42.26 MPa at higher dosages of 4%, 6%, 10%, and 12%, respectively.

-

• Air-Entraining Agents: The use of air-entraining agents showed a slight decrease in compressive strength as the dosage increased. Compressive strengths were recorded as 29.20 MPa, 28.96 MPa, and 28.60 MPa for 0.05%, 0.1%, and 0.2% concentrations, respectively. Spurina et al. 2022 reported strengths of 28.5 MPa and 23.5 MPa for 0.06% and 0.12% concentrations, respectively.

-

• Silica Fume: Silica fume significantly improved compressive strength, with recorded values of 40.03 MPa, 46.14 MPa, and 55.08 MPa at 5%, 10%, and 15% replacement levels, respectively.

-

• Fly Ash: Fly ash contributed to a progressive increase in strength with higher percentages. Our results showed a compressive strength of 35.13 MPa at 15% fly ash, 39.13 MPa at 25%, and 45.15 MPa at 40%. In comparison, Li et al. 2022. reported values of 46 MPa, 44 MPa, and 43.5 MPa for the same percentages. while Cheruvu et al. 2024 reported 37.5 MPa, 34.8 MPa, and 30 MPa, respectively.

-

• Ground Granulated Blast Furnace Slag (GGBFS): For GGBFS, the compressive strength at 20%, 45%, and 70% replacement levels was 35.10 MPa, 42.14 MPa, and 49.15 MPa, respectively. In comparison, Cheruvu et al. 2024 reported values of 40.0 MPa, 33.5 MPa, and 27.5 MPa for the same replacement levels.

-

• Metakaolin and Nano-Additives: Both metakaolin and nano-additives demonstrated significant strength enhancement, particularly at higher concentrations. For metakaolin, compressive strengths were recorded as 34.92 MPa, 39.61 MPa, and 45.15 MPa at 5%, 15%, and 20% replacement levels, respectively. In comparison, Bakera et al. (2019) reported even higher strengths of 66.7 MPa and 74.8 MPa for 15% and 20% metakaolin, respectively. For nano-silica, compressive strengths were observed at 40.03 MPa, 45.15 MPa, and 46.96 MPa for 0.1%, 1.5%, and 5% addition levels, respectively. However, Nasehi Ghashouieh et al. (2024) recorded a slightly lower strength of 39.8 MPa for 5% nano-silica.

-

• Zeolites and Fibers: For zeolites, the compressive strength results at 5%, 8%, and 15% replacement were 34.92 MPa, 37.11 MPa, and 40.03 MPa, respectively. For polypropylene fibers at 0.1%, 0.2%, and 0.3%, we achieved strengths of 32.09 MPa, 33.71 MPa, and 34.80 MPa. In comparison, Mashrei et al. 2018, reported values of 30.4 MPa, 32.0 MPa, and 28.2 MPa for the same polypropylene fiber percentages. For steel fibers at 0.5%, 1.5%, and 2%, our results were 35.10 MPa, 40.03 MPa, and 37.11 MPa, respectively. Jasim et al. 2024 however, reported compressive strengths of 25.73 MPa and 29.18 MPa for 0.5% and 1.5% steel fibers, showing mixed effects on strength, with noticeable improvements observed at higher concentrations.

-

• Chloride-Resistant Admixtures and Corrosion Inhibitors: These additives generally resulted in lower strength indices but showed slight increases at higher dosages.

-

• Bio-Based Admixtures: Bio-based admixtures improved compressive strength, with results of 31.91 MPa, 34.01 MPa, and 35.92 MPa recorded at 1%, 5%, and 10% dosages, respectively.

Overall Findings

The incorporation of various additives generally enhanced the concrete's strength, with the extent of improvement highly dependent on the additive type and its concentration. While silica fume and GGBFS stood out for their superior performance, other materials like fly ash, nano-additives, and biobased admixtures also demonstrated significant potential for improving concrete strength under diverse conditions.

-

4 Conclusions

This study systematically evaluated 16 concrete additives (SCMs, fibers, chemical/bio-admixtures) through laboratory experiments (w/b = 0.35-0.45) under sulfate/chloride/CO 2 exposures. The following new scientific results were obtained:

-

1. Silica Fume and GGBFS: Demonstrated superior performance, with silica fume increasing compressive strength by up to 50% and GGBFS providing excellent long-term durability, particularly in sulfate and chloride-rich environments.

-

2. Nano-Additives: Nano-silica and nano-titania significantly enhanced compressive strength (10– 30%) and reduced permeability by 50–70%, offering exceptional resistance to chemical attacks. Obeid, M.A.A.; Abu-Mahadi, M.I.; Nasrat, N.A.G.

-

3. Metakaolin: At 5–20% replacement, metakaolin improved compressive strength by up to 30% and reduced permeability by 20–30%, outperforming other SCMs in key durability metrics.

-

4. Fibers: Polypropylene and steel fibers improved toughness and crack resistance, with steel fibers showing a 29.3% increase in compressive strength at 1.5% dosage.

-

5. Bio-Based Admixtures: Exhibited potential for sustainable concrete, with variable but generally positive effects on strength and durability, though further research is needed for standardization.

-

6. Synergistic Effects: Combinations of additives, such as silica fume with fly ash or GGBFS, showed enhanced performance, suggesting tailored mixes can optimize durability for specific environmental conditions.

Effect of different materials and additives on concrete durability;

-

5 Acknowledgements

The authors would like to acknowledge the technical support by the concrete laboratory in the Civil Engineering Department at the Faculty of Engineering Technology, RUDN University.

-

6 Conflict of Interests

The authors declare no conflict of interest.