Effect of natural zeolite on the compressive strength and freeze-thaw resistance of Portland cement

Автор: Bayartsetseg E., Lkhagvajargal G., Batgerel D., Sarangerel D., Ochirkhuyag B.

Журнал: Вестник Бурятского государственного университета. Философия @vestnik-bsu

Рубрика: Химия

Статья в выпуске: 3, 2011 года.

Бесплатный доступ

Effects of zeolites in various natural deposits as replacement cementing material on mechanical performance of Portland cement were studied. The blended cement pastes with zeolites were cured at room temperature in air for various durations (1, 7 and 28 days). Mechanical performance of the blended cement samples such as setting time, volume of water, compressive strength, normal consistency and freeze-thaw resistance of the mortar are determined. The optimal substitution ratio was 20 wt. % of zeolite for all ages of blended cement pastes. It is revealed by adding 20% of natural zeolite into Portland cement, that the compressive strength increased from 485 kg/cm2 to 690 kg/cm2. It is clear that mechanical-chemical activation of natural zeolite is effective way in preparation of blended cement with zeolite.

Portland cement, zeolite, compressive strength, freeze-thaw resistance

Короткий адрес: https://sciup.org/148180181

IDR: 148180181 | УДК: 666.9.031

Текст научной статьи Effect of natural zeolite on the compressive strength and freeze-thaw resistance of Portland cement

In recent studies, various types of materials such as silica fumes, fly ash, coal bottom ash and zeolite have been investigated as Portland cement replacement materials [1–3]. Their substitution in Portland cement has been an interesting subject for research due to environmental and technical reasons. Clearly, different substitution materials will have different effects on the properties of the cement due to their chemical, physical and mineralogical characteristics [4].

Zeolites are crystalline aluminosilicate minerals, having a framework of [SiO 4 ] 4 - and [AlO 4 ] 5 - tetrahedral linked to each other at the corners by sharing their oxygen. Zeolites have many specific forms and could be found in natural hydrological closed system of volcanic materials in alkaline activation source, or synthesized from a wide variety of high Si-and Al starting materials. Zeolite substitution can improve the strength of concrete by the pozzolanic reaction with Ca(OH)2 [5]. In general, natural zeolite, like other pozzolanic materials, contributes to the strength of concrete better than the strength of cement [6]. Natural zeolite also prevents the undesirable expansion due to alkali–aggregate reaction. In this study, the physical properties of natural zeolite and its effects on the mechanical properties and freeze-thaw resistance of Portland cement were examined and the physical properties of the cement mixes were compared.

Materials and methods

Materials

Materials used in this study were Portland cement type 500 (PC-500) and natural zeolites. Portland cement was provided by Hotol Cement Company. The zeolite used was obtained from natural deposits in Tsa-gaantsav, Tushleg and Orgon in Mongolia. The chemical compositions of both PC-500 and zeolites are listed in table 1.

Table 1

Chemical composition of natural zeolites and Portland cement (PC-500)

|

Samples |

Composition, % |

||||||||

|

SiO 2 |

Al2O3 |

Fe 2 O 3 |

CaO |

MgO |

K 2 O |

Na 2 O |

H 2 O |

||

|

Natural Zeolite |

Tsagaantsav |

68.79 |

12.55 |

1.20 |

1.19 |

0.54 |

3.20 |

3.09 |

8.92 |

|

Tushleg |

63.00 |

14.20 |

1.30 |

1.60 |

1.20 |

2.40 |

2.70 |

9.80 |

|

|

Orgon |

66.70 |

14.00 |

2.16 |

2.76 |

2.01 |

3.90 |

1.06 |

4.82 |

|

|

PC-500 |

SiO 2 |

Al2O3 |

Fe 2 O 3 |

CaO |

CaO free |

FeO |

MgO |

||

|

21.55 |

5.54 |

3.76 |

64.95 |

1.53 |

0.66 |

1.34 |

|||

Activation of zeolite

Natural zeolite was activated by both thermal and mechano-chemical activation methods. Thermal activation was carried out in muffle stove at 2000C for 4 h and then compressed in the desiccator. Then zeolite was milled in the steel ball for 1-10 minutes where the ratio of steel ball and sample was 1:100. Mechanochemical activation of zeolite was done in the steel ball vibrated mill for 1-10 min where the ratio of steel ball and sample was 1:100. After that for 1-10 min than there was defined its surface [7].

Cement mixture

Portland cement and cement-zeolite mixtures were prepared as paste form. The powders of 10 wt. %, 15 wt. % and 20 wt. % of zeolite mixtures were added with distilled water by using water-to-cement ratio (w/c) of 0.65. Cement paste samples were then kept at room temperature in air for 1, 7 and 28 days.

Characterization and testing

Morphology and mineralogical compositions of cement pastes at various curing time were determined. The fracture samples were examined by using scanning electron microscope (SEM – Hitachi S4800 field emission gun scanning electron microscope). The small-flat piece samples were then crushed, ground to pass through a 150 mesh of sieve size to obtain fine powders.

Mineralogical compositions of these samples were examined by an X-ray diffractometer (МАХima X XRD-7000 diffractometer) using Сu (K α 1=1.5406, K α 2=1.54439) anode, Ni filter and Со-anode, Fe-filter X-ray pipes [8].

Mechanical performance. Mechanical performance of the blended cement samples was determined by measuring the compressive strength of the hardened mortar. After one day of hydration, the samples were separated from the mould plate, cured at room temperature for 1, 7 and 28 days and then subjected to a compressive strength test [9].

Freeze-thaw resistance. Normal thickened mortar of Portland cement and blended cement with zeolite was pressed in cube 2 x 2 x 2 cm, then placed in a freezer to reach -20 о С for 4 h. The samples are removed and immersed in water with temperature not less than +10оС and left for 4 h. This freezing and thawing process is called one cycle and was repeated 25 cycles. After 25 cycles the sample was dried and compressive strength was determined.

Results and discussion

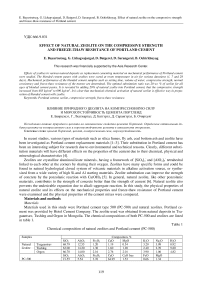

After activation of zeolites by the thermal and mechano-chemical activation methods, specific weight of natural zeolite was become 11748 cm2/g for thermal activation and 11712 cm2/g for mechano-chemical activation. The mechano-chemical activation of zeolite was chosen in this study because results of two methods were almost same. Fig. 1 shows the XRD patterns of natural and mechano-chemically activated zeolites. In comparison of XRD patterns of zeolite and activated zeolite peaks corresponding to the anortit and quartz minerals were disappeared. This means that content of zeolite in natural deposit was increased due to contrastive changes in clinoplilolite mineral. Other peaks were not changed.

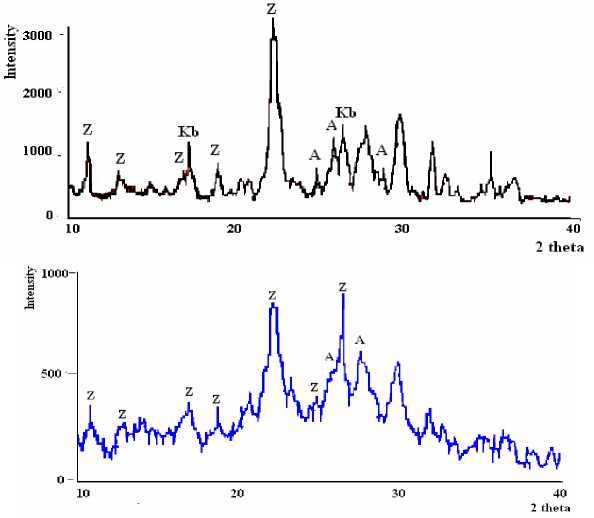

Fig. 2 shows the XRD patterns of blended cement pastes with the incorporating of 20 wt. % of zeolite, curing at 1, 7 and 28 days. The XRD results of blended cement pastes with 10 and 15 wt. % of zeolite are not shown in this study. The hydration products in blended cements are generally similar to those observed in pure Portland cement. In all samples, the main crystalline products were calcium hydroxide, calcium carbonate, ettringite together with unreacted zeolite and cement paste. An increase of curing time resulted in more hydration products.

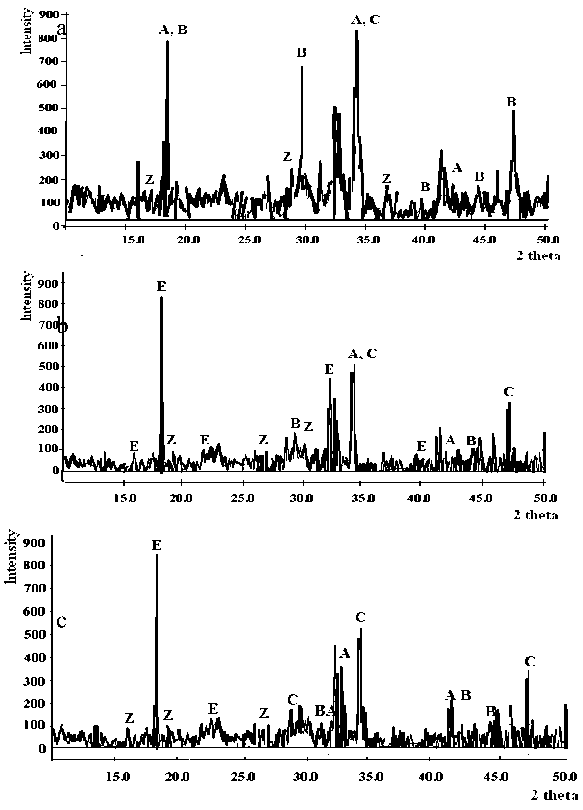

To study effect of curing time on blended cement pastes, in 1 and 7 days, reflection intensities of clinoptilolite mineral was higher, however after 28 day reflection intensities of clinoptilolit mineral were decreasing. It is clear that surface of blended cement paste was becoming homogeneous by insertion zeolite molecules into porous cement structures. It is possibly that by increasing duration of curing (fig. 2, curves a, b and c), the content of Ca(OH)2 rises, and more 3CaO SiO2 and 2CaO SiO2 converts into calcium hydrosilicate and calcium hydroxide. Fig. 3 illustrates the SEM images of mechano-chemically activated zeolite in Tushleg deposit and hydration products obtained from blended cements with 20 wt. % zeolite, at different curing time. Fig. 3 (b) showed that the ettringite and Ca(OH)2 formed in cement samples, curing for 1 day. Over the longer period of time as shown in fig. 3 (c and d), the development of dense microstructure generated showing the binding together of other hydrated products. In all of the cases, the same results were observed for zeolites in Urgun and Tsagaan Tsav deposits.

Fig. 1. The XRD patterns of natural and mechano-chemical activated zeolites in Tushleg deposits (A-alite, Kb-quartz, Z-zeolite)

Fig. 2. XRD patterns of blended cement paste with the incorporating of 20 wt. % of zeolite, at different curing times; a) 1day, b) 7 days and c) 28 days (A-alite, C-Ca(OH)2, B-belite, Z-zeolite, E-ettringite)

Fig. 3. SEM images: a) activated zeolite; b-d) hydration products obtained from blended cement with 20 wt. % of zeolite in 1, 7 and 28 days

The normal consistency, volume of water and setting times of blended cements are shown in table 2. From the results of the experiments, as increasing the weight percent of zeolite the volume of the normal consistency of mixtures was decreased. The decrease in setting time was evident at the beginning of setting times of zeolite-substituted cements. When the ratio of substituted materials was increased, beginning of setting time decreased. This decrease in beginning of setting time due to fineness of the cement can be explained in this way: when zeolite is ground with clinker, the fineness of the cement increases; hence, the hydration process becomes faster, and that reduces setting time. The volume of water decreased when the conetnt of zeolite was increased.

The compressive strength of zeolite-substituted cement pastes is given in table 3. The compressive strength in 28 days was 485 kg/cm2 for Portland cement (PC500), 825 kg/cm2 for blended cement with 20 wt. % of zeolite in Tushleg deposit, 795 kg/cm2 for blended cement with zeolite in Tsagaan Tsav deposit, 790 kg/cm2 for blended cement with zeolite in Urgun deposit. Among all types of zeolites, the blended cement with Tushleg zeolite was shown the best results. As seen in table 3, when the ratio of zeolite is 20%, compressive strength increases. In this case, the optimal substitution ratio becomes 20% for all ages of cement pastes. In the all days, the compressive strength of the zeolite blended cement paste increased when the content of zeolite increased.

Table 2

Normal consistency, setting time and volume of water of the cement mixtures

|

Zeolite |

Cement mixture, wt. % of zeolite |

Volume of water, ml |

Setting time, hrs.:min. |

Normal consistency, % |

|

|

Beginning of setting time |

End of setting time |

||||

|

PC500 (Portland cement) |

0 |

65 |

2:30 |

3:10 |

26.3 |

|

Tushleg activated zeolite |

10 |

93 |

1:45 |

3:24 |

20.6 |

|

15 |

90 |

2:25 |

3:09 |

20.0 |

|

|

20 |

87 |

2:16 |

3:32 |

19.3 |

|

|

Tsagaan Tsav activated zeolite |

10 |

96 |

1:38 |

3:12 |

21.3 |

|

15 |

94 |

2:00 |

2:59 |

20.9 |

|

|

20 |

91 |

2:06 |

3:26 |

20.2 |

|

|

Urgun activated zeolite |

10 |

96 |

1:49 |

3:00 |

21.5 |

|

15 |

94 |

2:00 |

2:21 |

20.9 |

|

|

20 |

91 |

2:12 |

3:36 |

20.6 |

|

Table 3

Compressive strength of the blended cements

|

Sample |

Compressive strength, kg/cm2 |

||||||||

|

1 day |

7 day \ |

28 day |

|||||||

|

Cement:zeolite, % |

|||||||||

|

90 :10 |

85:15 |

80:20 |

90 :10 |

85:15 |

80:20 |

90 :10 |

85:15 |

80:20 |

|

|

PC500 |

355 |

400 |

485 |

||||||

|

Tushleg zeolite |

400 |

435 |

475 |

550 |

590 |

610 |

745 |

780 |

825 |

|

Tsagaan Tsav zeolite |

405 |

425 |

430 |

540 |

535 |

580 |

725 |

760 |

795 |

|

Urgun zeolite |

395 |

420 |

405 |

615 |

635 |

665 |

780 |

755 |

790 |

Table 4

Effect of natural and mechano-chemically activated zeolite in Tushleg deposits on freeze-thaw resistance of cement

|

Sample |

Compressive strength, kg/cm2 |

|||||

|

After 28 day |

After 28 day 25 cycles |

|||||

|

Cement:zeolite,% |

||||||

|

90 :10 |

85:15 |

80:20 |

90 :10 |

85:15 |

80:20 |

|

|

PC500 |

525 |

435 |

||||

|

PC500:Natural zeolite |

700 |

695 |

735 |

645 |

620 |

680 |

|

PC500:Mechano-chemically activated zeolite |

725 |

760 |

795 |

685 |

715 |

765 |

Effect of Tushleg zeolite on freeze-thaw resistance of cement was shown in table 4. Compressive strength and freeze-thaw resistance were compared for blended cement mixture and cement without additives or zeolites. After 25 cycles in 28 days, compressive strength was 435 kg/cm2 for PC500, 680 kg/cm2 (1.56 times higher than PC500) for blended cement with natural zeolite, 765 kg/cm2 (1.76 times higher than PC500) for blended cement with mechano-chemically activated zeolite. The compressive strength of blended cement with mechano-chemically activated zeolite was the highest among the blended cements. Freeze-thaw resistance after 25 cycles for 20 wt. % of zeolite blended cement was the highest. After 25 freeze-thaw cycles, compressive strength loss was only 7.5% for blended cement with natural zeolite, and 3.8% for blended cement with mechano-chemically activated zeolite. It is clear that mechano-chemically activation of natural zeolite is effective way in preparation of blended cement with zeolite.

С onclusions

From this study, it is shown that the zeolite in the blended cement reacted with the Ca(OH)2 liberated from hydration of cement and water. This resulted in the reduction of Ca(OH) 2 in blended cements and led to the formation of calcium silicate and aluminate compounds. The optimal substitution ratio was 20 wt. % of zeolite for all ages of cement pastes. It is revealed that by adding 20% natural zeolite into Portland cement, the compressive strength increased from 485 kg/cm2 to 690 kg/cm2. After 25 freeze-thaw cycles, compressive strength loss was only 7.5% for blended cement with natural zeolite, and 3.8% for blended cement with mechano-chemically activated zeolite. It is clear that mechano-chemically activation of natural zeolite is effective way in preparation of blended cement with zeolite.

Cement mixtures obtained in this study require less amount of clinker, which results in increases in production and savings in energy. Such production would be economical advantages to conventional Portland cement and an environmentally friendly solution.