Effects of ultrasound waves on rehydration of carrot slices in osmotic drying pretreatment

Автор: Soheila Tahmasebi, Somaye Mirzaee, Mohammad Ali Shariati, Mehdi Kaviyani, Behnam Montazeri

Журнал: Биология в сельском хозяйстве @biology-in-agriculture

Рубрика: Актуальные исследования иностранных авторов

Статья в выпуске: 2 т.3, 2014 года.

Бесплатный доступ

In this study carrot slices were put in glucose osmotic 50 % at 1, 2 and 3 hr. Ultrasound waves, frequency 40 kH power 30 w/l, passed through container of osmotic solution and carrot slices. The results revealed that significant increasing of dry matter of sample by using ultrasound waves. pre osmotic time had a significant on dry material by increasing from 1 to 3 hr. sample treated by ultrasound waves lost water faster and their final dry solid was significantly more than control (without ultrasound treatment).

Ultrasound wave, osmotic drying, rehydration

Короткий адрес: https://sciup.org/14770279

IDR: 14770279 | УДК: 664-404

Текст научной статьи Effects of ultrasound waves on rehydration of carrot slices in osmotic drying pretreatment

Introduction Material and Method

Osmotic dehydration is one the new drying methods of food stuffs (Tavakolipour, 2002) which can be used in combination of hot air as preprocess before dehydration or as dehydrating method (Zargari, 1992; Fito et al, 1992). In this method , food slices put in an osmotic solution more than product (salty or sweet solu-tions).Osmotic pressure cause to gradually removing of cell wall’s water, penetrating a few of salts or minerals from solution to food stuff texture. Finally it observed that moisture has been decreased and dry solid increased (Rahman et al , 2007; Simal et al , 2003).

Water content of Food stuff decreases after osmotic dehydration while dry matter increases . there are some parameters including rehydration process including osmotic solution (type, concentration) , thickness of food stuff , shaking etc(Soti khaibani, 2003).

Required carrot bout freshly of fruit vegetable market, required glucose BX 80 bout from Shadineh Co Isfahan, Iran .

Slice Preparing

Carrots with 2 cm diameter were selected to perform experiments .first of all their head and tail which didn’t have suitable thickness cut , the middle part cut into slices with 2 cm diameter and their size , shape uniformed.

Preparing of Osmotic Solution

To prepare this solution glucose solution 50 % w/w with BX 80 % applied, diluted with distilled in ration 10:6 to produce a 50 % w/w solution.

Ultrasound Wave Treatment

To apply this treatment, ultrasound bath produced by pars Nahand co equipped with 3 ultrasound generator with 50 w power (150w together) used, carrot slices with osmotic solution in with 1:4 ratio (200 g slices and

800 g osmotic solution) mixed, put in an 1lit beaker in ultrasound bath filled by 5 L water as a waves transferring medium and temperature moderating, samples treated for 1-3 hr. Samples were shook every 1 min equally by glass bar during this time. Water temperature controlled during process, fixed in range 38-40 ˚c by removing some hot water. In the end, slices let to be removed their water by a metal net and dried by straw paper.

Rehydration Experiment

Since rehydration considers as one of the quality indexes of dried food , 20 g of all dried samples soaked in 200 ml distilled water at 20 ˚c for 1 hr , then dried by straw paper after removing water . water intake measured by the following formula:

A=(W-D)/D ×100

In which:

W= sample weight after rehydration

D= Dried sample weight before rehydration

A= moisture percent base on dry matter

All the results were analyzed by Duncan and tests using SPSS software.

Results and DiscussionResults of Rehydration Experiment

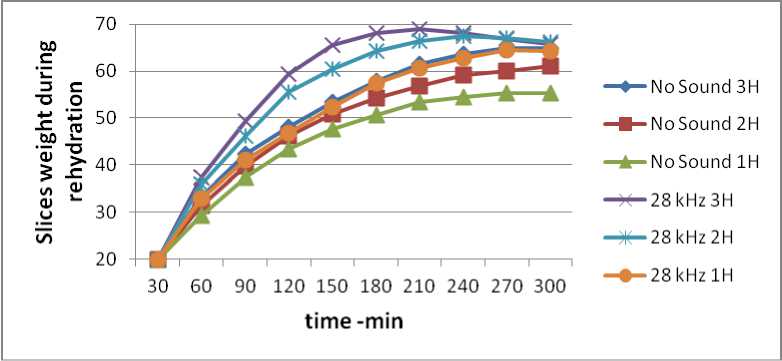

Figure 1 indicated that samples with no ultra sound treatment reached to constant weight in the last of period, while ultra sound treated samples reached to their maximum weight in 3rd hours, then their weight decreased. This implies that ultra sound treated samples have more porosity and more intake of materials of osmotic solution, therefore causes to more race of rehydration, but slices weight decreases gradually by absorbing more water and entering more absorbed materials into this water. Final weight was significantly more than control after 5 hr , although ultra sound treated samples need less time to rehydrate.

Figure 1. Rehydration of dried samples

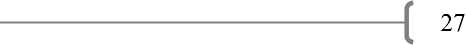

Figure 3. Comparison of averages of interaction effect

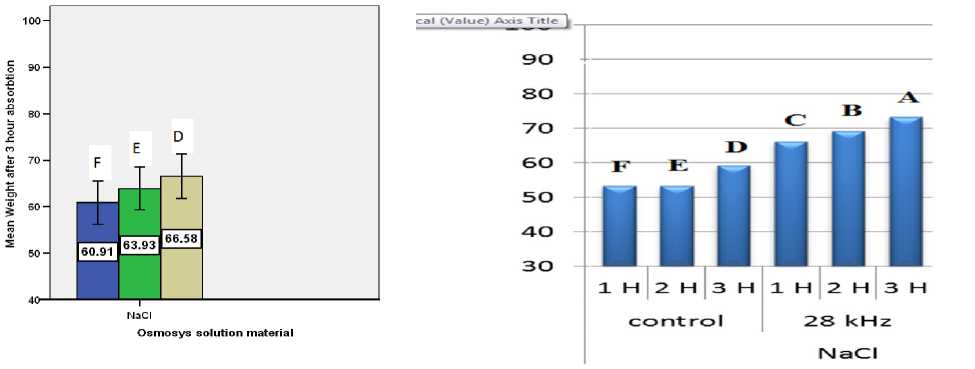

Figure 2. The effect of osmotic solution during pre osmotic process

Rehydration amount increased in 1-3 hr of pre osmotic treatment and the most rehydration observed in salty solution with no ultra sound treatment (Fig 3).

Conclusion

The most and the least rehydration observed in control (salty solution) after 3 hr and 1 hr respectively .the final weight of ultra sound treated samples were significantly more than control. Ultra sound treated samples also reached to the constant weight after 3 hr, then their weight subtract while samples with no ultra sound treatment reached to the constant weight to the end of period.

Список литературы Effects of ultrasound waves on rehydration of carrot slices in osmotic drying pretreatment

- Fito, P.; Chiralt, A, Barat, J.; Salvatori, D and Andrés, A. 1998. “Some advances in osmotic dehydration of fruit.” Food Science and Technology International, 4, 329-338.

- Rahman, MS, and Perera, CO. 2007.Drying and Food Preservation. pp.412. InRahman MS, Handbook of food preservation, 2nded., CRC press.

- Rastogi, NK, Raghavarao, K. 1997. Waterand solute diffusion coefficients ofcarrot as a function of temperature andconcentration during osmoticdehydration. Journal of Food Engineering34:429-440

- Rodrigues, S.; Fernandes, F.A.N. 2007 Ultrasound in fruit processing.In New Food Engineering Research Trends; Urwaye,A.P., ed.; Nova Science Publishers: Hauppauge, NY,;103-135.

- Sakoei,R.Alizadeh,M.2008. Investigation of Different Parameters of Combined method of Microwave and Osmotic Dehydration on Time of Kiwi Drying.18th National Iranian Conference on Food Science and Technology.

- Simal S., Benedito J., Clemente G., Femenia A., Rosselló C., 2003. Ultrasonic determination of Sonochem.3, S253-S260.

- Soleimani,J.Emamjomeh,Z., Ghasemzadeh,H,R.2008. Osmotic Pretreatment of Dried Carrot by Hot Air Method.Research in Agriculture and Horticulture.78,101-109.

- Sooti Khiabani,M.,Sehri,M., Emamjomeh,Z.2003. Investigation of Osmotic Conditions on the Rehydration Content of Peach

- Tavaklipour, H.2001. Drying of Food: Principals and Methods.Aeij Publication,Tehran.108.

- Zargari,A. 1992.Herbal Plants,1st issue.Tehran Medical Unviersity.682.