Engeneering of a cooling system for a reusable liquid-propellant rocket engine opereting on tripropellant fuel

Автор: Belyakov V. A., Vasilevsky D. O., Ermashkevich A. A., Kolomentsev A. I., Farizanov I. R.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 2 vol.22, 2021 года.

Бесплатный доступ

Currently, in the field of engine building, development of three-component propulsion systems (PS) is a very promising task. Liquid-propellant rocket engines (LPRE) operating at the initial stage of launching a launch vehicle (LV) on liquid oxygen + kerosene fuel and at high-altitude launch sites using cryogenic fuel (liquid oxygen + liquid hydrogen) are in particular interest. LPRE that use three-component fuel have a high pressure level in a combustion chamber (CC) (up to 30 MPa) and temperatures (up to 4000 K). In this regard, arise questions related to reliable cooling of such engines, as well as ensuring minimal hydraulic fluid losses in a cooling passage in order to further use re-frigerant as a working fluid for driving the turbine of a booster turbo pump unit (BTP). The object of research is a two-mode single-chamber three-component liquid-propellant rocket engine, made in a closed circuit with generator gas afterburning. Oxidizing agent is liquid oxygen, fuel is RG-1 kerosene and liquid hydrogen. Cooling of the chamber is combined: it consists of regenerative and internal. Regenerative cooling passage is formed by longitudinal integral-machined fins. Hipercritical hydrogen is used as an engine coolant. Internal cooling includes a tantalum coating applied to a fire wall of the chamber in a critical section. The article examines the problems of organizing cooling system (CS) and implementation of effective heat removal from a firing wall of a three-component rocket engine. Basing on existing liquid-propellant engine cooling systems, optimal circuit solutions and measures to remove thermal load in the most stressed places are proposed. A mathematical model has been developed for calculating a CS of a three-component LPRE. The results of the design calculation of cooling using several calculation methods are presented.

LPRE on three-component fuel, thermal protection of an engine body, mathematical model of LPRE, heat and mass transfer of three-component combustion products.

Короткий адрес: https://sciup.org/148321807

IDR: 148321807 | УДК: 629.7.036.54 | DOI: 10.31772/2712-8970-2021-22-2-316-327

Текст научной статьи Engeneering of a cooling system for a reusable liquid-propellant rocket engine opereting on tripropellant fuel

During engeneering of LPRE, special attention is paid to the development of engine cooling system. Existing liquid-propellant rocket engines that use high-boiling-point fuel as a cooler of CC are limited by boiling point of coolant medium in the jacket passage. Intensification of heat transfer in cooling jacket entails large hydraulic losses of fluid in the passage, this is especially typical for LPRE.

To achieve the highest efficiency and effectiveness of LPRE, it is proposed to use an additional fuel component as propellent. Operation of such liquid-propellant engine is possible when using a pair of fuel liquid oxygen + hydrocarbon fuel in the first section of the launch vehicle, in the second section - liquid oxygen + liquid hydrogen. It should be noted that during the entire flight, the engine is cooled with super-critical hy- drogen supplied to the cooling jacket by a separate pump of a turbo pump unit. This measure for organizing a cooling jacket of a three-component LPRE makes it possible to avoid burnout of the walls of CC during engine operation due to efficient heat removal of supercritical hydrogen, and also to reduce the excess pressure of a hydrocarbon pump in the first section of a launch vehicle.

However, at certain Km (ratio of fuel components in CC) and Pk (pressure in CC), the amount of liquid hydrogen supplied to the cooling jacket is not enough to ensure reliable engine cooling. Therefore, the authors of the work considered the use of a heat-protective coating of a fire wall of the chamber in the critical section made of tantalum.

Cooling system of rocket engine on three-component fuel

LPRE running on three-component fuel due to high pressure in the CC has a complex and intense cooling system.

Cooling system is as a set of inlet and outlet coolant manifolds, a cooling passage that provides reliable and sufficient cooling due to optimal geometric parameters of a cooling flow passage (ribs, thicknesses of inner and outer walls, etc.), a system of inlet and outlet openings, a system multi-circuit bypass.

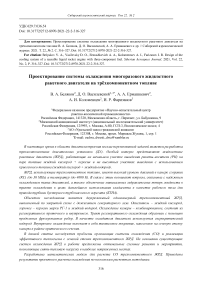

Gas dynamic profile of the engine, shown in fig. 1, was divided into 1200 design sections. As the initial data for cooling system design, the parameters obtained as a result of energy coupling of the engine were taken, as follows: mass flow rate, temperature and pressure at the inlet to cooling passage.

Рис. 1. Газодинамический профиль двигателя, работающего на трёхкомпонентном топливе

Fig. 1. The gas-dynamic profile of the engine operating on tripropellant fuel

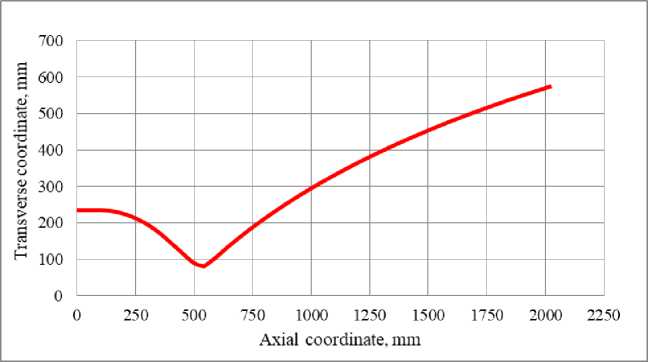

The cooling scheme [1] of LPRE operating on tripropellant fuel is shown in Fig. 2.

Cooling system of a three-component LPRE consists of 3 sections with a different number of longitudinal integral-machined fins and 3 coolant manifolds (one input and two output); in each underwater manifold [2] a number of openings are provided for supplying and removing refrigerant from cooling system channels. The inner wall of the regenerative-flowing part of the engine has a thickness of 0.8 mm along the entire length of the engine and consists entirely of copper alloy BrKh-0.8, the outer wall is made of stainless steel 12X18H10T. The thickness of load-bearing wall is chosen according to the strength conditions and is 3 mm.

Рис. 2. Схема охлаждения трехкомпонентного ЖРД

-

Fig. 2. The cooling system of three-component LPRE

Tank pressurization

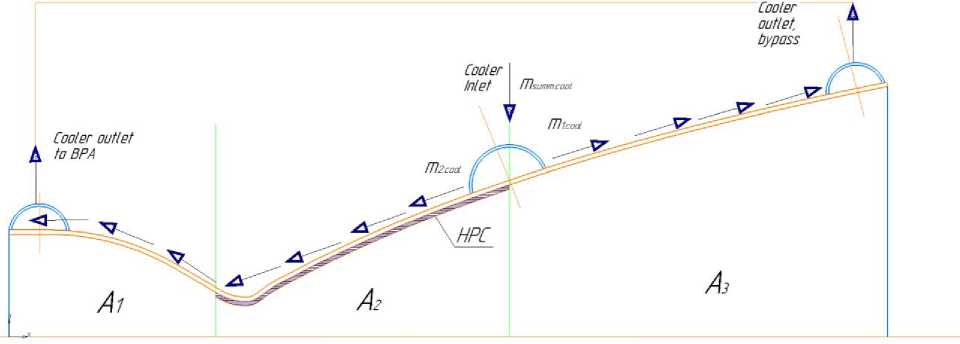

Рис. 3. Предлагаемая ПГС для ЖРД, работающего на трёхкомпонентном топливе

-

Fig. 3. The proposed PHS for rocket engine operating on tripropellant fuel

In the А 2 segment, a tantalum (Ta) heat-shielding coating [3] (TSP) 0.6 mm thick is applied to the inner fire wall. This coating has a high melting point (3290 K) and good adhesion (cohesion) to the surface of a fire wall.

Cooling system of LPRE works as follows.

Cumulative coolant-flow rate, equal to 9.6 kg/s, is supplied to the inlet manifold, located in the axial longitudinal coordinate of 1150 mm, through two rows of holes located in each channel, enters the cooling passage circuit. Pressure and temperature of the cooler at the inlet to the inlet manifold is 58.58 MPa and 43 K. Сooling passage consists of 2 separate circuits, independent of each other, into which different refrigerant flows enter.

The А 3 segment (corresponding to the second circuit of the two-circuit cooling system) for cooling the nozzle exit receives the coolant flow m 1cool equal to 1.6 kg/s, coolant-flow moves in direct flow to the outlet manifold and then through the bypass pipeline to the turbine drive of the booster turbopump assembly of fuel of liquid hydrogen, and then goes to the gas generator (GG) (see Fig. 3).

The А 1 and А 2 segments (corresponding to the first circuit of two-circuit cooling system) receive the cooler flow m 2cool equal to 8.0 kg/s; coolant-flow moves in reverse flow, cools the supersonic, subsonic and cylindrical parts of a nozzle, as well as choking section. Further, coolant-flow is directed to the outlet coolant manifold and to pipeline, where it is mixed with a flow rate from А 3 segment, and moves along the bypass pipeline to drive turbine drive of the booster turbopump assembly of fuel with subsequent supply to GG.

Calculation of cooling of a three-component LPRE according to V M Ievlev and D R Bartz methods

Cooling was calculated using the Rocket Propulsion Analysis (RPA) analytical program. The RPA program is a multi-platform analytical tool for conceptual and preliminary design of chemical rocket engines of various concepts (air-jet engines (AJE), LPRE, low-thrust liquid-propellant rocket engines (LTLPRE), low-thrust gas rocket engines (LTGRE), hydrojet engines (HE) ), solid propellant rocket engines (SPRE), combined rocket engines (CRE) and others).

The RPA program has its own calculation module for determining the preliminary appearance of cooling passage structure at early stages of design and analyzing cooling and thermal state of LPRE. The mathematical model used in the RPA program includes standard heat and mass transfer models (compliance with the heat balance, direction of heat flow, internal or external heat supply, heat removal, thermal conductivity of single-layer and multilayer walls, internal "blocking" of heat flow by blowing into the wall or boundary layer (influence on near-wall flows by active injection of a gas or liquid with a low temperature), entrainment of material with heat blocking, etc.), thermal protection and cooling (internal film cooling (barrier, film), the use of various heat-protective coatings, external radiation, regenerative-flow or autonomous), heat engineering calculation formulas for the selected design and developed surface of cooling passage (longitudinal and helical (spiral) fins, corrugations, slotted channels, tubes, etc.), heat exchange criterial Nusselt ratios (Nu) for various refrigerants and fluid dynamic one-dimensional and two-dimensional models describing the movement of gases and liquids in the gas passage of the GDS and the annular ducting of cooling passage.

For thermal protection and cooling of walls from the influence of high-enthalpy media in LPRE with different types of Laval nozzles (profiled, conical, spherical, with a central body, pear-shaped, etc.), the most widespread use of regenerative-flow or automatic cooling systems with various heat transfer surfaces in order to intensify heat transfer and remove additional heat removal (for cryogenic heat carriers and refrigerants). Therefore, the process of cooling LPRE is a heat and mass exchange [4] of hot gas (fuel combustion products) and refrigerant by means of thermal conductivity, as well as forced and free convection, taking into account regenerative heat exchange.

An interesting and rare direction in calculation of cooling system and heat exchange in a steam channel of a short linear heat pipe, which is geometrically similar to a Laval nozzle, is practiced by Rudetransservice LLC, located in Veliky Novgorod [5].

In the software package (PC) RPA [6], cooling system is designed. The program allows evaluating the value of heat flux density in a stationary supply, the preliminary design of cooling system, engine cooling according to the method of V.M. Ievlev standardized in the domestic engine-structure and the foreign meth- od of D R Bartz. Moreover, domestic technique of V M Ievlev is used as the main engineering calculation technique, which is in good agreement with experimental data [7; 8]. After the calculation, convergence of both methods was assessed.

The semiempirical method of V M Ievlev is based on the model of heat transfer of pulses and energy, as well as on an integral approximate solution of the boundary layer using empirical laws of friction and heat transfer, taking into account variability of thermal and physical properties of high-temperature media in the integral approximate solution of the boundary layer and in the flow core. A more detailed description of the technique is given in [9; 10].

The method of convective heat transfer in axially symmetric Laval nozzles by D R Bartz takes into account thickness of the integral approximate solution of the boundary layer, surface friction and heat flux density. The method is based on the integral solution of the equations of momentum and energy for a thin axial symmetric boundary layer with recalculation of the thermophysical and thermodynamic parameters of the "reference nozzle" to a calculated investigated nozzle, and the technique contains a coherent and accessible software algorithm for fast use in electronic computing machine (computer) - International Business Machines 7090 (IBM 7090). A more detailed description of D R Bartz's technique is given in [11; 12].

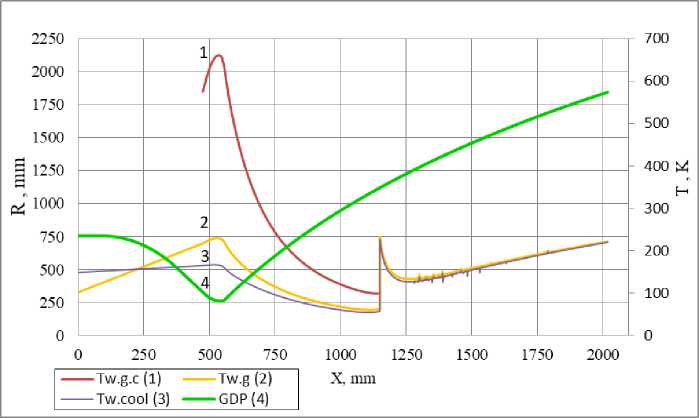

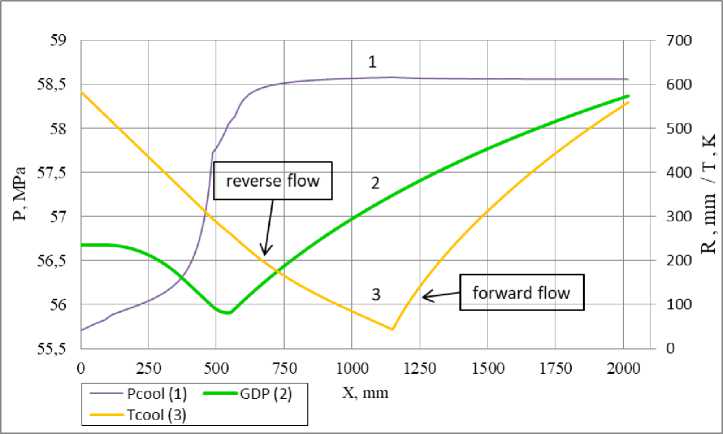

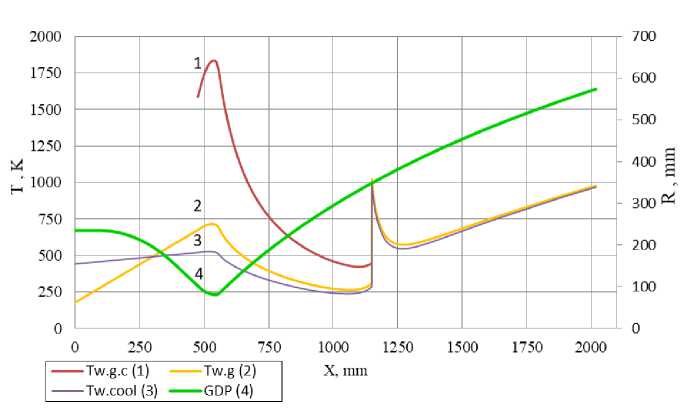

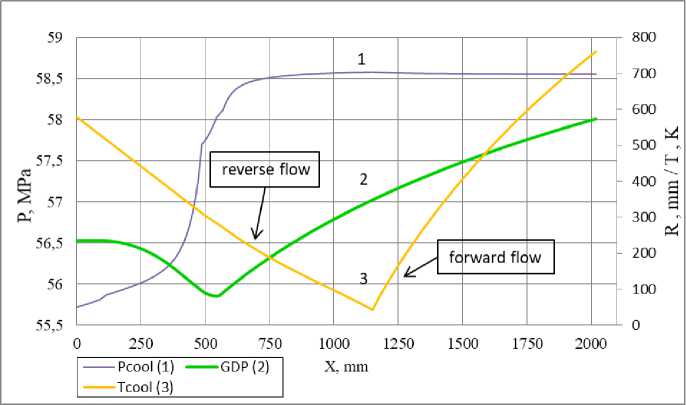

In Fig. 4–7 when calculating cooling by two methods, the following designations are accepted: Tс.g.c. -temperature of a heat-shielding coating on gas side; Tw.g. - wall temperature from the side of gas or coating; Tw.cool - wall temperature from the side of cooling liquid; Pcool - cooler pressure; Tcool - cooler temperature.

Calculation of cooling of a three-component rocket engine according to V M Ievlev method

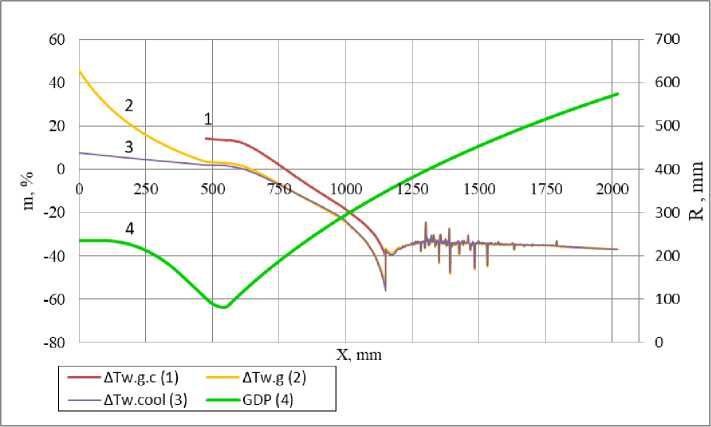

In accordance with the selected cooling system, the calculation of cooling was carried out by Ievlev’s method. The thermal state (TS) of the camera body is shown in Fig. 4. Hydraulic losses and calculated heating of the cooler are shown in Fig. 5.

When calculating by Ievlev’s method, a complete and high-quality picture of the TS of the camera body, the temperature state of the walls and TZP was obtained.

Calculation of cooling of a three-component rocket engine according to D R Bartz method

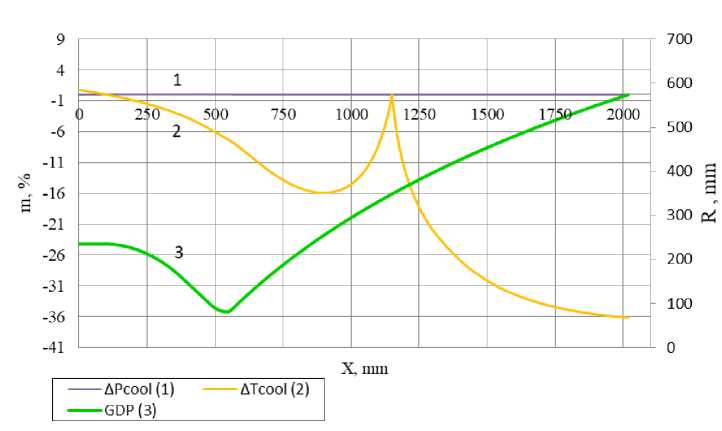

In accordance with the selected cooling system, the cooling calculation was carried out by Bartz method. The TS of the camera body is shown in Fig. 6. Hydraulic losses of a cooler [13; 14] and the calculated heating of a cooler is shown in Fig. 7.

When calculating by Bartz method, incomplete agreement with Ievlev method was obtained.

Рис. 4. ТС ЖРД, работающего на трёхкомпонентном топливе

Fig. 4. TS of an LPRE running on tripropellant fuel

Рис. 5. Гидравлические потери и подогрев охладителя в разных контурах ТО ЖРД

Fig. 5. Hydraulic losses and heating of the cooler at different contours of CJ LPRE

Comparison of the residuals of cooling calculations according to the methods of D.R.Bartz and V.M. Ievliv

As a result of calculating the cooling of a three-component liquid-propellant engine according to the methods of Bartz and Ievliv, an analysis of obtained parameters was carried out using residual formula for the deviation of calculation methods. Fig. 8 and 9 show deviations of the calculation results obtained by Ievlev and Bartz method.

Deviations in the calculations according to Bartz method from Ievlev method according to the TS of the body are no more than 40% in modulus, the error in calculating the heating of the cooler is no more than 36% in modulus, while the error in calculating hydraulic losses is small (less than 1%). Oscillatory nature of wall temperatures on gas and liquid side in the range from 1250 up to 1815 mm is associated with convergence of the calculation results by Ievlev method with a large number of calculated points.

Therefore, we can conclude that estimation of hydraulic losses, with a small deviation in accuracy, is correct to carry out and evaluate by both methods. TS of the chamber body and heating of the coolant can be more accurately assessed by Ievlev method as an accessible engineering technique that correlates well with experimental data in the literature and the test results of firing units of liquid-propellant rocket engines, GG, nuclear rocket engines (NRE), ignition devices, burners, steam and gas generators, evaporators ejectors and gas-dynamic pipes (GDP) [15] and other high-temperature power plants with atomization, chemical transformation and combustion of fuel with a high temperature in a combustion chamber (more than 900 K) [16].

Рис. 6. ТС ЖРД, работающего на трёхкомпонентном топливе

Fig. 6. TS of an LPRE running on tripropellant fuel

Рис. 7. Гидравлические потери и подогрев охладителя в разных контурах ТО ЖРД

Fig. 7. Hydraulic losses and heating of the cooler at different contours of CJ LPRE

Рис. 8. Невязка теплового состояния ЖРД, работающего на трёхкомпонентном топливе

Fig.8. The discrepancy of the thermal state of LPRE operating on tripropellant fuel

Рис. 9. Невязка гидравлических потерь и подогрева охладителя в разных контурах ТО ЖРД, работающего на трёхкомпонентном топливе

Fig. 9. Residual hydraulic losses and heating of refrigerant in different circuits of CJ LPRE operating on tripropellant fuel

Conclusion

The calculation of cooling system of a three-component rocket engine was carried out. Bartz and Ievlev methods for calculating cooling are considered. Based on the calculation results, the errors of two methods were obtained. According to the hull TS, the error was no more than 40% in modulus, the error in calculating heating of cooler was no more than 36% in modulus, the error in calculating hydraulic losses was less than 1%. Based on the convergence of the experimental and calculated data, the Ievlev method was chosen as the main technique. As a result of the calculation, the temperature and pressure of the refrigerant at the outlet from the primary circuit is 583.6 K and 55.73 MPa, from the second circuit - 558.85 K and 58.55 MPa. The maximum design temperature of the fire wall is 745.7 K, which is lower than the melting temperature of the

BRKh-08 material. The highest temperature of the tantalum coating is below the melting point of the coating material and is 2122.48 K.

As a result of calculations, it was revealed that, with the given parameters, when using precisely a two-circuit regenerative flow-through cooling system with thermal-protective coating applied to the fire wall in the A2 segment, full efficiency of the engine is obtained. Due to these measures, the TS of the chamber housing and coating is at a moderate and permissible level, therefore, the engine has reliable cooling.

Список литературы Engeneering of a cooling system for a reusable liquid-propellant rocket engine opereting on tripropellant fuel

- Gakhun G. G., Alekseev I. G., Berezanskaya E. L. et al. Atlas konstruktsiy ZHRD [ATLAS of LPRE design, Part 1]. Moscow, MAI Publ., 1969, 286 p.

- Berezhinsky R. A., Sokolov S. A., Gudkova S. R. et al. Modelirovanie rabochih processov i konstruktsiya elementov kamerj ZHRD [Modeling of working processes and construction of elements of the LPRE chamber]. Voronezh, VGTU Publ., 2002, 169 p.

- Dobrovolsky M. V. Zhidkostnye raketnye dvigateli, Osnovy proektirovaniya [Liquid rocket engines, Fundamentals of design]. Moscow, Bauman Moscow state technical University Publ., 2016, 461 p.

- Shevchenko Yu. N., Kishkin A. A., Tanasiyenko F. V. et al. [Calculation of complex heat transfer in the liquid circuit of the spacecraft thermal control system based on real topology and thermal properties]. Siberian journal of science and technology. 2019, Vol. 20, No. 3, P. 375–382 (In Russ.). Doi: 10.31772 / 2587-6066-2019-20-3-375-382.

- Seryakov A.V. [Investigation of flows in the steam channel of short linear heat pipes]. Siberian journal of science and technology. 2017, Vol. 18, No. 3, P. 592–603. (In Russ.)

- Ponomarenko A. RPA: Tool for Rocket Propulsion Analysis. Available at: http://propulsion-analysis.com (accessed: 10.10.2020).

- Ievlev V. M. Turbulenthoye dvizheniye vysokotemperaturnykh sploshnykh sred [Turbulent motion of high-temperature continuous media]. Moscow, Nauka Publ., 1975, 255 p.

- Ponomarenko A. RPA: Tool for Rocket Propulsion Analysis, Thermal Analysis of Thrust Chambers.Available at: http://propulsion‑analysis.com/downloads/2/docs/RPA_ThermalAnalysis. pdf (accessed: 10.10.2020).

- Kudryavtsev V. M., Vasiliev A. P. et al. Osnovy teorii i rascheta zhidkostyh raketnyh dvigatelej [Fundamentals of the theory and calculation of liquid rocket engines]. Moscow, Higher school Publ., 1975, 656 p.

- Salakhutdinov G. M. Razvitie metodov teplozashity v zhidkosntnyh rakentyh dvigatelyah [Development of methods of thermal protection in liquid rocket engines]. Moscow, Nauka Publ., 1984, 256 p.

- Elliot D. G., Bartz, D. R., Silver S. Culculation of turbulent boundary-layer grouth and heat transfer in axi-symmetric nozzles. Tech. Rep. JPL. 1963, No. 32-387, 45 p.

- Dewey M. S. A comparison of experimental heat-transfer coefficients in a nozzle with analytical predictions from Bartz’s methods for various combustion chamber pressures in a solid propellant rocket motor. A thesis submitted to the Graduate Faculty of North Carolina State University Raleigh in partial fulfillment of the requirements for the Degree DEPARTMENT OF Master of Science: Department of mechanical and aerospace engineering. Releigh, 1970. 99 p.

- Hobler T. Teploperedacha i teploombenniki [Heat transfer and heat exchangers]. Leningrad, Goskhimizdat Publ., 1961, 821 p.

- Shevchenko Yu. N., Kishkin A. A., Tanasiyenko F. V. et al. [Determining thermal resistances in the model of the liquid circuit of the spacecraft thermal control system]. Siberian journal of science and technology. 2019, Vol. 20, No. 3, P. 366–374. (In Russ.)Doi: 10.31772 / 2587-6066-2019-20-3-366-374.

- Zimin A. Yu. Razrabotka stenda ognevyh ispytanij zhidkostnogo raketnogo dvigatelya na toplive zhidkij kislorod I zhidkiy vodorod tyagoj 100 kN . Diplom specialista.[Development of a stand for fire tests of a liquid rocket engine powered by liquid oxygen and liquid hydrogen with 100kn thrust. Diploma of a specialist]. Moscow, MAI Publ., 2017, 106 p.

- Lebedinsky E. V. et al. Rabochie processy v zhidkostnom raketnom dvigatele i ih modelirovanie [Working processes in a liquid rocket engine and their modeling]. Moscow, Mashinostroenie Publ., 2008, 512 p.