Erosion coefficient of electrocontact processing of metals by a vibrating electrode-tool in electrolyte

Автор: Shestakov I.Y., Shestakov V.I., Remizov I.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.24, 2023 года.

Бесплатный доступ

Technological indicators of electrocontact processing of metals with a vibrating electrode-tool in an electrolyte have been studied quite fully. Knowledge of the erosion coefficient of this processing method will allow us to evaluate the performance of electrocontact processing in advance, at the stage of technological preparation of production. The article presents the methodology of the experiment, describes the installation based on a linear electrodynamic motor, which allows you to create a vibration of the electrode-tool and electrolyte flow in the interelectrode gap. The results of experimental studies are shown in the form of a graph of the dependence of the metal erosion coefficient on the water velocity in the interelectrode gap at various current densities. Based on the results and previous studies, it was assumed that the erosion coefficient depends in direct proportion on the voltage in the interelectrode gap and is inversely proportional to the volumetric heat capacity of the metal and its melting temperature. Based on the theory of electrical contacts and taking into account the features of electrocontact processing in the electrolyte, the definition of voltage in the contact zone has been refined. The theoretical value of the erosion coefficient exceeds the experimental value by two or more times.

Erosion coefficient, electrocontact processing, vibrating electrode-tool, electrolyte, current density, melting voltage

Короткий адрес: https://sciup.org/148329687

IDR: 148329687 | УДК: 621.9.048 | DOI: 10.31772/2712-8970-2023-24-1-204-210

Текст научной статьи Erosion coefficient of electrocontact processing of metals by a vibrating electrode-tool in electrolyte

In the production of aircraft parts, copy-piercing operations are used, which are carried out by electrophysical and electrochemical methods of metal processing [1–4].

These operations can be carried out by electro-contact processing with a vibrating electrode-tool both in air and in an electrolyte [5–8].

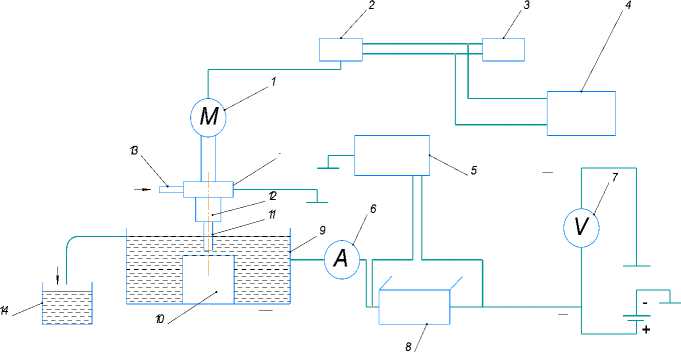

Fig. 1. Installation based on a linear electrodynamic motor:

1 – linear electrodynamic motor; 2 , 3 – pulse generators; 4 – power supply for an electrodynamic motor; 5 – oscilloscope; 6 – ammeter; 7 – voltmeter; 8 – shunt; 9 – bath; 10 – workpiece; 11 – electrode-tool;

12 – device; 13 – inlet fitting; 14 – dimensional capacity

Рис. 1. Установка на основе линейного электродинамического двигателя:

-

1 – линейный электродинамический двигатель; 2 , 3 – генераторы импульсов; 4 – блок питания электродинамического двигателя; 5 – осциллограф; 6 – амперметр, 7 – вольтметр; 8 – шунт;

-

9 – ванна; 10 – заготовка; 11 – электрод-инструмент; 12 – приспособление; 13 – штуцер входной;

-

14 – ёмкость мерная

In the above works, the technological indicators of the method (productivity, wear resistance of the electrode-tool, roughness of the machined surface, copying accuracy) were studied. However, in electrocontact processing, an important parameter is the erosion coefficient, which makes it possible to calculate the productivity of the method at the stage of technological preparation of production. The erosion coefficient for electrocontact machining with a rotating electrode-tool is considered in [9], however, there are no studies of the erosion coefficient for electrical machining with a vibrating cathode-tool.

For the experiments, we used a setup for electro-processing based on an electrodynamic drive [10], which was improved to ensure the flow regime of the electrolyte through the tool electrode (see Fig. 1).

Water, which is a weak electrolyte, was chosen as the electrolyte [11; 12]. Water has the following advantages: low cost, availability, non-flammability, the possibility of increasing the culture of production. Electroerosion machining in water at the same pulse energy is accompanied by a decrease in the wear of the tool electrode and an improvement in the surface quality [13].

Research methodology

A copper tube is used as a tool electrode, the outer diameter of which is 7.9 mm, the inner diameter is 5.8 mm. A workpiece ( 10 ) made of HVG steel is installed in the bath ( 9 ). The tool electrode ( 11 ) is fixed in the device ( 12 ) with a gap of 2–3 mm from the workpiece. Water is poured into the bath 15– 20 mm above the level of the workpiece. Through the fitting ( 13 ) water is supplied to the electrodetool ( 11 ) and the electrodynamic drive ( 1 ) is switched on. Then a constant voltage is applied to the tool electrode and the workpiece. During the experiment, the average values of current and voltage, the volume of electrolyte that passed through the interelectrode gap with the help of a measuring container ( 14 ), and the processing time are recorded. After processing, the dimensions of the round groove are measured – depth and diameter.

The current density is calculated by the well-known expression i = ICP

S, where Iср is the average value of the current, A; S is the cross-sectional area of the electrode, m2.

The consumption of power fluid flowing through the electrode-tool during processing is determined by

Q=р = V, т where V is the volume of water flowing during processing, м3; τ – processing time, s.

The area limited by the inner diameter of the electrode-tool (ET) and the value of the interelectrode gap (IEG) is calculated as follows:

S б = l -8 , where l is the circumference, m; δ is the effective value of the interelectrode gap by analogy with an alternating electrical sinusoidal voltage, m,

δ = 0,707·2·А, where A is the amplitude of ET oscillations.

The average speed of the electrolyte in the IEG:

υ = Q / S б .

The erosion coefficient is calculated by the formula

К эр = V ме / I ср * τ, where V ме is the amount of metal removed.

Research results

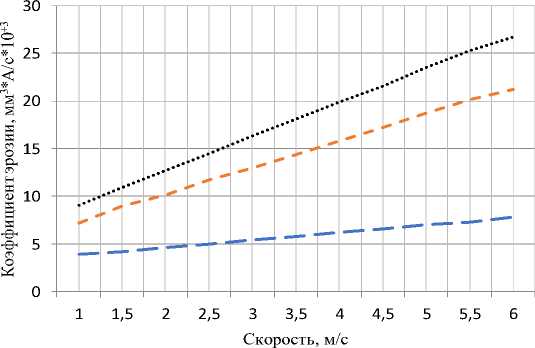

Based on the calculation results, a graph of the dependence of the erosion coefficient on the water velocity in the interelectrode gap (Fig. 2) was plotted at various current densities.

From Fig. 2 it follows that an increase in the velocity of water in the interelectrode gap leads to an increase in the erosion coefficient. This can be explained by the improvement in the removal of erosion products from the treatment zone, since the convective mass transfer is directly proportional to the water flow rate.

Fig. 2. Dependence of the metal erosion coefficient on the water velocity in the interelectrode gap at different current densities: row 1 – 44 A/cm2, row 2 – 91 A/cm2, row 3 – 97 A/cm2

Ряд1

Ряд2

Ряд3

Рис. 2. Зависимость коэффициента эрозии металла от скорости воды в межэлектродном зазоре при различных плотностях тока: ряд 1 – 44 А/см2; ряд 2 – 91 А/см2 ; ряд 3 – 97 А/см2

It can be seen from the graph that the coefficient of metal erosion during electrocontact processing with a vibrating electrode-tool depends on the current density. In turn, the current density is directly proportional to the electric field strength i = σ * E, (1) where σ is the electrical conductivity of the electrolyte. The electric field strength is determined by the expression

E = U / δ, (2) where U is electrode voltage.

From expressions (1), (2) it follows that the erosion coefficient of electrocontact processing of metals by a vibrating electrode-tool depends in direct proportion to the voltage on the electrodes. The voltage at the electrodes is made up of voltage drops in the near-cathode and near-anode regions and in the electrolyte layer [14].

In [9], it was concluded that the erosion coefficient depends on the specific volumetric heat capacity of the treated metal. Therefore, this dependence is inversely proportional. The same dependence of the erosion coefficient is also observed on the melting temperature of the treated metal. Taking into account the foregoing, it is possible to represent the dependence of the theoretical erosion coefficient on the thermophysical properties of the treated metal and the voltage drop across the contact by the expression

К т = U п / C v * T, (3)

where K т is the theoretical coefficient of erosion of the treated metal, m3/A*s; Up is the voltage drop across the contact in the anode region, V; Cv is the specific volumetric heat capacity of the treated metal, J/m3K; T is the melting point of the processed metal, K.

The voltage drop across the contact, at which the temperature at the point of contact reaches the melting point of the metal, is called the melting voltage [15]. It should be noted that, according to the author of [16], the melting temperature at metal contact is the highest that is admissible in a solid contact, and an increase in voltage only leads to fuse contacts. In our case, the fusion of the electrodes does not occur due to the short duration of contact.

Erosion products obtained as a result of electro contact processing are predominantly spherical in shape and have an oxidized surface, which indicates the melting of the processed metal [7].

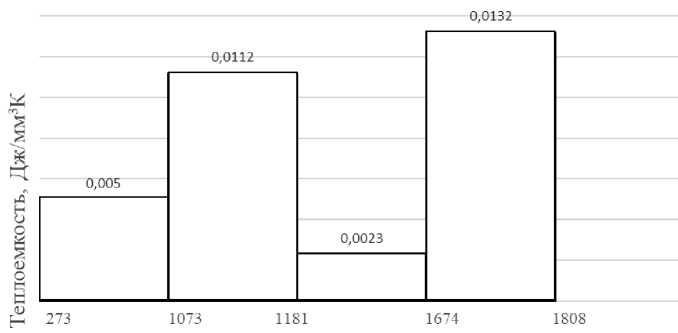

It is known that the heat capacity of metals and alloys increases with increasing temperature. The heat capacity of magnetic steels near the ferromagnetic phase transition increases by 40% compared to the heat capacity at room temperature [17]. The workpiece made of HVG steel contains no more than 3% of alloying components, so the heat capacity of the material will be determined by iron. The handbook [18] contains the formula and coefficients for calculating the specific molar heat capacity of iron in the tem- perature range from 273 to 2142 K. Using the known relationships, the specific volumetric heat capacity of iron was calculated in the specified temperature range. The calculation results are shown in Fig. 3.

Температура, К

Fig. 3. The dependence of the heat capacity of iron on temperature

Рис. 3. Зависимость теплоемкости железа от температуры

Multiplying the heat capacity by the temperature range and summing the results, we find the total area. Dividing this area by the entire temperature range of 1535 K, we obtain the average volumetric heat capacity equal to 0.0054 J/mm3K.

The melting voltage of iron is given in the handbook [19] U = 0.6 V, the melting temperature of iron [18] T = 1811 K. After substituting the data into expression (3), we get К т = 0.06 m3/A*s. From a comparison of the data shown in Fig. 2, it follows that the experimental values of the erosion coefficient are 2–3 times less than the theoretical value. This coefficient can be enhanced by increasing the current density and the velocity of the electrolyte in the gap. The current density is determined by the voltage (formulas (1) and (2)). However, the increase in voltage is limited by the transition of electrocontact processing to dimensional arc processing. During dimensional arc processing, the voltage on the electrodes must be at least 20–30 V [20; 21].

Conclusion

The erosion coefficient used to assess the resistance of contacts during electrical erosion can be used to evaluate the effectiveness of electrocontact processing with a vibrating tool electrode in an electrolyte. The experimental value of the erosion coefficient is less than the theoretical one, which indicates the need for research to improve the processing method under consideration.

Список литературы Erosion coefficient of electrocontact processing of metals by a vibrating electrode-tool in electrolyte

- Shmanev V. A., Filimoshin V. G., Karimov A. Kh. et al. Tekhnologiya elektrohimicheskoj obrabotki detalej v avia-dvigatelestroenii [Technology of electrochemical processing of parts in aircraft engine building]. Moscow, Mashinostroenie Publ., 1986, 168 p.

- Amitan G. L., Bajsupov I. A., Baron Y. M. Spravochnik po elektrofizicheskim i elektrohimicheskim metodam obrabotki [Reference book on electrophysical and electrochemical processing methods]. Leningrad, Mashinostroenie Publ., 1988, 719 p.

- Krymov V. V., Eliseev Yu. S., Zudin K. I. Proizvodstvo gazoturbinnyh dvigateley [Production of gas turbine engines.] Moscow, Mashinostroenie, Mashinostroenie-Flight Publ., 2002, 376 p.

- Moiseev V. A., Tarasov V. A., Kolmykov V. A., Filimonov A. S. Tekhnologiya proizvodstva zhidkostnyh raketnyh dvigateley [Technology for the production of liquid rocket engines]. Moscow, MSTU im. N. E. Bauman Publ., 2008, 381 p.

- Shestakov I. Ya., Rubanov S. V., Zolotykh E. I. [Research of electrocontact processing at vibration of an electrode-tool]. Materials, technologies, designs. Krasnoyarsk, 1996, P. 28–32 (In Russ.).

- Shestakov I. Ya., Stryuk A. I., Milenin V. N. [Electro-contact stitching of rivets]. Perspective materials, technologies, designs, economics. 2003, Is. 9, P. 81–84 (In Russ.).

- Shestakov I. Ya., Stryuk A. I., Tsukanov A. V. [Pulse electro-processing with a vibrating elec-trode-tool]. Vestnik SibGAU. 2004, No. 5, P. 253–258 (In Russ.).

- Shestakov I. Ya., Artyukova O. E., Remizov I. A. [Features of electro-contact-chemical treat-ment with a vibrating electrode-tool]. Vestnik SibGAU. 2013, No. 1 (47), P. 175–177 (In Russ.).

- Shestakov I. Ya., Shestakov V. I., Remizov I. A. [Erosion coefficient in electrocontact pro-cessing of metals]. Vestnik SAZH. 2022, No. 2, P. 337–346 (In Russ.).

- Fadeev A. A., Shestakov I. Ya., Artyukova O. E. [Designing a research facility for electrical pro-cessing based on an electrodynamic drive]. Vestnik SibGAU. 2010, No. 4 (30), P. 133–137 (In Russ.).

- Robinson R., Stokes R. Rastvory elektrolitov [Electrolyte solutions]. Moscow, IL Publ., 1963, 436 p.

- Salem R. R. Teoreticheskaya elektrohimiya [Theoretical electrochemistry]. Moscow, Vuzovskaya kniga Publ., 2001, 328 p.

- Stavitsky B. I., Konulin S. V. [On the question of the optimal form of idle voltage pulses and working current pulses during precision electrospark machining in water]. Electronic processing of materials. 1979, No. 3, P. 5–8 (In Russ.).

- Moroz I. I., Alekseev G. A., Vodyanitsky O. A. et al. Elektrohimicheskaya obrabotka metallov [Electrochemical treatment of metals]. Moscow, Mashinostroenie Publ., 1969, 208 p.

- Novikov Yu. N. Teoriya i raschyot elektricheskih apparatov [Theory and calculation of electri-cal apparatus]. Leningrad, Energoatomizdat Publ., 1986, 479 p.

- Holm R. Elektricheskie kontakty [Electric contacts]. Moscow, Foreign Literature Publ., 1961, 464 p.

- Babichev A. P., Babushkina N. A., Bratkovsky A. M. et al. Fizicheskie velichiny. Spravochnik [Physical quantities. Handbook]. Moscow, Energoatomizdat Publ., 1991, 1232 p.

- Andreeva T. V., Bolgar A. S., Vlasova M. V. et al. Svoystva elementov. V 2 chastyah. Ch. 1. Fizicheskie svojstva. Spravochnik [Properties of elements. In 2 parts. Part 1. Physical properties. Handbook]. Moscow, Metallurgy Publ., 1976, 600 p.

- Materialy v priborostroenii i avtomatike. Spravochnik [Materials in instrument making and au-tomation. Handbook]. Ed. Yu. M. Pyatina. Moscow, Mashinostroenie Publ., 1982, 528 p.

- Meshcheryakov N. G. Vysokoproizvoditel'naya razmernaya obrabotka dugovymi razryadami [High- performance dimensional processing by arc discharges]. Moscow, Mashinostroenie Publ., 1991, 40 p.

- Nosulenko V. I., Meshcheryakov G. N. [Dimensional processing of metals]. Electronic processing of materials. 1981, No. 1, P. 19–22 (In Russ.).