Estimation of the relaxation time of non-Newtonian oils

Автор: Abishova R.

Журнал: Бюллетень науки и практики @bulletennauki

Рубрика: Технические науки

Статья в выпуске: 1 т.11, 2025 года.

Бесплатный доступ

The article discusses a technique for identifying the features of the lifting process of abnormal oils that significantly affect the flow rate of the working agent. When assessing the relaxation time of non-Newtonian oils, it was found that with an increase in temperature, a degeneration of viscoelastic properties is noted, which in turn affects, under the same conditions, the specific consumption of the working composition, which tends to increase.

Non-newtonian oil, viscosity of bedded oil, shear rate, shear stress, effective viscosity

Короткий адрес: https://sciup.org/14131798

IDR: 14131798 | УДК: 622.276.5 | DOI: 10.33619/2414-2948/110/11

Текст научной статьи Estimation of the relaxation time of non-Newtonian oils

Бюллетень науки и практики / Bulletin of Science and Practice

UDC 622.276.5

The article considers the methodology of the process of lifting to the day surface of nonNewtonian oil, which, in turn, significantly affect the flow rate of the working agent.

When estimating the relaxation time of rheophysically complex oils, it was noted that as the temperature increases, the viscoelastic properties of reservoir fluid degenerate. These conditions lead to an increase in the specific flow rate of the working agent.

The previously published articles [1, 4] provide a methodology for calculating the rate of pressure change both in the bottomhole formation zone and in the wellbore. The presence in the “reservoir-well” system of delayed “response” times to the influence of the working agent, which is compressed gas, requires taking into account the relaxation times of the gas-liquid mixture both in the reservoir and in the wellbore. In this connection, it is relevant and of interest to determine the relaxation times from the data of normal well operation and search for ways to regulate this parameter. As regulation of relaxation times, and consequently, giving non-Newtonian oils Newtonian properties, the authors proposed numerous studies on the application of physical fields -pressure field, thermal fields, magnetic, electric, etc. [4, 5].

Thus, when using barotreatment of downhole production with rapid pressure changes, there is a possibility to control the rheological properties of formation fluids by selecting the technological mode of production. Experimental works on treatment of non-Newtonian oils by sequential unloading of the system were carried out. As a result of baro-treatment by unloading, the tested

Бюллетень науки и практики / Bulletin of Science and Practice Т. 11. №1 2025 fluid began to acquire Newtonian properties, but with preservation of nonlinear viscoelasticity. Evaluation of rheological properties before and after the experiment in the PVT bomb was carried out on a rotational viscometer Reotest-2 with the sequential application of a computer program.

In this connection, studies were carried out to reveal rheophysical properties of oil of NGDU “Narimanovneft”. After baro-treatment and temperature decrease it was observed that oils acquire Newtonian properties.

Estimation of relaxation time

To investigate the relaxation properties of reservoir fluid, we processed experimental data according to the method proposed by M. Cross [6] and more widely developed in [2, 3].

The essence of mathematical processing is to determine the relationship between the values of tangential shear stress (τ) and the values of effective viscosity ( η эф ) , in the following form:

11 T 2 (1)

П2ф = П2 + 4G42

here G-modulus of shear elasticity of the studied fluid; η t - is the true viscosity.

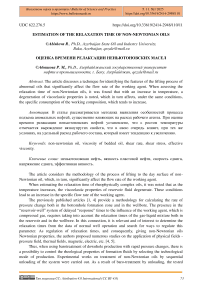

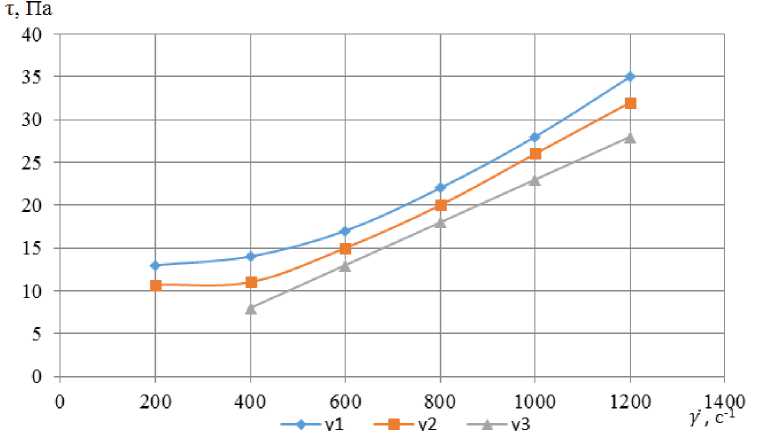

It should be noted that equation (1) will hold if η t and G take constant values, i.e., provided that the system is linear. The indices of the curves (Figure 1) of the dependence т = f(y) were recalculated in the coordinates ^^ = f(т2). According to the results of the performed calculation using the above formula, a new dependence was constructed and the obtained curves are presented in Figure 2. On the rectilinear part of the graph (Fig.2) the system has a linear character.

1- 30°C2 - 40°C; 3 - 50°C

Figure 1. Dependence of т = т(у) for the solution of transformer oil +10% tar at different temperatures

By analyzing the character of the curve it is possible to evaluate the interval of shear rates, as well as to identify the zone of curvature (nonlinearity).

According to the results of studies on rotoviscosimeter at different temperatures of transformer oil and tar sands solution, it was obtained that the areas parallel to the axis т2 , will correspond to the viscous flow of the tested fluid, and are characterized by linear dependence. The other zone of the graphical curve, corresponding to nonlinear sections, shows viscoelastic properties of the fluid.

Figure 2. Dependence of -^ = т2 for the solution transformer oil + tar at different temperatures: 1 -

Ч эф2

500, 2 - 400, 3 - 300

As the oil moves towards the bottom of the well, the pressure drops in its volume, causing gas to be released. The rate of change of formation pressure values is determined from the expression:

|dp| = M = d₽lu = ppi k = Др = д(_о_) 2

I dt dr dt dr m dr pm km km 2nhr

As can be seen from equation (2), the detection in the bottom-hole zone of inertial forces occurs well because of the change in the direction of filtration velocity, which leads to an increase in the influence of anomalous oil properties [1].

According to the experimental data on the viscometer Reotest-2, and using the Cross dependence (Cross), it is possible to calculate the relaxation time for different temperatures.

Conditionally assuming the conditions (х=т2, у= ^ ), then by the straight line equation the

4 2 dependence will take the form: Y = ах+b, where а = —т-т; b = ^.

' ’ 4G 2 4 ? ч 2

Let ф - be the angle of slope of the line to the abscissa axis, a and b be the segment that is cut off by the line on the ordinate axis. Then :

h

G = b~ (Па) 4*W

By differentiating (dividing) the value of the modulus of elasticity by the viscosity of the fluid, taking into account that t ° , the relaxation time of the solution is easily determined. The results of the mathematical analysis are shown in Table 1, from which it can be seen that the relaxation time of non-Newtonian oils will decrease with increasing temperature.

According to dependence (5) it pressure:

dp dt =

is possible to estimate the rate of change of formation

Я-От) 2 km 2nhr/

where d — is the diameter of the column.

According to the bench studies, it is shown that in the bottom-hole zone of the well the filtration velocity of liquid in the formation rock takes the highest value. However, the maximum speed of hydrocarbon gains at the walls of the well.

Table

RESULTS OF STUDIES ON RELAXATION TIME ESTIMATION

|

b |

Temperature, Т0, С |

Tilt angle,

|

True viscosity, T]t, мПа * с |

Modulus elastic modulus, G, Pа |

Relaxation time, t, c |

|

2 |

3 |

4 |

5 |

6 |

7 |

|

0,3 |

30 |

30/0,57 |

1,3 |

0,36 |

3,6 |

|

1,1 |

40 |

45/1 |

0,95 |

0,5 |

1,9 |

|

2,3 |

50 |

60/1,73 |

0,65 |

0,57 |

1,1 |

|

9 |

60 |

70/2,74 |

0,33 |

0,9 |

0,4 |

Results of the study

The obtained results show that for lifting the same volume of viscoelastic fluid (mixture of tar and transformer oil) it is necessary to inject a working agent of smaller volume than for the same flow rate of Newtonian fluid.

According to the results of analyzing the results of experimental studies, it was obtained that viscoelastic properties of anomalous oil can be used to improve technological processes of oil production.

The rheological properties of a non-Newtonian fluid were investigated on a Reotest-2 rotational viscometer.

Список литературы Estimation of the relaxation time of non-Newtonian oils

- Мирзаджанзаде А. Х., Аметов И. М., Хасаев А. М., Гусев В. И. Технология и техника добычи нефти. М.: Недра, 1986. 381 с.

- Салаватов Т. Ш., Дадашзаде М. А., Мамедова Е. В. Реодинамические особенности двухфазного потока // Нефтяное хозяиство Азербаиджана. 2012. №4. С. 30-32.

- Салаватов Т. Ш., Мамедова Е. В. К вопросу повышения производительности скважин // Проблемы разработки и експлуатации месторождении высоковязких нефтеи и битумов: Материалы международнои научно-практическои конференции. Ухта, 2012. Т. 1. С. 13. EDN: ZTQUNB

- Мамедова Е. В. Учет реологических своиств неньютоновских нефтеи в технологических процессах добычи нефти // Известия Азербаиджанскои инженернои академии. 2016. Т. 8. №4. С. 53-58.

- Brill J. P., Mukherjee H. K. Multiphase flow in wells. Henry L. Doherty Memorial Fund of Aime Society of Petroleum, 1999. V. 17.

- Cross M. M. Rheology of viscoelastic fluids: elasticity determination from tangential stress measurement // Journal of colloid and Interface Science. 1968. V. 27. №1. P. 84-90.