Evaluation of force-deformation characteristics of an actuator made of material with a shape memory effect for transformable space structures

Автор: Zimin V.N., Krylov A.V., Filippov V.S., Shakhverdov A.O.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 1 vol.24, 2023 года.

Бесплатный доступ

The prospects for the development of space technology are currently closely connected with the creation of fundamentally new large-sized space structures. When designing large-sized systems, the scheme of which allows for automatic configuration change of the structure, it is necessary to take into account shock loads. They inevitably arise when fixing the working state of the structure in orbit upon completion of the process of its opening. To ensure smooth, reliable and shock-free opening of large-sized space structures, it is proposed to use force drives with active elements made of titanium nickelide material with a shape memory effect. The proposed shape memory force actuator uses an active element in the form of a wire made of titanium nickelide material which is heated during opera-tion by passing an electric current through it. One of the main parameters for the opening drive of large-sized structures is its deformation-force characteristic. Experimental studies aimed at studying this characteristic of the active element of the actuator were carried out in the work. The study of the force-deformation characteristics was carried out under two types of loading: in one, the force changed during the test, and in the other it remained constant. It is worth noting that the amount of deformation that an active element can produce is directly related to the magnitude and nature of the resistance force applied to it. In the experiment, the active element demonstrated sufficient displacement under significant load. The experimental data obtained show the fundamental possibility of using active elements made of a material with a shape memory effect in the opening drives of large-sized space structures. The obtained characteristic will play an important role in the development of a mathematical model of the functioning of an active element made of a material with a shape memory effect for the opening of a space structure with transformable configuration.

Transformable space structure, drive, shape memory effect, force characteristics

Короткий адрес: https://sciup.org/148329678

IDR: 148329678 | УДК: 629.8:531.395 | DOI: 10.31772/2712-8970-2023-24-1-109-115

Текст научной статьи Evaluation of force-deformation characteristics of an actuator made of material with a shape memory effect for transformable space structures

Large-sized space structures are a promising direction in the development of rocket and space technology. The inevitable complication of structural schemes of promising space systems due to an increase in their operational functionality leads to the need to create large space structures. In the practice of creating space structures, a ground-based experiment plays a significant role. The performance of variable configuration space structures is determined mainly by how great the forces arising in them during deployment are, therefore, ensuring reliable deployment is associated with solving complex problems of mechanics [1; 2]. The process of changing the configuration occurs under the influence of power drives, which can be used as compressed or stretched springs, electric motors, etc. Research in the field of application of materials with a shape memory effect (SME) to create thermomechanical power drives for space systems causes an increased interest of scientists, engineers and designers [3; 4]. SME material can be used to create power drives due to its ability to restore large deformations and generate significant force [5–7]. The active element of such a power drive can be made in the form of a wire made of a SME material such as titanium nickelide [8–10]. For the successful use of such actuators for opening a variable configuration space structure, it is necessary to determine both the shape of the active element and its functionality. To determine the main characteristics of the active element, such as developed operational force, response time, working stroke (maximum displacement), experimental studies were carried out.

1. Experimental installation

To study the deformation-force characteristics of an active element made of material with PME, an experimental installation was developed and built (Fig. 1, a). During the experiments, the following characteristics of the drive were measured: the displacement created, the displacement resistance force, the temperature of the active element, and the change in the strength of the current flowing through the active element. To measure the displacement created by an active element made of a material with SME, a cable potentiometric displacement sensor was used, the measurement accuracy of which is 0.01 mm. The resistance force was measured using a digital dynamometer with a measurement accuracy of 0.2 N. All measurements were recorded at a frequency of 5 Hz using a personal computer. In order for the active drive element made of SME material to work when heated, it must first be deformed. Preliminary deformation was carried out by 10% on a separate installation using the above-described systems for measuring deformation-force characteristics. Since heating in outer space is most rationally carried out by passing an electric current through the active element, heating was also carried out in the experimental setup in the same way [11 –15].

A series of experiments was carried out, where a set of spring elements played a role of a payload. A different number of identical tension springs were fixed in parallel to the titanium nickelide wire (Fig. 1b). The number of springs varied from 1 to 7. In this case, the stiffness of the spring system varied from 20 to 175 N/mm. The initial force acting on the active element before heating was 40 N in all experiments of the series.

The results of measuring the change in the length of the active element in a series of experiments with spring elements are shown in Table 1: at the minimum resistance, the active element developed a force of 0.18 kN at a deformation of 4.2%, while at the highest resistance, the maximum force that the active element created was 0.68 kN, while the deformation of the active element was equal to about 2%.

Table 1

Test results with spring elements

|

Number of springs |

Initial sample length, mm |

The length of the pre-deformed sample, mm |

Sample length before heating, mm |

Sample length after heating, mm |

Max effort, kN |

Spring stiffness, N/mm |

|

1 |

160.0 |

176.0 |

174.0 |

167.0 |

0.18 |

20 |

|

2 |

160.0 |

176,0 |

174.0 |

168.0 |

0.33 |

42 |

|

3 |

159.7 |

177.6 |

173.8 |

167.0 |

0.41 |

49 |

|

4 |

160.0 |

177.1 |

174.1 |

170.0 |

0.52 |

106 |

|

5 |

160.8 |

178.4 |

174.7 |

171.0 |

0.56 |

135 |

|

6 |

160.2 |

178.8 |

175.2 |

171.3 |

0.62 |

146 |

|

7 |

159.4 |

176.8 |

172.8 |

169.4 |

0.68 |

175 |

а б

Рис. 1. Экспериментальная установка для испытаний с пружинными элементами: а – общий вид экспериментальной установки; б – набор пружинных элементов для создания усилия сопротивления

Fig. 1. Experimental installation for testing with spring elements: a – general view of the experimental installation; b – a set of spring elements for creating a resistance force

3. Load tests

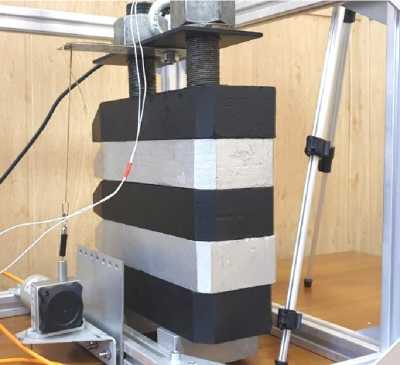

A series of experiments was carried out, where the active element was loaded with a constant force in the form of a set of weights suspended from it (Fig. 2, a). In this series of experiments, a set of different numbers of weights of the same mass was suspended from the active element (2, b). The initial force acting on the active element before heating in each experiment was equal to the weight of the suspended load. The mass of the dynamometer sensor was taken as the minimum mass.

а

б

Рис. 2. Экспериментальная установка для испытаний с грузами: а – общий вид экспериментальной установки; б – набор грузов для создания усилия сопротивления

Fig. 2. Experimental installation for testing with weights: a – general view of the experimental setup; b – a set of weights for creating a resistance force

In Table 2 shows the values of the length of the active element during the test, as well as the mass of the load attached to the active element in each test. This table shows that in a practically free state with a load of only 1 kg, the working deformation of the active element was 4.7%, while with a maximum load of 61.1 kg, the working deformation was 2.1%.

Table 2

Suspended mass test results

|

Number of load |

Original sample length, mm |

Length of pre-deformed sample, mm |

Sample length before heating, mm |

Sample length after heating, mm |

Load weight, kg |

|

0 |

159.6 |

175.7 |

172.5 |

164.4 |

1 |

|

1 |

160.2 |

176.4 |

173.0 |

165.7 |

10.8 |

|

2 |

160.4 |

176.5 |

173.6 |

166.4 |

17.9 |

|

3 |

159.7 |

175.7 |

172.7 |

166.2 |

24.6 |

|

4 |

160.2 |

176.3 |

173.1 |

167.1 |

31.9 |

|

5 |

159.9 |

175.9 |

173.1 |

168.0 |

39.3 |

|

6 |

160.5 |

176.6 |

173.7 |

168.9 |

46.1 |

|

7 |

160.0 |

176.1 |

173.0 |

168.4 |

53.6 |

|

8 |

159.9 |

176.0 |

172.7 |

169.1 |

61.1 |

Discussion of results

Opening large-sized space structures is a complex and highly loaded process. In the process of transformation, the opening drives need to overcome the forces arising in the hinges, as well as inertial forces. The deformation-force characteristics obtained in the work are an important step for creating a model for the deployment of large-sized space structures using drives with an active element made of a material with a shape memory effect.

Conclusion

In the process of experimental studies, the deformation-force characteristics of the active element of the drive were obtained. Two types of studies were carried out: in the first, the resistance force increased during the operation of the drive, and in the second, it remained constant. In all experiments, the shape memory active element produced significant deformation, even at very high resistance forces. It is worth noting that the amount of deformation that an active element can produce is directly related to the magnitude and nature of the resistance force applied to it. This feature must be taken into account when designing drives for opening large-sized structures. The results of the conducted studies show the possibility of using drives with an active element made of a material with a shape memory effect to deploy large-sized space structures.

Список литературы Evaluation of force-deformation characteristics of an actuator made of material with a shape memory effect for transformable space structures

- Lopatin A. V., Rutkovskaya M. A. [Overview of the designs of modern transformable space an-tennas. Part 1]. Vestnik SibGAU. 2007, No. 2 (15), P. 51–57 (In Russ.).

- Banichuk N. V., Karpov I. I., Klimov D. M. et al. Mekhanika bol'shikh kosmicheskikh kon-struktsii [Mechanics of large space structures]. Moscow, Faktorial Publ., 1997, 302 p.

- Ponomarev S. V. [Transformable reflectors of spacecraft antennas]. Vestnik Tomskogo gosudar-stvennogo universiteta. Matematika i mekhanika. 2011, No. 16, P. 110–119 (In Russ.).

- Zheng F. Affordable System Conceptual Structure Design of New Deployable Spaceborne An-tenna. 33rd AIAA International Communications Satellite Systems Conference and Exhibition. 2015, P. 4343.

- Zimin V. N., Krylov A. V., Filippov V. S., Shakhverdov A. O. [A drive made of a shape memory material for transformable space structures]. Sibirskii aerokosmicheskii zhurnal. 2022, Vol. 23, No. 1, P. 73–80 (In Russ.).

- Likhachev V. A., Razov A. I., Cherniavsky A. G. et al. Truss mounting in space by shape memory alloys. Proceedings of the First International Conference on Shape Memory and Superelastic Technologies. California, 1994, P. 245–248.

- Zimin V. N., Krylov A. V., Kuvyrkin G. N., Shakhverdov A. O. et al. Mathematical Modeling of Deployment Dynamics of Large Transformable Space Structures. Behavior of Materials under Impact, Explosion, High Pressures and Dynamic Strain Rates. Advanced Structured Materials. 2023. Vol. 176.

- Riad A., Ainamany A., Benzohra M. The shape memory alloy actuator controlled by the Sun’s radiation. Materials Research Express. 2017, Vol. 4, P. 7 075701.

- De Laurentis K. J., Fisch A., Nikitczuk J., Mavroidis C. Optimal design of shape memory alloy wire bundle actuators. Proceedings 2002 IEEE International Conference on Robotics and Automation (Cat. No. 02CH37292). 2002, Vol. 3, P. 2363–2368.

- Zimin V. N., Krylov A. V., Kuvyrkin G. N., Shakhverdov A. O. [On the issue of creating a shockless opening drive for transformable large space structures]. Vestnik NPO im. S.A. Lavochkina. 2022, No. 3(57), P. 47–51 (In Russ.).

- Schiedeck F., Hemsel T., Wallaschek J. The use of shape memory alloy wires in actuators. Sol-id state Phenomena. 2006, Vol. 113, P. 195–198.

- Zimin V. N., Krylov A. V., Shakhverdov A. O. Development of the mathematical model of the force actuator for deployment of large-sized space structures. Journal of Physics: Conference Series 1902(1). 2021, No. 1. P. 012115. DOI: 10.1088/1742-6596/1902/1/012115.

- Zimin V. N., Krylov A. V., Kuvyrkin G. N., Shakhverdov A. O. [Actuator made of a material with a shape memory effect for opening a transformable space structure]. Fundamental'nye i priklad-nye problemy tekhniki i tekhnologii. 2021, No. 4(348), P. 97–102 (In Russ.).

- Zimin V. N., Krylov A. V., Shakhverdov A. O. Development of the mathematical model of the force actuator for deployment of large-sizcd space structures. Journal of Physics: Conference Series 1902. 2021, P. 012115.

- Zimin V. N., Krylov A. V., Kuvyrkin G. N., Shakhverdov A. O. Mathematical and ground-based experiments when designing transformable space structures. AIP Conference Proceedings 2503. 2022, P. 020006.