Experimental determination factor to viscosity, elasticity and plasticity media for abrasive flow machining process

Автор: Snetkov P.A., Levko V.A., Pshenko E.B., Lubnin M.A.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 5 (26), 2009 года.

Бесплатный доступ

Numerical values of factors of viscosity, elasticity and plasticity of a media are established. Experimental dependences of viscosity and elasticity of environment on degree of its filling and granularity of abrasive grains are revealed.

Abrasive flow machining, rheological characteristics, viscoelastic media, flowable abrasive particles, shear rate

Короткий адрес: https://sciup.org/148176111

IDR: 148176111

Текст научной статьи Experimental determination factor to viscosity, elasticity and plasticity media for abrasive flow machining process

The one of the new types of such processing is abrasionextrusion processing (AFM), which is consist in removing the layer of material from the surface of the treated channel at extruding under pressure through it, working environment, consisting of a viscosity and elasticity foundation, filled of solid working elements (most often – abrasive or diamond grains).

AFM is difficult process. In its implementation there are a number of physical phenomena that influence for quality and productivity of processing. For the introduction of abrasive extrusion processing in the production of specific details must be made a sufficiently large volume of experimental studies, related with determining the optimum composition of the working environment and modes of its extrude, caused by physical-mechanical and geometrical characteristics of processed channels. Such researching needs a lot of costs, which constituting up to 60 % of the total cost of implementing this technology in production.

The main parameters of technological process of abrasive extrusion processing is the volume of the working environment, pressure of the hydraulic system installation in burst and the host operating cylinder of installations for AFM, value (dispersion) and percentage (concentration) of abrasive grains in the working environment, its physical and mechanical characteristics, and also the number of processing cycles. The geometric characteristics of the processed feed have great influence on the quality and productivity of the process – its radius and length, area and perimeter of the cross-sectional and also initial physical and chemical properties of the surface layer.

Cutting ability of the working environment as abrasive tools depends of flow’s conditions in the processed channel and its viscoelastic and plastic properties. Viscous and plastic properties determine its fluidity, the elastic properties – stiffness. For the theoretical calculations of the flow characteristics of working environment with AFM it needs to experimentally establish dependence of the effective viscosity η, Poisson’s ratio and Young’s modulus of working environment of the degree of its filling and dispersion of abrasive grains.

Characteristics of the working environment depends on the degree of filling of the polymer base ( Ka concentration of abrasive grains in the medium), of their size ( Ba grits), and also of a pressure in filing cylinder P in.

If the Ka and Ba are changed, changes are not only in the density с the medium and its viscosity, but also in its rheological characteristics – coefficients of tangential and normal stresses, flow velocity and shear rate, and also all the curves of the shear flow dependency of shear stress.

Because the nature of viscous flow abrasive medium at the extrusion processing a circular channel with big length the same to fluid flow in a capillary viscometer, for the researching of viscous properties a similar method was developed, based on the experimentally established values of maximum flow rate ωmaxanddropofpressures ΔP on the section of a cylindrical channel L length and diameter d. Substituting the experimental values ωmax and ΔP ininthe transformed Puayzel’s formula for known L and d value of the effective viscosity η is defined.

Δ P η = ω max

R 2 8⋅ L .

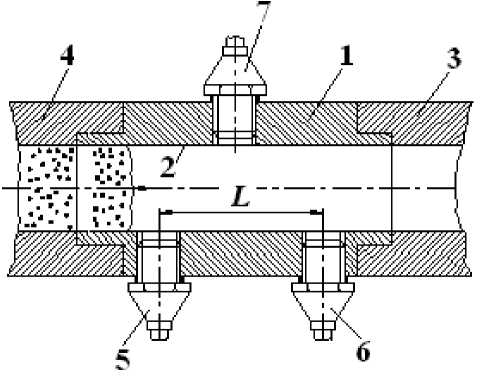

For registration the parameters system of defined set of research was applied. Experiments were conducted on an experimental set UESH-25 with using a special device (fig. 1).

Device consists of a steel hull 1, which was subjected to heat treatment, with round channel 2 with 25 мм in diameter, coinciding with the diameter of working cylinders 3 and 4 UESH-25 – installation, with pressure sensors 5 and 6 , and also a temperature sensor 7 .

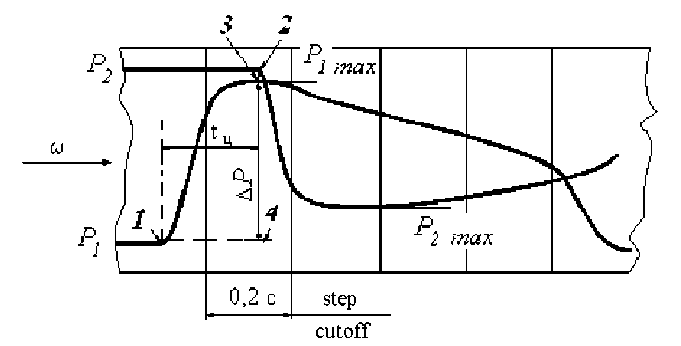

On the oscillogram (figure 2) pressure change in the current moment in sections of sensor 5 ( P 1) and 6 ( P 2) recorded. Time is defined on the oscillogram for step cutoff t c =0.2с . On the line P 1 the start point of deviation from the zero level of evidence 1 is revealed. Similarly, the beginnings of the emergence of the pressure’s environment at point 2 for the line P 2 is found. Through found points 1 and 2 vertical lines to the lines P 1 and P 2 are held pursuant. The distance t c between the normals corresponds to the minimum duration of an environment from cross-section 1 to cross-section 2 . By the known distance between cross-sections ( L =0.07 м) and t c maximum speed of flow ωmax is calculated in this section. Then find the point 3 ,

Fig. 1. Device for the study of viscous and plastic properties: a– scheme; b – the body of device with two adapters

b

Fig. 2. Scheme of registration data on the oscillogram

which is intersection of the normal through the point 2 , lying on P 2 line, and point 4 by P 1 line.

The exact values of physical quantities t c and A P were calculated taking into account the calibration of sensors and size of step cutoff t c. Thepressuredifferencebetweenthe two cross-sections A P = P 1 - P 2 equal to the distance between points 3 and 4 on the oscillogram, multiplied by the scale calibration. Six experiments with randomization of time and temperature controlled environment was conducted for each experimental conditions.

The researching of dependence the coefficient n of Ba and Pin was carried out according to Kono plan ( m =2, n =3). For the mathematical processing the coding variables X = Ba ; X 2 = P in ; Y 1 = n was produced. Granularity Ba and the pressure P in were varied factors. Each experiment was repeated six times with randomization time. Terms of experiments on the nine modes and experimental results are given in table 1.

As a result of studies found that the higher the degree of filling polymer base working environment by abrasive, the higher its effective viscosity. Bigger factor observed when lesser magnitude filled with abrasives at equal weight’s filling Ka abrasives of different grain Ba .

Increasing of P in during extrusion of environment improves processing’s conditions by increasing shear stress and flow rate of the medium and the velocity gradient.

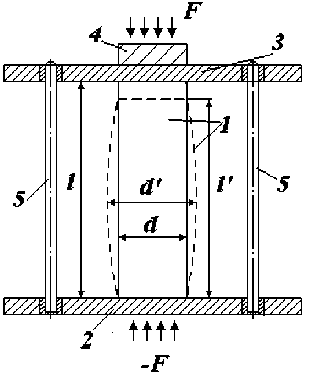

Young’s modulus and Poisson’s ratio is characterized elastic properties of the working environment. Elastic characteristics of the medium depend of degree of filling Ka and dispersion of the filler Ba. The numerical values of these indicators are needed when calculating the contact working environment with workpiece and evaluated by change in length l - l' and diameter d' - d of sample of environment during its compression load F (fig. 3).

Guides axle 5 installed in bronze bushings of base 2 devices with interference, and in the sleeve weight plates 3 – with sliding landing. The sample of working environment is forming in the working cylinder of the experimental setup UESH 25, determined in a certain position that ensures its dimensional stability. The nominal diameter of the specimen before the deformation d = 25 mm, the nominal length of the specimen before deformation l = 50 mm. Cross-sectional area of the sample – S = 0.00049 m 2. Measuring the size of the sample was held by using calipers and micrometers.

The mass of weight plates and additional cargo were chosen so, that specimen is deformed predominantly elastically and linear dependence of its size on the applied load was carried. Total weight was 150 g . Waiting time was 3...10 seconds.

It is possible to experimentally determine their values, based on the definitions of Young’s modulus and Poisson’s ratio ц:

-

m, I ' — I {d - d ') / d F = g = E ---; ,L---2—, и

- S l (l ’-1)/1

where mload – mass of the applied load.

Fig. 3. Device and circuit measurement of Young’s modulus and Poisson’s ratio environment: 1 – sample of the working environment; 2 – base adjustment; 3 – weight bracket; 4 – extra weight; 5 – steered axles; 6 – micrometer

Table 1

Dependence the coefficient n of Ba and P in

|

№ |

Ba , |

P in , |

г], Пa-c |

|

1 |

300 |

9,0 |

36,892 |

|

2 |

400 |

9,0 |

36,093 |

|

3 |

500 |

9,0 |

29,215 |

|

4 |

300 |

7,5 |

32,368 |

|

5 |

400 |

7,5 |

30,402 |

|

6 |

500 |

7,5 |

23,204 |

|

7 |

300 |

6,0 |

27,283 |

|

8 |

400 |

6,0 |

24,166 |

|

9 |

500 |

6,0 |

16,223 |

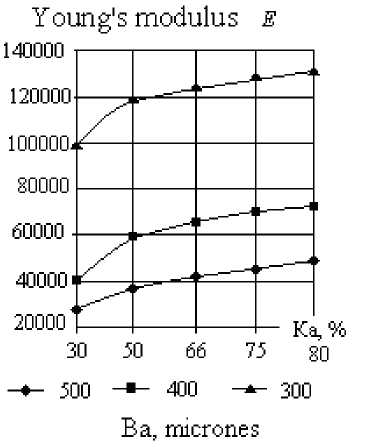

Table 2 shows the results of studies of Young’s modulus depending on the degree of the working media content and size of abrasive filler.

Experimentally determined (fig. 4) that an increase of Ka for more than 80 %, fixed abrasive in polymer-based environment is significantly reduced. This phenomenon leads to loss of yield and environmental fallout of grains of the polymer base that significantly impairs the conditions of abrasive-extrusion processing. Therefore, this figure was adopted for the boundary condition for the maximum degree of filling. The value of Poisson’s ratio µ of the polymer base without abrasive filler – 1.34, for filling among its experimentally measured value varies in the range 0.4…0.42.

Fig. 4. Dependence of Young’s modulus of the working environment on the degree of filling of abrasive grains and the quantity of abrasive filler

Young’s modulus E increases with the degree of filling and reduced dispersion of abrasive grains. This effect is explained with the help of the transformed Kargin– Slonimsky–Rous model [1], which is describe the working environment as a visco-plastic medium full of elastic chains formed by abrasive grains and the polymer base.

In polymer-based unfilled chain abrasive grains are absent. Reduction of dispersion of the filler with the same mass filling leads to an increase in the number of abrasive grains in the medium. The greater the number of abrasive grains in the medium to longer chains occurs in the environment, length of segments which, in turn, decreases. Shorter segments of the chain cause its high elasticity and viscosity. The plasticity of the medium reduced.

To assess the cutting properties of the studied working media used the method of simplices with the same initial data and constraints, composition of the medium and P in. The results of experimental studies abrasive extrusion processing showed that the optimum cutting ability, measured by the value of surface roughness after treatment or change in processing Δ Ra , value of the material removed layer Δ h , is achieved using a composition of the working environment in which the elasticity of the medium is maximal. The coefficients of viscosity and plasticity at the same time used to set the boundary conditions abrasive extrusion processing specific details. Numerical indicators of viscosity, elasticity and plasticity of the working environment depends on the geometric characteristics of the processed channel and the requirements of the surface layer of detail.

The developed technique allowed to determine experimentally the flow rate ωmax and the coefficient of effective viscosity 3 of media of difaferent compositions with abrasive flow machinig process, which can be used to calculate the pressure-spending environment characteristics in the processed channels.

The degree of influence of filling abrasive Ka , Ba quantities of abrasive grains and the inlet pressure P in of viscous, elastic and plastic properties of the medium were set. With increasing P in and content of abrasive in the medium Ka environmental factors 3 increases. This is due to the fact that with increasing shear rate more intensively destroyed the spatial structure of the medium. The effective viscosity, shear and normal stresses become larger. Sofora mediumgrit Ba =400micronswith P in=6MPa– η = 24,166 Pa ; with P in=9MPa–η = 36,093 Pa , i. e. is 65...70 % more.

Table 2

Elastic characteristics of working environments

|

Ba , мкм |

Ka , % |

Young’s modulus |

Poisson’s ratio |

|

0 |

0 |

22,760 |

1.34 |

|

320 |

30 |

97,955 |

0.411 |

|

320 |

50 |

119,600 |

0.411 |

|

320 |

66 |

124,300 |

0.411 |

|

320 |

75 |

128,250 |

0.411 |

|

320 |

80 |

132,500 |

0.411 |

|

400 |

30 |

40,480 |

0.40 |

|

400 |

50 |

59,200 |

0.40 |

|

400 |

66 |

65,100 |

0.40 |

|

400 |

75 |

70,400 |

0.40 |

|

400 |

80 |

73,100 |

0.40 |

|

500 |

30 |

27,000 |

0.42 |

|

500 |

50 |

37,000 |

0.42 |

|

500 |

66 |

42,000 |

0.42 |

|

500 |

75 |

46,000 |

0.42 |

|

500 |

80 |

51,000 |

0.42 |

Experimental determination of the coefficients of viscosity, elasticity and plasticity allows for the theoretical calculations of accuracy, productivity and quality abrasive extrusion processing. Obtained numerical values of the elastic-visco-plastic medium allow the choice of contact of abrasive grains [2]. Having established contact on the proposed methods [3; 4] it possible to calculate the performance of AFM and the roughness of the treated surface details.