Features of synthesis of composite material based on silicon dioxide and carbon nanotubes

Автор: Simunin M.M.

Журнал: Сибирский аэрокосмический журнал @vestnik-sibsau

Рубрика: Технологические процессы и материалы

Статья в выпуске: 4 т.19, 2018 года.

Бесплатный доступ

Today, there are many papers showing the effectiveness of the use of carbon nanotubes as additives to composites. Their use in polymers is especially successful, but the efficiency of their use in ceramics poses many questions. The aim of the work was to study the effect of the addition of carbon nanotubes on the properties of ceramics. For this purpose, pure silica, obtained by the hydrolysis of tetraethoxysilane in an alkaline medium, was taken as a model. The obtained granules of the material were well sintered at 900 ° C and it was decided to compound this material with carbon nano- tubes. Depending on the method of introducing, the result turned out to be diametrically opposite. Nanotubes intro- duced during the synthesis of silica played a role in the formation of silicon dioxide grains and effectively compacted the material, increasing its hardness. On the contrary, nanotubes grown in ceramic pores wedged the grain of silicon dioxide, making the material softer. In the first case, it is important to note that the synthesis of ceramics is not affected by the synthesis of nanotubes. In turn, nanotubes always affect the process of forming ceramics. This influence leads to a change in the structure of the grains of ceramics, and as a consequence of the mechanism of interaction between them, which in turn changes the density and strength of the ceramics. In the second case, in order to grow nanotubes in the pores and cavities of the ceramic material, one must first im- pregnate the ceramic material with a catalyst. Thus, there is a requirement for a precursor of the catalyst - the absence of its interaction with ceramics. The second requirement is for inertness of the ceramics, both to the catalyst and to the entire synthesis process. In addition, it is necessary that the structure of the pores does not change during the synthesis, i.e. they did not close during the synthesis of nanotubes, but provided transportation of the starting materials and reac- tion products. Therefore two mechanisms that affect the formation of a composite ceramic material have been described. The described composite can be used in the rocket and space industry for compounding ceramic fairings and thermal insu- lation.

Quartz ceramics, carbon nanotubes, composite materials

Короткий адрес: https://sciup.org/148321886

IDR: 148321886 | УДК: 666.3.015 | DOI: 10.31772/2587-6066-2018-19-4-698-702

Текст научной статьи Features of synthesis of composite material based on silicon dioxide and carbon nanotubes

Introduction.

TOe unique: croperiies of carbon nanotubes such as ilicir etrengih and chemical seslsdmcc 2; 2] determinetheinterestin their useasanaddiSivc to various moteriols Ira the pucdurrtein m composites- /Ot present time,tSerearcaloeol’works [3-8Sch

Materials used and experiment. Carlon ncnotiia)es were obtaiiirU front etdonol [15t on a [Ni (NH3)6]C12 [0o-- coacus at atemysrainrcof600 °C.

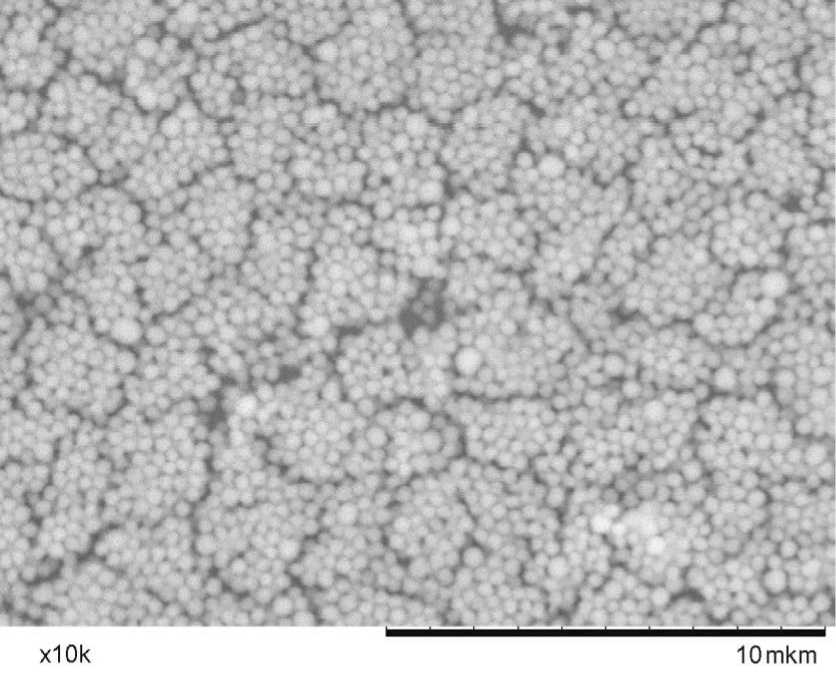

As a model aarc.mies, sue useC qiiacic ceramics pro-ducsU from s illшгf eO cesnm.e ammodta and tetraethoxysilane blrtatnsd dp annealing In coSesh susponsion. The strupture oS sune deramics is groins hi amyoCuius SiO2 (hie. 1) wiitht ties siee of 2OO-5PO nm. Ccramir material was oliOoscУ hy hclyolysis oh tetraet/eoxysilone followed by sol-eed precrpttotionoad anneatnig af9OO °C.

Since ihh cOdicu:ncy of pirdci ntiorao of nanotubes witO osramrc parricide Soar not atways ptvh pn effective result, and ti is veiy OifCicait to псЫсуо aniUoimiSy of distribution oh nonotubes in htas oare, tern atlC0.ors iiseO enly two md:koits, whieu onlorqnSusO шsiaolm mixOnt. On the one hood, cabcot nanoubees can ^it into reramics during its Oomiation lOmn a saepecoion, ted oo the other hand, cobbon попоШЬ/п can aheady lie s>loced m ceramics by growing them in poresanddovitisr of themaSerial.

Ti imptant oanoiuaas inid ccsamioe ai die growth stoee, the ColtowHig msselod oois used. The nanotubes were dispersed Уу atnosoaad in 2-propanol to obdain a stoble col-odd. Oded dieiseosioc contain tog 0.1 шо1. % of nonotubes was ноОсПп-! io Oth'ccthoxylildcc in m volume rotio of l:0O,rerqpctively. Afterthai, ammdetawoe added to tOa mintaod and tire tnopenaon wos retieved by oeitotion. Ths syepsncton| after cyytng, was oadtaled ot *000 °C.

The scowth od nono1ur)ea in csraпrics coos proveyed by introducing n cota/yst into the oo-hs of mcmtice annealed ot *0(00 °C and -nos carried cat m a irmpeeotofe of 600 °C hrom etiiacoS. Toe cahtlysa was akOed into ceramics by impreenotinethe finished material with a precaosor.

Results,

hr d.. 2 ph

Msesening itir hpiOssse oO caarcia rompasites clearly indicoin die hartipeiglfs or aiC■gmOtr ogtainhd on carbon nonotubes, compared wttts rec opnucaa at die time time, the y-owse od ^ardinn nanotubed seducr^d tide hrhngth of corbonnanol:ur)esisee ^aMt).

Vidkeds ceraann: hardness

|

I'yqe oOcemmic |

Viseorahisxnlees number |

|

VltsksouH2NT |

300 MPa |

|

Ceratiilassolhdosdidlntrbon nonoSubodispersion |

1GPa |

|

Cclm^cesriпa^hNladIX)\vn in poros |

200 MPa |

Fig.l.QuartzceramScs. Soanningclcolrocmicroseopy

Рис.1. Кварцевая керамика. Растровая электронная микроскопия

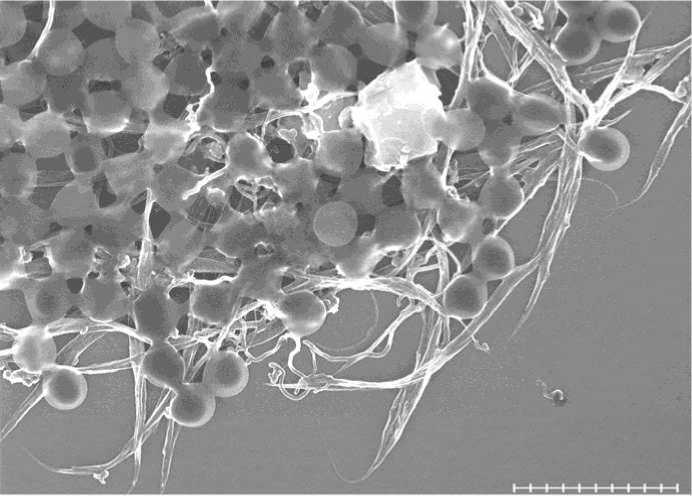

Рис. 2. Кварцевая керамика, образцы равной массы. Слева - композит, полученный синтезом керамики в дисперсии углеродных нанотрубок, справа - композит с углеродными нанотрубками, выращенными в порах керамики

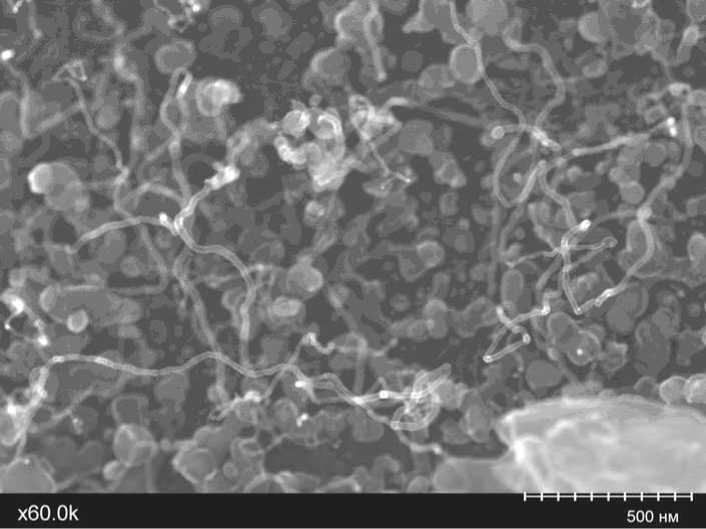

A siaшficgnt Caaceate in the: hardness of ceramics grown ea ihe basis oS carbon aenotubes (fig. 3, a) is explained by hie more densn scucteno nC ring origixal ceramic rcains, which was ereeted by r motsix of carbon nanotubes. That it in iSo colloin.. tOr formation oC silica particles poceeeUeh not only io solums, but nlso on the surface ot aaabon ngeolubas, wind ied ta n aigntficant compaction ot theentire marariataftegailnagiing.

30k 1 мкм

а

b

Fig.З.Comoonitenasedonuhartgcaromics: a -aarfmiatohiainedwicrl aarbahnaubtubes; b -aarfmias witr wawnaegbognanotubesin it

а - керамика, выращенная на основе углеродных нанотрубок; б - керамика с выращенными углеродными нанотрубками

The decrease in the litircln<2f>ss of ceramics with carbon nanotubes frown igig. 3, b ) ^oau]cacтb to the inti al one can Ue pupli/neb by the: deformations be ceramics tttit occur whit tee krowtit ci «bitbon cllnotulcth, which have a wedgsngeOfect nncasinns.

Conclusion. he hsic wofk> carbbs tsnouncbfs were placed in аегагтаз ethecer during its formation from a suspension. or by growtng heme tn pureo ana tiavKaff of ceramics.

In the jfnsi arase, it is important to noth tdht are synthe-sisoOsbkatoUnrdoeonetafCe<Уthc aenmctюnofcaramics. Nanotubes xOnyyi tnHunncb tire keoneco oO Поспис- ce-ramics.Thismflunneelnnnbto lifhiiingc mУueslnka'tc/e of the ccnmcb sarticlee, and as a I'esul't ob the mkcSbnism of interaction among them, which changes tire tlecin.ity and strength oO ceramicSl

. In thee skcon

Список литературы Features of synthesis of composite material based on silicon dioxide and carbon nanotubes

- Iijima S. Helical microtubes of graphitic carbon. Nature. 1991, Vol. 354, P. 56-58.

- Avouris Ph. Carbon nanotube electronics. Chem Phys. 2002, Vol. 281, P. 429-445.

- Rupesh Khare, Suryasarathi Bose Carbon Nanotube Based Composites. A Review Journal of Minerals & Materials Characterization & Engineering. 2005, Vol. 4, No. 1, P. 31-46.

- Thostenson E. T., Ren Z. F., Chou T. W. Advances in the science and technology of carbon nanotubes and their composites: a review. Compos Sci Technol. 2001, Vol. 61, P. 1899-1912.

- Subhranshu Sekhar Samal, Smrutisikha Bal Carbon Nanotube Reinforced Ceramic Matrix Composites: A Review. Journal of Minerals & Materials Characterization & Engineering. 2008, Vol. 7, No. 4, P. 355-370.