Flexible composite structures with controlled physical and mechanical characteristics

Автор: Likhachev A.N.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 1 vol.24, 2023 года.

Бесплатный доступ

The article presents the results of theoretical and experimental studies that are the basis for the devel-opment of a new class of aerospace engineering structures that allow implementing approaches to create structures with variable morphological and functional characteristics of products. Condensed soft sub-stances, such as elastomers, gels, gradually become functional elements on the basis of which the creation of soft machines and electronics develops [1–3]. Research in this direction has led to the creation of struc-tures with a special architecture that are mechanically compatible, deformable and capable, with a certain combination, of perceiving and transmitting a signal, changing their shapes and physical characteristics (thermal conductivity, electrical conductivity, etc.). The use of such structures in a certain sense models the multifunctionality observed in biological objects and structures (skin, muscles, nervous tissue) [4–7]. The creation of structures that change their shape, structure and change their functional and operational char-acteristics in the process of work, taking into account changing external and internal conditions, is an ur-gent task for many systems of aerospace technology. In this paper, morphologically changeable structures are considered, which include reconfigurable antennas, aircraft wings with variable shape and geometry, flexible robotic systems [8]. The use of such systems with flexible structural elements makes it possible to create structures capable of overcoming unpredictable obstacles due to their adaptive geometry, fit into limited spaces and withstand significant loads and vibrations. One of the most important tasks in the devel-opment of such systems is the organization of a distributed actuation system associated with the problem of creating an internal structure of actuators integrated into a flexible composite design of actuators made of elastic materials. In a number of works for the operation of thermoactive actuators, the use of rigid nano-particles as surface heating elements or as fillers for composites that are electrically sensitive, magnetical-ly sensitive and/or photoreactive has been investigated [9–13]. However, surface heating elements are lim-ited in use beyond a thickness of several hundred micrometers due to their low intrinsic thermal conductivi-ty [14]. In addition, rigid components significantly change the mechanical properties of the structure being created, which limits the morphological capabilities of the structures being created. For example, in [15], it is shown that reducing the electrical resistance for a thermal heater to acceptable values requires an increase in the filler to 15% of the mass of the structure, while the deformation of the actuation of the struc-ture is reduced by 35.0%. In this paper, overcoming the above limitations is carried out by creating a ma-terial architecture that dramatically expands the range of properties and dynamic functions of the heating element being developed for the actuator. Multifunctionality is achieved by embedding metal fibers of a certain configuration into an elastic medium based on polydimethylsiloxane elastomer, which provide mo-bility and conformality of the deformable structure of the actuator during its operation. It is shown that the inclusion of metal fibers of a certain configuration in the structure of the actuator does not interfere with its ability to change shape and perform mechanical work in response to external stimuli. Shape morphing in the absence of an external load can be programmed in the composite structure by including fibers with certain stiffness and thermal characteristics in it so that it can reversibly switch between programmed morphologies using electrical or thermal stimulation. Together, these properties allow the composite to demonstrate a rich variety of functionality, which allows it to simultaneously realize sensory and dynamic characteristics.

Reconfigurable structures, morphological characteristics, functional properties, actuators, phase transition, composite structures

Короткий адрес: https://sciup.org/148329684

IDR: 148329684 | УДК: 669.78 | DOI: 10.31772/2712-8970-2023-24-1-177-187

Текст научной статьи Flexible composite structures with controlled physical and mechanical characteristics

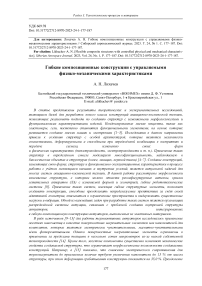

The problem of creating structures with a variable shape and size, adapting to changing external conditions during the operation of the product, is relevant for many problems in aerospace technology, such as the creation of large space structures, fine tuning and correction of the optical systems of vehicles, the creation of reconfigurable antennas, etc. In this article, morphologically variable structures are considered, which include reconfigurable antennas, aircraft wings with variable shape and geometry, and flexible robotic systems [16]. The use of such systems with flexible structural elements makes it possible to create structures that can overcome unpredictable obstacles due to their adaptive geometry, fit into limited spaces and withstand significant loads and vibrations. One of the most important tasks in the development of such systems is the organization of a distributed system of activation, associated with the problem of creating the internal structure of actuators integrated into a flexible composite structure. The main structural elements of such systems are considered, in particular, the architecture of the heating element (HE) of a thermoactive actuator [17]. A new type of HE based on a composite electrically and thermally conductive material (CETM) has been developed. It has a number of attractive properties, such as high specific rigidity, high thermal and electrical conductivity, good damping ability, and the ability to adjust the properties of CETM. The composite structure of HE (Fig. 1) consists of an elastic matrix based on polydimethylsiloxane and randomly arranged metal fibers assembled into a ribbon structure. Metal fibers can be bonded with a polymer binder or remain unbonded and are made in the form of a matrix material.

б

а

Рис. 1. Нагревательный элемент ( а ), микроструктура нагревательного элемента ( б )

Fig. 1. Heating element ( a ), мicrostructure of the heating element ( b )

This system is intended for heating and subsequent cooling of the active structure of the actuator, which, from the point of view of its operation, puts forward a number of ambiguous requirements. It should be easily deformable during the operation of the actuator, have a high thermal conductivity, which makes it possible to quickly heat and cool the working material of the actuator, be electrically conductive, and change its characteristics under the action of a control signal proportional to the deformation of the actuator.

Statement of the research problem

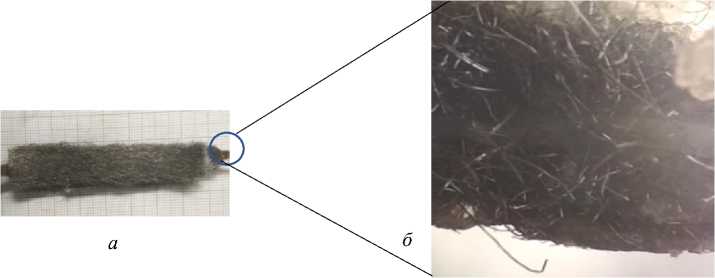

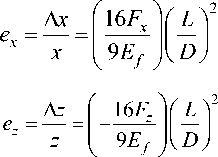

The task of the study being solved at this stage was to create an engineering analytical method for calculating such a structure with an assessment of the influence of the key features of the anisotropic structure on its strength, electrical conductivity and thermal conductivity. In this case, the characteristic stresses and strains obtained using the strain energy density were applied to determine the strain of the fibrous filler. To describe a stochastic fibrous material, a three-dimensional periodic model of rods in contact with each other was constructed, based on continuum mechanics. Predicting the deformation characteristics of a three-dimensional array of bonded fibers is a difficult task, especially if they are irregularly arranged. For a random distribution of fiber orientation, the deviation of a fiber segment will be limited to adjacent segments. It is assumed that when averaged over the volume, the effects of the constraint will be negated; in that case the overall deformation can be predicted by summing the contributions of individual segments taken in isolation. Net axial elongation (∆X/X) and net transverse compression (∆Z/Z) are predicted according to equations (1) and (2) respectively:

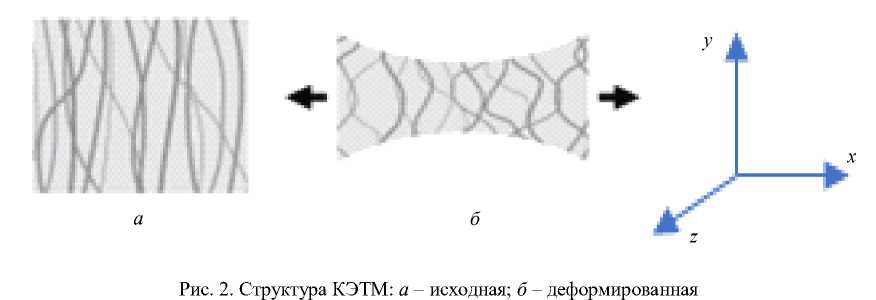

where F x and F z are the components of the applied load; E f is the fiber modulus; L , D are the length and diameter of the fiber, respectively. The resulting deformation of the fiber matrix leads to a change in shape, as shown in Fig. 2.

Fig. 2. CETM structure: a – initial; b – deformed

The predicted shape changes obtained using equations (1) and (2) are shown in Fig. 2 and depend on the aspect ratio of the fiber segment, L/D. Axial elongation was measured for a single fiber structure, while the aspect ratio of fiber segments for bundled fiber arrays was estimated from micrographs (Fig. 1.) According to the results of the experiment, it was found that the measured deviations are larger than those predicted by the model, on average by 20–25 %. However, in this case close agreement is not expected with the experiment, since in reality the deformation behavior of the fiber network is complex, and the shape changes caused by the external action on CETM can be significant. Under this assumption, electrical resistance, which is a fundamental physical quantity, is no longer constant throughout the sample.

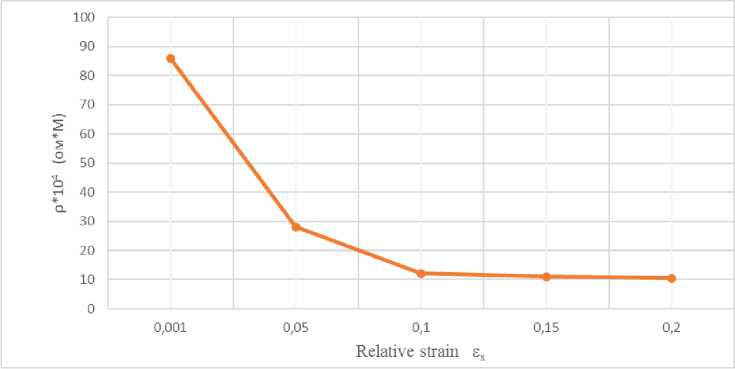

In this work, mathematical models are evaluated in terms of electrical resistance, which depends on the size of the sample. At the same time, a significant piezoresistive effect is observed (resistance changes by an order of magnitude) when the composite is subjected to uniaxial tension or transverse compression, which is associated with a rearrangement of the internal structure of the construction and a change in the nature and number of contacts of the electrically conductive structure. The piezoresis-tive response of the material can be controlled by changing the parameters of the filler structure (its anisotropy), the dimensions of the fibers ( L, D ), their volume fraction in the composite material, and the rigidity of the contact between the matrix and the fibers. Anisotropy in the orientation of metal fibers results leads to the anisotropy of the conductivity of the composite. The flow of electric current through CETM structure depends on the anisotropic properties of the filler and differs by an order of magnitude depending on how the axes of most fibers are located (perpendicular or along the direction of the current), which explains the difference in the resistance of CETM (7.6 Ohm - the fibers are located parallel to the direction of the current, 84 Ohm - perpendicular). The electrical and mechanical anisotropy of CETM material can be reduced by fabricating a layered composite with the majority fiber axis of each conductive layer oriented in different directions. However, this significantly increases the rigidity of CETM structure. It becomes similar to multilayer composite structures used in the creation of orthotropic structures with high rigidity. Tests were carried out to evaluate the specific resistance of CETM sample during its stretching (Fig. 3). These measurements were made using a four-point probe to compensate for the effect of contact resistance, and the resistivity values were obtained by taking into account geometric changes in the sample during its elongation.

Рис. 3. Зависимость изменения сопротивления КЭТМ от величины относительной деформации при растяжении

Fig. 3. Changes in the CETM resistance from the magnitude of the relative strain under tension

The influence of the relative strain that occurs during tension of the above described structure of metal fibers located inside the silicone polymer matrix on the change in the resistance of CETM sample is illustrated in Fig. 3. The elastically deformable silicone matrix leads to bending of thin pliable metallic filler filaments, changing the conditions of contact of individual fibers with each other, and, consequently, affecting the total electrical resistance of CETM sample under study. The graph in Fig. 3 characterizes the dependence of the resistivity on the deformation of the sample, which was elongated in the direction perpendicular to the axis of most of the fibers of the metal filler, while the direction of the current corresponded to the direction of sample elongation. The graph shows the decrease in resistivity from 89.0 x 10-4 Ohm*m at a relative strain of 0.001 to 10.0 x 10-4 Ohm*m, at a relative strain of 0.20. The latter is associated with a change in the structure of CETM material, which leads to an increase in the number of contacts in the structure and their denser packing during its deformation. The main structural elements of such a system were studied, in particular, the architecture of the heating element of a thermoactive type actuator [1], based on the use of elastic fibers located inside the structural element of the heater, made of silicone elastomer. Studies have shown that as the fiber diameter decreases, the quality of the architecture improves, the number of fiber contacts obtained with each other increases, and the length between contacts decreases. Compaction of the material of the structure of the metal filler occurs after the deformation of the material, a separate metal fiber. At the same time, due to the plasticity of the contact zone between the fibers, the localization of deformation causes a significant bending of the fiber made of metal, as a result of which the magnitude of the macroscopic deformation of the structure of the conductive filler at a given voltage becomes significantly larger. The influence of the initial density of the material on its electrical characteristics was investigated. For this purpose, compression tests of material samples with different initial density (80.120 and 180 kg/m3) were carried out. Despite the relatively low electrical conductivity of the sample material, the use of steel fibers for the manufacture of CETM is rational, which is associated with the peculiarities of the combination of electrical and mechanical properties of such filler. The functional utility of this approach in creating a deformable conductive material is associated with the following positive qualities of the created structure: a) metal fibers provide electrically conductive paths through the fiber network of the filler structure; b) the realization of high elasticity of the entangled fibrous structure makes it possible to realize a high degree of deformation under loading without its destruction; c) the high modulus of elasticity of metal fibers makes it possible to create reversible deformations of the structure under dynamic loading and return to the original CETM geometry after the load is removed. The extensibility of CETM metal structure is achieved by bending individual thin metal fibers. When such a structure of metal filler is stretched in a direction perpendicular to the axis of most of the fibers, the fibers bend and take up distant positions from each other. The bending stiffness of a metal structure, assuming that it has the shape of a rod, is given by the formula

EID 4

K= 64 , where E is the modulus of elasticity; I is the moment of inertia; EI is bending stiffness, fiber diameter is D.

A thin metal filler in the form of tangled fibers was chosen because the bending rigidity depends nonlinearly on the diameter of the metal fiber, and with a decrease in the fiber diameter, their compliance increases significantly, which favorably affects the functioning conditions of such a structure under alternating loads characteristic of the operation of an actuator, part of which is a heater made of CETM. In this work, metal fibers with an average fiber diameter of ~30 µm as a conductor for CETM were used, which made it possible to create a conductive composite capable of reversible deformation. The designed structure combines the elasticity of elastomers with the electrical conductivity of a metallic conductor, creating a pliable conductive material that can be embedded in the body of a deformable structure such as a soft robot. Suggested solutions are related to the creation of CETM capable of implementing the concept of a deformable elastic heater that allows organizing an electrical path in any required direction, including perpendicular to the plane of the metal fibers in the elastomeric structure. The experiments confirmed that the samples have high elongation with an elongation at break of 380 ± 12% (n = 5 measurements). The destruction of the structure occurred as a result of delamination between the elastomer layer and the electrically conductive fibrous structure of CETM. This tensile strain resistance of the sample exceeds the requirements for most functional devices in which such elements can be used. A tensile study of CETM sample showed that CETM resistance changes slightly when the sample is elongated up to 200%. A small change in resistance (<0.3 Ohm) was observed when the sample was subjected to a cyclic test (number of loading cycles is 800 at 100% elongation). The test results showed that although the resistance of the specimens changed at initial load (<1.5 Pa), this change decreased at higher specimen loading. CETM resistance <2.0 Ohm was achieved for all specimens with a compressive load >1.5 Pa.

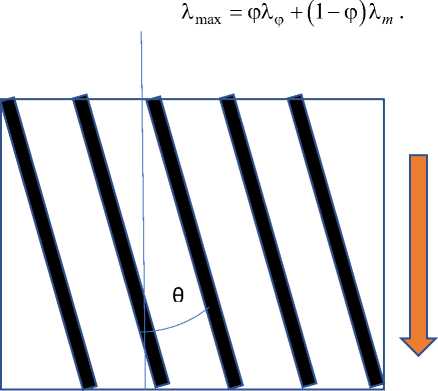

To determine the heat transfer during heating and cooling of HE, the problem of heat transfer for a fibrous medium oriented at an angle θ with respect to the heat flux (Fig. 4). The problem is considered under the assumption that the continuous and dispersed phases (metal fibers) are in the form of parallel plates (layers) and form an angle θ with the direction of the heat flow. An approach is considered using the simplest models; the system consists of plane-parallel layers of materials with different thermal conductivity coefficients λ ƒ and λ m for the fiber and the matrix, respectively. The percentage of fibers in the layer is φ. When the material layers are located along the heat flow, the thermal conductivity of the system will be maximum and is determined from expression (4)

Direction of heat flow

Рис. 4. Схема структуры волокнистой среды КЭТМ с заданной ориентацией

Fig. 4. Diagram of the structure of a fibrous medium of a CETM with a given orientation

In the case of the arrangement of the layers perpendicular to the direction of the heat flow, the thermal conductivity of the system is minimal and equal to

1 Х f X m

min "фХm + (1 — ф)Хf •

In real structures, the layers of heat-conducting material are located at an angle θ with respect to the heat flow (Fig. 4). Using expressions (4) and (5), the resulting expression for the effective thermal conductivity of such a system can be written:

Х ef =^max cos (^ +X Lx S i n (^

For the case of random distribution of fibers, solutions based on the two-phase effective thermal conductivity model (Hamilton model) [17] were used:

Х eff a + ( n — 1 ) + ( n — 1 )( a — 1 ) ф

Х m a + ( n — 1 ) + ( 1 — а ) ф

Here α = λ f / λ m ; n is the empirical shape factor ( n = 6 for cylinder-shaped fibers).

When considering the stochastic model of fiber distribution, the following relationship was used:

Х e = fm? . (8)

Using the approach proposed by Toll [18], an equation was used to calculate the maximum packing density of fibers without restrictions based on a statistical analysis of the distribution of fiber-to-fiber contact points:

N 0

ф =

4 2

---7 + g +1 п rff where N0 is the number of fiber-to-fiber contact points, which is assumed to be 8, and f and g are con-lf stants depending on the fiber orientation distribution; r^ = — is the relative length of the fiber def df pending on its length lf and diameter df . For a random three-dimensional arrangement of fibers, equation (9) is transformed into the following:

ф =

.

rf + 3

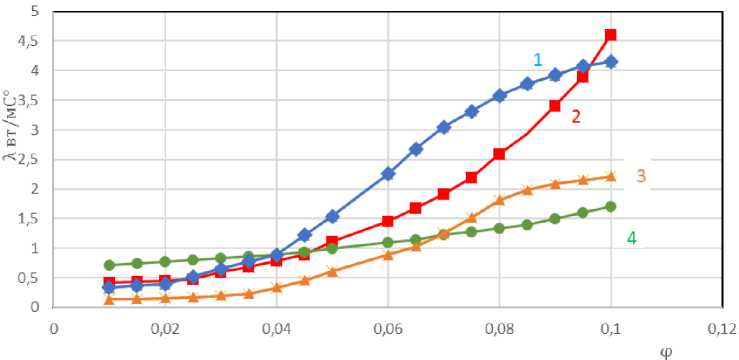

Fig. 5 shows comparison of the calculation results and experiment to determine the effective thermal conductivity of a CETM sample based on silicone elastomer and metal fibers at various values of the fiber content φ max in CETM and the orientation angles of the fibers with respect to the heat flux θ.

Рис. 5. Зависимость теплопроводности КЭТМ от относительного объёма волокон λ eff = F (φ) и угла ориентации волокна θ. Результаты экспериментальных измерений:

1 – θ = 0°, 3 – θ = 45°. Результаты расчёта: 2 – θ = 0°; 4 – θ = 45°

Fig. 5. The dependence of the thermal conductivity of the CЕTM on the relative volume of the fibers λ eff = F (φ) and the angle of orientation of the fiber – θ. Results of experimental measurements:

1 – θ = 0°, 3 – θ = 45°. Calculation results: 2 – θ = 0°; 4 – θ = 45°

Conclusion

An elastically deformable heating element for elastomeric actuators based on silicone elastomers and metal fibers for use in controlled “smart” composite structures was developed and studied. The developed design of CETM has a low resistance to electric current and can be easily embedded in flexible structures such as reconfigurable antennas, flexible robotic devices, etc. Unlike conventional wires, CETM can be used to distribute electric current and potential throughout the body of a soft device when the structure is subjected to large elastic deformations (more than 100%) in the course of its operation. The combination of electrical conductivity, deformability and conformity of CETM allows creating electrical connections with solid metal components during their movement and shape change. These properties make it easier to interface conventional hard electrical components with soft devices and also enable the creation of fully soft electrical devices. The use of such systems based on CETM makes it possible to solve the problem of creating electrical connections for deformable structures using an elastomeric polymer. CETM can be useful in soft robotics, where the creation of deformable electrical connections using elastomers will facilitate the incorporation of rigid electrical and mechanical components into soft structures. Combining soft actuators with CETM-based electrical components designed to be embedded in soft devices is an important step towards creating soft robots that can perceive and respond to the external environment. In this work, an experimental and theoretical study of conductive heat transfer in an elastomeric matrix with a metallic fibrous material was carried out. For a theoretical study, several approximation models were used - Toll and Hamilton - to calculate the effective thermal conductivity for two laying directions (0° and 45°) of metal fibers in an elastic medium. Using adjoint modeling, the following main conclusions were made:

-

1. The results calculated using the Hamilton and Toll models for CETM for metal fibers randomly distributed in an elastic medium agree satisfactorily with the results obtained experimentally. Therefore, this approach makes it possible to predict the effective thermal conductivity of such a structure.

-

2. Experiments have shown an exponential decrease in the thermal conductivity of the structure with an increase in the angle between the direction of the heat flow and the orientation of the fiber. The proposed model does not allow tracking such a dependence, which indicates the need for its refinement.

-

3. The use of approaches based on a multiphase model containing isolated and conductive fibers made it possible to determine the effect of the volume fraction of fibers on the effective thermal conductivity of a composite electrical-thermal-conducting material (CETM). From the presented experimental and calculated results, it follows that this dependence is close to linear, except for the zone with a high content of metal fibers (φ>0.06), which indicates the nonlinearity of the processes of formation of contacts between the fibers of the metal filler.

Список литературы Flexible composite structures with controlled physical and mechanical characteristics

- White T. J., Broer D. J. Programmable and adaptive mechanics with liquid crystal polymer net-works and elastomers. Nat. Mater. 2015, No. 14, P. 1087–1098.

- Rich S. I., Wood R. J., Majidi C. Untethered soft robotics. Nat. Electron. 2018, No. 1, P. 102–112.

- Yang C., Suo Z. Hydrogel ionotronics. Nat. Rev. Mater. 2018, No. 3, P. 125–142.

- Liu Y., Pharr M., Salvatore G. A. Lab-on-skin: A review of flexible and stretchable electronics for wearable health monitoring. ACS Nano. 2017, No. 11, P. 9614–9635.

- Behl M., Razzaq M. Y., Lendlein A. Multifunctional shape-memory polymers. Adv. Mater. 2010, No. 22, P. 3388–3410.

- Mirvakili S. M., Hunter I. W. Artificial muscles: Mechanisms, applications, and challenges. Adv. Mater. 2018, No. 30, P. 1704407.

- Jeon S.-J., Hauser A. W., Hayward R. C. Shape-morphing materials from stimuliresponsive hy-drogel hybrids. Acc. Chem. Res. 2017, No. 50, P. 161–169.

- Wermter H., Finkelmann H. Liquid crystalline elastomers as artificial muscles. e-Polymers. 2001, No. 1, P. 013.

- Chambers M., Zalar B., Remškar M. et al Actuation of liquid crystal elastomers reprocessed with carbon nanoparticles. Appl. Phys. Lett. 2006, No. 89, P. 243116.

- Courty S., Mine J., Tajbakhsh A. R., Terentjev E. M. Nematic elastomers with aligned carbon nanotubes: New electromechanical actuators. Europhys. Lett. (EPL). 2003, No. 64, P. 654–660.

- Marshall J. E., Ji Y., Torras N. et al.Carbon-nanotube sensitized nematic elastomer composites for IR-visible photo-actuation. Soft Matter. 2012, No. 8, P. 1570–1574.

- Kularatne R. S., Kim H., Boothby J. M., Ware T. H. Liquid crystal elastomer actuators: Synthe-sis, alignment, and applications. J. Polym. Sci. Part B Polym. Phys. 2017, No. 55, P. 395–411.

- Shahinpoor M. “Electrically activated artificial muscles made with liquid crystal elastomers” in Smart Structures and Materials 2000: Electroactive Polymer Actuators and Devices (EAPAD) (Inter-national Society for Optics and Photonics. 2000, Vol. 3987, P. 187–193.

- Yang L., Setyowati K., Li A. et al. Reversible infrared actuation of carbon nanotube–liquid crystalline elastomer nanocomposites. Adv. Mater. 2008, No. 20, P. 2271–2275.

- Agrawal A. et al.Electromechanically responsive liquid crystal elastomer nano-composites for active cell culture. ACS Macro Lett. 2016, No. 5, P. 1386–1390.

- Likhachev A. N. [Research on the creation of deformable flexible composite structures with variable stiffness based on hydraulic principles]. Aktual'nye problemy zashchity i bezopasnosti: tr. XXV Vseross. nauch.-prakt. konf. RARAN. T. 1. Vooruzhenie, voennaya i spetsial'naya tekhnika [Actu-al problems of protection and safety: tr. XXV All-Russian. scientific-practical. conf. RARAN. T. 1. Armament, military and special equipment]. 2022, P. 93–96 (In Russ.).

- Likhachev A. N. [Experimental and theoretical studies of the creation of morphing composite structures based on a controlled flexible frame with variable stiffness]. Reshetnevskie chteniya: mate-rialy XXV Mezhdunar. nauch. konfer. [Reshetnev readings: materials of the XXV Intern. scientific conf.]. (November 10–13, 2021, Krasnoyarsk): at 2 pm / under the general ed. Yu. Yu. Loginova; Sib. state aerospace un-t. Krasnoyarsk, 2021, P. 100–101 (In Russ.).

- Jagjiwanram, Singh R. Effective thermal conductivity of highly porous two-phase systems. Ap-plied Thermal Engineering. 2004, Vol. 24, P. 2727–2735.

- Toll S. Packing Mechanics of Fiber Reinforcements. Polymer Engineering and Science. 1998, Vol. 38, No. 8, P. 1337–1350.