Foam metals high-temperature electrical characteristics investigation

Автор: Kirko Vladimir I., Dobrosmislov Sergey S., Gusev Alexander O., Simakov Dmitry A., Stepanov Egor I.

Журнал: Журнал Сибирского федерального университета. Серия: Техника и технологии @technologies-sfu

Статья в выпуске: 3 т.1, 2008 года.

Бесплатный доступ

In the work presented we have carried out experimental investigations of high- temperature electrophysical properties of foam metals. We have obtained data of foam nickel and foam copper resistivity and temperature coefficients of resistance (TCR) versus their plane deformation degree within the temperature range from 100 to 950 ºС.

Foam metals, high-temperature electro-physical properties

Короткий адрес: https://sciup.org/146114468

IDR: 146114468 | УДК: 669.967

Текст научной статьи Foam metals high-temperature electrical characteristics investigation

Foam metals possess a number of elastic and electric properties [1] that allow one using them as a conducting medium, being exposed to different elastic influences. For example, they can be used as a conducting variator of a material thermal expansion coefficient in electric steel – foam metal – cermet joints [2, 3].

The main aim of present paper was to investigate the dependence of electrical features of the materials based on foam nickel and foam copper on their temperature and plane deformation degree.

Experimental

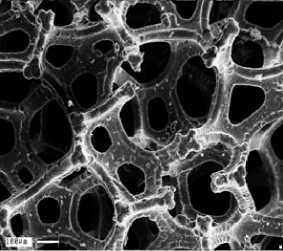

Electrical characteristics have been measured with the help of 4-probe method, as in paper [4]. The foam metal specimens have been covered with a high- temperature coating to avoid high-temperature oxidation. Plane deformation has been accomplished by means of a hydraulic press. In Fig. 1, there is presented the image of the initial foam nickel structure, having been obtained with the help of a raster electron microscope (REM).

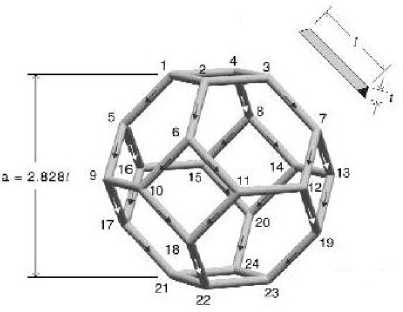

Such structure can be described by a model suggested in [4], where the foam structure is considered as a set of polyhedron cells, presented in Fig. 2.

According to the model given, there have been obtained the following dependences to calculate a relative density and electrical conductivity.

Fig. 1. The image of the initial foam nickel structure

(a)

( b )

Fig. 2. Polyhedron cell of the foam metal with an open porosity ( a ). The polyhedron cell edge ( b )

Fig. 3. Dependences of relative electro-conductivity on relative density of foam copper (curve 3) and foam nickel (curve 1) are compared to experimental data of foam aluminium (curve 2) and to the theoretical model [4]

YL = 0,2296 x γ 0

2. #2Л 3,V

1 + M + 0,625R | ;

l 2 J

— - 0,4082 x l -1 I О 0 I l J

σ 0,4082

t 1 2 + t2 2 l2

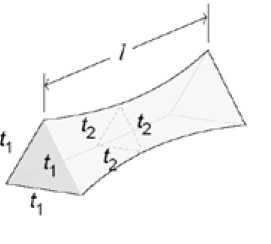

where t1, t2 and l are the characteristic sizes of the tetragonal cell edges, and γ, γ0 are the foam and foam material densities, respectively, σ, σ0 are the foam and foam mate rial conductivities. The formula given (2) is used at t1 = t2.

In Fig. 3 there are presented dependences of relative electro-conductivity on relative density of foam nickel and foam copper having been obtain ed in present paper in comparison to the theoretical model, as well as to the experimental data of foam aluminium from [4].

As it can be seen in Fig. 3, the dependences are practically linear and, if there is no plan e deformation (γ⁄γ0 = 0,045), the data of foam nickel and copper coincide well with that of foam aluminium from [4]. Further discrepancy at higher relative densities can be explained by the fact that in present paper higher values of foam metal densities have been reached by plane defo rmation of the specimens which leads to distortions of the foam metal cells.

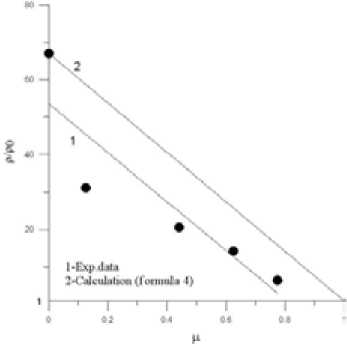

In Fig. 4 there are shown dependences of the foam metal resistivity on t ^ he metal plane deformation degree at Т = 20 °С.

Foam metal resistivity decreases with the deformation degree increasing, and the curve can be presented by the linear relationship of the following type:

p = P 00

ρ 0 ρ 0

P = ,

ρ 0

where µ is the deformation degree, ρ00, ρ0 are the resistivities of the corresponding foam metal in its initial state (at µ = 0) and metal, respectively.

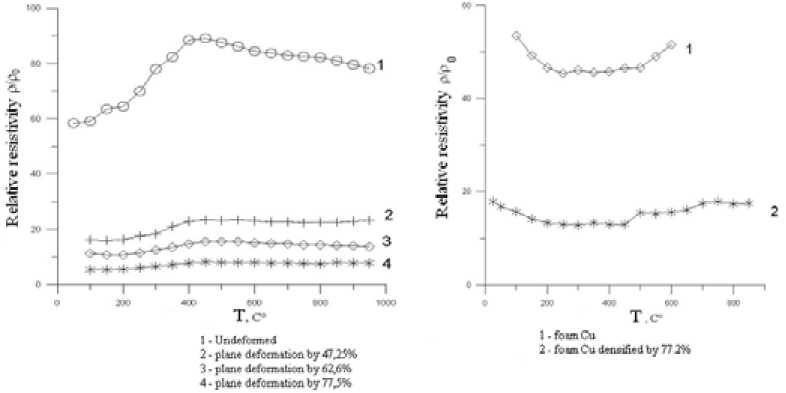

In Fig. 5, there are shown relative resistivity dependences on the temperature at different deformation degrees.

As it can be seen in the figure, the foam metals resistivity changes its values within the range from 20 % to 25 % with temperature increasing. However, at high degrees of plane deformation, it remains practically unchanged.

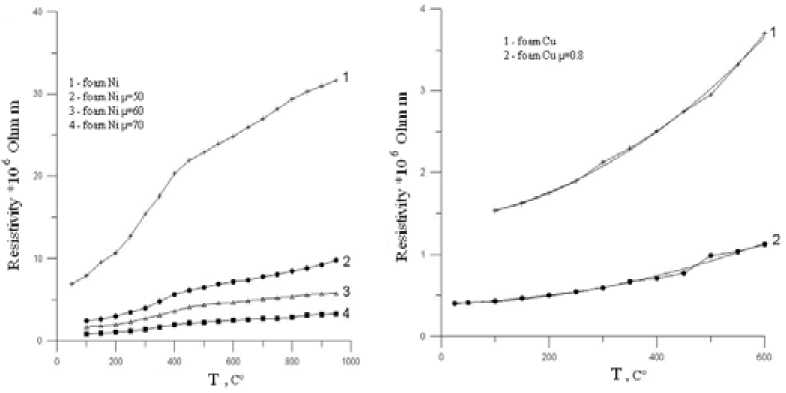

In Fig. 6, there are presented temperature dependences of the foam nickel resistivity at different degrees of its plane deformation ( a ), with different pore sizes ( b ) and, in the last case, at approximately equal density.

As follows from the figure, all foam nickel temperature dependences have a bend at a temperature near the pure nickel Curie point (360 °С). The foam nickel Curie point is slightly overrated (by 40 ºC) and can be caused by an increased level of impurities, dissolved in its crystal structure and formed during the technological process of its preparation. It can also be the result of some other reasons, preventing the motion of domain walls.

(а)

( b )

Fig. 4. Dependences of the foam copper ( a ) and foam nickel ( b ) resistivities on the metals plane deformation degree at Т = 20 °С

(a) (b)

Fig. 5. The foam nickel ( а ) and the foam copper ( b ) relative resistivity dependences on the temperature at different deformation degrees. Here ρ and ρ0 are the resistivities of the foam and of a solid material, respectively, versus temperature

(a)

(b)

Fig. 6. Temperature dependences of foam nickel ( a ) and copper ( b ) resistivities at different plane deformation degrees

(a)

(b)

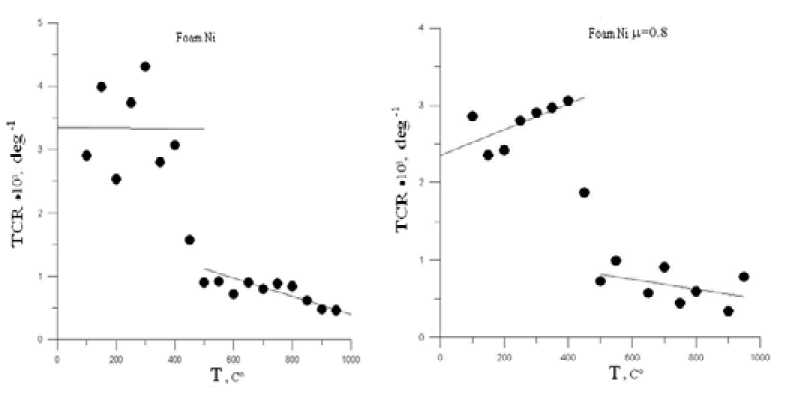

Fig. 7. Temperature dependences of foam nickel TCR at μ = 0 ( а ) and μ = 0,8 ( b )

(a)

( b )

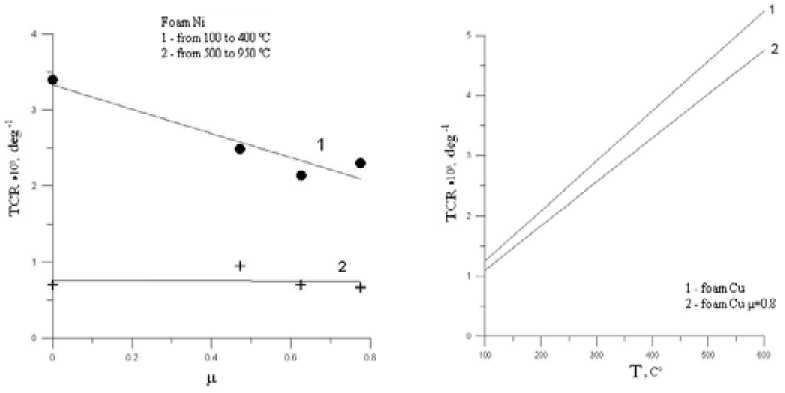

Fig. 8. Foam nickel TCR dependences on its plane deformation degree μ within the temperature ranges from 100 to 400 ºС (curve 1) and from 400 to 500 ºС (curve 2) ( a ), foam copper TCR vs. temperature ( b )

Increase of the degree of the foam metal plane deformation leads to decrease of their resistivity which is due to pores’ closing. In this case, the temperature coefficient of resistance (TCR) goes down too, as it follows from Fig. 6.

Temperature dependences of foam nickel TCR are given in Fig. 7 at different degrees of plane deformation.

As it follows from the figure, the TCR undergoes a sudden change at the Curie point caused by a second-order phase transition. It decreases linearly within the temperature range from 450 to 950 °С.

Within the temperature range from 100 to 400 ºC, the foam nickel TCR is slightly (practically, linearly) decreasing with the growth of the plane deformation degree (Fig. 8 a ). The absolute TCR value is within that for technical nickel (2.7•·103 deg-1) [5]. At temperatures higher than 500 ºC, foam nickel TCR does not depend on its deformation degree. Foam copper’s TCR is going down linearly with temperature, but is decreasing with the deformation degree growth (Fig. 8 b ).

Conclusions

In present paper, we have carried out the investigations of high-temperature electrical properties of foam nickel and copper versus temperature and plane deformation degree. The work has shown that the foam metal resistivities and TCRs decrease with the increase of the deformation degree. Thereat, in the former the dependence is linear. At high deformation degrees (μ > 0,5), the ratio of the foam metal resistivity to the metal one at the same temperature is practically independent of the temperature. Foam nickel TCR within the temperature range from 100 to 400 ºС corresponds to that of technical nickel. It decreases linearly with the increase of the deformation degree.

Acknowledgments

The authors express their gratitude to the “RUSAL Engineering Co Ltd” for their assistance in the preparation of the paper.