Formation of the structure, mechanical and tribological properties of high chrome steel by electronic-ion-plasma nitrogen

Автор: Eresko S.P., Ivanov Yu.F., Petrikova Ye.A., Teresov A.D., Klopotov A.A.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 4 vol.22, 2021 года.

Бесплатный доступ

The purpose of this work is to detect the regularities of formation of the structure, mechanical and tribological properties of high-chromium steel subjected to complex treatment combining irradiation with a pulsed electron beam and subsequent nitriding in a low-pressure gas discharge plasma using a plasma generator with an incandescent cathode “PINK”. The object of the study was heat-resistant corrosionresistant austenitic steel grade AISI 310S. The relevance and practical significance of the research is due to the relatively low level of hardness and wear resistance of steels of this class, which have a wide range of applications in modern industry, including in the rocket and space industry. Irradiation of AISI 310S steel with a pulsed electron beam was carried out at the SOLO installation, subsequent nitriding (the QUINTA installation). It was found that irradiation of samples at an electron beam energy density of 30 J/cm2, 200 microseconds, 3 pulses and subsequent nitriding at a temperature of 793 K for 3 hours led to the following changes in mechanical properties. The maximum microhardness reached values of 19 GPa (exceeds the hardness of steel before modification by 11.2 times and the hardness of steel after electron beam irradiation by 8 times). The wear parameter has changed to values k = 0.7106 mm3/Nm (less than the wear parameter of steel before modification by more than 700 times and less than the wear parameter of steel after electron beam irradiation by more than 750 times). The thickness of the hardened layer is 40 microns. It was found that the samples that have the maximum (90.6 %) content of nitride phases (chromium and iron nitrides) in the surface layer. It was established that after nitriding at a temperature of 723 K in the surface layer of steel, iron and chromium nitrides are formed in the form of nanoscale particles of rounded shape. At nitriding temperatures of 793 and 873 K, a plate-type structure formed by alternating parallel plates of iron nitride and chromium nitride is formed in the surface layer of steel.

Complex processing, pulsed electron beam, gas discharge plasma, high-alloy steel, structure, properties

Короткий адрес: https://sciup.org/148329599

IDR: 148329599 | УДК: 621.785.53 | DOI: 10.31772/2712-8970-2021-22-4-688-699

Текст научной статьи Formation of the structure, mechanical and tribological properties of high chrome steel by electronic-ion-plasma nitrogen

Special, as well as corrosion-resistant and stainless steels are the second most used material in the rocket and space industry after aluminum-based alloys. Relatively low hardness and wear resistance are negative characteristics of austenitic stainless steels, reducing durability of products made from this material. Modification of the surface of metals and alloys by complex processing, combining in various sequences saturation of the surface layer with atoms of gas elements (nitrogen, carbon, oxygen), the deposition of thin layers of various metals, followed by mixing under high-energy pulsed electron beams, the deposition of solid and superhard wear-resistant coatings, etc. is one of the most promising methods for improving the service characteristics of a material [1–3]. The most common ion-plasma nitriding method in industry, including stainless steels, is a method based on the use of an anomalous glow discharge [1; 2; 4; 5]. The advantage of this method is relative simplicity of both devices and process implementation. Its main disadvantages are associated with a rather high pressure at which it is implemented, which does not allow for effective ion cleaning of the treated surface during nitriding, significantly increasing duration of treatment.

Another way to obtain gas plasma for chemical-thermal treatment is based on the use of arc discharges (plasma concentration (1015–1018) m–3 in volumes up to several m3). Currently, the most promising method is the formation of a low-pressure discharge with a heated cathode, which provides the generation of a plasma flow without microdroplets [6–9]. Using a combined cathode, including hot and hollow cathodes, the PINK plasma generator was developed at the Institute of High Current Electronics of the Siberian Branch of the Russian Academy of Sciences [9].

In recent years, methods of combined surface treatment of parts and products have been actively developed. One of the promising options for combined processing is the use, in addition to nitriding, of irradiating the material with a pulsed electron beam [10]. Electronic sources based on an explosive emission cathode are widely used [11; 12] and with plasma cathodes [13; 14]. The “SOLO” installation of UNU “UNIQUUM”, which was used in the studies considered in this work, is equipped with an electronic source with a plasma cathode based on a low-pressure pulsed arc discharge with grid stabilization of the cathode plasma boundary and an open anode plasma boundary, allows generate an electron beam with a current of up to 300 A, an electron energy of up to 25 kV, a pulse duration of (20–200) µs, a pulse energy density of up to 80 J/cm2, and a pulse repetition rate of up to 15 s-1 [15– 17]. All parameters can be adjusted steplessly and independently of each other. Using accelerating voltage up to 25 kV does not require additional radiation protection.

The purpose of this work is to reveal the patterns of structure formation, mechanical and tribological properties of high-chromium steel subjected to complex processing, combining irradiation with a pulsed electron beam and subsequent nitriding in a low-pressure gas discharge plasma using a plasma generator with a hot cathode "PINK".

Material and research methods

The material of the study was samples of steel AISI 310S. The samples were in the form of plates with dimensions of (15 x 15 x 5) mm. The steel was irradiated using a SOLO facility [17] (18 keV, (10 and 30) J/cm2, 200 µs, 3 pulses, 0.3 s-1, residual argon pressure 0.02 Pa). Nitriding (723–873 K, 1–5 h) was carried out on a QUINTA unit equipped with a PINK plasma generator. The study of the structure and phase composition of the material was carried out by the methods of scanning and transmission diffraction electron microscopy, X-ray diffraction analysis. The properties of the modified layer were characterized by microhardness and wear resistance.

Research results and discussion

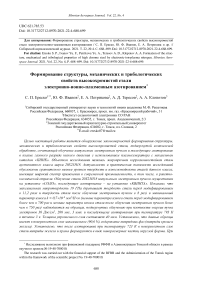

It is shown that irradiation of steel with a pulsed electron beam leads to a significant transformation of structure of the surface layer of steel. At an electron beam energy density of 10 J/cm2 (200 μs, 3 pulses), firstly, several microtwinning systems are revealed within one grain (fig. 1, a); secondly, the number of bending extinction contours increases, which indicates an increase in the amplitude of in- ternal stress fields and an increase in the number of stress concentrators (fig. 1, b); thirdly, the scalar density of dislocations increases by 1.5 (relative to the initial state).

Рис. 1. Структура поверхностного слоя стали, облученной импульсным электронным пучком (10 Дж/см2, 200 мкс, 3 имп.)

-

Fig. 1. Structure of the surface layer of steel irradiated with a pulsed electron beam (10 J/cm2, 200 microseconds, 3 pulses).

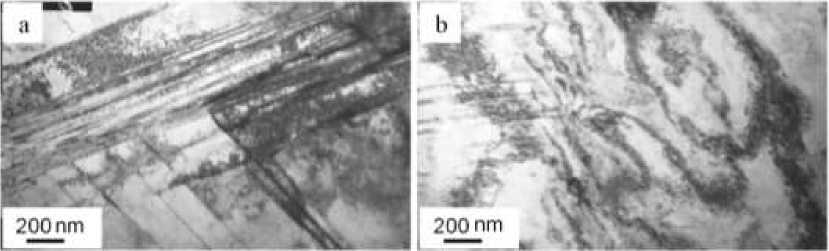

Increasing the energy density of an electron bunch to 30 J/cm2 leads to melting surface layer and the formation of a structure of cellular crystallization (fig. 2, a ).

Рис. 2. Структура поверхностного слоя стали, облученной импульсным электронным пучком (30 Дж/см2, 200 мкс, 3 имп.)

-

Fig. 2. Structure of the surface layer of steel irradiated with a pulsed electron beam (30 J/cm2, 200 microseconds, 3 pulses)

The cell size varies within 300–400 nm. There is a dislocation substructure in the bulk of the cells (fig. 2, b ). The scalar dislocation density is 2.3x1010 cm-2, i.e., lower than the scalar dislocation density of the surface layer of steel irradiated with an electron beam in the mode of solid-phase modification of the material (10 J/cm2, 200 μs, 3 pulses). Particles of the second phase are revealed along the boundaries and at the junctions of the boundaries of crystallization cells. Analysis of microelectron diffraction patterns allows us to state that these particles are predominantly chromium carbide.

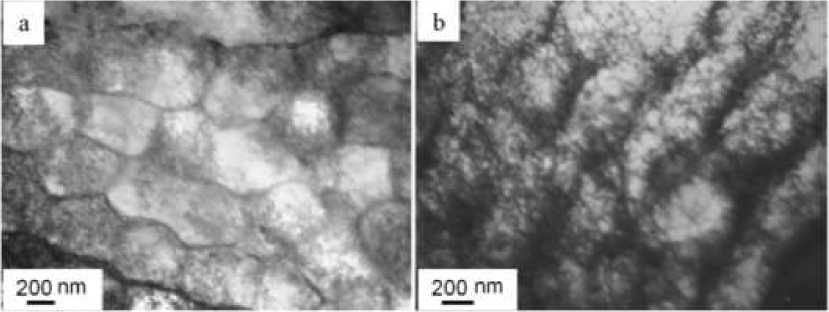

It has been established by X-ray diffraction analysis that, regardless of the mode of irradiation and subsequent nitriding, a multiphase polycrystalline structure is formed in the surface layer of steel (fig. 3). The main phases of the studied samples are α-Fe and γ-Fe, as well as iron nitride of Fe4N composition and chromium nitride of CrN composition. The maximum (90.6 %) content of nitride phases was found in the surface layer of steel that had undergone preliminary treatment with a pulsed electron beam (30 J/cm2, 200 μs, 3 pulses) and subsequent nitriding at 793 K for 3 h.

2 ® , degree

Рис. 3. Участок рентгенограммы образца стали 20Х23Н18, подвергнутой комплексной обработке (30 Дж/см2, 200 мкс, 3 имп. + 793 К, 3 ч)

-

Fig. 3. X-ray section of a AISI 310S steel sample subjected to complex treatment (30 J/cm2, 200 microseconds, 3 pulses + 793 K, 3 hours)

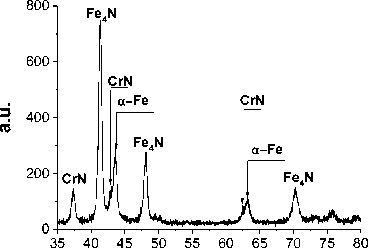

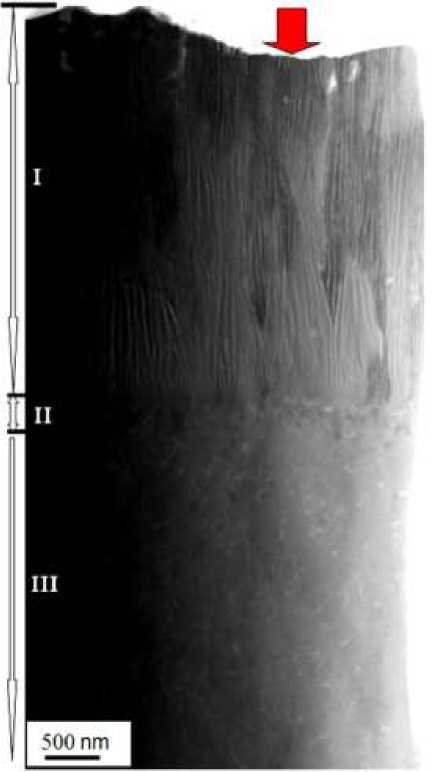

The phase morphology and the defective substructure of a modified layer of AISI 310S steel were studied by transmission electron diffraction microscopy (JEM 2100F instrument, JEOL). An electron microscopic image of the cross-sectional structure of the surface layer of a steel sample subjected to complex treatment (30 J/cm2, 200 μs, 3 pulses + 793 K, 3 h) is shown on Fig.4 a . It is clearly seen that emerging structure is multilayered. The surface layer (fig. 4, layer No. I), which has a columnar (lamellar) structure, the transition layer (fig. 4, layer No. II), which has a nano-sized grain-type structure, and a layer of thermal diffusion influence (fig. 4, layer III), which has a grain-type structure with nanosized particles of the second phase is revealed. The thickness of layer I reaches 3.5–4 µm, the thickness of layer II is 0.35–0.45 µm; the thickness of layer III is ≈35 µm. Using the methods of microdiffraction analysis and a dark-field technique, it was established that the surface layer of steel is formed by alternating plates of iron and chromium nitrides. This type of structure is formed after nitriding at temperatures of 793 and 873 K. Nitriding at a temperature of 723 K leads to the formation of a multiphase grain structure of submicron sizes in the surface layer of the steel (fig. 5). Nanosized (5– 12 nm) inclusions of iron and chromium nitrides are observed in grain volume.

Mechanical (microhardness) and tribological (dry friction wear resistance) tests of samples of AI-SI 310S steel subjected to complex processing made it possible to identify modification modes for each of the nitriding temperatures that showed the best properties. The highest set of properties was found in samples subjected to irradiation (30 J/cm2, 200 µs, 3 pulses) and subsequent nitriding (793 K, 3 h). The thickness of the hardened layer of these samples is 40 μm, the hardness on the modification surface is 19 GPa (it exceeds the hardness of steel before modification by 11.2 times and the hardness of steel after irradiation with a pulsed electron beam by 8 times); wear parameter (reciprocal value of wear resistance) - 0.7 x 10 —6 mm3/N x m (less than steel wear parameter before modification equal to 495 x 10 —6 mm3/N x m, more than 700 times and less steel wear parameter after electron beam irradiation, equal to 520 x 10 -6 mm3/N x m, more than 750 times).

The analysis of isothermal cross sections of triple diagrams of the Cr-Fe-N, Cr-Ni-N, Fe-Ni-N and Cr-Fe-Ni systems made it possible to establish that in the Fe-Ni-N system there is a narrow region of a solid solution based on the phase y(Fe, Ni), and in the Cr-Fe-Ni system - a vast area of a three-component solid solution (Cr, Fe, Ni) (fig. 6) [21]. All this made it possible to assume that in the four- component system Cr-Fe-Ni-N it is possible to form a four-component solid solution (Cr, Fe, Ni, N) based on the γ(Fe, Ni) phase.

It should be noted that the method presented in this article for modifying the surface of metals and alloys by an intense pulsed electron beam, which makes it possible to significantly improve physical and mechanical properties of the surface layers of metals and alloys, is considered in sufficient detail in [22–28].

Рис. 4. Электронно-микроскопическое изображение структуры поперечного сечения образца стали 20Х23Н18, подвергнутой комплексной обработке (30 Дж/см2, 200 мкс, 3 имп. + 793 К, 3 ч); изображение, полученное методами STEM

Fig. 6. Isothermal sections of triple systems Cr - Fe–N [18], Cr - Ni–N [19], Fe–Ni - N [20] и Cr - Fe–Ni [21]

Conclusion

Surface treatment of AISI 310S steel specimens was carried out using a complex method that combines in a certain sequence irradiation with a pulsed electron beam and nitriding in a low-pressure gas discharge plasma using a plasma generator with a hot cathode "PINK". It has been established that after nitriding at a temperature of 723 K, in the surface layer of irradiated steel samples, iron and chromium nitrides are formed in the form of rounded nanosized particles. At nitriding temperatures of 793 and 873 K, a lamellar-type structure is formed in the surface layer of steel, formed by alternating parallel plates of iron nitride and chromium nitride. It is shown that the maximum microhardness, 19 GPa (exceeds the hardness of steel before modification by 11.2 times and the hardness of steel after irradiation with an electron beam by 8 times) and the minimum wear parameter, k = 0.7 x 10 - 6 mm3/N x m (more than 700 times less than the steel wear parameter before modification and more than 750 times less than the steel wear parameter after electron beam irradiation), are observed on samples irradiated at an electron beam energy density of 30 J/cm2, 200 µs, 3 pulses and subsequent nitriding at a temperature of 793 K for 3 hours. The thickness of the hardened layer is 40 µm. It has been established that the samples that demonstrated the highest values of hardness and wear resistance have the maximum (90.6 %) content of nitride phases (chromium and iron nitrides) in the surface layer.

Список литературы Formation of the structure, mechanical and tribological properties of high chrome steel by electronic-ion-plasma nitrogen

- Arzamasov B. N., Bratuhin A. G., Eliseev Ju. S., Panajoti T. A. Ionnaya himiko-termicheskaya obrabotka splavov [Ionic chemical-thermal treatment of alloys]. Moscow, MGTU Publ., 1999, 400 p.

- Berlin E. V., Koval’ N. N., Sejdman L. A. Plazmennaya himiko-termicheskaja obrabotka poverhnosti stal’nyh detaley [Plasma chemical-thermal surface treatment of steel parts]. Moscow, Tehnosfera Publ., 2012, 464 p.

- Kovalja N. N., Ivanova Ju. F. Jevolyuciya struktury poverhnostnogo sloja stali, podvergnutoy elektronno-ionno-plazmennym metodam obrabotki [Evolution of the structure of the surface layer of steel subjected to electron-ion-plasma processing methods]. Tomsk, NTL Publ., 2016, 304 p.

- Lie Sh., Liang W., Yizuo W., Chunhua W. Plasma nitriding of AISI 304 austenitic stainless steel with pre-shot penning. Surface and Coatings Technology. 2010, Vol. 204, No. 20, P. 3222–3227.

- Mirjani M., Shafyei A., Ashrafizadeh F. Plasma and gaseous nitrocarburizing of C60W steel for tribological applications. Vacuum. 2009, Vol. 83, No. 7, P. 1043–1048.

- Meletis E. I. Intensified plasma-assisted processing: science and engineering. Surface and Coatings Technology. 2002, Vol. 149, No. 2-3, P. 95–113.

- Wei R., Benn C. R., Cooper C. V. High Intensity Plasma Ion Nitriding of AerMet 100 Martensitic Steel. Plasma Process. Polym. 2007, Vol. 4, No. 1, P. 700–706.

- Oliveira R. M., Goncalves J. A. N., Ueda M., Rossi J. O., Rizzo P. N. A new high-temperature plasma immersion ion implantation system with electron heating. Surface and Coatings Technology. 2010, Vol. 204, No. 18-19, P. 3009–3012.

- Shhanin P. M., Koval’ N. N., Goncharenko I. M., Grigor’ev S. V. [Generation of volumetric plasma by an arc discharge with an incandescent cathode]. Fizika i himiya obrabotki materialov. 2001, No. 3, P. 16–19 (In Russ.).

- Gribkov V. A., Grigoriev F. I., Kalin B. A. Perspektivnye radiacionno-puchkovye tehnologii obrabotki materialov [Promising radiation-beam technologies of materials processing]. Moscow, Kruglyy stol Publ., 2001, 528 p.

- Nazarov D. S., Ozur G. E., Proskurovsky D. I. Production of Low-Energy, High-Current Electron Beams in a Reflected Discharge Plasma-Anode Gun. Proc. of 11th IEEE Int. Pulsed Power Conference. Baltimore, USA, 1997, Vol. II, P. 1335–1340.

- Engelko V., Mueller G., Bluhm H. Influence of particle fluxes from target on characteristics of intense electron beams. Vacuum. 2001, Vol. 62/2-3, P. 97–103.

- Gavrilov N. V., Gushenec V. I., Koval’ N. N. Istochniki zaryazhennyh chastic s plazmennym emitterom [Sources of charged particles with a plasma emitter]. Ekaterinburg, UIF Nauka Publ., 1993, 148 p.

- Grigoriev S. V., Koval N. N., Devjatkov V. N., Teresov A. D. Effect of intensified emission during the generation of a submillisecond low-energy electron beam in a plasma-cathode diode. Proc. 9th Intern. Conf. On Modification of Materials with Particle Beams and Plasma Flows. Tomsk, 2008, P. 19–22.

- Koval N. N., Ivanv Yu. F. Nanostructuring of surfaces of metalloceramic and ceramic materials by electron-beams. Russian Physics Journal. 2008, Vol. 51, P. 505–516.

- Ivanov Yu. F., Krysina O. V., Petrikova E. A. et al. Complex electron-ion-plasma treatment of titanium: methods, structure, properties. High Temperature Material Processes. 2017, Vol. 21(1), P. 53–64.

- Koval N. N., Ivanov Yu. F. Jelektronno-ionno-plazmennaja modifikacija poverhnosti cvetnyh metallov i splavov [Electron-ion-plasma modification of the surface of non-ferrous metals and alloys]. Tomsk, NTL Publ., 2016, 312 p.

- Raghavan V. The Cr-Fe-N System in Phase Diagrams of Ternary Iron Alloys. Indian Inst. Metals, Calcutta. 1987, Vol. 1, Р. 171–182.

- Hertzman S. A. Study of Equilibria in the Fe-Cr-Ni-Mo-C-N System at 1273 K. Metallurgical Transactions, Section A: Physical Metallurgy and Materials Science. 1987, Vol. 18, Р. 1767–1778.

- Frisk K. A. Thermodynamic Evaluation of the Fe-Ni-N System. Z. Metallkd. 1991, No. 82, Р. 59–66.

- Lee B.-J. A. Thermodynamic Evaluation of the Fe-Cr-Ni System. J. Korean Inst. Met. 1993, Vol. 31, Р. 480–489.

- Ivanov Yu. F., Yeresko S. P., Klopotov A. A., Rygina M. Ye., Petrikova Ye. A., Teresov A. D. [Structural-phase state and properties of hypereutectic silumin treated with a pulsed electron beam]. Sibirskiy aerokosmicheskiy zhurnal. 2021, Vol. 22, No. 2, P. 371–382 (In Russ.).

- Ivanov Yu. F., Teresov A. D., Gromov V. Ye., Budovskikh Ye. A., Klopotov A. A. [Structural- phase states of nanostructured surface layers of VT1-0 titanium after combined electron-ion-plasma treatment]. Reshetnevskiye chteniya: materialy XVIII Mezhdunarodnoy nauchnoy konferentsii. Krasnoyarsk, 2014, Ch. 1, P. 291–293 (In Russ.).

- Ivanov Yu. F., Yeresko S. P., Klopotov A. A., Petrikova Ye. A., Gromov V. Ye. [Features of the structural-phase state on the surface of silumin, formed by methods of electron-ion-plasma treatment]. Reshetnevskiye chteniya: materialy XXI Mezhdunarodnoy nauchnoy konferentsii. Krasnoyarsk, 2017. Ch. 1, P. 615–617 (In Russ.).

- Ivanov Yu. F., Yeresko S. P., Akhmadeyev Yu. X., Lopatin I. V., Klopotov A. A. [Development of a combined electron-ion-plasma method for the formation of multiphase submicro-nanosized alloys based on aluminum]. Reshetnevskiye chteniya: materialy XVIII Mezhdunarodnoy nauchnoy konferentsii. Krasnoyarsk, 2018, Ch. 1, P. 490–492 (In Russ.).

- Ivanov Yu. F., Klopotov A. A., Yeresko S. P., Petrikova Ye. A., Lopatin I. V. [Multicycle surface alloying of silumin with titanium]. Reshetnevskiye chteniya: materialy XXIII Mezhdunarodnoy nauchno-prakticheskoy konferentsii. Krasnoyarsk, 2019, Ch. 1, P. 526–528 (In Russ.).

- Ivanov Yu. F., Yeresko S. P., Akhmadeyev Y. K., Lopatin I. V., Klopotov A. A. [Development of a combined electron-ion-plasma method for the formation of multiphase submicro-nanoscale alloys based on aluminum]. Sibirskiy zhurnal nauki i tekhnologiy. 2019, Vol. 20, No. 1. P. 88–98 (In Russ.).

- Yeresko S. P., Ivanov Yu. F., Petrikova Ye. A., Teresov A. D., Klopotov A. A. [Complex electron- ion-plasma method of nitriding high-alloy steel]. Reshetnevskiye chteniya: мaterialy XXV Mezhdunarodnoy konferentsii. Krasnoyarsk, 2021, Ch. 1, P. 555–557 (In Russ.).