History of creation and relevance of the international standard IATF-16949: 2016

Автор: Abduvakhidov Khalilillo Shukrullo

Журнал: Life Sciences and Agriculture.

Рубрика: Технические науки

Статья в выпуске: 3-4 (7-8), 2021 года.

Бесплатный доступ

This article discusses the history and relevance of a certificate for compliance with the automotive industry standard known as IATF 16949: 2016.

Automotive industry, standard, compliance, certificate, quality management, IATF-16949, ISO / TS 16949

Короткий адрес: https://sciup.org/14124723

IDR: 14124723

Текст научной статьи History of creation and relevance of the international standard IATF-16949: 2016

Competition in the automotive market has been and remains very high. Large domestic and foreign manufacturers place more and more stringent requirements on their suppliers. This is understandable, each consumer, both final and intermediate, wants to be sure of the quality of the purchased product. To achieve this goal, all major vehicle manufacturers mandatorily require their suppliers to be certified to meet the requirements of the automotive sector standard known as IATF 16949: 2016.

IATF ISO 16949: 2016 is a new quality management system (QMS) standard for enterprises in the automotive industry. It is based on ISO

9001: 2015, which was released in October 2016.

It replaced the version of ISO / TS 16949, which has been in effect since 1999. The updated standard is a technical specification developed based on the experience of leading automobile manufacturing countries such as Germany, France, Italy, USA, and defines the requirements in the field of design, manufacturing, installation and service of automotive products.

The purpose of the document remains constant quality control at all stages of production with an emphasis on reducing the risks of possible losses along all supply chains.

The IATF ISO 16949 standard is a system that establishes the quality requirements for all processes of the automotive industry without exception and affects all categories of suppliers of automotive products without exception:

from small manufacturers to the largest corporations, in whatever category a company belongs to.

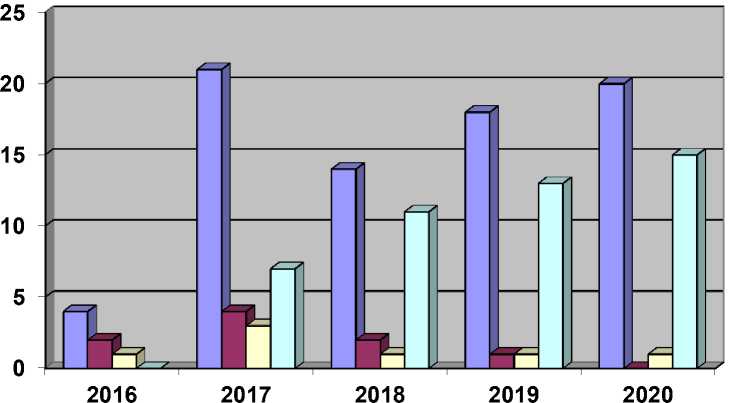

□ ISO 9001 □ ISO 14001 □OHSAS 18001 □ IATF 16949

Statistics on the implementation of the IATF-16949 standard with other standards

Therefore, the implementation of the ISO 16949 system is necessary for car manufacturers, service products for them, spare parts and even accessories. In other words, if an enterprise wants to take its place in the supply chain of its products to the market (national or international), then this standard will become the main guide to the goal of auto parts manufacturers. And the principles of even the old version of TS 16949 have helped hundreds of companies in a rather specific industry to achieve a certain and convenient order in quality management.

When implementing and certifying the QMS according to the 16949 standard, you have the following opportunities:

-

- ensure control not only at the end point of production, but also at every stage, which will significantly increase the quality of the finished product;

-

- use the certificate as an advertising tool to attract potential customers;

-

- expand opportunities for entering the international automotive market;

-

- become a competitive participant in tenders of various levels and increase your chances of winning in the struggle for lucrative contracts with government agencies, as well as domestic and foreign car manufacturers;

-

- increase the prestige and status of your enterprise;

-

- to extract the maximum economic effect from a sharp reduction in the number of rejects;

-

- become an attractive object for investment;

-

- reduce the amount of waste;

-

- get the opportunity to lend on more favorable terms.

QMS according to the IATF standard is a mechanism, when launched, your company will begin to heal and multiply itself. However, to achieve this effect, you have to try. The implementation of 16949 since 2018 has its own characteristics, its own differences from the well-known ISO 9001 standard, on the basis of which it was developed. It is much more complicated and the requirements are more stringent. Given that every enterprise in the automotive industry is unique in its essence, the system cannot be bought, copied or stolen. It can only be developed individually. This means that a formal approach will not work here. Moreover, templates for systems can be built using the old TS 16949 version.

After all the documentation is developed by a specialized expert, it should be implemented and take its place of honor in the life of the enterprise. To put it more precisely, the enterprise must live according to the IATF standard.

It should be noted that while the system exists only on paper and the management and all specialists do not understand its essence, no cardinal changes for the better will occur. The best that a manager can do in this situation is to organize training for his employees, from management to workers. Otherwise, obtaining a certificate will not only be difficult, but impossible.

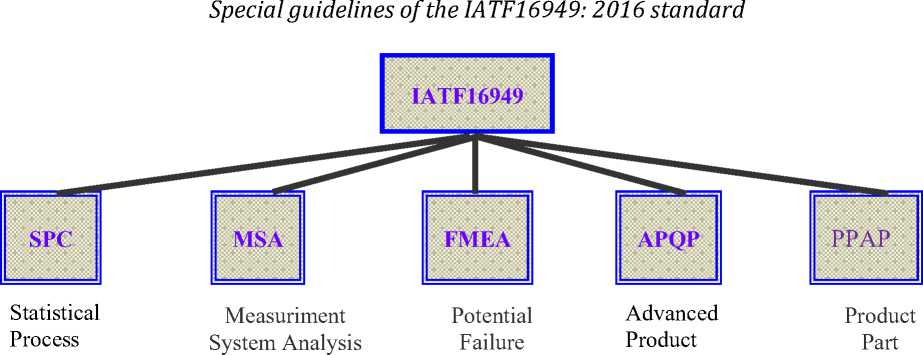

Control

Mode and Effects Analysis

Apptoval Process

Quality Planning and Control Plan

Список литературы History of creation and relevance of the international standard IATF-16949: 2016

- ISO 9000:2015 Сифат менежмент тизими. Асосий низом ва атамалар

- ISO/ TS 16949:2009 (R) (Учинчи нашр), Сифат менежменти тизими. «Автомобилсозлик саноатидаги бутловчи қисм ва материал етказувчи корхона-ташкилотлар учун ISO 9001:2008 бўйича махсус талаблар» Техник шарт., 2009-06-15.

- O`zDSt ISO 9000:2009 Сифат менежмент тизими. Асосий низом ва атамалар.

- Э.Деминг, Дж.Журан, Ф.Кросби, К.Исикав, А.Фейгенбаум, Т.Тагути Гуру менеджмента качества и их концепции: www.management.com.

- www.standartno.ru