Honeycomb fillers manufacturing technology from polymeric composite materals

Автор: Rudenko M. S., Mikheev A. E., Girn A. V.

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Technological processes and material science

Статья в выпуске: 2 vol.22, 2021 года.

Бесплатный доступ

The honeycomb filler is an integral part of the spacecraft's sandwich panel. Currently, a honeycomb filler made of aluminum alloys is used. The proposed technology makes it possible to replace the honeycomb filler material from aluminum alloys with polymer composite materials (PCM). The main difference between the developed technology for the production of honeycomb filler by the RTM method is that corrugated tape is glued during the formation of the composite material. This is a separate process in the existing methods for the production of honeycomb cores from PCM. This paper presents the results of creating a prototype of a honeycomb filler by the RTM-method, a technological process has been developed.

Honeycomb filler, polymer composite material, RTM method.

Короткий адрес: https://sciup.org/148321813

IDR: 148321813 | УДК: 67.02 | DOI: 10.31772/2712-8970-2021-22-2-391-397

Текст научной статьи Honeycomb fillers manufacturing technology from polymeric composite materals

The three-layer structure (TS) is one of the main power elements of modern spacecraft (SC). TS consists of two load-bearing layers, filler, located between the load-bearing layers, and frame elements. Bearing layers perceive longitudinal loads (tension, compression, shear) in their plane and transverse bending moments. The main feature of three-layer structures with a filler is that as a result of the separation of the bearing layers at a certain distance from each other, a greater ratio of the structure's stiffness to its mass is achieved [1– 6].

At the present time, in the elemens of SC honeycomb filler from aluminum alloys are most widely used, this is connected with the simplicity of their production and their low cost, but they have disadvantages associated with the strength and physicochemical characteristics [7–12]. Also, polymer composite materials (PCM) are used as a material for honeycomb fillers. At the present moment, there are several technologies for the production of cellular core from PCM:

-

1) stretching the glued package - the method consists in gluing dry reinforcing layers, stretching them in a technological device to obtain the shape of a honeycomb cell, dipping into a binder, drying and polymerization in an oven. This method can be used to produce a large number of honeycomb products, which are mainly used in aircraft and helicopter construction. The precision characteristics of this honeycomb fillers are not suitable for space technology application;

-

2) gluing corrugated sheets - the method consists in making a single or double corrugated strip in a hexagonal molding tooling and gluing them together in an oven. This method has low efficiency and requires a lot of auxiliary equipment;

-

3) the method of volumetric weaving - the method is similar to the method of stretching a glued package with the difference that the honeycomb package is formed not by gluing sheets, but by weaving on a Jaccard shuttle loom. As a result, the layers are fastened together by interweaving the threads along the lines in a checkerboard pattern, depending on the layer [13–15].

Experimental part

The aim of the work is to develop a process diagram and technology for manufacturing a honeycomb filler from PCM using the RTM (Resin Transfer Molding) method. The RTM method consists in placing a dry reinforcing filler in a special sealed mold, the inner surfaces of which repeat the outer surface of the product (in the impregnation of the resin filler under pressure), and polymerization in the mold. The RTM method has the following advantages in comparison with other methods: the ability to manufacture parts of complex shapes; tight dimensional tolerance; mechanical properties are comparable to autoclave molding; high performance.

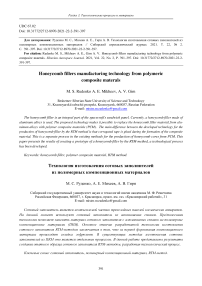

A scheme is proposed and a technological process for manufacturing a honeycomb filler from PCM is developed (Fig. 1).

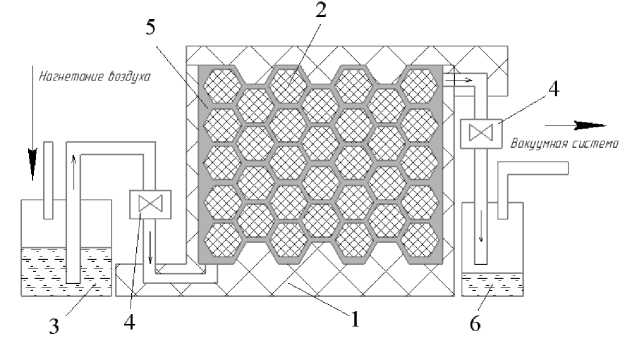

Reinforcing material 2 (Fig. 2) is cut out according to the size of the product, taking into consideration the curvature of the cellular strip. Dry reinforcing material 2 (fiberglass, carbon fiber) is laid on the hexagonal surface 1 . The first layer of fiber 2 is pressed by rigid hexagonal rods 3 . The next layer of fiber 2 is laid on top and similarly pressed by rods 3 . This is repeated until the structure is fully loaded. The last layer is pressed by the lid to the hexagonal surface 4 .

In order to reduce the internal stress of the dry reinforcing material during installation, it is molded in such a way as to tightly contact the hexagonal surface. This happens until the snap-in is fully loaded. The structure is closed with side covers and sealed, then a binder is fed into it under pressure, which impregnates the fibers.

Fig. 1. Scheme of manufacturing a honeycomb filler from PCM by the RTM method:

1 – structure body; 2 – hexagonal rod; 3 – a container with a binder; 4 – locking device; 5 – zone of impregnation of dry reinforcing material with a binder; 6 –reservoir for excess binder

Рис. 1. Схема изготовления сотового заполнителя из ПКМ методом RTM:

1 – корпус конструкции; 2 – гексагональный стержень; 3 – емкость со связующим; 4 – запорное устройство; 5 – зона пропитки сухого армирующего материала связующим; 6 – ёмкость для излишек связующего

Fig. 2. Laying scheme for dry reinforcing material:

1 , 4 – hexagonal surfaces; 2 – reinforcing material; 3 – hexagonal rods

Рис. 2. Схема укладки сухого армирующего материала:

-

1 , 4 – шестигранные поверхности; 2 – армирующий материал; 3 – гексагональные стержни

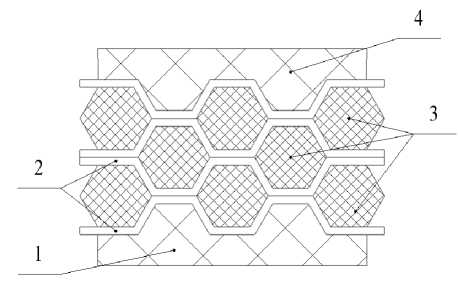

For the production of a prototype of a honeycomb filler, technological equipment was designed and constructed (Fig. 3), which consists of a body, side covers and a set of hexagonal rods (inserts). The design of the equipment should ensure:

-

1) rigidity and strength;

-

2) hermitisation the internal cavity;

-

3) anti-adhesive properties.

The snap-in was made on a «Hercules 2018» 3D printer. Printing material: PETG plastic. Nozzle diameter 0.5 mm. Layer height 0.15 mm.

The following materials were selected for the prototype of the honeycomb filler:

– reinforcing material - glass fabric T-11 (GOST 19170-2001);

– binders – epoxy resin ED-20 (GOST 10587–84) with cold hardening agent ETAL-45 (TU 2257-04518826195-01).

The technological process of manufacturing a prototype consists of the following stages:

Application of a layer of release wax to the tooling to ensure anti-adhesive properties.

Cutting out the reinforcing material.

Laying reinforcing material into the body of the tooling with pressure with hexagonal rods.

Installation of the top and two side covers.

Rig-in sealing.

Connection of a vacuum system for supplying epoxy resin to the tooling.

Preparing the resin and feeding it under pressure into the structure.

Polymerization time of the resin in the rig-in (24 hours).

Removal of the honeycomb block from the tooling structure.

Processing on a grinding machine to remove excess resin from the ends of the product.

Removing the hex rods from the honeycomb block, finishing.

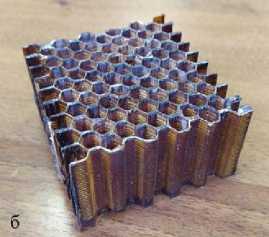

As a result, a prototype of a honeycomb filler was manufactured (Fig. 4), which confirms the realizability of the technology.

Fig. 3. Technological rig-in:

1 – tooling body; 2 – top cover; 3 – side cover; 4 – hexagonal rod; 5 – side bar

Рис. 3. Технологическая оснастка:

-

1 – корпус оснастки; 2 – верхняя крышка; 3 – боковая крышка;

4 – гексагональный стержень; 5 – боковой стержень

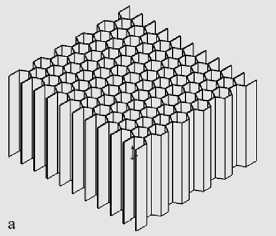

Fig. 4. PCM honeycomb filler: a – model; b – prototype

Рис. 4. Сотовый заполнитель из ПКМ: а – модель; б – опытный образец

The characteristics of the prototype are presented in the table. The mass of the prototype is 45.03 g; the volume mass is 220 kg/m3.

The characteristics of the prototype

|

The Characteristics |

The prototype |

|

Cell Form |

Hexagon |

|

HF Size |

|

|

- length, mm |

73 |

|

- width, mm |

70 |

|

- height, mm |

40 |

|

Cell size |

8 |

|

Weight, g |

45,03 |

|

Volume, m3 |

2·10–4 |

|

Bulk weight, kg / m3 |

220,15 |

|

Filler weight, g |

21,834 |

|

Volume fraction of the filler, % |

38 |

Conclusion

The results of the work show that the proposed method can be used to produce honeycomb fillers not only with a hexagonal cell, but also with many different variations of shapes. The shape and size of the cell will depend only on the shape and size of the insert. When using the technology of stretching a cellular package, it is impossible to achieve this.

It is also possible to produce honeycomb fillers with different curvature and install embedded elements at the molding stage, thereby not gluing them into the finished detail.

As a result, the technology for manufacturing cellular fillers from polymer composite materials by the RTM method is developed. This method can be adapted for the mass production of industrial products.

Список литературы Honeycomb fillers manufacturing technology from polymeric composite materals

- Panin V. F., Gladkov Yu. A. Konstruktsii s zapolnitelem [Constructions with filler]. Moscow, Mashinostroenie Publ., 1991, 272 p.

- Khaliulin V. I., Shapaev I. I. Tekhnologiya proizvodstva kompozitnykh izdeliy [Technology of production of composite products]. Kazan', Izd-vo Kazan. gos. tekhn. un-ta Publ., 2003.

- Achilles Petras Design of Sandwich Structures: Doct. Diss. 1998. P. 5–7.

- Grabin B. V. Inzhenernye osnovy konstruirovaniya kosmicheskikh apparatov [Engineering bases of spacecraft design]. Moscow, MAI Publ., 2018, 255 p.

- Testoedov N. A., Nagovitskin V. N., Permyakov M. Yu. [The use of three-layer honeycomb structures in spacecraft]. Vestnik SibSAU. 2016, Vol. 17, No. 1, P. 200–211 (In Russ.).

- Endogur A. I., Vainberg M. V., Ierusalimsky K. M. Sotovye konstruktsii: Vybor parametrov i proektirovanie [Cellular structures: choice of parameters and design]. Moscow, Mashinostroenie Publ., 1986, 192 p.

- Melnikov D. A., Petrov A. P., Gromova A. A. et al. [Calculation of the ratio of the components of the prepreg brand VPS-53/120, determination of the physical-mechanical and operational characteristics of fiberglass]. TRUDY VIAM. 2019, No. 1 (73), P. 92–104 (In Russ.).

- Urakova A. S., Nagovitsin V. N. [Application of cellular panels in satellite technology]. Reshetnevskie chteniya [Reshetnev readings]. 2018, P. 179–180 (In Russ.).

- Minakov V. T., Postnov V. I., Shchvets N. I. et al. [Features of manufacturing three-layer honeycomb panels with a polymer filler of hot curing]. Aviatsionnye materialy i tekhnologii. 2009, No. 4 (12), P. 15–18 (In Russ.).

- Zlotenko V. V., Ishenina N. N. [Features of mechanical processing of aluminum honeycomb structures] Vestnik SibSAU. 2005, No. 6, P. 209–211 (In Russ.).

- Slivinsky, V. I., Tkachenko, G. V., Slivinsky M. V. [Efficacy of cell structures in aircraft]. Vestnik SibSAU. 2005, No. 6, P. 169–173 (In Russ.).

- A. A. Ivanov, S. M. Kashin, V. I. Semenov Novoe pokolenie sotovykh zapolniteley dlya aviatsionno-kosmicheskoy tekhniki [New generation of cell aggregates for aerospace engineering]. Moscow, Energoatomizdat Publ., 2000, 584 p.

- Pershin A. M. [Computational study of static stability of cellular aggregates made of composite materials]. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta. 2014, No. 5 (47), chast' 1, P. 118–123 (In Russ.).

- Kryukov A. M., Volkova V. S., Murashkin Yu. G. et al. Sposob izgotovleniya sotovykh zapolniteley [Method of manufacturing honeycomb fillers]. Patent RF, No. 2651012, 2018.

- Kryukov A. M., Volkova V. S., Murashkin Yu. G. et al. Sposob izgotovleniya trekhsloynykh paneley slozhnoy krivizny [Method of manufacturing three-layer panels of complex curvature]. Patent RF, No. 2680571, 2018.