Impact of flue gas recirculation on the efficiency of hot-water boilers

Автор: Zajacs Aleksandrs, Zeiza-Seleznova Anastasija, Rusovs Dmitrijs

Журнал: Строительство уникальных зданий и сооружений @unistroy

Статья в выпуске: 8 (93), 2020 года.

Бесплатный доступ

The topicality of the work is related to the fact that the combustion processes of various fuels, such as heat production, produce emissions that are harmful to the environment. The combustion of fossil fuels produces nitrogen oxides, which are about 10 times more dangerous than carbon monoxides. There are different methods to reduce nitrogen oxides emissions and one of effective methods is flue gas recirculation. Despite efficiency, flue gas recirculation has an impact on the efficiency of the boiler. The efficiency coefficient for the hot-water boiler was calculated with and without flue gas recirculation. The calculation with flue gas recirculation leads to a slight reduction in the efficiency factor, herewith flue gas recirculation reduced emissions of nitrogen oxides by 44,5%.

Flue-gas recirculation, natural gas boiler, nitric oxide

Короткий адрес: https://sciup.org/143172536

IDR: 143172536 | УДК: 69 | DOI: 10.18720/CUBS.93.4

Текст научной статьи Impact of flue gas recirculation on the efficiency of hot-water boilers

Rapid urban growth has caused evident consequences to the global environment. Most of the attention of residents is focused on the problems of CO2 emissions and related problems. However, the problems associated with urban growth including much more aspects that needs to be considered to maintain sustainable lifestyle on our planet. Urban environment is associated with dense building which requires constant improvement in terms of energy-efficiency in order to correspond to the growing requirements. Many environmentally friendly solutions for existing and new buildings are possible and described in [1]–[3]. Regarding individual heating systems there are huge advantages reached during last decades (2000-2020) by increasing the efficiency of thermal energy production and combining fossil fuels and renewables in most efficient way [4]. But for major cities with high population density district heating systems are considered as most efficient way of heating, and thus requires to be carefully studied for sustainable development pathways [5]. In the existing district heating systems fossil fuels are still dominating source for thermal energy production. The combustion processes of various fuels produce emissions which are harmful to the human living environment. The main harmful elements of flue gases are nitrogen oxides (NOx), carbon dioxide (CO2), carbon monoxide (CO), sulfur dioxide (SO2), particulate matter and others. The point of the work is to study the impact of flue gas recirculation on the efficiency of a natural gas hot water boiler to reduce nitrogen oxide emissions.

-

1.1 Nitrogen oxides (NOx)

Nitrogen oxides (NOx) are the main toxic components of natural gas and fuel oil combustion [6], [7].Nitrogen oxides are considered to be major pollutants for the reason that in addition to environmental problems, they cause health-threatening problems such as photochemical smog [8], acid rain sand, ozone layer depletion. Nitrogen oxides have a negative effect on human health, mainly on the respiratory system. [9], [10], [11].

The abbreviation NOx stands for nitrogen monoxide (NO) and nitrogen dioxide (NO2), which are produced in flue gas as the result of reactions of nitrogen and oxygen. Nitric oxide is a colourless poisonous gas and nitrogen dioxide is a very poisonous gas with a brownish tinge. NOx, emitted during combustion, consists of 95% NO and 5% NO2 [12].

-

1.2 NOx formation mechanisms

Currently, three mechanisms of nitrogen oxide formation are known: fuel NO x mechanism, thermal NO x mechanism and prompt NO x mechanism. [6], [7].

Fuel NO x is formed on reactions after the release of fuel bound nitrogen when fuel is heated during devolatilization. Important primary nitrogen-containing components are ammonia (NH 3 ) and hydrogen cyanide (HCN). If sufficient O 2 is available, these components will mainly convert to NO trough different reaction routes. In fuel-rich conditions NO will react with NH3 and HCN forming N 2 . Formation of fuel NO x depends mostly on chemically bound fuel nitrogen content in the fuel. Thus, fuel NO x is produced at low temperature [8].

The reactions of thermal formation of nitric oxide are characterized by a high activation energy; therefore, nitrogen oxides are formed at high temperatures above 1800°K. The reactions can be expressed by extended Zeldovich mechanism [9][10][11]:

0 + N2^N0 + N,(1)

N + 02^ N0 + 0,(2)

N + 0H ^ N0 + H(3)

The concentration of thermal nitrogen oxides rapidly increases in the combustion zone, and its maximum values are in the zone of the maximum combustion temperature.

However, Fenimore's studies on the combustion of hydrocarbon fuels showed that, in a very short period of time, nitrogen oxides are formed in front of the flame by a mechanism different from Zeldovich mechanism. The detected nitric oxide is called prompt [1]. Formation of NOx by prompt NOx mechanism takes place in reactions of atmospheric nitrogen with hydrocarbon radicals in fuel-rich regions by reactions [8]:

CH + N2 ^ HCN + N, (4)

HCN + 02 ^ N0 + ••■. (5)

The formation of prompt nitric oxide occurs at temperatures of 1200 - 1600°K, when the thermal formation of nitrogen oxide does not occur [9].

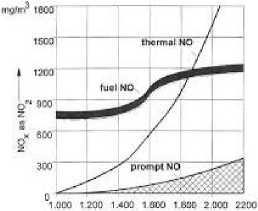

The correlation between combustion temperature and NO x formation is shown in Figure 1.

ComDu«w tempefatwe

Figure 1. The correlation between combustion temperature and NOx formation mechanisms [12].

Although the positive correlation between fuel, prompt NOx and temperature are approximately linear, the amount of thermal NOx increases disproportionately with increasing combustion temperature.

-

1.3 NOx reduction methods

In recent years, environmental protection requirements have become more stringent, that is why the fight against toxic emissions into the atmosphere has become especially important.

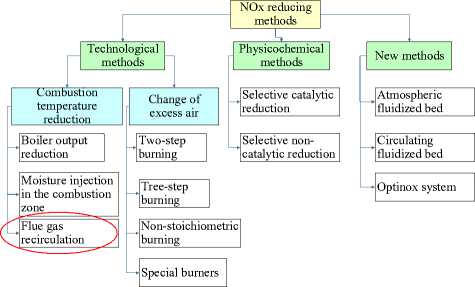

Currently, a large number of methods for reducing the concentration of nitrogen oxides in flue gases are known, and they can be divided into two large groups: cleaning flue gases by chemical or physicochemical methods, as well as technological methods [13].

The chemical or physicochemical method is based on the reducing of nitrogen oxide amount in the flue gases formed during combustion, while the technological method is based on preventing the formation of nitrogen oxide during combustion[14][15][16]. New methods of reducing oxides are also emerging. Anoverall picture of reducing nitrogen oxides methods is shown in Figure 2.

Figure 2. Nitrogen oxides reducing methods.

Flue gas recirculation (FGR) belongs to technological method, as a way to reduce combustion temperature. The flue gas recirculation method became widespread in the late 1970s and since has been widely used in boiler technology. This method involves taking part of the flue gas from the fluepipe and pump it into the active combustion zone (furnace).

A standard forced draft burner has an excess of oxygen to ensure complete combustion. The recirculation of flue gases, in turn, reduces the excess oxygen and partially replaced by inert flue gases, which mix and absorb some of the flame energy, thereby reducing the temperature. NOx production increases exponentially with increasing temperature, so a maximum combustion temperature reduction can easily reduce NOx emissions up to 7-80%. The flue gas temperature is usually around 250 350OC

[17][18][19] .

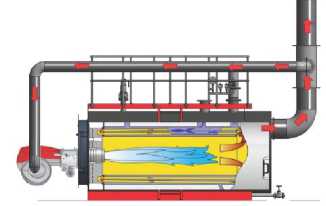

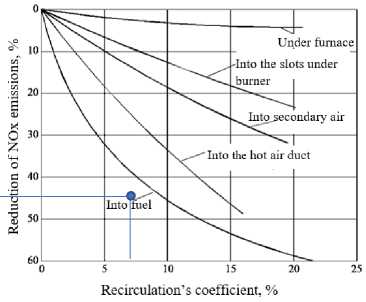

Practically, the flue gas recirculation ducting (shown in Figure 3) connects between a special port on the burner air intake and a branch in the flue close to the boiler outlet – and, potentially, a fan – with the flow of flue gas being modulated by a damper. The duct is insulated to reduce condensate formation, and includes condensate drainage points in the duct adjacent to the burner inlet.

Recirculation’s coefficient, %

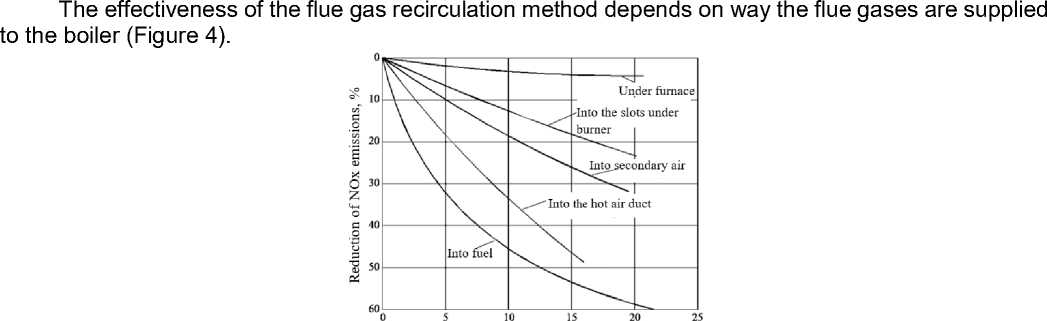

Figure 4. Reduction of NOx formation depending on therecirculation gasesinput method[12].

Figure 3. A boiler with flue gas recirculation [16].

It is important how flue gases are suppled, because with the recirculation of 1% of flue gases, the boiler efficiency decreases by 0.03 - 0.06% [11].The most efficient way, how to supply flue gas to the boiler is with fuel [20].

2 Materials and Methods 2.1 Main data of the analyzing object

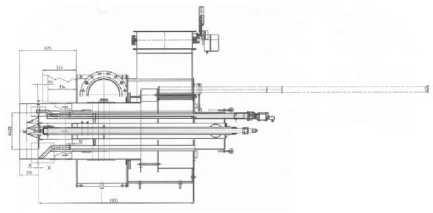

As the object of research is hot-water boiler “BOSCH UT – M 64”. The boiler is installed in one of the heating plants in Riga (Figure 5).

Figure 5. Hot-water boiler “BOSCH UT M-64”.

Boiler’s output is 18 MW, fuel – natural gas, reserve fuel – diesel. The boiler is equipped with a flue gas recirculation to reduce the nitrogen oxide content to 50 mg/Nm3 (permissible value). The recirculated flue gas is supplied together with the secondary air directly to the burner.

Boiler design is three-pass single-flame tube/smoke tube technology. The inserted flame tube ends in an inner, fully wetback smoke gas reversing chamber, which leads into the first smoke tube pass. The first smoke tube pass and second smoke tube pass are free of flow components. The functional round design ensures optimal pressure resistance [21].

Also, hot-water boiler is equipped with LOW-NOx burner - ELCO RPD 70. Burner is shown in Figure 6.

Figure 6. Burner ELCO RPD 70.

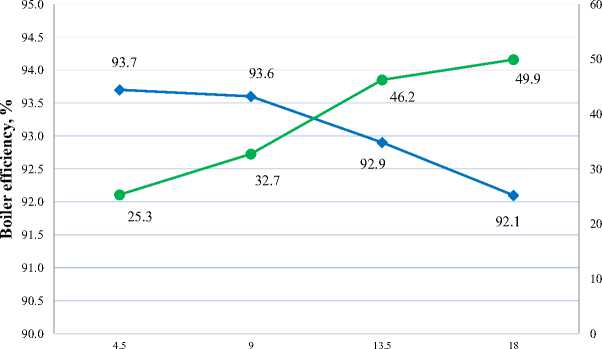

Dependence of the boiler“BOSCH UT M-64” efficiency and NOx emissions on the boiler outputis shown in Figure 7. Boiler efficiency slightly decreases with increasing boiler output, however, nitrogen oxide emissions increase.

Boiler output, MW

—♦— Efficiency • NOx emissions

Figure 7.Dependence of the boiler efficiency and NOx emissions on the output.

All the data necessary for calculations are collected in Table 1. For calculations were taken two boiler operating regimes (o.r.) - at maximum output and at reduced output.

TABLE I

D ATA FOR CALCULATIONS

|

Nr. |

Parameter name |

Symbol |

Measureme nt |

Values |

|

|

1.o.r. |

2.o.r. |

||||

|

Gas parameters |

|||||

|

1. |

Low heat value |

Q t |

kJ nm3,g |

36485 |

|

|

2. |

Specific heat capacity |

Сд |

kJ nm3,g- T |

1,557 |

|

|

3. |

Temperature |

ta |

T |

5,59 |

|

|

4. |

Enthalpy |

^■д = Сд " ta |

kJ nm3,g |

1,557 ∙ 5,59 = 8,7 |

|

|

5. |

Сombustion energy |

Q c = Qt + h g |

kJ nm3,g |

36485 + 8,7 = 36494 |

|

|

Hot-water boiler parameters |

|||||

|

6. |

Boiler output |

Q i |

MW |

18,11 |

5,58 |

|

7. |

Air temperature |

t a. |

T |

25,1 |

14 |

|

8. |

Excess air coefficient |

г» out ab |

- |

1,11 |

1,15 |

|

9. |

Flue gas temperature |

Л out ° fg |

T |

174,72 |

98,5 |

|

10. |

RGR fan frequency |

- |

Hz |

50,81 |

|

|

11. |

Heat loses due to chemical underburnin g |

Q 3 |

% |

0 |

|

|

12. |

Heat loses from external cooling |

Q s |

% |

0,09 |

1,48 |

|

13. |

Recirculatio n coefficient |

r |

% |

0,126 |

0,403 |

|

Another data |

|||||

|

14. |

Electricity costs |

€/kWh |

0,18 |

||

|

15. |

Natural gas costs |

€/m3 |

0,21 |

||

2.2 Methods

The coefficient of efficiency of a hot-water boiler is the ratio of the useful heat (consumed to generate steam hot water) to the available heat of the heating boiler.

The boiler efficiency η [%] can be calculated using the forward balance (6) or reverse balance (7) equation[13]:

77 = ^100, (6)

Ч с

7 = 100 - (q + q 3 + q4 + q5 + q 6 ). (7)

In equation (6) Q [kJ/kg]is the amount of useful heat used and Q c [kJ/kg]is available heat.

In equation (7) boiler efficiency directly depends on heat loses q x : q 2 - with flue gas, q 3 - due to chemical underburning, q 4 - with mechanical underburning, q 5 - from external cooling, q 6 - with the physical heat of the ash.

The main difference in efficiency calculation is the calculation of losses with flue gases with (8) and without (9) FGR. More precisely, in calculating the enthalpy of flue gases [22]:

(H f д -“^ н а )Х100- Ч 4 )

q 2 = -------Ч-------,

г ( н /5^ 1+г ) -“^ а )^ 100-| ? 4 )

q 2= ----------чс----------

.

Equation (8) is for heat loses without FGR and enthalpy is taken simply for flue gases H fg [kJ/m3], but in equation (9) for calculations with FGR there is also recirculation coefficient r.

r = Vfs

' T70Ut ,

V fg

Recirculation coefficient r is equal to the ratio of the flow rate of recirculating gases to flue gas massflow rate.

Calculating the enthalpy of flue gases, their temperature must be taken into accounts, as well as the composition of natural gas. H0 a [kJ/m3]is air enthalpy.

Fuel – consumption rate is calculated using the equation (11) and flue gas mass flow – equation (12):

BP-^^ (100-9 4 ),

У out _ и . d . 273+ ^ fд

■

Vfg VhfB,,-——

3 Results and Discussion

Using the inverse balance equation (7), the boiler efficiency was calculated for two operating regimes. All data is shown in Table 2.

TABLE II

R ESULTS

|

Nr . |

Parameter name |

Symbol |

Measureme nt |

Values |

|

|

1.o.r. |

2.o.r. |

||||

|

Without FGR |

|||||

|

1. |

Heat loses with flue gas |

Q i |

% |

6,96 |

4,09 |

|

2. |

Efficiency |

'/ |

% |

92,95 |

94,43 |

|

3. |

Fuel – consumption rate |

bp |

nm3,g h |

1922 |

583 |

|

4. |

Flue gas mass flow |

17 OUt v fa |

m3,dg h |

37793 |

9814 |

|

With FRG |

|||||

|

5. |

Heat loses with flue gas |

Q i |

% |

7,96 |

5,94 |

|

6. |

Efficiency |

4r |

% |

91,95 |

92,58 |

|

7. |

Fuel – consumption rate |

bp |

nm3,g h |

1944 |

594 |

The results show that when flue gas recirculation is taken into account, the boiler efficiency decreases. If the boiler is operating at maximum output, decrease is 1%, but if output is reduced, then decrease is 1,85%.

Although, at boiler maximum output, if recirculation coefficient is 13%, nitric oxides emissions decreases by 44,5%. It happens because of LOW-NOx burner, which reduces NOx emissions to 90 mg/m3. There are no data about NOx emissions when boiler is operating without flue gas recirculation.

Figure 8 . Comparison of the obtained value with theoretical values.

Fig. 8 shows, that obtained values conform with theoretical data. Since the flue gas recirculation for the boiler is supplied with secondary air directly to the burner, the result is better than recirculation with just secondary air, but worse than with fuel.

From viewpoint of economic, at maximum boiler output, the total costs of flue gas recirculation are 13,24 €/h. Only electricity and gas costs are taken into account, and installation, working costs and service life are not included.

4 Conclusions

Combustion of fossil fuels releases repugnant substances into the atmosphere together with flue gases, such as nitrogen oxides, carbon dioxide and monoxides, sulfur dioxide, particulate matter etc. The most harmful of these is nitric oxide.

There are several methods for reducing nitrogen oxides in flue gases, which can be divided into three groups: physicochemical methods, technological methods and new methods. To maximize the reduction, combine physicochemical and technological methods.

One of the technological methods is flue gas recirculation, which is one of the most effective methods. Despite the efficiency of the method, theoretically, the recirculation of 1% of flue gases, can decrease the boiler efficiency by 0.03 - 0.06%.

Boiler efficiency directly depends on heat losses. The important value for the heat loss calculation with flue gases is enthalpy.

The boiler “BOSCH UT M - 64” efficiency at maximum output with the FGR is less than 1% than in the case when flue gas recirculation was not taken into account.

Flue gas recirculation reduces NO x emissions by 44.5% attheboiler “BOSCH UT M - 64” maximum output. The recirculation ratio in this case should be 13%. Consequently, NO x emissions will be lower at lower outputs.

5 Acknowledgements

This work has been supported by the European Regional Development Fund within the Activity 1.1.1.2 “ Post-doctoral Research Aid ” of the Speci fi c Aid Objective 1.1.1 “ To increase the research and innovative capacity of scienti fi c institutions of Latvia and the ability to attract external fi nancing, investing in human resources and infrastructure ” of the Operational Programme “ Growth and Employment ” (1.1.1.2/VIAA/2/18/344).

Список литературы Impact of flue gas recirculation on the efficiency of hot-water boilers

- Korniyenko, S., Popova, E. "Green" construction in Russia and other countries. Construction of Unique Buildings and Structures. 2017. 55(4). Pp. 134. DOI: 10.18720/CUBS.55.5

- Gorshkov, Alexander Sergeevich Vatin, Nikolai Ivanovich Rymkevich, P.P. Climate change and the thermal island effect in the million-plus city. Construction of Unique Buildings and Structures. 2020. 89. DOI: 10.18720/CUBS.89.2

- Vilinskaya, A.O., Nemova, D.V., Davydova, E.I., Gnam, P.A. Rising the energy efficiency class of public building. Construction of Unique Buildings and Structures. 2015. 36(9). Pp. 7-17. DOI: 10.18720/CUBS.36.1

- Borodinecs, A., Bogdanovics, R., Prozuments, A., Tihana, J., Gaujena, B. Evaluation of hybrid heating systems with a combination of fossil and renewable energy sources. IOP Conference Series: Earth and Environmental Science. 2019. DOI: 10.1088/1755-1315/297/1/012050

- Zajacs, A., Borodiņecs, A. Assessment of development scenarios of district heating systems. Sustainable Cities and Society. 2019. DOI: 10.1016/j.scs.2019.101540

- Abián, M., Peribáñez, E., Millera, Á., Bilbao, R., Alzueta, M.U. Impact of nitrogen oxides (NO, NO2, N2O) on the formation of soot. Combustion and Flame. 2014.

- DOI: 10.1016/j.combustflame.2013.07.015

- Glarborg, P., Miller, J.A., Ruscic, B., Klippenstein, S.J. Modeling nitrogen chemistry in combustion, Progress in Energy and Combustion Science 2018.

- DOI: 10.1016/j.pecs.2018.01.002

- Korpela, T., Kumpulainen, P., Majanne, Y., Häyrinen, A. Model based NOx emission monitoring in natural gas fired hot water boilers. IFAC-PapersOnLine. 2015.

- DOI: 10.1016/j.ifacol.2015.12.409

- Batrakov, P.A. The Nitrogen Oxide Formation Studying at Natural Gas Combustion in Non-circular Profile Furnaces of Fire-tube Boilers. Procedia Engineering. 2016.

- DOI: 10.1016/j.proeng.2016.07.646

- Zeldovich, Y.B. Regime classification of an exothermic reaction with nonuniform initial conditions. Combustion and Flame. 1980.

- DOI: 10.1016/0010-2180(80)90017-6

- Zeldovich, Y.B. 26. Oxidation of Nitrogen in Combustion and Explosions. Selected Works of Yakov Borisovich Zeldovich, Volume I 2015,

- DOI: 10.1515/9781400862979.404

- Task Force on Techno-economic Issues. Reduction of NOx emissions. http://tftei.citepa.org/en/industrial-sources/reduction-of-nox-emissions#formation-process-in- combustion.

- Gholami, F., Tomas, M., Gholami, Z., Vakili, M. Technologies for the nitrogen oxides reduction from flue gas: A review, Science of The Total Environment, 2020.

- DOI: 10.1016/j.scitotenv.2020.136712

- Environmental Protection Agency (EPA). Nitrogen oxides (NOx), why and how they are controlled. Epa-456/F-99-006R. 1999. DOI:EPA 456/F-99-006R.

- Kröcher O., Selective catalytic reduction of NOx. Catalysts, MDPI, 2018,

- DOI: 10.3390/catal8100459

- Bell, R.D., Buckingham, F.P. An Overview of Technologies for Reduction of Oxides of Nitrogen from Combustion Furnaces. MPR Associates NOx Reduction Overview. 1990. https://api.semanticscholar.org/CorpusID:52025566

- Ballester, J.M., Dopazo, C., Fueyo, N., Hernández, M., Vidal, P.J. Investigation of low-NOx strategies for natural gas combustion. Fuel. 1997.

- DOI: 10.1016/S0016-2361(97)85521-4

- Lysova E., Paramonova O., Samarskaya N., Gyrova O., Tsarevskaya I., Application of physical and energetic approach to estimation and selection of atmospheric protection systems for energetic devices, MATEC Web of Conferences 170, 04013 (2018),

- DOI: 10.1051/matecconf/201817004013

- A.A.Khan, W. Jonga, P.J.Jansens, H.Spliethoff, Biomass combustion in fluidized bed boilers: Potential problems and remedies, Fuel Processing Technology, 2009,

- DOI: 10.1016/j.fuproc.2008.07.012

- Yu, B., Lee, S., Lee, C.E. Study of NOx emission characteristics in CH4/air non-premixed flames with exhaust gas recirculation. Energy. 2015.

- DOI: 10.1016/j.energy.2015.08.023

- Bosch. Bosch Thermotechnology2020, https://www.bosch- thermotechnology.com/corporate/en/company/production-sites/legal-notes-uk.html

- Men, Y., Liu, X., Zhang, T., Performance comparison of different total heat exchangers applied for waste heat recovery, Applied Thermal Engineering, 2021,

- DOI: 10.1016/j.applthermaleng.2020.115715