Impact of the reinforcement technique on characteristics of composite tubular structures

Автор: E. A. Trifonova, A. V. Zhukov, V. V. Savitsky, V. V. Batrakov

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 4 vol.21, 2020 года.

Бесплатный доступ

Different composite elements including tubular structures are used as support structures in spacecraft optical systems. The compliance with the specified dimensional stability over a wide temperature range, in particular from –269 up to 100 °C, is important for the design of tubular structures. The promising method of manufacturing tubular structures of CM – radial braiding combined with RTM molding method is discussed in this paper. In addition, the paper describes the method of determining the optimal reinforcement technique for a braided perform which allows to reduce geometrical deflections occurring during a molding process. The impact of the reinforcement technique on the dimensional stability of tubular structures is illustrated in this paper by the example of several reinforcement techniques and manufacturing methods. The paper also contains the analysis of these techniques and the determination of the optimal one to comply with the specified characteristics.

Dimensional stability, composite materials, reinforcement technique, preform.

Короткий адрес: https://sciup.org/148321777

IDR: 148321777 | УДК: 621.792 | DOI: 10.31772/2587-6066-2020-21-4-535-547

Текст научной статьи Impact of the reinforcement technique on characteristics of composite tubular structures

Introduction. Composite materials (CM) occupy a significant part among materials used in the manufacture of spacecraft structures. Their advantages over traditional materials are the combination of such properties as high strength, stiffness, low coefficient of thermal expansion. The use of CM in spacecraft design has made it possible to significantly reduce the weight characteristics of modern spacecraft, and it has expanded the capabilities of designers in the search of new solutions and design features in the development of a spacecraft body, assemblies and critical parts.

A distinctive feature of CM structures is that the material and structure are manufactured simultaneously. Therefore, the technological features of the production of the material, which make it possible to provide the specified parameters, are taken into account in the process of developing a composite structure. Thus, the CM manufacturing technology is an integral part of a composite structure design process.

Currently, Russian and foreign specialists are working on the creation of space observatories. Modern space observatories are designed to undertake studies of various types of objects in the Universe with ultra-high sensitivity (in single-telescope mode) and record high angular resolution (in ground-space interferometer mode) in the millimeter and infrared wavelength ranges. The ultra-high sensitivity of a space telescope operating in deep vacuum and ultra-low temperatures is achieved by actively cooling the mirror system and receiving equipment to the temperature of 4.5 K. The record resolution of the cryogenic space telescope is achieved by its joint work with large ground-based telescopes in interferometer mode in an ultra-long working orbit in the vicinity of the L2 Lagrange point in the Sun – Earth system that is located at the distance of 1.5 million km from the Earth. In this case, the distance between the Earth and the space observatory will reach 2 million km. The space observatory includes a two-mirror cryogenic space telescope with a main parabolic mirror with a diameter of 10 m deployable in the specified orbit, consisting of 24 deployable lobes and a stationary central mirror of 3 m in diameter. This telescope is installed on the space platform through a transitional truss and central power structures: reflector supporting truss, cooling support and unrefrigerated container. The working ranges of the wavelengths of the cryogenic space telescope are 0.02–3 mm and 0.3–16 mm and they determine the requirements for the cryogenic space telescope precision and the space platform: the accuracy of the working surface (standard deflection) of the main parabolic mirror (after its opening) is 10 µm; the accuracy of orientation and stabilization of a space platform with a cryogenic space telescope should be no worse than 1 "and 0.2", respectively [1].

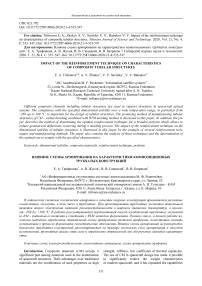

The quality of data obtained from outer space depends, among other things, on the accuracy of the mutual positioning of the components of the telescope (including the counter-reflector relative to the reflector). The layout chart of the shape and size-stable tubular elements (rods) in the structure of the space observatory, providing positioning of the reflector and counterreflector, is shown in fig. 1.

To ensure the functioning of the telescope in case of failure of orbital alignment mechanisms, the supporting elements of a counter-reflector structure must ensure the accuracy of the position of the main elements of the optical system after launching spacecraft into orbit. The design of a supporting tubular structure should exclude the occurrence of deformations leading to twisting around its longitudinal axis by more than 1' in the operating temperature range.

To ensure the structural rigidity at the stage of launching, it is advisable to fix screen lobes to the telescope counter-reflector [2]. Based on the task of the supporting tubular structure of a counter-reflector, they need to have high strength and stiffness characteristics, such as:

– elasticity modulus in the direction along its axis of a supporting tubular structure must be at minimum 200 GPa;

– ultimate compression strength in the direction along the axis must be at minimum 800 MPa;

– the coefficient of linear thermal expansion along the axis of a supporting tubular structure should be no more than |0,8x10-6| 1/ ° C in the temperature range from minus 269 to plus 100 ° C.

Thus, one of the main elements being investigated in this work are tubular structures – rods made of composite material with high requirements for rigidity, strength, and shape stability.

The overview of the methods of manufacturing tubular structures. The analysis of the factors influencing dimensional stability. Currently, the main methods for the manufacture of tubular structures made of CM are:

– contact molding with the laying of a resin-impregnated fibrous canvas on the mold;

– winding resin-impregnated fiber onto a cylindrical shape;

– pultrusion or molding of shaped products by pulling a fiber through a polymer bath and a gage die hole;

– radial braiding in combination with RTM technology [3–8].

Radial braiding is the most suitable method to manufacture tubular products that meet specified parameters. The product is usually obtained by braiding the mandrel. Unlike threads during winding, during radial braiding threads are intertwined. This ensures that the braided part resists twisting and shearing.

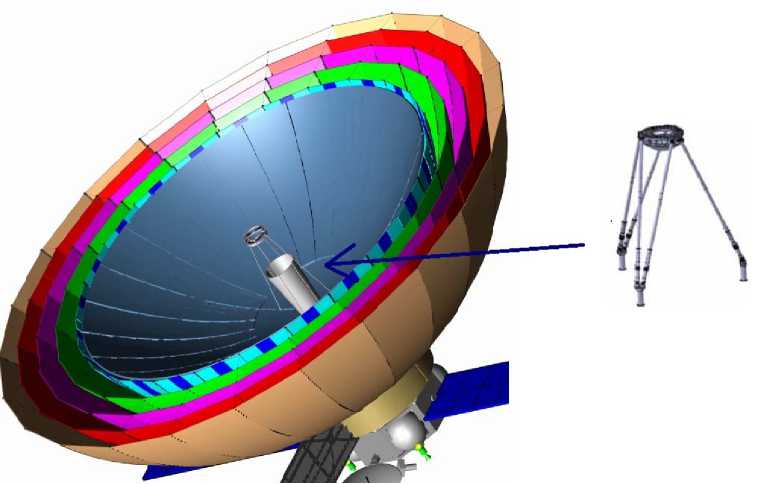

The result is a seamless design with high structural integrity. In the course of its development, the technology of the braiding process has shown its advantages, such as reducing production costs due to the mechanization of the process and reducing the share of manual labor, the possibility of using it in serial production. The braiding process is shown in fig. 2.

Typical reinforcement of braided preforms can be biaxial and triaxial (fig. 3, a ). At triaxial braiding (fig. 3, b ), the third thread is added in the longitudinal direction, along the braiding axis.

At biaxial braiding, the braiding angle can vary from 10 to 85 degrees. Parts with small braiding angles are characterized by high axial strength and rigidity, while parts with large braiding angles have high circumferential strength.

This technology allows us to braid any type of reinforcing material – carbon fiber, glass fiber, aramid fiber, natural fiber, etc., as well as to combine various types of fibers [9–12].

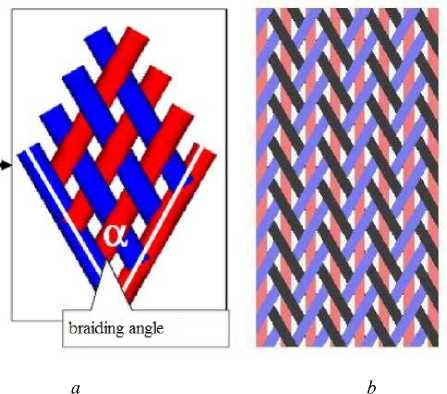

The RTM molding method is the process of impregnating a reinforcing material with a binder substance that is injected under excessive pressure (up to 10 bar) into a closed rigid mold. The process allows us to achieve high precision manufacturing of parts. This method makes it possible to manufacture parts with volumetric filling with a reinforcing material 55 ± 5%. The scheme of the method is shown in fig. 4.

One of the most important indicators of the shape stability of tubular structures is the minimization of their rotation along the axis.

In theory, a properly designed tubular structure with an ideal reinforcing structure should not twist when thermally loaded. However, in practice, it is almost impossible to obtain such an element. Twisting of tubular structures can occur both due to structural and technological imperfections.

Constructive imperfections include deflection from symmetry in the laying, the presence of additional elements, etc. Accordingly, the most advanced design is a cylindrical tubular structure without fittings and flanges with a constant wall thickness and balanced quasiisotropic laying. However, in this case, it will be impossible to obtain required axial physical and mechanical characteristics and a low CLTE (coefficient of linear thermal expansion). As a rule, when designing a supporting tubular structure, it is necessary to find a reasonable compromise between stiffness, strength, CLTE, shape stability, integrity, and manufacturability.

Fig. 1. Layout chart of the supporting tubular structure in the construction of space observatory

Рис. 1. Схема расположения опорного трубчатого элемента в конструкции космической обсерватории

Fig. 2. Process of radial braiding of a tubular structure

Рис. 2. Процесс плетения трубчатого элемента

Fig. 3. Type of braiding: a – biaxial braiding; b – triaxle braiding

Рис. 3. Виды плетения: а – двухосное плетение; б – трехосное плетение

Fig. 4. RTM molding method diagram

Рис. 4. Схема метода формования RTM

Even if the design of a tubular structure has no flaws, certain deflections necessarily occur during its manufacture. The deflections may include:

-

– unevenness and deflection from a given angle of reinforcement;

-

– uneven filling ratio;

-

– difference in properties of reinforcing fibers from different batches;

-

– the influence of molding equipment during heating and cooling.

The manufacture of a shape-stable tubular structure requires solutions that are clearly verified at every stage.

In this work, the following main proposals of a constructive and technological nature are made:

-

– the layers of the reinforcing structure of a supporting tubular structure must have a symmetrical – balanced triaxial structure;

-

– technological slope for mandrel extraction should be minimal;

-

– the reinforcement scheme should provide the least sensitivity of shape stability to technological deflections, while maintaining the required physical and mechanical characteristics;

-

– deflections from the nominal reinforcement angle and the filling factor should be minimized;

-

– when designing supporting tubular structures, it is necessary to take into account the probability of microcracking during thermal cycling [13–15].

Developing a method for calculating the deformations of a supporting tubular structure when subjected to thermal loadings. The purpose of the calculation is to determine the optimal reinforcement scheme in which the effect of structural and technological imperfections on the value of the angle of twisting of a supporting tubular structure relative to the longitudinal axis will be minimal.

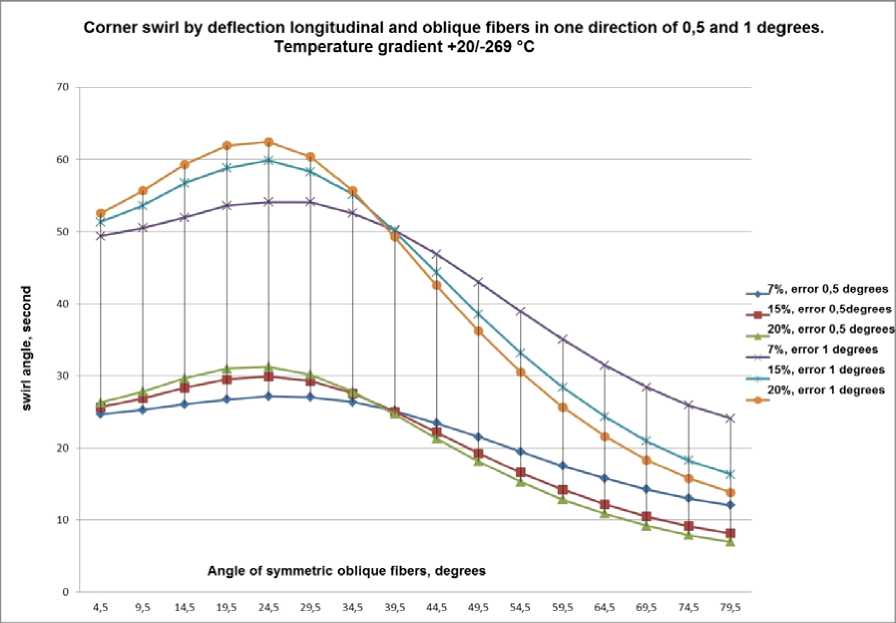

For the triaxial reinforcement scheme 0±φ°, where φ is the angle of symmetric oblique fibers, the following problems were solved:

-

1) the angles of rotation of a supporting tubular structure relative to the longitudinal axis are determined for the angles of oblique symmetrical fibers 5–90 ° with an error of the braiding angles of longitudinal and oblique fibers equal to 0.5 ° and 1.0 ° for their ratios of 7, 15 and 20 %, and for temperature gradients –100/+20, –100/+100 and +20/–269 °C;

-

2) the dependences of the longitudinal modulus of elasticity, strength and coefficient of linear thermal expansion (CLTE) on the ratio of longitudinal and oblique symmetric fibers for the optimal reinforcement angle were determined;

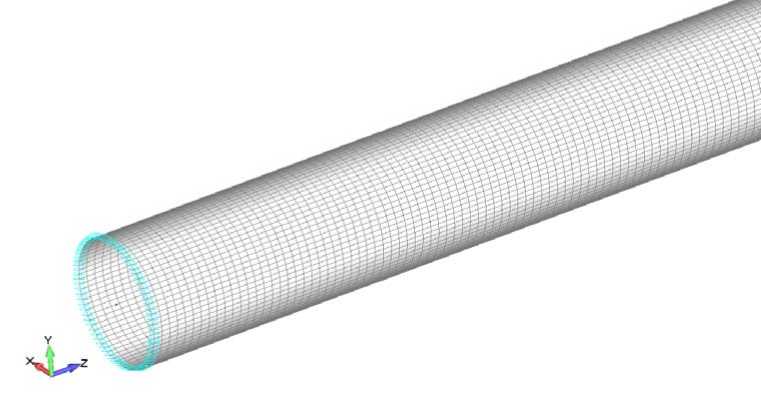

The design of a supporting tubular structure is shown in fig. 5.

The calculation was carried out in the Femap with NX Nastran program. The finite element mesh of the models of the supporting tubular structure is shown in fig. 6. The temperature loading was set in the form of a temperature difference and fixing along one of the ends with a restriction of 6 degrees of freedom (rigid restraint) was performed.

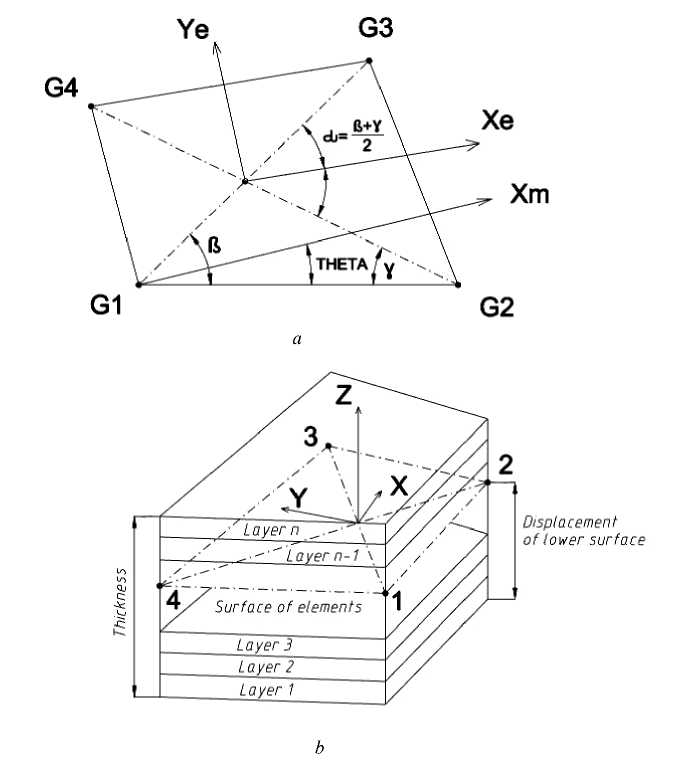

To calculate a supporting tubular structure, the shell elements PLATE and LAMINATE from the Femap with NX Nastran finite element library were used.

PLATE is a combined flat shell element (fig. 7, a ) that bears membrane, shear and bending loads. It is used for any structures consisting of thin plates or shells.

Setting the desired direction of material properties is carried out by rotating the axis of orientation of the Xm material.

LAMINATE (layered) is similar to an element of type PLATE and consists of one or more layers (fig. 7, b). It is used for modeling multilayer composite plates and shells. The internal coordinate system is similar to the elements of the PLATE type. Setting the desired direction of mate- rial properties is carried out by rotating the axis of orientation of Xm material properties.

The direction of the Z axis is taken as the zero direction of fibers (fig. 7). Counterclockwise direction is taken as a positive angle.

The following model of a composite with a reinforcing filler made by the radial braiding method was taken. The wall of the supporting tubular structure with total thickness h consists of n layers. One layer conventionally represents interlaced fibers with the orientation of 0° (along the generatrix of the cylinder) and ±φ° (oblique fibers) and has a total thickness t. Each of the n layers of thickness t was divided into 5 more sublayers with an average sublayer with the orientation of 0° and extreme sublayers ± φ ° to balance the package (fig. 8, a ).

To take into account the volume ratio of longitudinal and oblique fibers νf0 and νfφ %, respectively, the thicknesses of sublayers were set in proportion to this ratio: 0,01∙νf0∙t – 0° sublayer; 0,01∙νf0∙t – sublayers ±φ °.

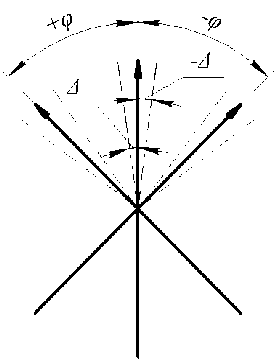

The scheme for determining the angles φ of symmetric oblique fibers and the deflection error Δ is shown in fig. 8, b .

The characteristics of carbon fiber-reinforced plastics with M46J fibers and the characteristics of carbon fiber-reinforced plastics with T300 fibers are presented in table.

Calculation of the axial twist of a supporting tubular structure depending on the reinforcement error. Let us determine the angles of rotation of a supporting tubular structure relative to the longitudinal axis for different angles of reinforcement with the axial fibers M46J and oblique fibers T300, depending on the error of braiding angles, the ratio of longitudinal and oblique fibers, and the temperature gradient.

The wall thickness of the supporting tubular structure is h = 3.5 mm. The number of layers n = 14.

To take into account the ratio of longitudinal and oblique fibers equal to 93 and 7 %, respectively, the thicknesses of the sublayers were set in proportion to this ratio: 0.2325 mm – 0° sublayer; 4×0.004375 mm – sublayers ±φ °.

Fig. 5. Construction of a supporting tubular structure

-

Рис. 5. Конструкция опорного трубчатого элемента

Fig. 6. Finite-element model mesh of a supporting tubular structure without flange

Рис. 6. Конечно-элементная сетка модели опорного трубчатого элемента без фланца

Fig. 7. Shell element: a – PLATE type; b – LAMINATE type

Рис. 7. Оболочечный элемент: а – типа PLATE; б – типа LAMINATE

-ф

0°

-ф

а b

Fig. 8. Single layer scheme, scheme for determining the angles of oblique fibers and errors: a – one layer; b – location of oblique fibers

Рис. 8. Схема одного слоя, схема определения углов косых волокон и погрешностей: а – один слой ; б – расположение косых волокон

For the ratio of longitudinal and oblique fibers equal to 85 and 15 %, respectively, the thickness of the sublayers: 0.2125 mm – 0° sublayer; 4×0.0375 mm – sublayers ±φ°.

For the ratio of longitudinal and oblique fibers equal to 80 and 20 %, respectively, the thickness of the sublayers: 0.2 mm – 0° sublayer; 4×0.05 mm – sublayers ±φ°.

The total number of layers was 14×5 = 70 in all cases.

The possibility of deflection of longitudinal and oblique fibers in one direction or in opposite directions was taken into account.

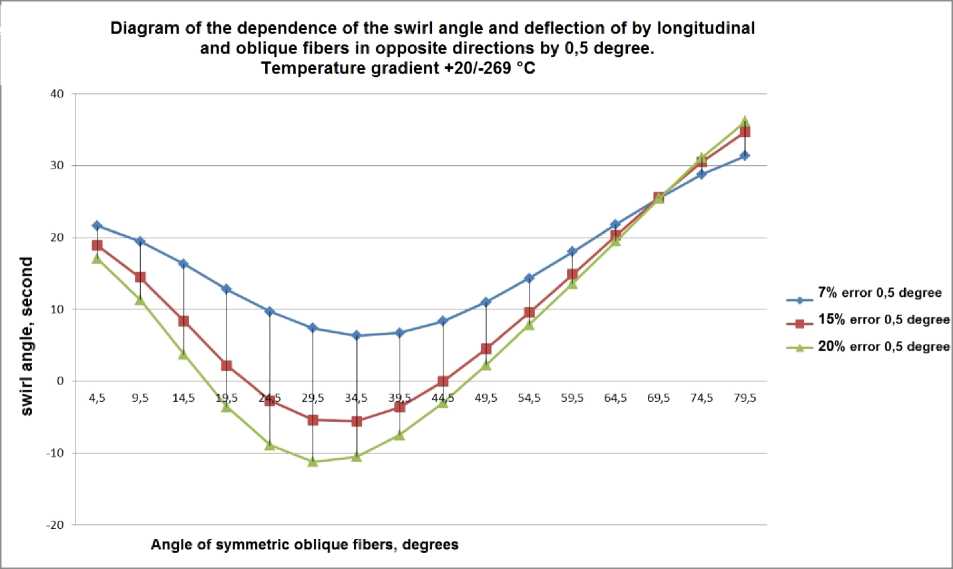

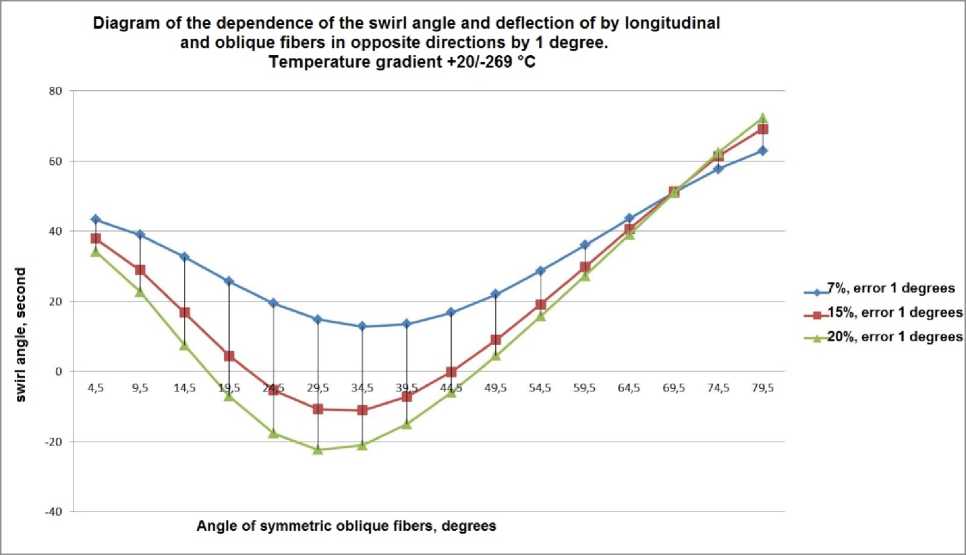

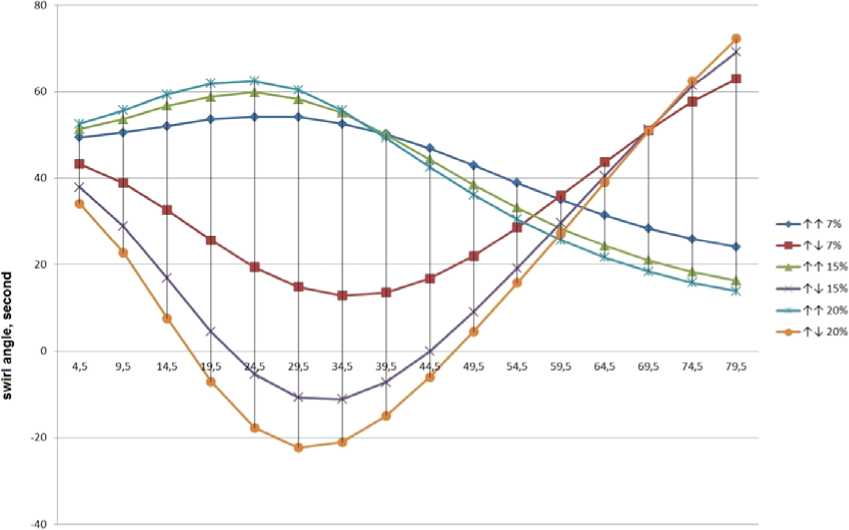

The calculation results are shown in fig. 9–12.

Determination of the optimal reinforcement scheme. Based on the analysis of the graphs in fig. 9–12, the following conclusions can be drawn:

– the swirl angle of the supporting tubular structure increases when increasing the deflection error of longitudinal and oblique symmetrical fibers;

– when the longitudinal and oblique fibers are deflected in one direction at the reinforcement angles ±φ° up to 40°, the swirl angle of the supporting tubular structure increases when increasing the proportion of oblique fibers;

– when the longitudinal and oblique fibers are deflected in one direction at the reinforcement angles ±φ° more than 40°, the swirl angle of the rod decreases when increasing the proportion of oblique fibers;

– when the longitudinal and oblique fibers are deflected in opposite directions at the reinforcement angles ±φ° up to 70°, the swirl angle of the supporting tubular structure increases when decreasing the proportion of oblique fibers;

– when the longitudinal and oblique fibers are deflected in opposite directions at reinforcement angles ±φ° more than 70°, the swirl angle of the supporting tubular element decreases when decreasing the proportion of oblique fibers;

Characteristics of carbon fiber-reinforced plastics used for calculation

|

Modulus of elasticity |

Parameter |

Carbon fiber M46J |

Carbon fiber T300 |

|

Modulus of tension (0°) |

E 1 , Pa |

2.45E+11 |

1.25E+11 |

|

Modulus of tension (90°) |

E 2 , Pa |

6.9E+9 |

7.8E+9 |

|

Modulus of shear |

G 12 , Pa |

3.9E+9 |

4.4E+9 |

|

Poison's ratio |

µ 12 |

0.87 |

0.79 |

|

Longitudinal strength (0°) |

σ+ B1 , Pa |

2.16E+9 |

1.76E+9 |

|

Longitudinal strength (90°) |

σ+ B2 , Pa |

45000000 |

80000000 |

|

Compression strength (0°) |

σ B1 , Pa |

980000000 |

1.57E+9 |

|

Compression strength (90°) |

σ B2 , Pa |

0 (no information available) |

0 (no information available) |

|

In-plane shear strength |

τв12, Pa |

59000000 |

98000000 |

|

Interlaminar shear strength |

τ13, Pa |

83000000 |

108000000 |

|

Monolayer thickness |

δ, m |

0.00025 |

– |

|

CLTE of fiber (longitudinal direction) |

α1, 1/C° |

–4,E-7 |

9,E-7 |

|

CLTE of matrices (orthogonal direction) |

α2, 1/C° |

3.75E-5 |

3.75E-5 |

– with a certain proportion of oblique symmetric fibers, there are two values of the reinforcement angles at which the swirl angle of the supporting tubular structure will be zero for the case of deflection of longitudinal and oblique fibers in opposite directions;

– at the reinforcement angles ±φ° = 60°, it is optimal if two types of error appear – when longitudinal and oblique fibers deflect in one direction or in the opposite direction.

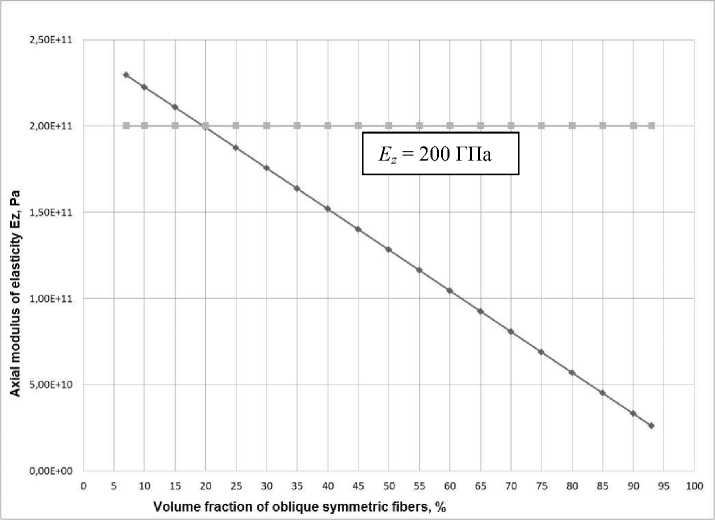

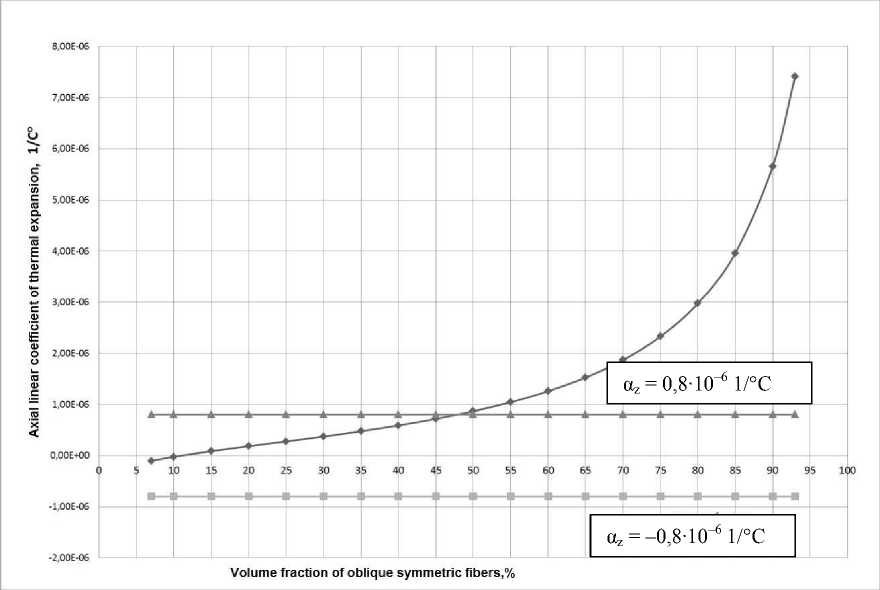

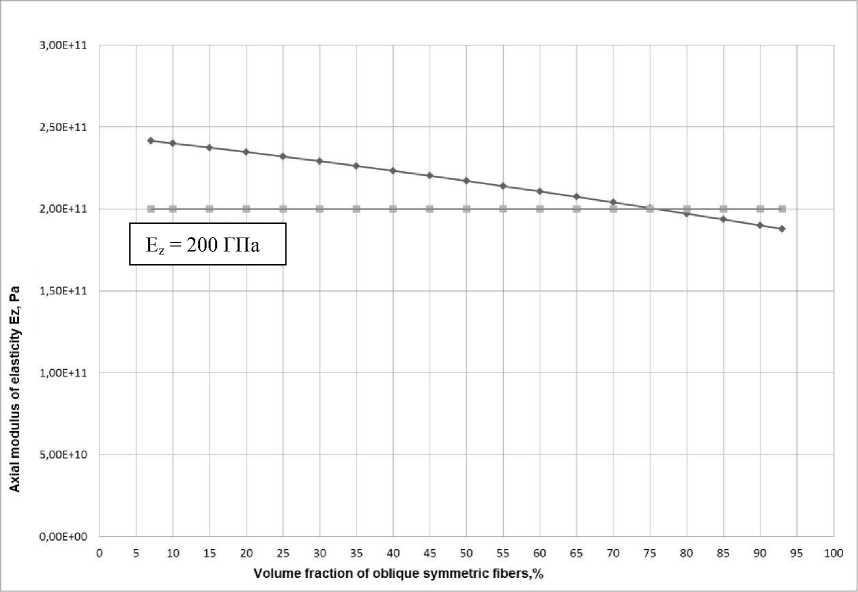

Determination of the reinforcement scheme that meets the requirements for the physical and mechanical characteristics of the material of the supporting tubular structure. Using the Femap with NX Nastran program, the dependence of the axial modulus Ez of elasticity and axial CLTE αz on the volume fraction of oblique symmetric fibers (fig. 13, 14) was determined for the following design:

– wall thickness of the supporting tubular element h = 3.5 mm;

– number of layers n = 14;

– laying 0±60 ° with axial fibers M46J and oblique T300, respectively, with the composite volumetric filling of 60%.

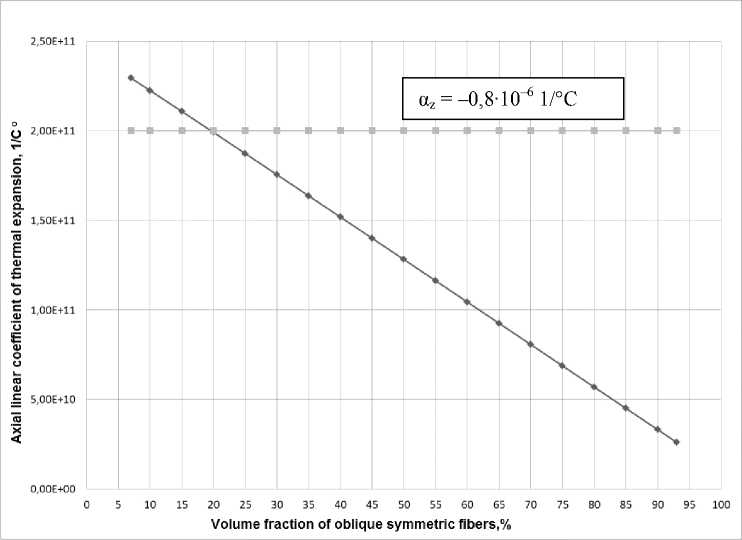

Using the Femap with NX Nastran program, the dependence of the axial modulus Ez of elasticity and axial CLTE αz on the volume fraction of oblique symmetric fibers (fig. 15, 16) was determined for the following design:

– wall thickness of the supporting tubular structure h = 3.5 mm;

– number of layers n = 14;

– laying 0 ± 4 ° with M46J fibers with a composite volumetric filling of 60 %.

The following conclusions can be drawn from the analysis of the graphs:

– laying 0 ± 60° with M46J and T300 fibers allows obtaining the required axial CLTE αz with the fraction of oblique fibers up to 48 %, but the required axial modulus of elasticity Ez with the fraction of oblique fibers may only be up to 20 %;

– laying 0 ± 14 ° with M46J fiber allows to obtain the required axial CLTE αz with the proportion of oblique fibers up to 23 % (taking into account technological limitations, the amount of oblique fibers is 50.75 %), the required axial modulus of elasticity Ez with the proportion of oblique fibers is up to 75 %;

– laying 0 ± 60° with M46J and T300 fibers is less sensitive to the influence of structural and technological imperfections on the value of the swirl angle of the supporting tubular structure relative to the longitudinal axis;

– laying 0 ± 60° with M46J and T300 fibers meets the requirements for axial modulus of elasticity and CLTE with oblique fibers up to 20 % and has approximately 2 times less torsion around the longitudinal axis compared to the laying 0 ± 14°.

Fig. 9. Swirl angle at deflection of longitudinal and oblique fibers in one direction by 0.5 and 1.0 degrees. Temperature range +20/–269 °С

Рис. 9. Угол закрутки при отклонении продольных и косых волокон в одном направлении на 0,5° и на 1,0°.

Диапазон температур +20/–269 °С

Fig. 10. Swirl angle at deflection of longitudinal and oblique fibers in opposite directions by 0,5 degree. Temperature range +20/–269 °С

Рис. 10. Угол закрутки при отклонении продольных и косых волокон в противоположных направлениях на 0,5°.

Диапазон температур +20/–269 °С

Fig. 11. Swirl angle at deflection of longitudinal and oblique fibers in opposite directions by 1 degree. Temperature range +20/–269 °С

Рис. 11. Угол закрутки при отклонении продольных и косых волокон в противоположных направлениях на 1,0°. Диапазон температур +20/–269 °С

Diagram of the dependence of the swirl angle and deflection of by longitudinal and oblique fibers in different directions by 1 degree

Temperature gradient *207-269 ”C

Angle of symmetric oblique fibers, degrees

Fig. 12. Swirl angle at deflection of longitudinal and oblique fibers in different directions by 1 degree. Temperature range +20/–269 °С

Рис. 12. Угол закрутки при отклонении продольных и косых волокон в различных направлениях на 1,0°. Диапазон температур +20/–269 °С

Fig. 13. Diagram of the dependence of the axial modulus of elasticity Ez on volume fraction of oblique symmetric fibers for braiding scheme 0 ± 60° with M46J, T300 fiber types

Рис. 13. Зависимость осевого модуля Ez упругости от объемной доли косых симметричных волокон для укладки 0 ± 60° с волокнами M46J и T300

Fig. 14. Diagram of the dependence of the axial CLTE αz on volume fraction of oblique symmetric fibers for braiding scheme 0 ± 60° with M46J, T300 fiber types

Рис. 14. Зависимость осевого КЛТР αz от объемной доли косых симметричных волокон для укладки 0 ± 60° с волокнами M46J и T300

Fig. 15. Diagram of the dependence of the axial modulus of elasticity Ez on volume fraction of oblique symmetric fibers for braiding scheme 0 ± 14° with M46J fiber type

Рис. 15. Зависимость осевого модуля упругости Ez от объемной доли косых симметричных волокон для укладки 0 ± 14° с волокном M46J

Fig. 16. Diagram of the dependence of the axial CLTE αz on volume fraction of oblique symmetric fibers for braiding scheme 0 ± 14° with M46J fiber type

Рис. 16. Зависимость осевого КЛТР αz от объемной доли косых симметричных волокон для укладки 0 ± 14° с волокном M46J

Conclusion. On the basis of the considered methods of manufacturing supporting tubular structures, in order to ensure the requirements of shape stability, it is advisable to use the method of radial braiding in combination with the RTM technology of molding a product. The analysis of the considered preform reinforcement schemes shows that to ensure the specified parameters, the optimal one is braiding with the fiber laying of 0 ± 60° with the volume fraction of oblique fibers up to 20 %.

Список литературы Impact of the reinforcement technique on characteristics of composite tubular structures

- Kardashev N. S., Novikov I. D., Lukash V. N. [Overview of scientific task for the Millimertron observatory]. Uspekhi fizicheskikh nauk. 2014, No. 12, P. 1319–1352 (In Russ.).

- Federal'noe kosmicheskoe agentstvo [Space observatory Millimertron] (In Russ.). Available at: http://millimetron.ru/index.php/ru/ (accessed 16.03.2020).

- Mikhaylin Yu. A. Spetsial'nye polimernye kompozitsionnye materialy [Special polymer materials]. St.Petersburg, Nauch. osnovy i tekhnologii Publ., 2009, 58 p.

- Kirillov V. N., Startsev O. V., Efimov V. A. [Climatic resistance and damageability of polymer composite materials, problems and solutions]. Aviatsionnye materialy i tekhnologii. 2012, No. S, P. 412–423 (In Russ.).

- Mikhaylin Yu. A. Konstruktsionnye polimernye kompozitsionnye materialy [Structural polymer composite materials]. St.Petersburg, Nauch. osnovy i tekhnologii Publ., 2008, 820 p.

- Maksimov G. Yu. Teoreticheskie osnovy razrabotki kosmicheskikh apparatov [Theoretical foundations of spacecraft development]. Moscow, Nauka Publ., 1980, 320 p.

- Smerdov A. A., Tairova L. P., Timofeev A. N. [Method of design and experimental development of dimensionally stable tubular rods made of carbon fiber]. Konstruktsii iz kompozitsionnykh materialov. 2006, No. 3, P. 12–23 (In Russ.).

- Mikhaylov V. V. K voprosu o mekhanike razrusheniya pri rastyazhenii elementov iz vysokoprochnykh armirovannykh plastikov s poverkhnostnymi i skvoznymi treshchinami [On the issue of tensile fracture mechanics of high-strength reinforced plastic elements with surface and through cracks]. Moscow, Nauka Publ., 1981, P. 278–281.

- Samipur S. A., Khaliulin V. I., Batrakov V. V. [Development of a technology for the manufacture of composite tubular elements for aerospace purposes by the method of radial braiding]. Problemy mashinostroeniya I nadezhnosti mashin. 2018, No. 3, P. 90–95 (In Russ.).

- Meleshko A. I., Polovnikov S. P. Uglerod, uglerodnye volokna, uglerodnye kompozity [Carbon, carbon fibers, carbon composites]. Moscow, Sayns Press Publ., 2007, 189 p.

- Tkachuk A. I., Grebeneva T. A., Chursova L. V., Panina N. N. [Thermoplastic binder. Present and future]. Trudy VIAM. 2013, No. 11. (In Russ.). Available at: http//www.viam-works.ru (accessed 13.03.2020).

- Kozhanov D. A. [Modelling tensile behavior of flexible woven composites]. Nizhniy Novgorod, NIIM NU, 2017, 117 p.

- Endruweit A., Ermanni P. The in-plane permeability of sheared textiles. Experimental observations αz = –0,8·10–6 1/°C and a predictive conversion model. Composites. Part A. 2004, No. 35 P. 439–451. Doi: 10.1016/j.compositesa.2003.11.002.

- Vernet N., Ruiz E., Advani S. Experimental determination of the permeability of engineering textiles. Composites. Part A. 2014, No. 61 P. 172–184. Doi: 10.1016/j.compositesa.2014.02.0101359-835X/.

- Robert S. Pierce, Brian G. Falzon, Mark C. Thompson Permeability Characterization of Sheared Carbon Fiber Textile Preform POLYMER COMPOSITES, 2018, P. 2287–2298.