Implementation of additive 3D printing technology in the development of an experimental oxygen-hydrogen low thrust rocket engine

Автор: V.V. Koshlakov, S.V. Mosolov, A.G. Klimenko, E.Sh. Akbulatov, V.P. Nazarov, E.V. Gerasimov

Журнал: Siberian Aerospace Journal @vestnik-sibsau-en

Рубрика: Aviation and spacecraft engineering

Статья в выпуске: 3 vol.25, 2024 года.

Бесплатный доступ

Creating the spacecraft propulsion systems with high energy efficiency and minimal weight and size parameters is an urgent scientific and technical task of the domestic rocket engine industry. At the same time, requirements are put forward to optimize the cost and time of design, development and manufacturing of engines, as well as environmental safety at all stages of the product life cycle. In this regard, it is proposed to use advanced laser 3D printing technologies (additive technologies) from metal powder using CAD models of engine parts in the production of space low thrust rocket engines (LTRE). Laser melting technology on modern 3D printers makes it possible to produce complex monolithic engine structures without the use of labor-intensive and resource-intensive operations of machining, welding, and soldering, as well as a significant reduction in the volume of fitting and assembly operations, control and measuring work, and a decrease in the influence of some non-production factors. The article discusses issues of practical application of promising technologies in the creation of LTRE. The results of fire tests are presented, which will be used to refine the previously developed calculation models of oxygen-hydrogen LTRE when creating advanced rocket engines for spacecraft. The object of the study was an experimental sample of LTRE with a nominal thrust of 150 N using gaseous propellant components oxygen and hydrogen, developed and manufactured using additive technology. The experimental LTRE is considered as a prototype of the engine for orientation, stabilization and launching of the oxygen-hydrogen upper stage. The purpose of the work is to study the effectiveness of previously unexplored design solutions for organizing mixture formation and cooling of an oxygen-hydrogen LTRE, to determine their influence on the perfection of the working process and the thermal state of the engine chamber. Fire tests were carried out in single switching mode with a duration sufficient for the LTRE chamber to reach a stationary thermal regime, with the determination of the energy characteristics and thermal state of the structure.

Low thrust rocket engine, additive technologies, Inconel 718, bench fire tests

Короткий адрес: https://sciup.org/148329746

IDR: 148329746 | УДК: 621.454 | DOI: 10.31772/2712-8970-2024-25-3-320-336

Текст научной статьи Implementation of additive 3D printing technology in the development of an experimental oxygen-hydrogen low thrust rocket engine

One of the consistent trends in developing domestic and foreign rocket and space technology is the widespread use of additive technologies (AF – Additive Fabrication, additivity – addition) [1–3], the main essence of which is the sequential layer-by-layer build-up of metallic or non-metallic material in accordance with the command-application program of 3D modeling. In the rocket engine manufacturing, the most promising method of additive technologies is considered to be SLM (Selective laser melting) technology of 3D printing, implemented in the form of laser melting of metal powder using CAD models for the specific engine parts [4–6].

The selective laser melting technology makes it possible to create complex monolithic mixing heads of rocket engines with nozzles providing minimal hydraulic and gas-dynamic losses, complexprofile parts of turbopump units, cooling ducts of liquid rocket engine (LRE) chambers with artificial roughness and other structural elements of engines.

Therefore, additive technologies open up opportunities to develop rocket engines with improved energy efficiency characteristics while simultaneously reducing the weight-dimension characteristics of products.

Simultaneously, the rocket and space industry should deal with the assignment of forming a technological system for post-printing processing parts with a focus on innovative electrochemical and electrophysical methods [7].

Analyzing the state of the problem

Analyzing the scope of application of additive technologies in the rocket engine manufacturing, it is advisable to consider the possibility of manufacturing low-thrust liquid rocket engines (LTRE) using the SLM printing method.

In terminology, liquid rocket engines are defined by GOST 22396-77 “Low-thrust liquid rocket engines” as actuators of the control system of spacecraft with a thrust from 0.01 to 1600 N. LTRE are divided into separate types according to various characteristics. In particular, according to their purpose, they are usually classified into the following types [8]:

-

– orientation LTRE;

-

– stabilization LTRE;

-

– correction LTRE;

-

– revers LTRE and others.

The specific operating conditions of low thrust liquid-propellant rocket engines in space, the features of their functional parameters and characteristics cause great difficulties in designing low-thrust rocket engines [9]. The assignment of designing and engineering-technological testing the low thrust liquid-propellant rocket engines is determined by the following factors:

-

– low propellant consumption;

-

– few mixing unit elements;

-

– complexity in creating regenerative cooling;

-

– difficulty in organizing effective mixture formation and ensuring high combustion efficiency.

The above mentioned factors, in their turn, create special problems in ensuring an acceptable thermal state of the engine chamber, which is determined by the temperature reserve of the wall in the critical section zone, preventing overheating of the mixing unit and boiling of propellant components in heat-stressed pulse modes.

Domestic liquid-propellant rocket engines use two-component and single-component propellant. High-boiling self-igniting components are used as two-component propellant: unsymmetrical dimethylhydrazine (UDMH – propellant) and nitrogen tetroxide (NT – oxidizer). The single-component propellant is usually hydrazine, which is gasified by a catalytic exothermic decomposition reaction. The scientific, technical and educational literature describes the physical, chemical and energy characteristics of these propellants quite fully, and their advantages and disadvantages are known. The previous research highlighted their reliability and trouble-free ignition, stability of the working process in various operating modes of the low thrust liquid-propellant rocket engine with these components.

Simultaneously, the rocket and space industry states new requirements for spacecraft (SC) and their propulsion systems (PS). The industry focuses on the tasks of optimizing the cost and time of design, development and production of engines, creation of propulsion and power plants for spacecraft with minimal mass and dimensional parameters with high power density. The environmental safety factors during ground testing, refueling, storage and operation of products are of primary importance.

Currently, research and design organizations, fields of the industry, with the involvement of scientists and specialists from the Russian higher education system, create the promising propulsion systems for new generation spacecraft, including small spacecraft for various purposes, as well as those using environmentally friendly propellant [12]. The scientific and technical groundwork in the direction of low thrust rocket engines using environmentally friendly propellant components is currently based on the results of research conducted at JSC NIIMash [13], JSC A. M. Isaev Design Bureau of Chemical Machine Building [14], PJSC RSC Energia [15], Bauman Moscow State Technical Univer- sity [16], Moscow Aviation Institute [17], JSC State Research Center “Keldysh Center” [18], and others.

Concept of a promising low-thrust rocket engine

This article examines a fundamentally new model of a low-thrust rocket engine (LTRE) with the following design and technological features and characteristics:

-

– propellant component are environmentally friendly gaseous substances (hydrogen H 2 and oxygen O 2 or methane CH 4 and oxygen O 2 );

-

– engine chamber is made of heat-resistant alloy using SLM printing technology in the form of a monolithic product;

-

– thermal protection of the chamber is provided by an internal cooling system by creating a wall layer together with regenerative cooling by a gaseous component;

-

– control system ensures multiple switching on and off to the engine in accordance with the operating cyclogram without changing the thrust value and the ratio of propellant components.

In order to study the possibility of practical implementation of these theoretical assumptions, JSC State Research Center “Keldysh Center” has developed an advanced model of a low thrust rocket engine operating on gaseous propellant components: oxygen and hydrogen. The engine chamber is manufactured using additive SLM printing technology made of Inconel 718 powder material [19; 20] as a single part without welded or soldered joints.

The camera was manufactured due to the Cooperation Agreement among JSC “State Scientific Center of the Russian Federation “M. V. Keldysh Research Center” and the Federal State Budgetary Educational Institution of Higher Education “Reshetnev Siberian State University of Science and Technology” with the participation of the university’s industrial partner OOO “Polychrome” (Krasnoyarsk). The entire printing process is implemented on the ASTRA 420 3D printer, developed and manufactured at this enterprise.

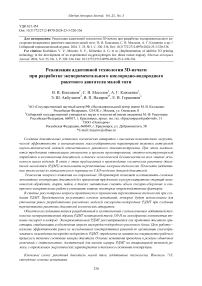

Fig. 1 presents the general view of the engine chamber. The combustion chamber (CC) has a spherical shape to ensures a uniform distribution of heat flows and temperature gradient throughout the entire volume of the sphere if the heat capacity of hydrogen is high. The internal diameter of the combustion chamber is about 33 mm. The critical section diameter is 12 mm. The supersonic part of the nozzle has the shape of a cone with a half-angle of 20°, the expansion ratio of the nozzle F = 11. The regenerative cooling path has 16 channels, the thickness of the fire wall is 0.6 mm, the height of the cooling channels is 1 mm, the thickness of the fins is 0.8 mm. The mixture formation scheme provides for the supply of the entire oxygen consumption through one nozzle with a diameter of 8 mm, located along the central axis of the chamber.

The design of the low thrust rocket engine is calculated for operation at a combustion chamber pressure p cham from 7 to 10 kg/cm2, a total propellant consumption ṁ ∑ from 30 to 40 g/s and a ratio of propellant components K m from 3 to 4.5, the calculated thrust value is 150 N.

Рис. 1. Общий вид камеры РДМТ

Methodology and 3D printing technology of the LTRE chamber

The technical capabilities of the ASTRA 420 3D printer make it possible to achieve relatively high speeds of volumetric construction of parts with the necessary adjustment of the laser power in the dynamic modulation mode of the laser spot [21–23].

Fig. 1. General view of the LTRE chamber

Therefore, when developing the methodology and technology to manufacture an experimental model of the LTRE chamber, the main task was to maintain a balance between maintaining optimal energy-physical parameters that ensure the specified quality of the product and reducing the overall printing time according to the program of the scientific experiment.

Based on the results of testing the technology for printing products of similar sizes made of Inconel 718 metal powder, to manufacture the studied sample of the experimental chamber, the operating mode parameters are determined and presented in Table 1.

Operating mode parameters

Table 1

|

Laser power, W |

Laser beam speed, mm/s |

Laser beam diameter, µm |

Shading step, µm |

Idle speed, mm/s |

|

300 |

600 |

190 |

150 |

600 |

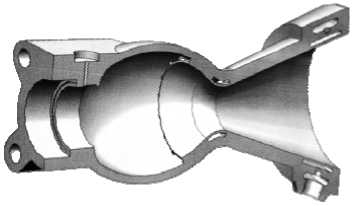

To produce the parts with different spatial configurations, the general and individual approaches were analyzed. It was decided that for each printing case it was necessary to use individual patterns, which represented a separate path of the laser beam with the corresponding segmentation into layers. Areas with a thickness of up to 1.5 mm were scanned without changes, with continuous shading. The remaining area was cut off and scanned in a checkerboard pattern, in small sections without changing the overall printing speed (Fig. 2).

When preparing the low thrust rocket engine project for printing, more than 40% of the entire time turned out to be spent idling the laser beam through the empty center of the combustion chamber. This happened because all the shading was considered as one element, which was filled track by track, without skipping empty areas without shading. The same also applies to other products that have a similar configuration – a cavity with a volume greater than the surrounding metal wall (Fig. 3).

To optimize operation time, additional segmentation into equal parts around the central axis was used. Since all areas were considered independently of each other, they were scanned one by one without moving through the chamber cavity. Simultaneously, the required scanning angle was maintained over the entire area (Fig. 4).

Рис. 4. Сегментированное изделие с указанным ходом лазерного луча

Рис. 2. Сегментация изделия и паттерны печати

Fig. 2. Product segmentation and printing patterns

Рис. 3. Штриховка цилиндрических изделий:

-

1 – сканирование изделия;

-

2 – холостой ход

Fig. 3. Shading cylindrical products: 1 – scanning of the product; 2 – idling

Fig. 4. Segmented product with a specified laser beam path

Optimized print time was 46 hours, compared to 75 hours with conventional shading. Upon visual inspection of the product, no obvious tendency of the external relief to porosity was detected (Fig. 5).

Preparation of the experimental LTRE to the bench test

The current state of the theory and practice of developing rocket engines does not allow to create new products that differ from previous analogues in many parameters and characteristics without conducting experimental research and bench tests close to the actual conditions of their operation. The main purpose of testing is to obtain reliable information about the condition of the tested product, which is subsequently used to solve scientific, design and technological problems. Therefore, testing is a vital part of programs and projects to develop highly efficient and reliable engines.

Experimental LTRE preparation to the bench test consists of installing the necessary fittings onto the engine to

Рис. 5. Камера РДМТ. Вид сбоку и сверху

Fig. 5. LTRE chamber. Side and top view

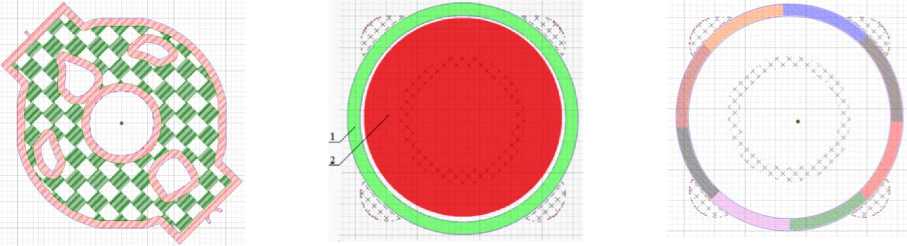

ensure propellant supply, ignition of components, and securing the product on the bench. Fig. 6 demonstrates the assembled LTRE design solution.

Рис. 6. Экспериментальный РДМТ:

1 – свеча зажигания; 2 – корпус; 3 – измерение давления в камере сгорания;

4 – камера сгорания с соплом; 5 – подача водорода; 6 – форсунка кислорода; 7 – подача кислорода

-

Fig. 6. Experimental LTRE:

-

1 – spark plug; 2 – housing; 3 – the combustion chamber pressure measurement;

4 – combustion chamber with nozzle; 5 – hydrogen inlet; 6 – oxygen injector; 7 – oxygen inlet

Engine chamber 4 has got an M14x1.5 connection for supplying hydrogen to the cooling tract. Hydrogen, passing through the cooling channels, moves along the walls of the combustion chamber to its initial section, leaves the cooling tract, mixing with oxygen.

Housing 2 has a M14x1.5 connection to join the oxygen supply solenoid valve and a threaded M18x1 socket for installing the CД-55AHM spark plug 1 . The pressure in the combustion chamber is taken through the M12x1.25 fitting 3 .

Test unit

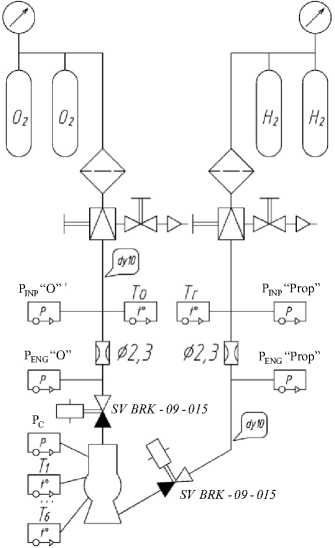

Tests of the developed experimental unit of the oxygen-hydrogen low thrust rocket engine were conducted at bench 7 of JSC State Research Center “Keldysh Center”. Fig. 7 presents the pneumohy-draulic scheme of the experimental unit.

The unit ensures the supply of the required oxygen and hydrogen flow rates to the LTRE and the determination of their actual values by using flow-metering nozzles operating at a supersonic pressure drop.

To supply gaseous propellant components, the pipelines are used with a diameter of d SI = 10 mm. The tests were carried out in continuous modes according to the cyclogram with simultaneous sending of commands to open the propellant solenoid valves and the spark plug. The spark plug switched off in 0.2 s after the start. The duration of the LTRE fire activations was 1–45 s.

Supplying gaseous propellant components to the engine inlet is carried out from cylinders with pressure reduction to the values provided for in the test program.

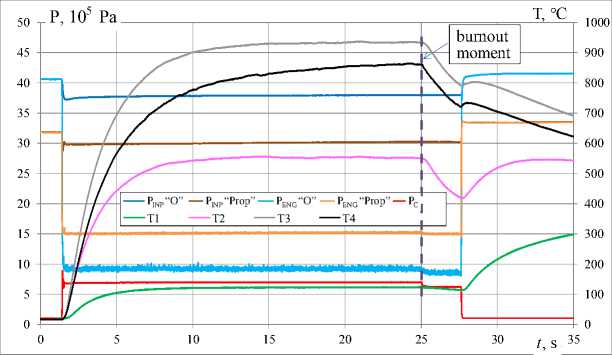

During the tests, the recorded data are the values of the pressures of the propellant components in front of the flow-metering nozzles Р INP “О” and Р INP “Prop”, after the nozzles (that is the pressure at the entrance to the LTRE) Р ENG “О” and Р ENG “Г” and in the combustion chamber p C , as well as the temperatures of gaseous oxygen and hydrogen.

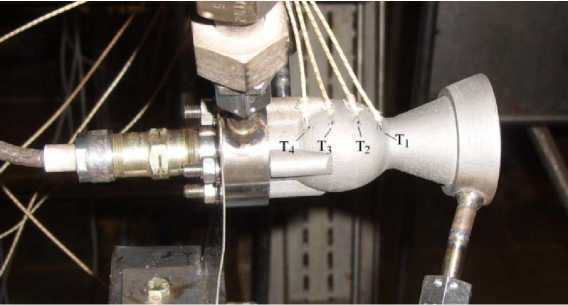

Using chromel-alumel thermocouples, temperatures were measured on the outer surface of the chamber T 1 – T 4 . Fig. 8 demonstrates the LTRE equipped with thermocouples and installed on a test bench.

Рис. 7. Пневмогидравлическая схема экспериментальной установки

-

Fig. 7. Pneumohydraulic diagram of the test unit

The parameters obtained as a result of the LTRE tests are used to determine the consumption complex β using the relationship:

β=

Р ⋅ F

m Σ

where F c is the critical cross-sectional area of the engine nozzle; ṁ ∑ is the total mass flow rate of propellant, which consists of the oxidizer flow rate ṁ о and the propellant flow rate ṁ prop .

The coefficient of the consumption complex ϕ β is defined as the ratio of the experimentally obtained value β to the theoretical β Т , obtained as a result of the thermodynamic calculation for the values of K m and р C corresponding to the mode of the test performed:

в Ф₽Х

The coefficient ф р is determined by the quality of mixing and combustion and characterizes the perfection of the operation process in the combustion chamber.

With the maximum values of measurement errors of pressure and temperature sensors, the total error in determining the mass flow rate of each of the propellant components does not exceed 0.7 %, the maximum error in determining the experimental value of the flow complex, taking into account the accuracy of determining the diameter and flow rate coefficient of the nozzles, is no more than 2.2 %.

Рис. 8. Экспериментальный РДМТ, установленный на стенде

-

Fig. 8. Experimental LTRE mounted on a bench

Results of experimental research

Table 2 summarizes the data on all tests of the low thrust rocket engine. In total, 12 fire tests were conducted within the framework of the experimental program.

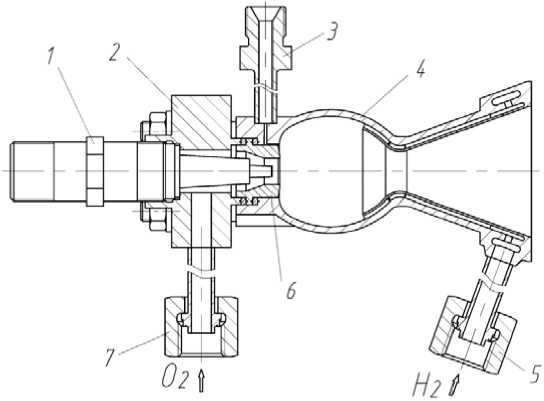

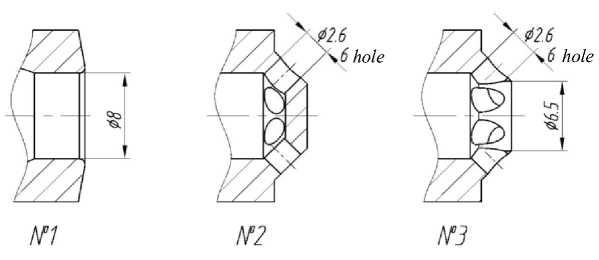

During the tests of the experimental LTRE, three variants of the oxygen injector were investigated (Fig. 9).

Рис. 9. Схемы вариантов форсунки кислорода

-

Fig. 9. Diagrams of oxygen injector options

Injector option № 1 is a single 8mm diameter hole located on the chamber axis. Option № 2 has 6 holes with a diameter of 2.6 mm, directed at an angle of 45 ° to the camera axis. Option № 3 is derived from option № 2 by adding a 6.5 mm diameter hole aligned with the camera axis.

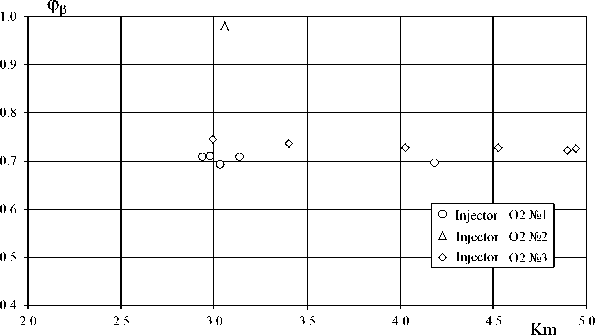

Fig. 10 shows the dependence of the coefficient of the consumption complex on the ratio of propellant components, indicating a significant influence of the type of oxygen injector on the perfection of the operation process.

Table 2

Test results

|

Test № |

о о а |

t ign. |

P INP “O” |

Р ENG “О” |

Р INP “Prop” |

Р ENG “Prop” |

p C |

ṁ о |

ṁ prop |

ṁ ∑ |

K m |

α |

β |

ϕβ |

|

s |

105 Pa |

105 Pa |

105 Pa |

105 Pa |

105 Pa |

g/s |

g/s |

g/s |

– |

– |

m/s |

– |

||

|

1 |

№ 1 |

1 |

30.1 |

40.3 |

7.8 |

19.7 |

6.4 |

29.6 |

10.1 |

39.6 |

2.94 |

0.37 |

1806 |

0.71 |

|

2 |

5 |

30.6 |

40.3 |

7.8 |

19.6 |

6.5 |

30.0 |

10.1 |

40.1 |

2.98 |

0.38 |

1812 |

0.71 |

|

|

3 |

45 |

34.2 |

42.7 |

8.6 |

20.7 |

7.1 |

33.5 |

10.7 |

44.1 |

3.14 |

0.40 |

1800 |

0.71 |

|

|

4 |

20 |

31.2 |

40.4 |

8.4 |

19.4 |

6.4 |

30.8 |

10.1 |

40.9 |

3.04 |

0.38 |

1762 |

0.69 |

|

|

5 |

20 |

35.1 |

32.9 |

8.8 |

16.1 |

6.5 |

34.6 |

8.3 |

42.9 |

4.19 |

0.53 |

1714 |

0.70 |

|

|

6 |

№ 2 |

7 |

31.4 |

40.3 |

10.7 |

19.8 |

9.1 |

31.0 |

10.1 |

41.1 |

3.06 |

0.39 |

2500 |

0.98 |

|

7 |

№ 3 |

5 |

31.6 |

25.2 |

8.0 |

12.7 |

5.8 |

31.4 |

6.4 |

37.8 |

4.90 |

0.62 |

1729 |

0.72 |

|

8 |

11 |

30.7 |

40.2 |

8.8 |

19.4 |

6.9 |

30.5 |

10.2 |

40.7 |

3.00 |

0.38 |

1900 |

0.74 |

|

|

9 |

30 |

32.2 |

37.1 |

8.8 |

18.0 |

6.8 |

31.8 |

9.4 |

41.2 |

3.40 |

0.43 |

1859 |

0.74 |

|

|

10 |

30 |

34.9 |

34.0 |

9.1 |

16.7 |

6.9 |

34.6 |

8.6 |

43.2 |

4.03 |

0.51 |

1802 |

0.73 |

|

|

11 |

30 |

36.2 |

31.4 |

9.2 |

15.6 |

6.9 |

35.9 |

7.9 |

43.9 |

4.52 |

0.57 |

1768 |

0.73 |

|

|

12 |

27 |

37.9 |

30.1 |

9.2 |

15.1 |

7.0 |

37.6 |

7.6 |

45.2 |

4.95 |

0.62 |

1736 |

0.73 |

Рис. 10. Зависимость коэффициента расходного комплекса от соотношения компонентов топлива

-

Fig. 10. The Combustion efficiency dependence from the mixture ratio

The first 5 tests were carried out with injector option № 1.

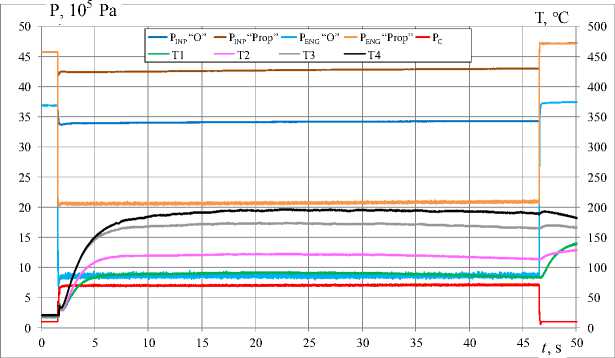

Fig. 11 shows the change in the recorded parameters during test № 3 with a duration of 45 s. Temperature records Т 1 – Т 4 indicate that the combustion chamber reaches a steady-state thermal regime within ~15 s.

It is noted that when using the oxygen injector option № 1, low completeness of propellant combustion is achieved, characterized by values of the consumption complex coefficient of no more than ϕ β = 0.71. The measured temperatures were also low and did not exceed 200 C. The characteristics obtained using injector № 1 are not acceptable for oxygen-hydrogen low thrust rocket engines. The low completeness of propellant combustion is probably explained by the stabilization of the flame at some distance from the outlet section of the oxygen injector, which, given the short length of the combustion chamber, significantly reduces the volume in which propellant combustion occurs.

Рис. 11. Изменение параметров работы РДМТ в процессе испытания № 3 (форсунка № 1, ṁ ∑ = 44 г/с, K m = 3,1)

Fig. 11. The operating parameters changes of LTRE during test № 3 (injector № 1, ṁ ∑ = 44 g/s, Km = 3.1)

In order to improve the characteristics of the low thrust rocket engine, oxygen injector option № 2 was installed in test № 6.

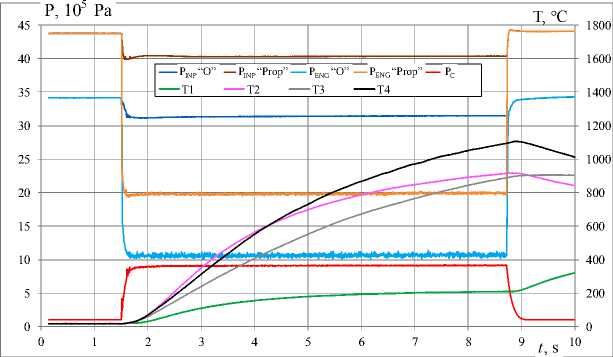

The new injector configuration has significantly changed the operation process in the LTRE chamber. The coefficient of the consumption complex increased to a value of ф р = 0.98, which indicates a practically uniform mixing of the propellant components and their combustion throughout the entire volume of the combustion chamber. Oxygen directed through 6 holes actually destroys the hydrogen curtain, resulting in an intense increase in the measured temperatures on the outer surface of the combustion chamber during test № 6 (Fig. 12). Test № 6 was stopped at the 8th second, when the Т 4 temperature at the initial section of the chamber reached 1,100 C, which is close to the limit for the Inconel 718 material. Further tests with injector № 2 were not performed, since longer firing would inevitably result in burnout of the chamber.

Рис. 12. Изменение параметров работы РДМТ в процессе испытания № 6 (форсунка № 2, ṁ ∑ = 41 г/с, K m = 3,1)

Fig. 12. The operating parameters changes of LTRE during test № 6 (injector № 2, ṁ ∑ = 41 g/s, K m = 3.1)

For further testing, a central hole with a diameter of 6.5 mm was additionally made in injector № 2. The resulting injector № 3 was installed in the LTRE design during tests № 7–12.

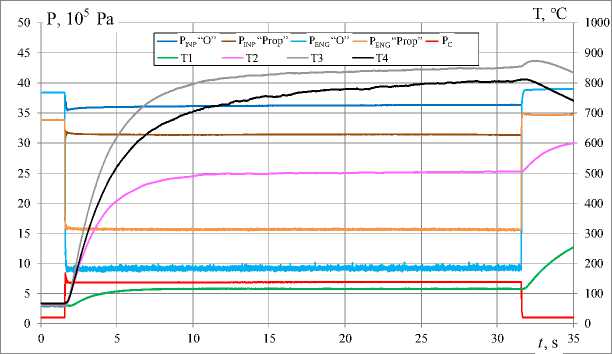

The injector № 3 configuration made it possible to obtain a more acceptable combination of complete propellant combustion and thermal state of the structure. Tests of the LTRE with oxygen injector № 3 were carried out with a successive increase in the ratio of propellant components (Table 2). The duration of tests No. 9–12 was set equal to 30 s, which ensured that the measured temperatures of the combustion chamber reached steady-state values.

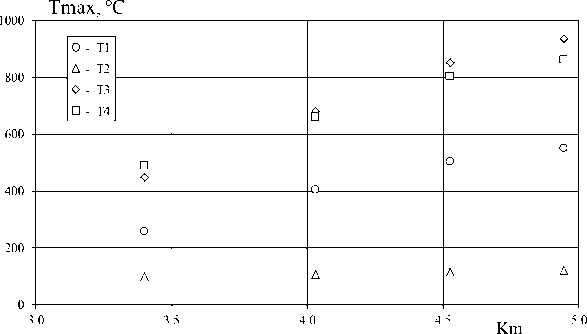

An increase in the ratio of the propellant components was accompanied by a corresponding increase in combustion chamber temperatures (Fig. 13).

Test No. 11 (Fig. 14, 15) demonstrated the design operability with a propellant component ratio of K m = 4.5, which allows to achieve high energy-mass perfection of the PS). A further increase in the ratio of propellant components to K m = 4.95 in test № 12 (Fig. 16) resulted in burnout of the combustion chamber wall at the 24th second. The burnout (Fig. 17) occurred in a section that had only boundary cooling with hydrogen.

Рис. 13. Зависимость максимальных температур на наружной поверхности камеры сгорания от соотношения компонентов топлива

Fig. 13. The maximum temperature dependence on the outer surface of the combustion chamber on the mixture ratio

Рис. 14. Изменение параметров работы РДМТ в процессе испытания № 11 (форсунка № 3, ṁ ∑ = 44 г/с, K m = 4,5)

Fig. 14. The operating parameters changes of LTRE during test No. 11 (injector No. 3, ṁ ∑ = 44 g/s, K m = 4.5)

Рис. 15. Огневая работа РДМТ на испытании № 11 ( ṁ ∑ = 44 г/с, K m = 4,5)

Fig. 15. Hot fire of LTRE on test № 11 ( ṁ ∑ = 44 g/s, Km = 4.5)

Рис. 16. Изменение параметров работы РДМТ в процессе испытания № 12 (форсунка № 3, ṁ ∑ = 45 г/с, K m = 4,95)

Fig. 16. The operating parameters changes of LTRE during test No. 12 (injector No. 3, ṁ ∑ = 45 g/s, K m = 4.95)

Рис. 17. Элементы РДМТ после испытаний

Fig. 17. The LTRE elements after testing

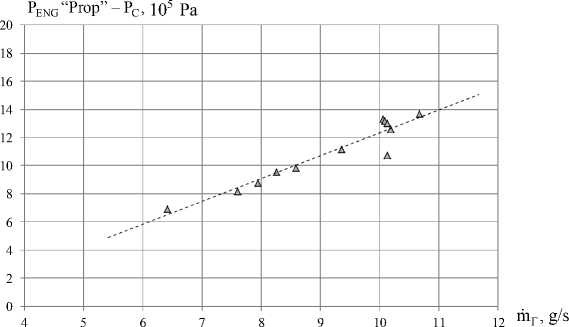

The pressure drop along the hydrogen line Рinp “Prop” – pC (Fig. 18) in the studied range of hydrogen consumption from mProp = 6.4-10.7 g/s amounted to 6.9-13.7 • 105 Pa. The main contribution to the hydraulic resistance of the propellant line is made by friction losses in the cooling channels. High hydraulic resistance of the cooling tract in oxygen-hydrogen low-thrust rocket engines is undesirable, since it may require an increase in the supply pressure of the propellant components to the engine. Further, in order to limit pressure losses along the fuel line, it is necessary to rationally profile the flow part of the cooling tract, as well as reduce the roughness of the walls of the cooling channels after manufacturing using the 3D printing method.

Рис. 18. Зависимость перепада давлений по линии водорода от расхода водорода

-

Fig. 18. The pressure drop dependence along the hydrogen line on hydrogen flow rate

Conclusion

As a result of the tests, the researched basic design of the oxygen-hydrogen low-thrust rocket engine, manufactured using the additive 3D printing technology, with features such as a combination of regenerative and boundary cooling, mixture formation with counter-current supply of oxygen and hydrogen and a spherical combustion chamber, demonstrated operability at a sufficiently high ratio of propellant components .

The main disadvantage of the studied scheme is the insufficient completeness of fuel combustion, characterized by the values of the coefficient of the consumption complex of no more than ϕ β = 0.74, whereas to obtain a specific impulse of thrust J SI = 3950 m/s, this indicator should be no less than ϕ β = 0.88.

This fact, as well as the need to have reserves for the permissible ratio of propellant components, do not allow us to recommend the scheme without changes for further development.

Nevertheless, the conducted research made it possible to study the properties of the LTRE chamber manufactured using additive technology. The obtained experimental data will be used to refine previously developed calculation models of oxygen-hydrogen low-thrust rocket engines and in the development of an improved design of an oxygen-hydrogen low-thrust rocket engine.

It is noted that in the design of an oxygen-hydrogen low-thrust rocket engine with regenerative cooling, when the coolant – hydrogen – flows from the nozzle to the initial section, the maximum temperatures are realized not in the region of maximum heat flows in the critical section of the nozzle, but at the exit from the cooling tract, where the coolant temperature reaches its highest values.

Therefore, it could be concluded that the use of additive technologies opens up opportunities for the implementation of promising design and engineering solutions in the field of space propulsion engineering.

Список литературы Implementation of additive 3D printing technology in the development of an experimental oxygen-hydrogen low thrust rocket engine

- Logacheva A. I. [Additive technologies for rocket and space technology products: prospects and problems of application]. Tekhnologiya legkikh splavov. 2015, No. 3, P. 39–44 (In Russ.).

- NASA tests limits of 3D-prnting with powerfull rocket engine check. Available at: http://nasa.gov (accessed: 26.05.2024).

- Belov S. V., Volkov S. A., Magerramova L. A. et al. [Prospects for the use of additive technologies in the production of complex parts of gas turbine engines from metal materials]. Sbornik nauchnykh trudov nauchn. konf. “Addivnye tekhnologii v rossiyskoy promyshlennosti” [Сollection of scientific papers Scientific. Conf. “Additive technologies in Russian industry”]. Мoscow, 2015, P. 101–102 (In Russ.).

- Terekhov M. V., Filippova L. B., Martynenko A. A. et al. Additivnye tekhnologii [Additive technologies]. Мoscow, Flinta Publ., 2018, 74 p.

- GOST R 59036–2020. Additivnye tekhnologii. Proizvodstvo na osnove selektivnogo lazernogo splavleniya metallicheskikh poroshkov. Obshchie polozheniya [State Standard R 59036–2020. Additive technologies. Production based on selective laser melting of metal powders. General provisions]. Moscow, Standartinform Publ., 2020. 22 p.

- Additive Manufacturing. With Amperprint for 3D-Printing you Have the Powder to Create. Available at: https://www.hoganas.com/en/powder-technologies/additive-manufacturing/3d-printingpowders/ (accessed: 26.05.2024).

- Akbulatov E. Sh., Nazarov V. P., Gerasimov E. V. [Characteristics research of a low thrust rocket engine manufactured using additive SLM technology]. Siberian Aerospace Journal. 2023, Vol. 24, No. 4, P. 682–696. Doi: 10.31772/2712-8970-2023-24-4-682-696 (In Russ.).

- Nazarov V. P., Piunov V. Yu., Yatsunenko V. G., Savchin D. A. [Characteristics of low thrust liquidpropellant rocket engines testing process]. Siberian Aerospace Journal. 2021, Vol. 22, No. 2, P. 339–354. Doi: 10.31772/2712-8970-2021-22-2-339-354 (In Russ.).

- Nazarov V. P., Piunov V. Yu., Golikovskaya K. F., Nazarova L. P. [Simulation modeling of bench test conditions of liquid rocket engines of low-thrust]. Мaterialy ХХVI Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials ХХVI Intern. Scientific. Conf. “Reshetnev reading”]. Krasnoyarsk, 2022, P. 191–192 (In Russ.).

- Akbulatov E. Sh., Nazarov V. P., Shhelkanov A. N., Koval R. V., Gerasimov E. V. [Development and implementation of innovative additive technologies for printing low thrust rocket engines]. Мaterialy ХХVII Mezhdunar. nauch. konf. “Reshetnevskie chteniya” [Materials ХХVII Intern. Scientific. Conf. “Reshetnev reading”]. Krasnoyarsk, 2023, P. 149–151 (In Russ.).

- Mosolov S. V., Partola I. S. [Russian rocket engine building perspertives in modern conditions]. Idei K. E. Tsiolkovskogo v teoriyakh osvoeniya kosmosa: Materialy 58-kh Nauchnykh chteniy [Ideas of K. E. Tsiolkovsky in theories of space exploration: Materials of the 58th Scientific Readings]. Kaluga, 2023, P. 94–96 (In Russ.).

- Lovtsov A. S., Mosolov S. V., Goza D. A., Selivanov M. Yu. [Prospects for the development of engine installations space vehicles]. Materialy II Otraslevoy nauchno-prakticheskoy konferentsii “Sozvezdie Roskosmosa: traektoriya nauki” [Materials II Industry Scientific and Practical Conf. “Roscosmos Constellation: The Trajectory of Science”]. Krasnoyarsk, 2023, P. 29 (In Russ.).

- Kutuev R. H., Lebedev I. N., Salich V. L. [Development of advanced low thrust rocket engines with ecologically friendly propellants]. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta. 2009, No. 3 (19), P. 101–109 (In Russ.).

- Ageenko Yu. I, Lapshin E. A., Morozov I. I., Pegin I. V., Ryzhkov V. V. [Results of experimental studies of parameters of low-thrust rocket engines operating on gaseous oxygen-hydrogen fuel]. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta. 2014, No. 5 (47), P. 35–45 (In Russ.).

- Barsukov O. A., Vesnovatov A. G., Mezhevov A. V. et al. [Axial overload engine engine for eco-friendly upper stages]. Trudy mezhdunarodnoy nauchno-tekhnicheskoy konferentsii “Problemy i perspektivy razvitiya dvigatelestroeniya” [Proceedings of the international scientific and technical conf. “Problems and prospects for the development of engine building”]. Samara, 2003, P. 14–19 (In Russ.).

- Antonov Yu. V., Yagodnikov D. A., Novikov V. I., Lapitskiy V. I., Burkaltsev V. A. [Experimental study of working process in combustion chamber of low- thrust engine using gaseous components methane + oxygen]. Vestnik MGTU im. N. E. Baumana. Seriya Mashinostroenie. 2007, No. 2, P. 35–43 (In Russ.).

- Vorobiev A. G., Borovik I. N., Ha S. [Analysis of nonstationary thermal state of a low-thrust liquid rocket engine taking into account injection, evaporation and combustion of liquid fuel droplets]. Vestnik Samarskogo gosudarstvennogo aerokosmicheskogo universiteta. 2014, No. 1 (43), P. 30–40 (In Russ.).

- Kochanov A. V., Klimenko A. G. [Study of problems to create rocket microthrusters with pollution- free fuels]. Vestnik MGTU im. N. E. Baumana. Seriya Mashinostroenie. 2006, No. 3 (64), P. 64–73 (In Russ.).

- Eiselstein H. L. Age-hardenable nickel alloy. Patent US, no. 3046108A, 1962.

- Pedash A. A., Lysenko N. A., et. al. [Structure and properties of samples from Inconel 718 alloy obtained using selective laser melting technology]. Aviatsionno-kosmicheskaya tekhnika i tekhnologiya. 2017, No. 8, P. 46–54 (In Russ.).

- GOST R 59184–2020. Additivnye tekhnologii. Oborudovanie dlya lazernogo splavleniya. Obshchie trebovaniya [State Standard R 59184–2020. Additive technologies. Equipment for laser melting. General requirements]. Moscow, Standartinform Publ., 2020. 18 p.

- Preobrazhenskaya E. V., Borovik T. N., Baranova N. S. Tekhnologii, materialy i oborudovanie additivnykh proizvodstv [Technologies, materials and equipment for additive manufacturing]. Мoscow, RTU MIREA Publ., 2021, 173 p.

- Gu D. D., Meiners W., Wissenbach K., Poprawe R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. International Materials Reviews. 2012, No. 57 (3), P. 133–164.