Improvement of thread tracking mechanism on universal sewing machines

Автор: Sirojova M.S.

Журнал: Мировая наука @science-j

Рубрика: Основной раздел

Статья в выпуске: 6 (51), 2021 года.

Бесплатный доступ

In this article highlights of improvement of thread tracking mechanism on universal sewing machines.

Thread, sewing machines, universal sewing machines, mechanism of sewing machines

Короткий адрес: https://sciup.org/140266123

IDR: 140266123 | УДК: 001

Текст научной статьи Improvement of thread tracking mechanism on universal sewing machines

Implementation of radical changes in the economy of our country, consistent transition of the Republic's economy from the main raw material direction to the path of production of competitive products, the country's export potential has set new tasks before each sphere of production. In particular, the development of the sewing industry, providing our people with high-quality, beautiful clothes are among the important tasks facing the employees of the light industry. Of course, in order to fulfill these tasks, it will be necessary to increase the volume of production of sewing products, improve their quality, create enterprises with new highly effective techniques.

Currently, the sewing enterprises of our homeland are replenished with equipment produced on the basis of the latest achievements of Science and technology. Through the equipping of machinery and equipment with a variety of devices, the integration and automation of technological processes continues. In the field of sewing and knitwear production, now thousands of sewing equipment, sewing machines, shearing and ironing presses are produced. Therefore, it is important to increase the reliability of equipment, provide maintenance for repairs. With the transition to market relations, scientific research works are carried out in a number of institutions and research centers of design in order to improve such constructions of economic connection between enterprises, firms and household service houses and repair enterprises using equipment belonging to the sewing and knitting industry.

Universal sewing machines directly participate in the formation of a straight line shuttle bahya series of two threads 4 pieces and 2 pieces. Bahya plays a primary role in the quality yield of the row with adjustable relative to each other. As a result of the high-speed operation of the main mechanisms of the abovementioned universal sewing machines, the occurrence of ingestions (sizing) as a result of internal and external forces occurring in the kinematic pairs in them leads to a violation of the quality of the bahya series [3]. The main threads of the sewing machines mentioned above. Sewing machines, forming a shuttle and chain bahya, are made of the following main threads:

-

- needle mechanism;

-

- shuttle and Rivet threads;

-

- material thrust mechanism;

-

- thread tensioner (thread tensioner) mechanism;

-

- trigger thread the above-mentioned series of main threads also includes threads, such as a separator, which is used in some sewing machines. More mechanisms divided into differentiated and automated groups. Mechanism integrated circuits and devices include:

-

- material routers;

-

- measurement and roller push mechanism;

-

- thread stretching of woven straps under the needle;

-

- connectors, restrictive devices;

-

- trimmer mechanisms the finisher edge;

-

- search results;

-

- needle cooling device, etc. These mechanisms have different constructions and working principles depending on the functions and technological requirements of sewing machines. The automated mics and devices group includes:

-

- automatic stop device;

-

- automatic stop in the desired position of the needle;

-

- scraping yarn and webbing materials with vertical blade;

-

- trimming the bottom thread;

-

- automatic lifting of the trigger;

-

- provide information when the lubrication process is broken and the thread is disconnected;

-

- automatic draining of gaskets from the ores;

-

- product counter, etc.

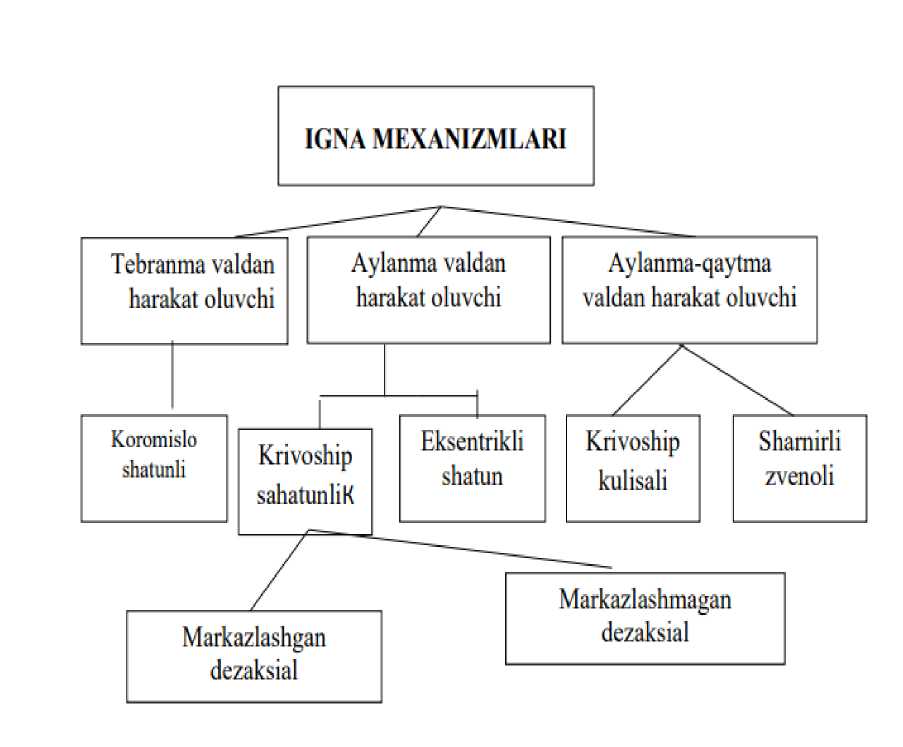

A machine made of special and automatic elements is called a specialised and automated sewing machine. The mechanism of the needle-through the needle, through which the gauze is injected, acts as a delivery so that the upper thread is connected to the lower thread. Types of needles are shown in the following scheme. In sewing machinery, centralized and decentralized krivoship shatun needles are widely used. Mechanisms of this type are used mainly in high-speed machines, since they are used in needle. Needle loops are divided into the following according to the movement of the needle:

-

- the hook-the return mover needle;

-

- the direction to which the finisher is pushed;

-

- the horizontal swing moving needle with a cross-sectional or longitudinal;

-

- with a moving needle on the Sagittarius tray.

Distributor in sewing machines, forming a flat chain stitch mechanism available. dispensers bahya on the side of the finisher surface delivered function between threads. Delivered mechanism one of the main characteristics is the vibration relative to the axis of the trigger starlet is the location of the arrow. Single or double divider sewing machines will be.

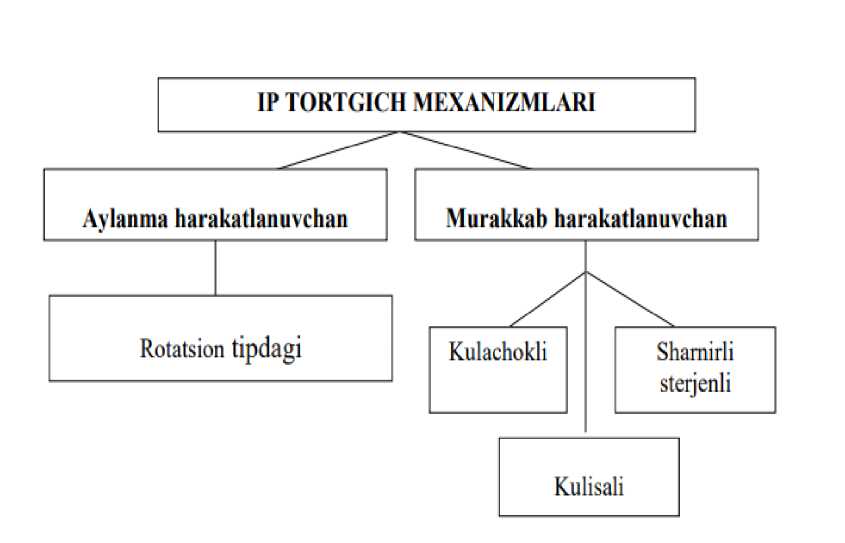

Rope pull mechanism - a thread that can be spent when forming a bow serves for stretching the transmission and seam.

Список литературы Improvement of thread tracking mechanism on universal sewing machines

- Single-thread chainstitch cycling machine for sewing buttons and tacke. - Printed in Germany. 04.96. 31.

- Twin needle locktitch machine with botton feed, needle feed and alternating foot top feed. - Printed in Germany. D/GB/SU. 08.96. 32.

- Qizi F. N. F. Modernization Of Uzbek Language And National-Spiritual Heritage In National Culture //The American Journal of

- United States Patent №3811392. Double chain stitching method and Devices for sewing machine. 21.05.94, Inventor- Noboru Kasuga (Japan)